Construction method of cement-soil-rock gravity wall with composite mixing of bucket hob wheel

A construction method, hob wheel technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as foundation pit instability, enclosure wall deformation, large vibration and noise, and achieve wide ground adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

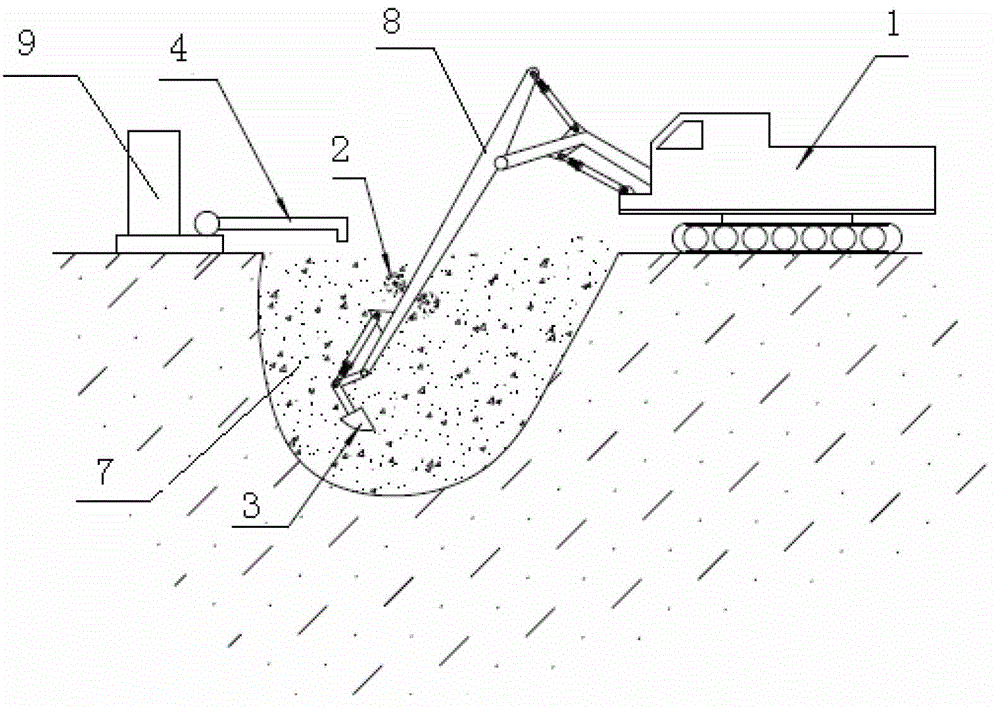

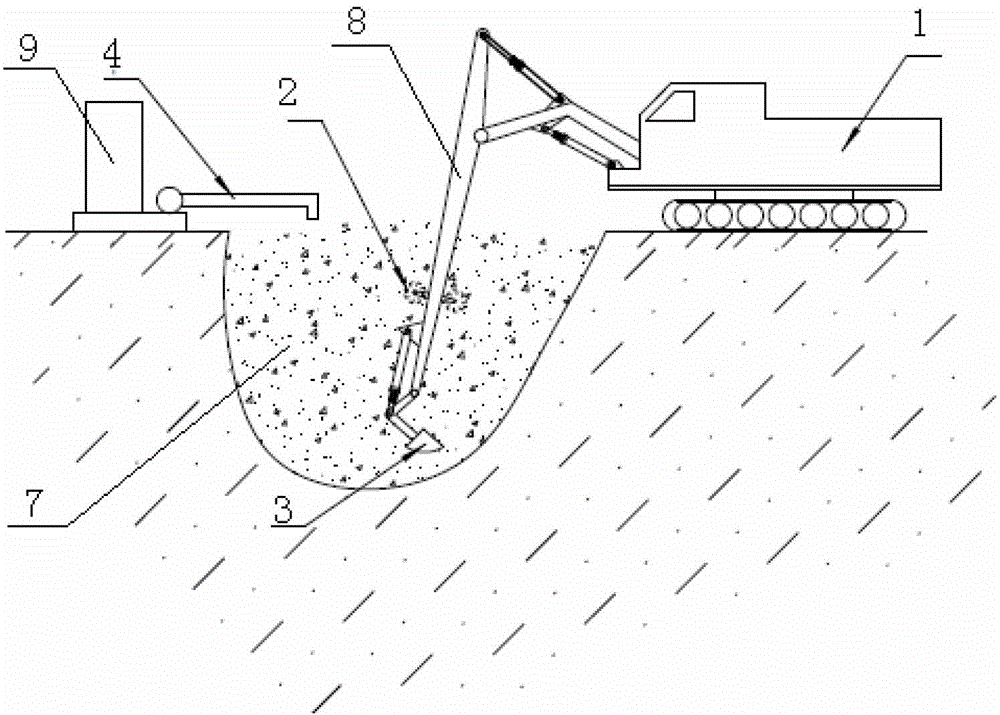

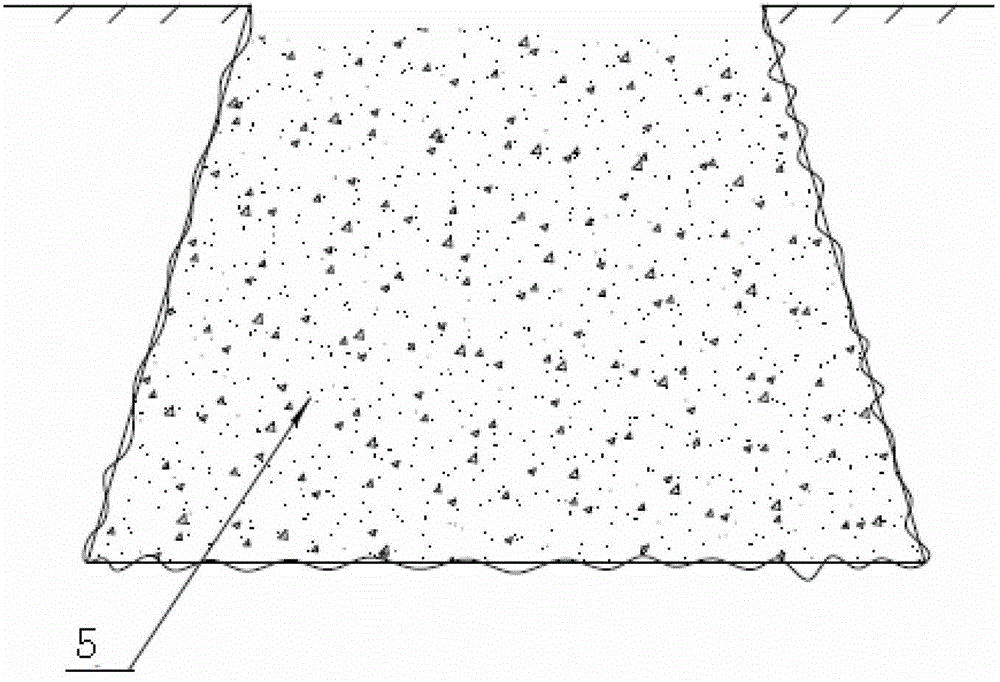

[0021] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. figure 1 Schematic diagram for the bucket hob wheel compound mixing cement earth stone gravity wall construction at the beginning of construction. figure 2 It is a schematic diagram of the bucket hob wheel compound mixing cement earth stone gravity wall construction operation. Such as figure 1 and 2 As shown, the present invention is equipped with a hob 2 on the mechanical swing arm 8 of the crawler hydraulic bucket excavator 1, and the hobs 2 are one or more groups, and the grid bucket 3 of the crawler hydraulic bucket excavator 1 enters When the soil layer is excavated, a mud truck 9 is installed on the soil pit 7 limits dug out, and a mud pipe 4 is stretched out on the mud truck 9, and the outlet of the mud pipe 4 is aimed at the earth pit 7 dug out, and Mud enters the mud pipe 4 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com