A kind of foam drilling fluid based on nano silicon dioxide material

A nano-silica and nano-material technology, applied in the field of drilling fluid, can solve the problem that foam drilling fluid cannot meet strict requirements, and achieve the effect of meeting cuttings carrying requirements, reducing erosion and good rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The foam drilling fluid based on nano-silica material provided in this example includes water, a foaming agent, a foam stabilizer and nano-silica particles with a particle size of 10-20 nm, wherein the foaming agent is lauryl Sodium benzenesulfonate and foam stabilizer are selected from carboxymethyl cellulose.

[0026] The preparation method of the foam drilling fluid based on nano-silica material provided in this embodiment is as follows:

[0027] First, according to the following mass percentages: foaming agent 0.1%, foam stabilizer 0.1%, nanomaterials 0.05-0.125%, water balance, weigh water, foaming agent, foam stabilizer and nanomaterials;

[0028] Then add water to the stirring device first, then add foaming agent, foam stabilizer and nanomaterials in sequence, and stir for 60s at a speed of 10,000 rpm to obtain a foam drilling fluid based on nano-silica materials.

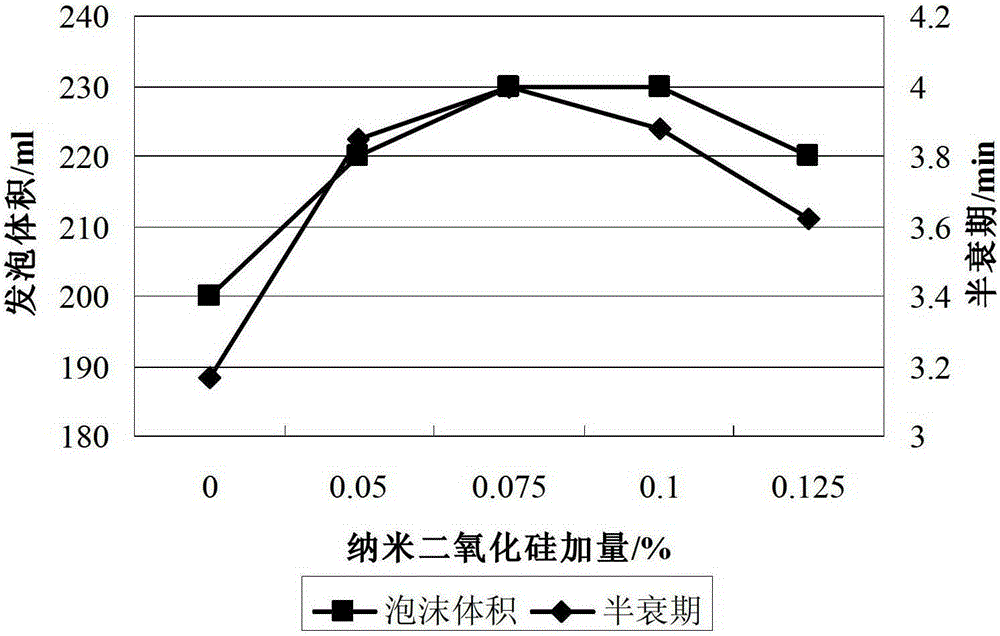

[0029] In this example, in order to investigate the effect of the addition amount of nano-silica ...

Embodiment 2

[0035] The foam drilling fluid based on nano-silica material provided in this example includes water, a foaming agent, a foam stabilizer and nano-silica particles with a particle size of 10-20 nm, wherein the foaming agent is lauryl Sodium benzenesulfonate and xanthan gum are selected as foam stabilizer.

[0036] The preparation method of the foam drilling fluid based on nano-silica material provided in this embodiment is as follows:

[0037] First, according to the following mass percentages: foaming agent 0.1%, foam stabilizer 0.1%, nanomaterials 0.05-0.125%, water balance, weigh water, foaming agent, foam stabilizer and nanomaterials;

[0038] Then add water to the stirring device first, then add foaming agent, foam stabilizer and nanomaterials in sequence, and stir for 60s at a speed of 10,000 rpm to obtain a foam drilling fluid based on nano-silica materials.

