Adjustable multiple coil extruding and expanding drilling tool

An adjustable and helical technology, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of reduced pile side friction resistance, affecting the pile depth, and large amount of soil extrusion, so as to improve the pile side soil friction resistance and Effects of foundation pile bearing capacity, strong penetration hole-forming ability, and wide-stratum adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

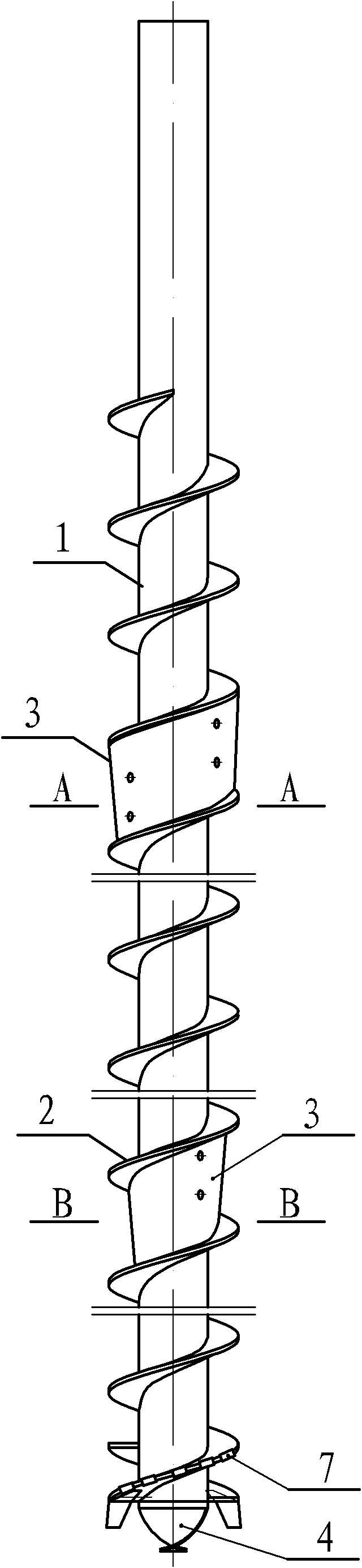

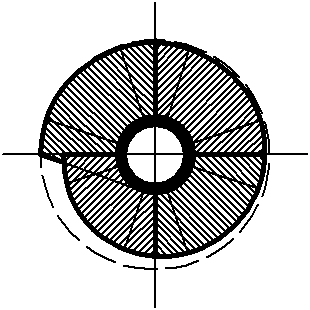

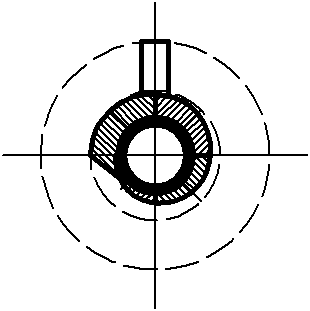

[0031] Such as figure 1 and Figure 4 As shown, the adjustable multistage helical extruding and expanding drilling tool of the present invention comprises a hollow connecting rod 1, and the middle and lower part of the outer wall of the connecting rod 1 is provided with a helical blade 2, and the helical blade 2 can be an equal-pitch helical blade, or can be It is a helical blade with unequal pitch. The edge of the helical blade 2 is welded and fixed with a plurality of alloy cutting teeth 7, which are used to improve the drilling and abrasion resistance of the drilling tool. The bottom end of the connecting rod 1 is provided with a drill bit 4.

[0032] A plurality of spiral extruded bodies 3 are coaxially connected in series at any position on the connecting rod 1, only two of which are schematically drawn in the figure, and the specific quantity required is determined according to the geological conditions of the construction site, usually in Between 2-4, the spiral extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com