Diameter-expanding fixing cylinder for preventing hole collapse of pile foundation pit

A technology for fixing cylinders and foundation pits, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of steel casings being difficult to lower, damage, and large surrounding loads, etc., to achieve firm and reliable devices, good operability, The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

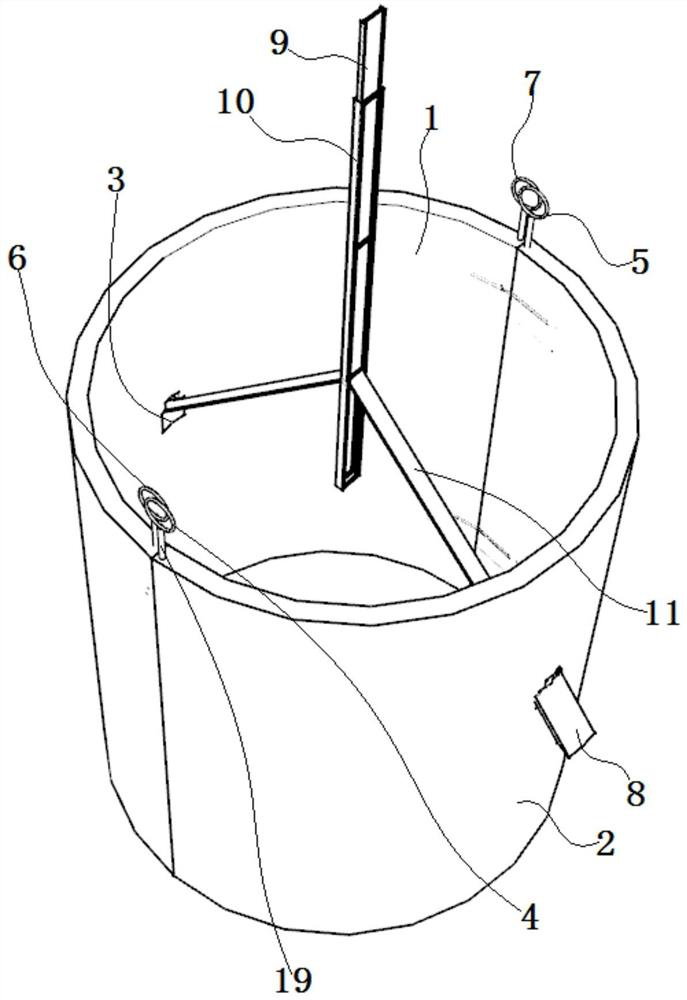

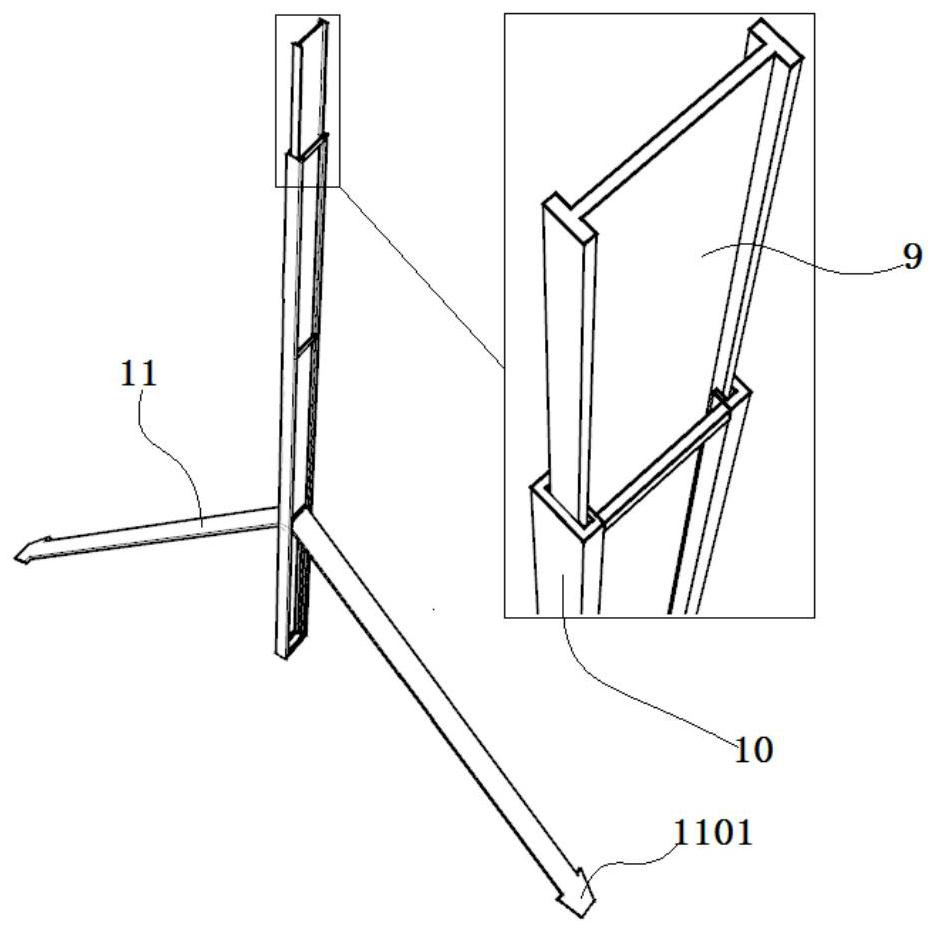

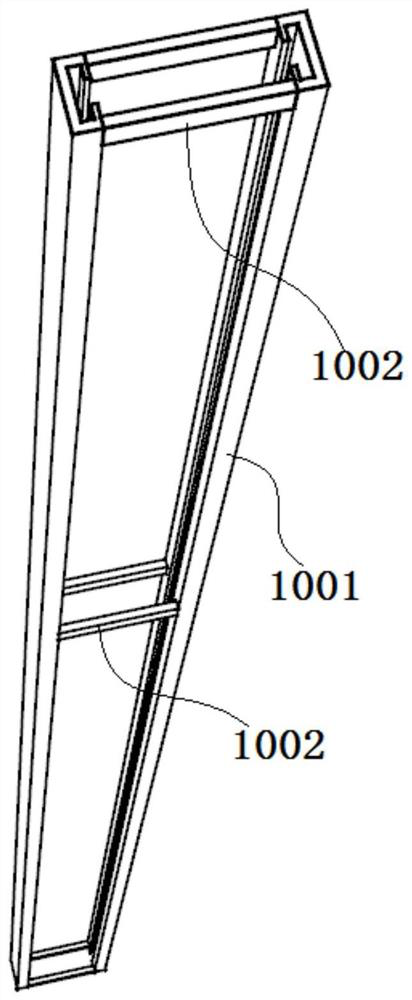

[0053] This embodiment discloses a fixed tube for preventing pile foundation pit from collapsing and expanding its diameter, which includes a tube wall I1, a tube wall II2 and a bifurcated lowering rod.

[0054] The cylinder wall I1 and the cylinder wall II2 are respectively two arc-shaped plates bisected by a vertical cylinder along the axis, and the openings of the cylinder wall I1 and the cylinder wall II2 are opposite to each other.

[0055] see figure 1 Or 7, the cylinder wall I1 and the cylinder wall II2 are provided with a through hole 3, the through hole 3 runs through the inner and outer sides of the cylinder wall I1 and the cylinder wall II2, the through hole 3 on the cylinder wall I1 and the vertical edge of the cylinder wall I1 The arc of the cylinder wall II2 is 90°, and the arc of the through hole 3 on the cylinder wall II2 and the vertical edge of the cylinder wall II2 is 90°.

