Hydrophobic and oleophobic wave-absorbing material and preparation method thereof

A wave-absorbing material, hydrophobic and oleophobic technology, applied in the field of coatings, can solve problems such as the adhesion of oil stains and food residues, the complex production process of wave-absorbing materials, and the impact on application. , Good hydrophobic and oleophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

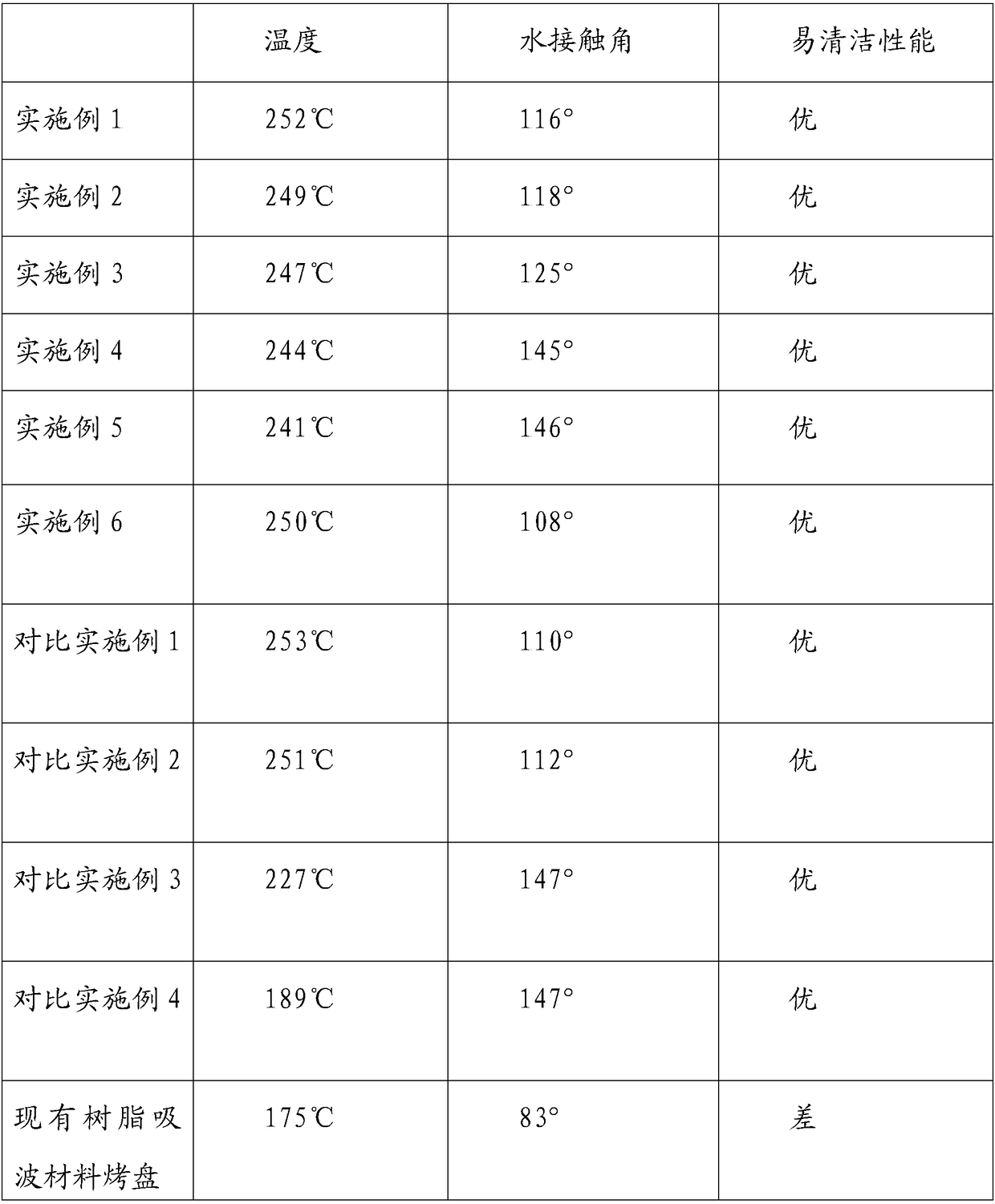

Examples

preparation example Construction

[0064] A preparation method of the above-mentioned hydrophobic and oleophobic wave absorbing material includes the following steps: mixing the components together according to the proportion to prepare the hydrophobic and oleophobic wave absorbing material. For specific operations, you can follow the steps below:

[0065] 1) Mix the wave absorbing material binder and the auxiliary agent evenly according to the proportion to obtain the mixture;

[0066] 2) Mix the mixture in step 1) and the wave absorbing material uniformly to obtain a hydrophobic and oleophobic wave absorbing material.

[0067] A kitchen appliance product includes a substrate and a coating layer arranged on the surface of the substrate, and the coating layer is made of the above-mentioned hydrophobic and oleophobic wave-absorbing material. During the preparation, the above-mentioned hydrophobic and oleophobic wave absorbing material is sprayed on the surface of the base material of the kitchen appliance product, and...

Embodiment 1

[0070] A hydrophobic and oleophobic wave absorbing material and a preparation method thereof. Each component of the material is calculated by mass percentage, and the binder of the wave absorbing material is 87%, the wave absorbing material is 12%, and the auxiliary agent is 1%. Wherein, the wave absorbing material is in powder form, and the particle size of the wave absorbing material is 15 nm.

[0071] The preparation method is as follows:

[0072] 1) Preparation of adjuvant and wave absorbing material binder mixture:

[0073] Mix 87kg of hydrophobic and oleophobic ceramic material with 1kg of additives (additives include: 0.5kg of adhesion-increasing and leveling agent J-50, 0.2kg of antifoaming agent AMAFCA and 0.3kg of suspension thickener xanthan gum), 500r / min Stir mechanically at a speed of 10 minutes, and after mixing uniformly, the mixture is prepared;

[0074] 2) Mix the mixture with the absorbing material:

[0075] Add 5kg of β-SiC, 4kg of ZnO, 2.95kg of nano graphite and ...

Embodiment 2

[0077] A hydrophobic and oleophobic wave absorbing material and a preparation method thereof. Each component of the material is calculated by mass percentage, and the binder of the wave absorbing material is 89%, the wave absorbing material is 10.2%, and the auxiliary agent is 0.8%. Wherein, the wave absorbing material is in powder form, and the particle size of the wave absorbing material is 25 nm.

[0078] The preparation method is as follows:

[0079] 1) Preparation of a mixture of additives and wave-absorbing material binder:

[0080] Mix 89kg of hydrophobic and oleophobic ceramic material with 0.8kg additives (additives include: 0.4kg adhesion-increasing leveling agent J-50, 0.2kg defoamer AMAFCA and 0.2kg suspension thickener xanthan gum), 500r / Stir mechanically for 10 minutes at min speed, mix evenly, and make a mixture;

[0081] 2) Mix the mixture with the absorbing material:

[0082] Add 4kg of β-SiC, 3kg of ZnO, 3.14kg of nano graphite and 0.06kg of Ce to the mixture prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com