Foam drilling fluid and preparation method thereof

A drilling fluid and foam technology, applied in the field of oil drilling fluid, can solve the problems of small foaming volume and short half-life time, and achieve the effect of good suspension performance, strong anti-pollution ability and solving reservoir pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

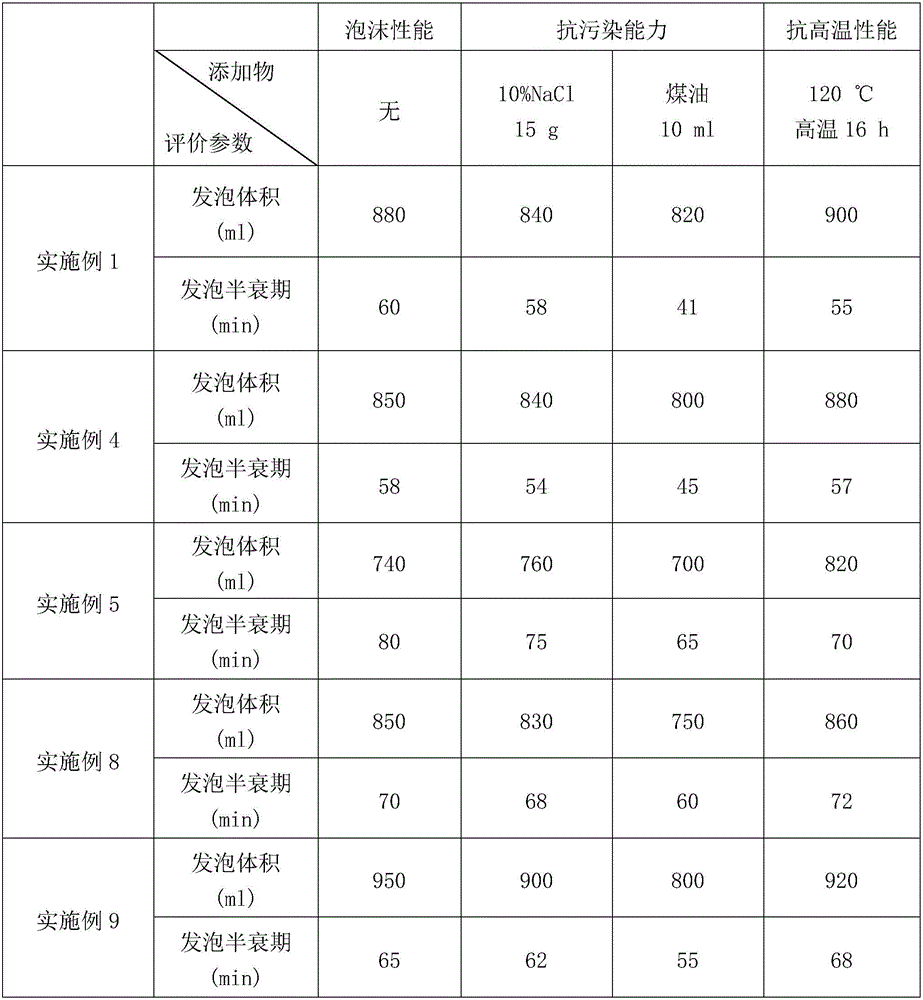

[0016] Under normal temperature and pressure conditions, disperse 3g of sepiolite in 142.5g of deionized water for 10 hours of prehydration treatment (prehydration treatment is to dissolve sepiolite in water to make its fiber structure more stretchable, and it takes a certain amount of time ), then add 3g sodium lauryl sulfate and 1.5g sodium dodecylbenzenesulfonate. Wherein the mass percentages of sodium lauryl sulfate (the first foaming agent), sodium dodecylbenzenesulfonate (the second foaming agent) and sepiolite (inorganic fiber) are respectively 2%, 1%, 2%. %. Stir evenly at 60°C and foam at room temperature with a mixer at 5000 rpm for 5 minutes to obtain foam drilling fluid with a foam volume of 880ml and a foam half-life of 60 minutes.

[0017] The foaming effect of the foam drilling fluid prepared in this embodiment is as follows: figure 1 shown.

Embodiment 2

[0019] Under normal temperature and pressure conditions, 4.5g of sepiolite was dispersed in 138.75g of deionized water for 12 hours of prehydration treatment, and then 4.5g of sodium dodecylsulfate and 2.25g of sodium dodecylbenzenesulfonate were added. Wherein the mass percentages of sodium lauryl sulfate (the first foaming agent), sodium dodecylbenzenesulfonate (the second foaming agent) and sepiolite (inorganic fiber) are respectively 3%, 1.5%, 3%. %. Stir evenly at 80°C and foam at room temperature at 7,500 rpm for 4.5 minutes to obtain a foam drilling fluid with a foam volume of 860ml and a foam half-life of 65 minutes.

Embodiment 3

[0021] Under normal temperature and pressure conditions, 1.5g of sepiolite was dispersed in 139.5g of deionized water for prehydration treatment for 8 hours, and then 6g of sodium dodecylsulfate and 3g of sodium dodecylbenzenesulfonate were added, of which ten The mass percentages of dialkyl sodium sulfate (the first foaming agent), sodium dodecylbenzenesulfonate (the second foaming agent) and sepiolite (inorganic fiber) are 4%, 2%, and 1%, respectively. Stir evenly at 60°C and foam at room temperature with a mixer at 5000 rpm for 5 minutes to obtain a foam drilling fluid with a foam volume of 960ml and a foam half-life of 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com