Matte brick stain-proofing agent and preparation method thereof

An antifouling, matte technology, used in antifouling/underwater coatings, paints containing biocides, coatings, etc., can solve the problem that the antifouling performance is difficult to meet the market requirements, the light reflection coefficient is low, and the visual function is reduced. and other problems, to achieve the effect of maintaining the decorative effect for a long time, excellent electrical insulation performance, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

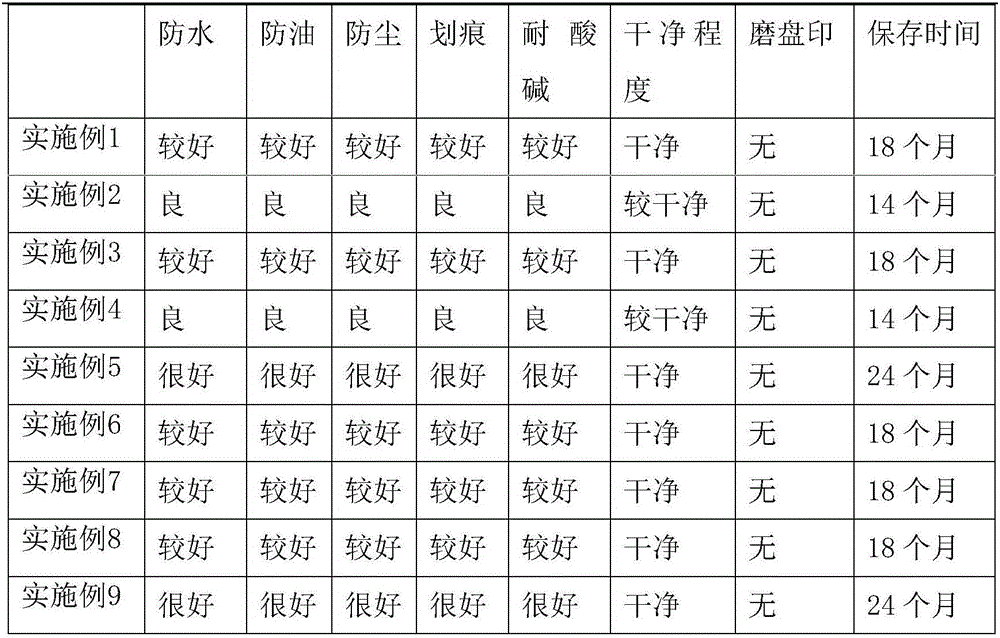

Examples

Embodiment Construction

[0021] Below, in conjunction with specific embodiment, the present invention is described further:

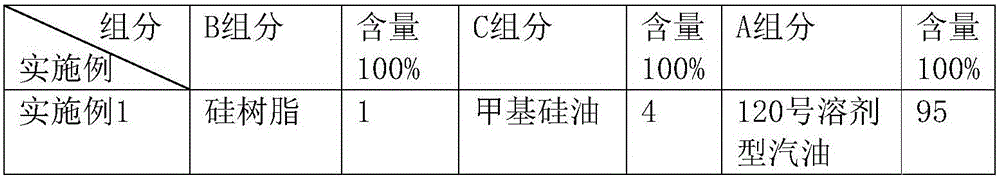

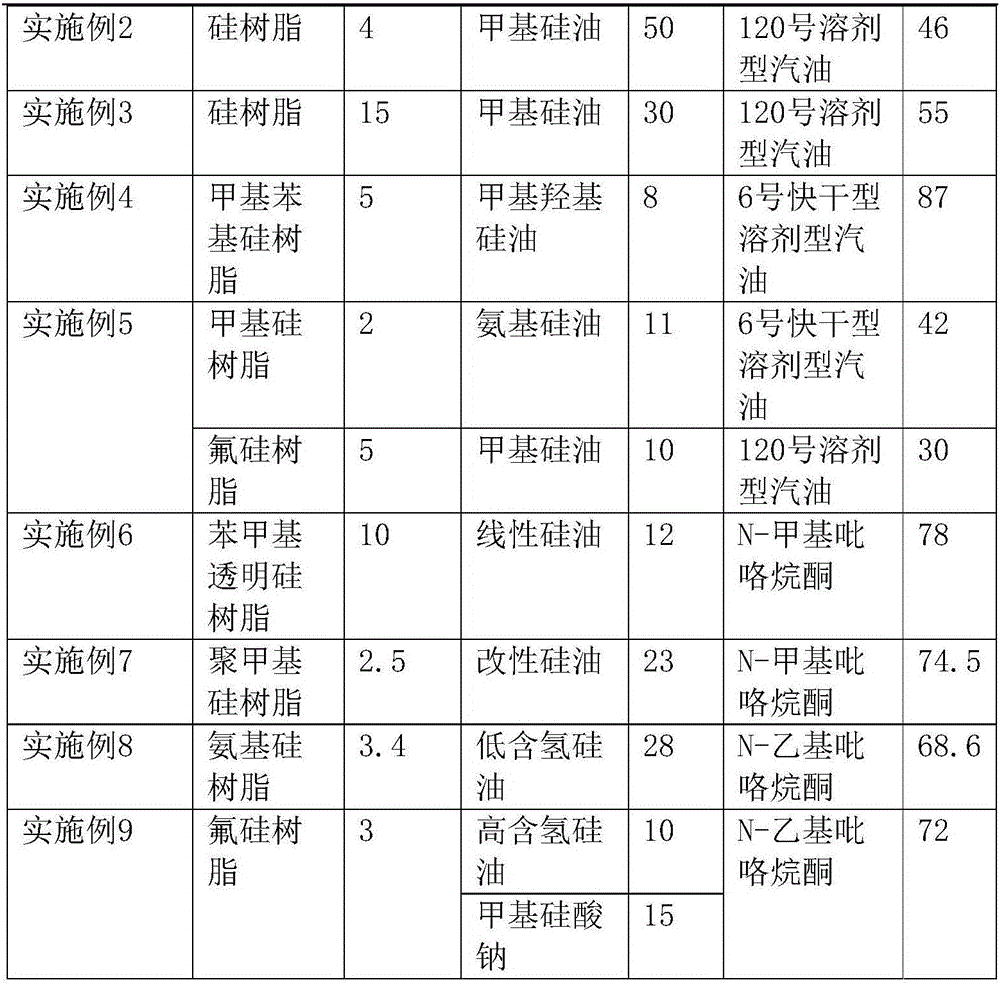

[0022] A matte brick antifouling agent, made of the following components in terms of weight percentage: 1%-15% of B component, 4%-50% of C component, and the balance of A component; the total of each component The parts by weight are 100%; component A is an organic solvent, component B is a silicone resin, and component C is at least one of the following components: silicone oil, organosiloxane monomer.

[0023] Wherein, the A component of preferred scheme comprises non-polar solvent and polar solvent; Described non-polar solvent is selected from No. 120 solvent-type gasoline, No. 6 quick-drying type solvent-type gasoline wherein one or two; The described The polar solvent is selected from one or both of N-methylpyrrolidone and N-ethylpyrrolidone.

[0024] Among them, the silicone resin of the preferred solution is selected from one or more of methylphenyl silicone resins, met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com