Solvent-free UV curing hardening liquid, preparation method thereof and hardened film

A curing hardening, solvent-free technology, applied in the field of hardening film, solvent-free UV curing hardening liquid, to achieve good hydrophobicity, enhanced hardness and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

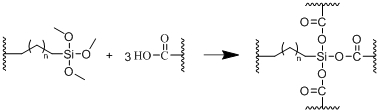

[0038] Wherein, the preparation method of the special silicon-modified resin comprises the following steps:

[0039] S01: acrylic acid soft monomer, acrylic hard monomer, and carboxyl group-containing acrylic acid monomer and photoinitiator are stirred and mixed, and UV light is reacted;

[0040] S02: adding monomers containing siloxane groups dropwise, and performing UV light reaction to obtain a special silicon-modified resin with a molecular weight of 5000-15000.

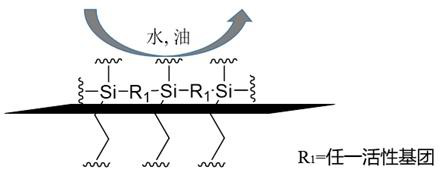

[0041] The solvent-free UV curing liquid of the present invention is introduced into the hardening liquid by using special silicon-modified resin, which can significantly enhance the hardness and scratch resistance of the cured film compared with other similar hardening liquids on the market; The introduction also makes the hardened film have good hydrophobic properties.

[0042] The specific embodiment of the present application also provides a solvent-free UV curing solution, which is prepared by the above-men...

Embodiment 1

[0066] This embodiment provides a method for solvent-free UV curing of the hardening solution and its hardening film, specifically:

[0067] Polyurethane or acrylate prepolymer 50 parts

[0068] Dilute monomer 5 parts

[0069] 1 part photoinitiator

[0070] Special silicon modified resin 5 parts

[0071] Weigh the above components respectively, put them into a stirring tank, and stir at a constant speed for 1-2 hours to obtain a solvent-free UV curing hardening solution with a measured viscosity of 4000mPa.s. Use the above hardening solution to coat / coat on PET, and cure by UV lamp irradiation for 15s to obtain a cured film. The thickness of the PET substrate is 188 μm, and the thickness of the coating is 7 μm. According to GB / T 6739-2006, the film hardness is 5H; 0000# steel wool scratch resistance test, 1kg load, 10,000 times back and forth without scratches; according to GB / T 30693-2014, the water contact angle is 102°.

Embodiment 2

[0073] This embodiment provides a method for solvent-free UV curing of the hardening solution and its hardening film, specifically:

[0074] 80 parts polyurethane or acrylate prepolymer

[0075] Dilute monomer 40 parts

[0076] 8 parts of photoinitiator

[0077] 20 parts of special silicon modified resin

[0078] Weigh the above components respectively, put them into a stirring tank, and stir at a constant speed for 1-2 hours to obtain a solvent-free UV curing hardening solution with a measured viscosity of 2600mPa.s. Use the above hardening solution to coat / coat on PET, and cure by UV lamp irradiation for 45s to obtain a cured film. The thickness of the PET substrate is 188 μm, and the thickness of the coating is 15 μm. According to GB / T 6739-2006, the film hardness is 8H; 0000# steel wool scratch resistance test, 1kg load, 12000 times back and forth without scratches; according to GB / T 30693-2014, the water contact angle is 105°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com