[0056] The two through holes 3 are located on the same horizontal plane, which is ...

Embodiment 2

[0079] This embodiment discloses a fixed tube for preventing pile foundation pit from collapsing and expanding its diameter, which includes a tube wall I1, a tube wall II2 and a bifurcated lowering rod.

[0080] The cylinder wall I1 and the cylinder wall II2 are respectively two arc-shaped plates bisected by a vertical cylinder along the axis, and the openings of the cylinder wall I1 and the cylinder wall II2 are opposite to each other.

[0081] see figure 1 Or 7, the cylinder wall I1 and the cylinder wall II2 are provided with a through hole 3, the through hole 3 runs through the inner and outer sides of the cylinder wall I1 and the cylinder wall II2, the through hole 3 on the cylinder wall I1 and the vertical edge of the cylinder wall I1 The arc of the cylinder wall II2 is 90°, and the arc of the through hole 3 on the cylinder wall II2 and the vertical edge of the cylinder wall II2 is 90°.

[0082] The two through holes 3 are located on the same horizontal plane, which is ...

Embodiment 3

[0101] The main structure of this embodiment is the same as that of Embodiment 2. Further, the slide bar A14, slide bar B, slide bar C, and slide bar D are all arc-shaped rods, and the radii of these arc-shaped rods are all in line with the cylinder wall I1 and the cylinder wall. The radius of wall II2 matches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com