Drilling-fixing integrated device and method for yolk coal terrane

A technology of soft coal and rock formations, applied in the field of coalbed methane development, can solve problems such as collapsed holes, and achieve the effects of increasing porosity, reducing difficulty, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

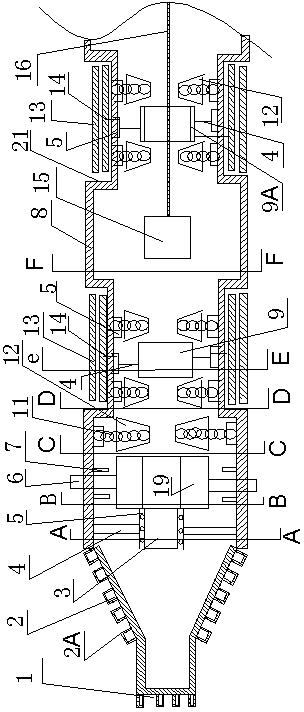

[0035] In this embodiment, the forward direction is the drilling direction of the drill bit.

[0036] Such as figure 1 As shown, the drilling-solid integration device for soft coal and rock formations of the present invention includes a drill pipe 8 and an extruding helix 2 with a truncated cone shape, and the drill pipe 8 is connected to an external power mechanism in transmission. The end with a larger diameter of the extruded helix 2 is its rear end and is fixedly connected to the front end of the drill rod 8 in a screwed manner, and the end with a smaller diameter of the extruded helix 2 is its front end and is provided with a drill bit 1 (The drill bit 1 is preferably set integrally with the extruding helix 2, and the drill bit 1 can also be set separately and fixedly connected to the front end of the extruding helix 2), and the diameter of the drill bit 1 is the same as that of the front end of the extruding helix 2 .

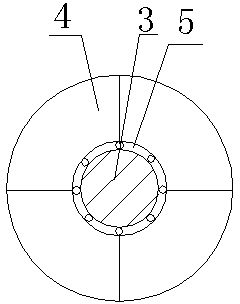

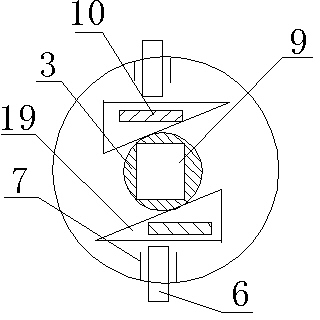

[0037] Such as figure 1 with figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com