Preparation method of stearamide concrete foaming agent compounded component and application thereof

A stearamide-type concrete technology, which is applied in the field of compounding and modifying concrete foaming agents, and the preparation of stearamide-type concrete foaming agent composite components, can solve the problem of bubble rupture and is not suitable for the production of low-density foam concrete , poor foam stability and other issues, to achieve the effect of lower surface tension, small critical micelle concentration, and excellent foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

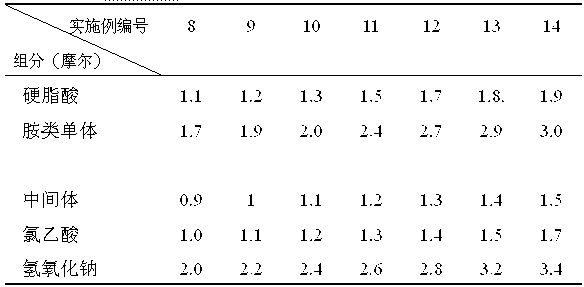

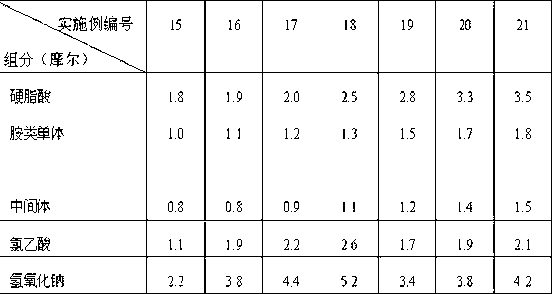

Examples

Embodiment 1

[0018] A preparation method of a stearylamide type concrete foaming agent composite component, comprising the following steps:

[0019] Add 14.2 grams of stearic acid and 20 milliliters of toluene into a three-necked flask with a condensing device, heat to dissolve the stearic acid completely, add 8.3 grams of hydroxyethylethylenediamine, rapidly raise the temperature to 155°C and keep it warm for 4 hours. After cooling, the yellow solid crude product was washed with acetone and vacuum-dried to obtain 14.5 grams of white stearyl hydroxyethyl ethylenediamine intermediate, with a yield of 78.4%;

[0020] Mix 11.1 g of stearyl hydroxyethyl ethylenediamine intermediate with 20 ml of water, stir and heat up to 80-95°C, slowly add sodium chloroacetate aqueous solution with a mass concentration of 15-30%, and keep warm for reaction after the addition is complete 3 hours. Cool, filter out the insoluble matter, and obtain a white emulsion-like viscous liquid, which is the composite co...

Embodiment 2

[0022] A preparation method of a stearylamide type concrete foaming agent composite component, comprising the following steps:

[0023] Add 27 grams of stearic acid and 40 milliliters of toluene into a three-necked flask with a condensing device, heat to dissolve the stearic acid completely, then add 3 grams of ethylenediamine, rapidly raise the temperature to 130°C, and then react at 130-150°C After 8 hours, after cooling, the yellow solid crude product was washed with absolute ethanol and dried to obtain 21.5 grams of white stearyl ethylenediamine intermediate, with a yield of 76.4%;

[0024] Mix 17.8 grams of stearyl ethylenediamine intermediate with 35 milliliters of water, stir and raise the temperature to 80-95 ° C, slowly add an aqueous solution of sodium chloroacetate with a mass concentration of 15-30%, and keep it warm for 3 hours after the addition is completed. After cooling, the insoluble matter is filtered off to obtain the foaming agent composite component of so...

Embodiment 3

[0026] A preparation method of a stearylamide type concrete foaming agent composite component, comprising the following steps:

[0027] Add 25.6 grams of stearic acid and 35 milliliters of toluene into a three-necked flask with a condensing device, heat to dissolve the stearic acid completely, then add 5.8 grams of hexamethylenediamine, rapidly raise the temperature to 160°C and keep it warm for 3 hours, after cooling, The yellow solid crude product was washed with absolute ethanol and dried to obtain 26 grams of white hexamethylene stearyl diamide intermediate, with a yield of 89.1%;

[0028] Mix 25.9 g of hexamethylene stearyl diamine intermediate and 60 ml of water, stir and raise the temperature to 80-95°C, slowly add an aqueous solution of sodium chloroacetate with a mass concentration of 15-30% dropwise and keep it warm for 3 hours. After cooling, the insoluble matter is filtered off to obtain hexamethylene stearyl diamide sodium acetate foaming agent composite component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com