Self-drilling type single-liquid and double-liquid grouting reinforcement device and using method

A double-fluid grouting and reinforcement device technology, which is applied in vertical shaft equipment, earthwork drilling, directional drilling, etc., can solve problems such as tension in mining sequence, substandard anchoring quality, and rupture of anchoring agent, so as to alleviate the tension in mining connection, Solve the effect of insufficient anchoring and avoid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

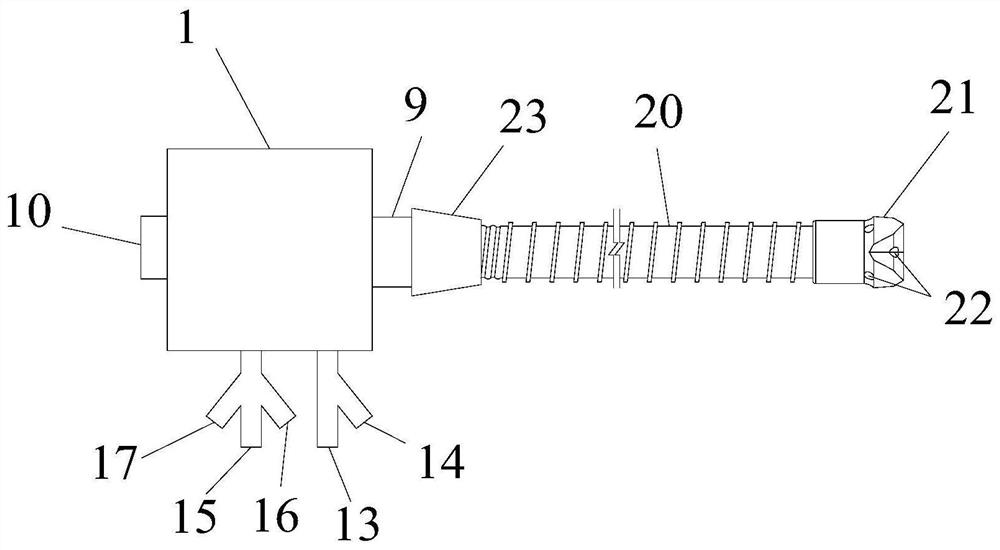

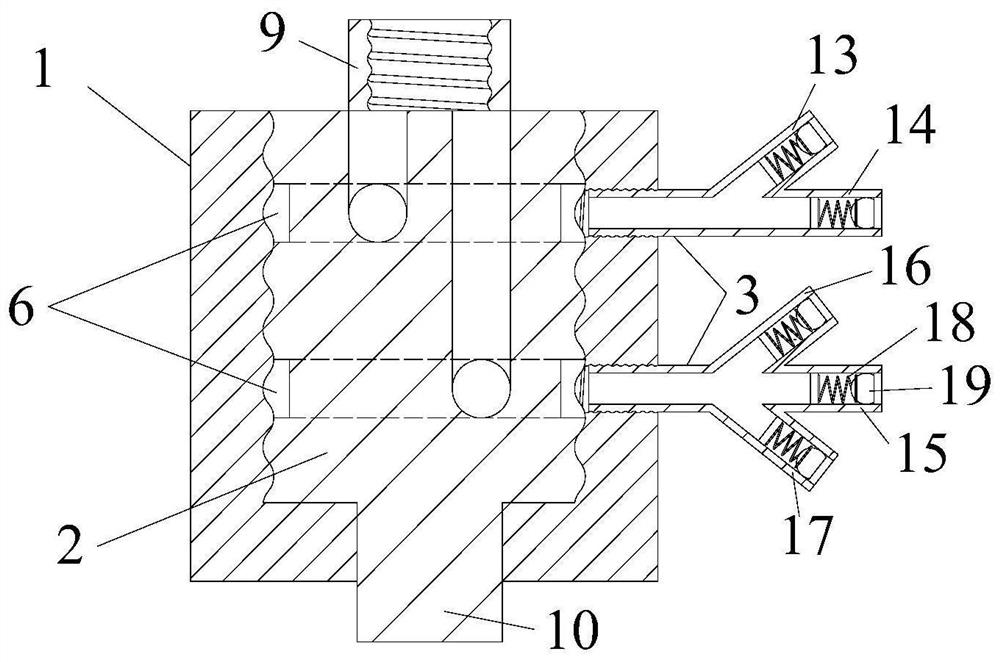

[0036] Such as Figure 1-Figure 8 As shown, a self-drilling single-double liquid grouting reinforcement device includes: a grouting joint and a self-drilling hollow pipe body; the grouting joint includes a sleeve 1, a liquid guide 2 and a liquid inlet pipe 3;

