Coal mine air cylinder and manufacturing method thereof

A production method and air duct technology, which are used in mine/tunnel ventilation, mining equipment, earth-moving drilling and other directions to achieve good wear resistance and tear resistance, good antistatic effect, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

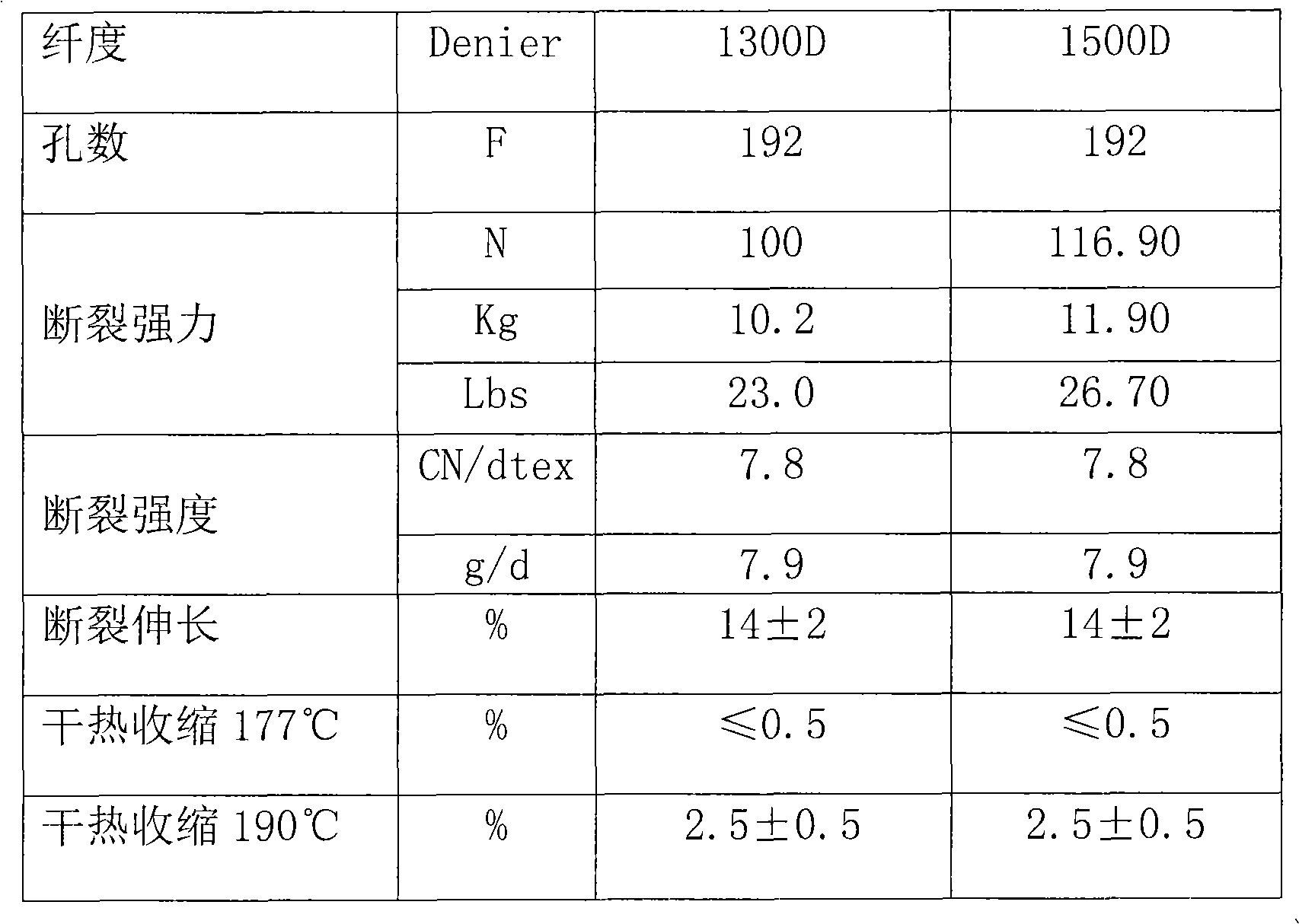

[0022] A kind of air duct for coal mines, comprising a grid base cloth and a PVC calendered film laminated on the base cloth, the PVC calendered film is divided into an upper film and a lower film, the base is arranged between the upper film and the lower film, and the thickness of the upper film is 20 filaments, the lower film is 16 filaments, and the outer surface of the PVC calendered film is coated with an antistatic agent; the polyester fiber filament grid base fabric is woven from 1300D ultra-low shrinkage twisted polyester fiber filaments as warp and weft threads; PVC calendered film is made by weight from the following components:

[0023] 100 parts of SG-70 resin, 47 parts of phthalic plasticizer, 15 parts of phosphate triester plasticizer, 10 parts of cationic plasticizer, 15 parts of cold-resistant plasticizer, 2.5 parts of epoxy plasticizer, 8 parts of inorganic flame retardant, 60 parts of inorganic filler, 0.2 part of anti-aging agent, 0.1 part of antibacterial a...

Embodiment 2

[0031]A kind of air duct for coal mines, comprising a grid base cloth and a PVC calendered film laminated on the base cloth, the PVC calendered film is divided into an upper film and a lower film, the base is arranged between the upper film and the lower film, and the thickness of the upper film is 20 filaments, the lower film is 16 filaments, and the outer surface of the PVC calendered film is coated with an antistatic agent; the polyester fiber filament grid base fabric is woven from 1500D ultra-low shrinkage twisted polyester fiber filaments as warp and weft threads; PVC calendered film is made by weight consisting of the following components:

[0032] 100 parts of SG-70 resin, 45 parts of phthalic plasticizer, 10 parts of phosphate triester plasticizer, 8 parts of cationic plasticizer, 8 parts of cold-resistant plasticizer, 2 parts of epoxy plasticizer, 8 parts of inorganic flame retardant, 60 parts of inorganic filler, 0.2 part of anti-aging agent, 0.1 part of antibacteri...

Embodiment 3

[0036] A kind of air duct for coal mines, comprising a grid base cloth and a PVC calendered film laminated on the base cloth, the PVC calendered film is divided into an upper film and a lower film, the base is arranged between the upper film and the lower film, and the thickness of the upper film is 20 filaments, the lower film is 16 filaments, and the outer surface of the PVC calendered film is coated with an antistatic agent; the polyester fiber filament grid base fabric is woven from 1300D ultra-low shrinkage twisted polyester fiber filaments as warp and weft threads; PVC calendered film is made by weight consisting of the following components:

[0037] 100 parts of SG-70 resin, 50 parts of phthalic plasticizer, 20 parts of phosphate triester plasticizer, 12 parts of cationic plasticizer, 25 parts of cold-resistant plasticizer, 5 parts of epoxy plasticizer, 12 parts of inorganic flame retardant, 65 parts of inorganic filler, 1 part of anti-aging agent, 0.1 part of antibacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com