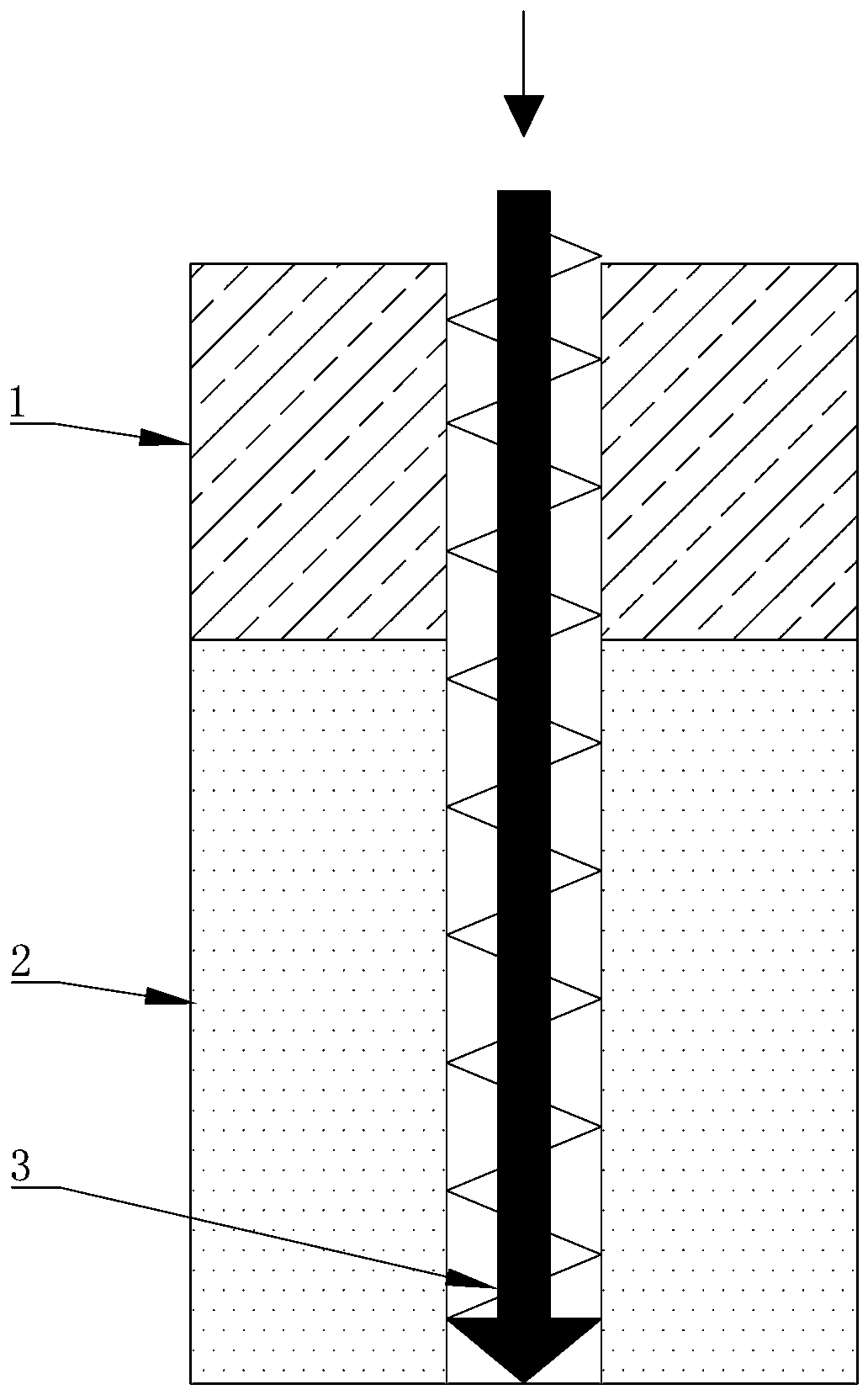

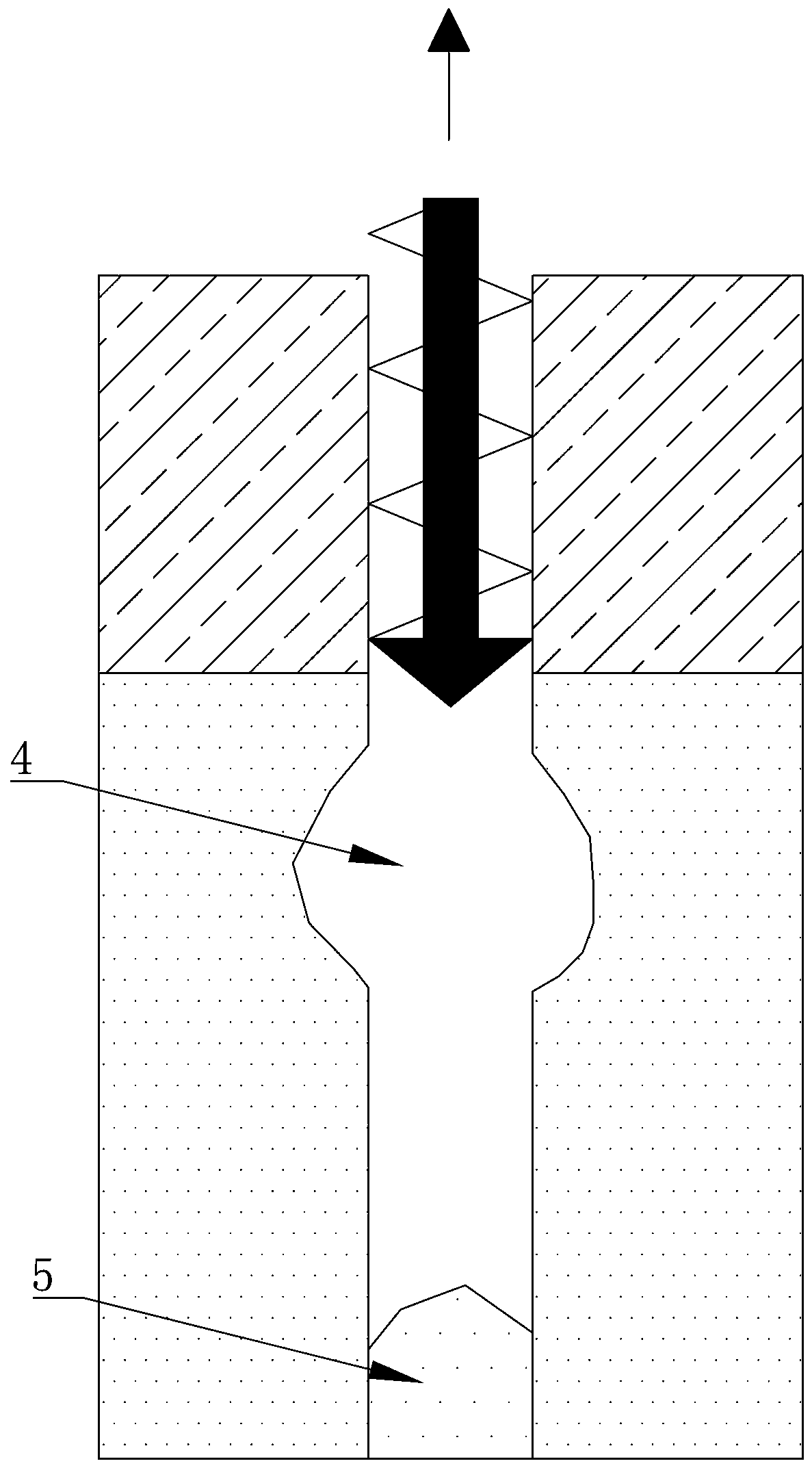

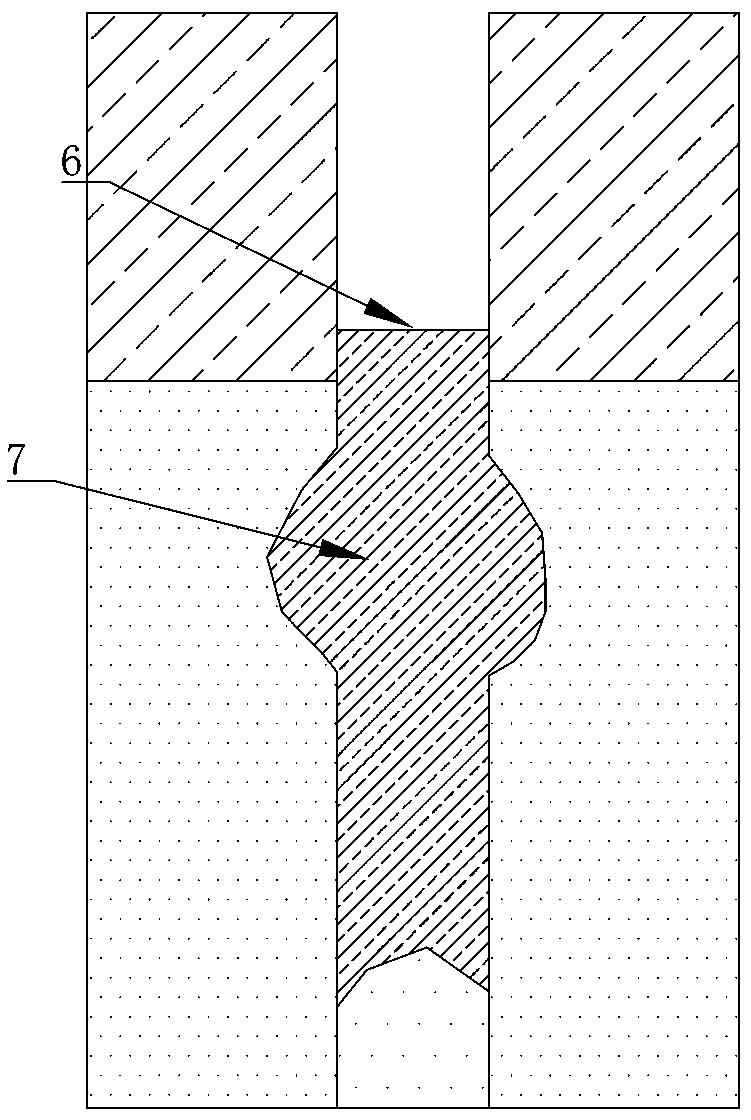

Non-excavation in-situ replacement filling spiral drilling method of unconsolidated stratum

A non-excavation, loose technology, applied in the direction of drilling equipment and methods, drill bits, drilling equipment, etc., can solve problems such as hole collapse, and achieve the effects of cost saving, stability improvement, and construction process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0033] Our construction team entered the Laishui County civil air defense foundation pit support site. A 26-meter auger drilling rig entered the site to construct slope protection piles. The pile diameter is 600mm, the pile spacing is 1200mm, and the number of piles is 330. On September 30, the drilling rig was in place and started piling. On the second day of construction, the drilling rig encountered loose and weak ground, and the hole wall collapsed, making it difficult to drill and hindered. Through understanding, it is known that the collapsed section is a loose silty sand layer, the dry cohesion of the formation is extremely poor, and its characteristic value of bearing capacity is far smaller than the value provided by the investigation report.

[0034] Considering that the formation is dry, we want to achieve the purpose of pore formation by increasing the water content of the formation. After a day of hard work, it is quite difficult to implement this idea. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com