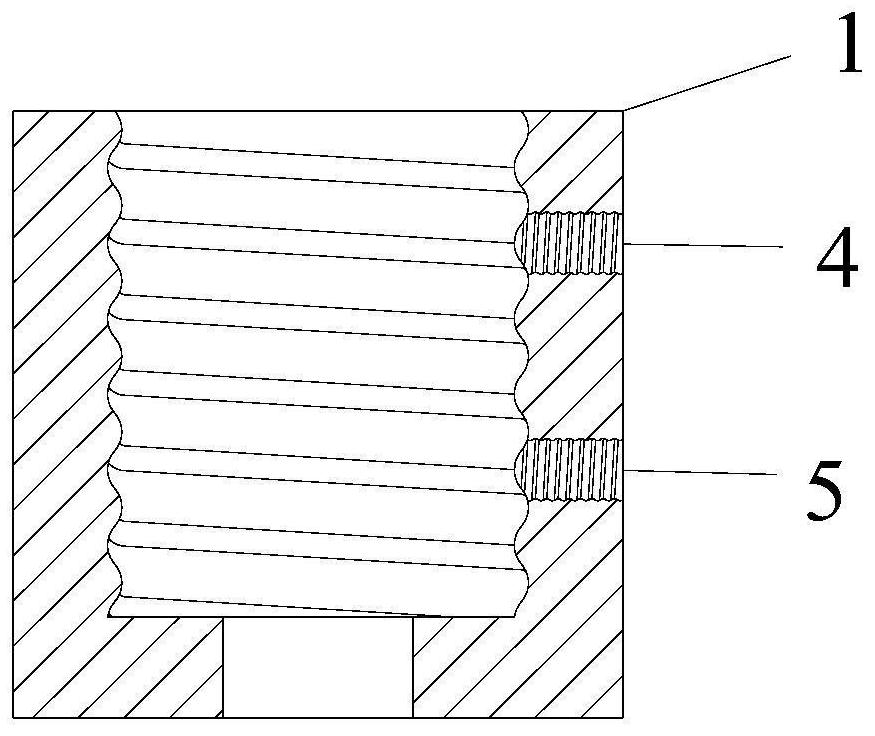

[0037] A The side of the sleeve 1 has two through holes 1 4 and 5 through holes distributed in the radial direction and penetrating the sleeve;

[0038] There are two circumferential grooves on the outside of the liquid guide 2 described in B, and the sleeve 1 is sleeved on the outside of the liquid guide 2. The connection method is any one of screw connection, welding or interference assembly, so that the two circumferential grooves Two independent ring-directed liquid inlet channels 6 of all or part of rings are formed, and the independent ring-directed liquid inlet channels 6 communicate with through hole one 4 and through hole two 5 respectively. There is a vertical blind hole 7 on both sides of the axis, and there...

Embodiment 2

[0042] The method of using the self-drilling single and double liquid grouting reinforcement device includes the following steps:

[0043] S1: Connect the tail end of the self-drilling hollow pipe body with the drilling device through the drill pipe connecting sleeve, then move the pipe body to the position where the hole is to be drilled in the coal and rock wall, open the drilling device to drill, and drill to the designed After the depth, inject high-pressure air to clean the bottom of the hole, and remove the drilling device.

[0044] S2: First screw the grout stopper from the end of the pipe body to the hole of the drilled hole, then screw the upper protrusion of the grouting joint to the end of the hollow pipe body, and connect the straight pipe to A of the double-liquid grouting The liquid injection pipe and the straight pipe two are connected to the B liquid injection pipe of double-liquid grouting. By controlling the ratio of the two grouts, the slow-setting grout is ...

Embodiment 3

[0048] Connect the same kind of grout injection pipe for full-length grouting reinforcement, and other steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com