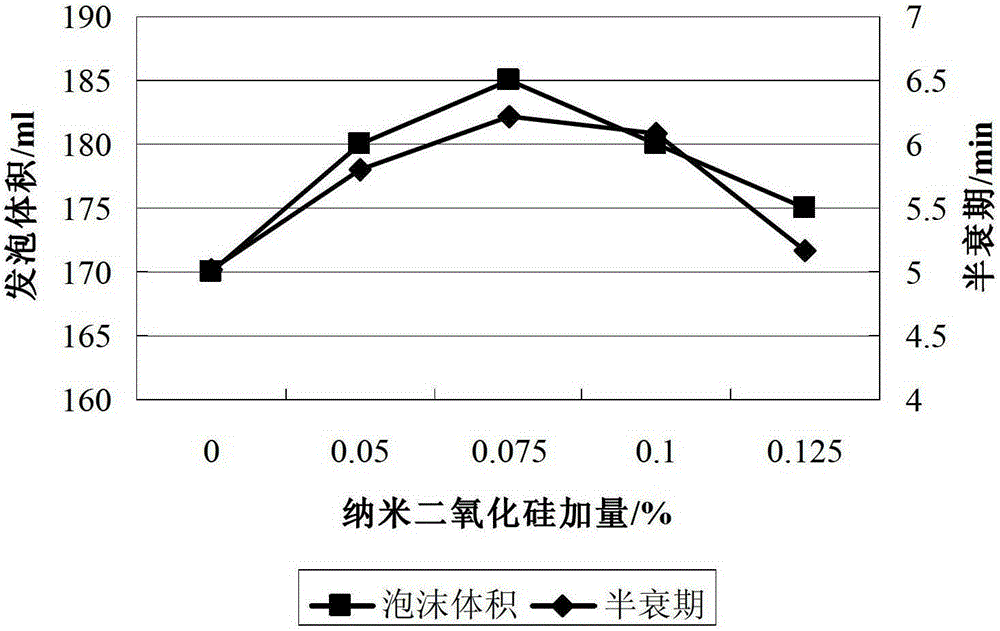

[0039] In this example, in order to investigate the effect of the addition amount of nano-silica on the foaming...

Embodiment 3

[0045] The foam drilling fluid based on nano-silica material provided in this example includes water, a foaming agent, a foam stabilizer and nano-silica particles with a particle size of 10-20 nm, wherein the foaming agent is lauryl Sodium sulfate, foam stabilizer select carboxymethyl cellulose for use.

[0046] The preparation method of the foam drilling fluid based on nano-silica material provided in this embodiment is as follows:

[0047] First, according to the following mass percentages: foaming agent 0.1%, foam stabilizer 0.1%, nanomaterials 0.05-0.125%, water balance, weigh water, foaming agent, foam stabilizer and nanomaterials;

[0048] Then add water to the stirring device first, then add foaming agent, foam stabilizer and nanomaterials in sequence, and stir for 60s at a speed of 10,000 rpm to obtain a foam drilling fluid based on nano-silica materials.

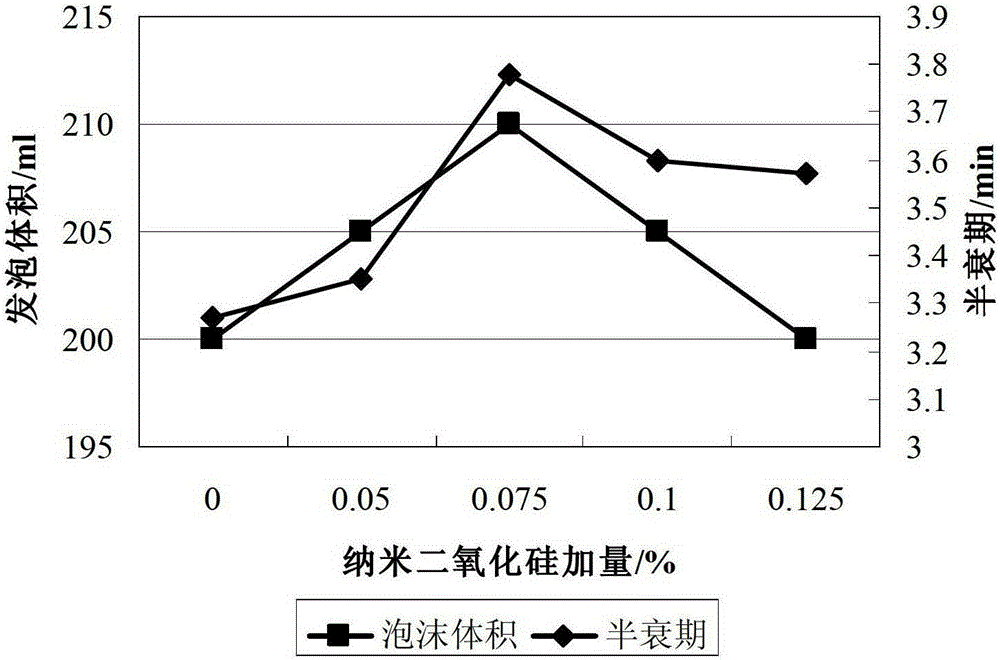

[0049] In this example, in order to investigate the effect of the addition amount of nano-silica on the foaming vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com