A step-by-step grouting reinforcement method for extremely broken surrounding rock in underground engineering

A technology of grouting reinforcement and underground engineering, which is applied in underground chambers, earthwork drilling, shaft equipment, etc. It can solve the problems of unguaranteed anchoring force, anchor rod sticking, easy segregation and precipitation of grout, etc., and solve the problem of surrounding rock Collapsing holes and sticking drills, enhancing its own bearing capacity, and improving the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

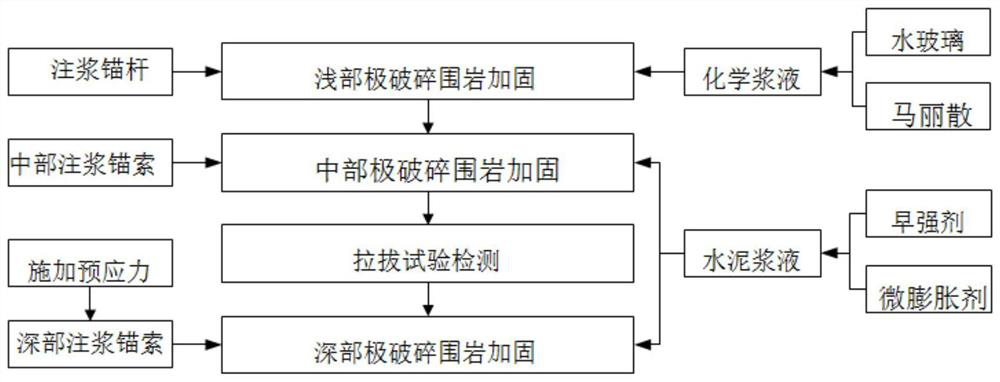

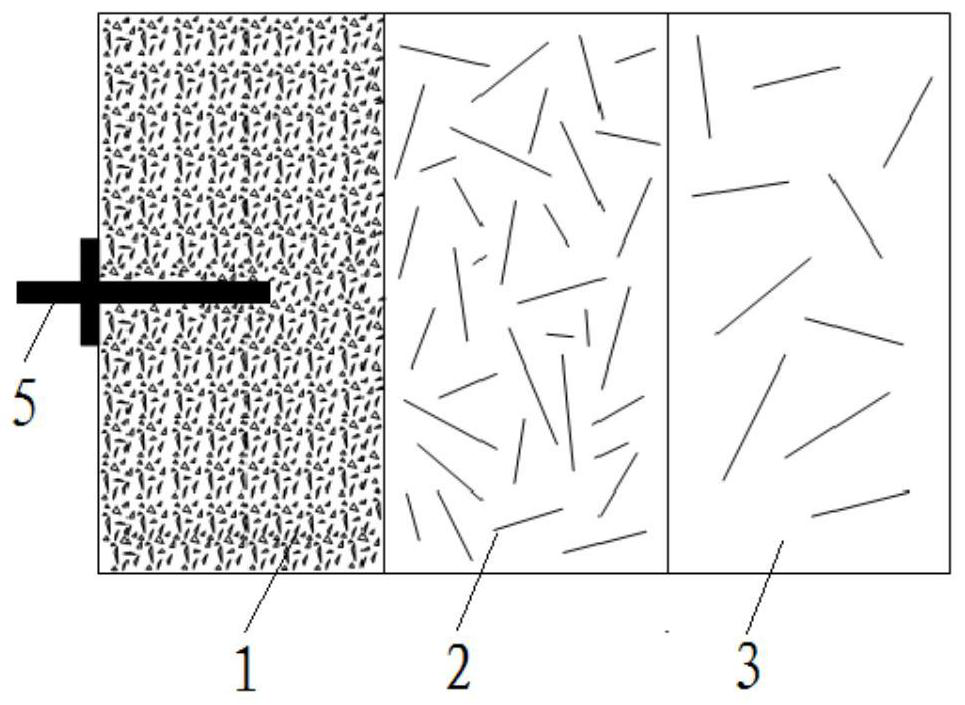

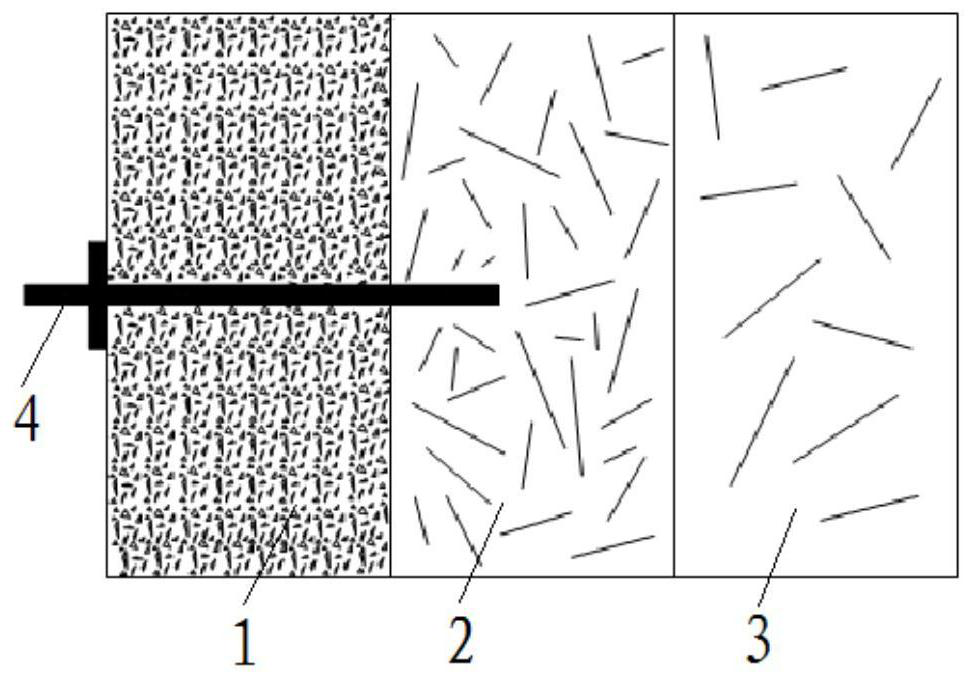

[0027] refer to Figure 1-4 As shown, the underground engineering extremely broken surrounding rock step-by-step grouting reinforcement method of the present invention comprises the following steps:

[0028] S1. Perform grouting reinforcement on the extremely broken surrounding rock 1 in the shallow part;

[0029] S2. Grouting and reinforcing the extremely broken surrounding rock 2 in the middle through the grouting anchor cable 4 in the middle;

[0030] S3. Perform a pull-out test on the central grouting anchor cable 4 to determine whether the pull-out force reaches the set range, if yes, execute step S4, and if not, execute step S5;

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com