Patents

Literature

169results about How to "Avoid collapsing holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

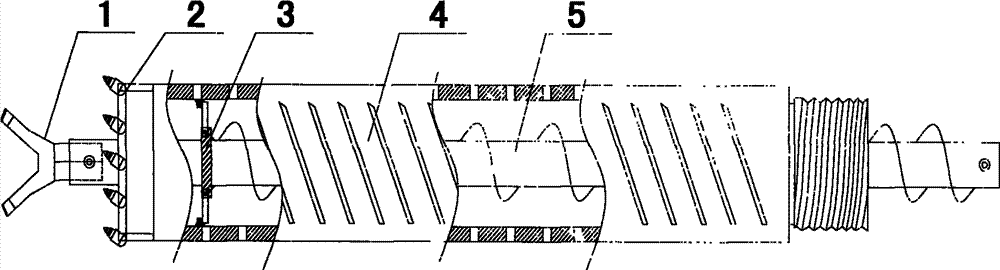

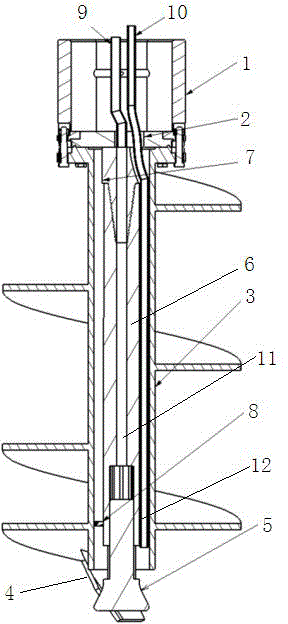

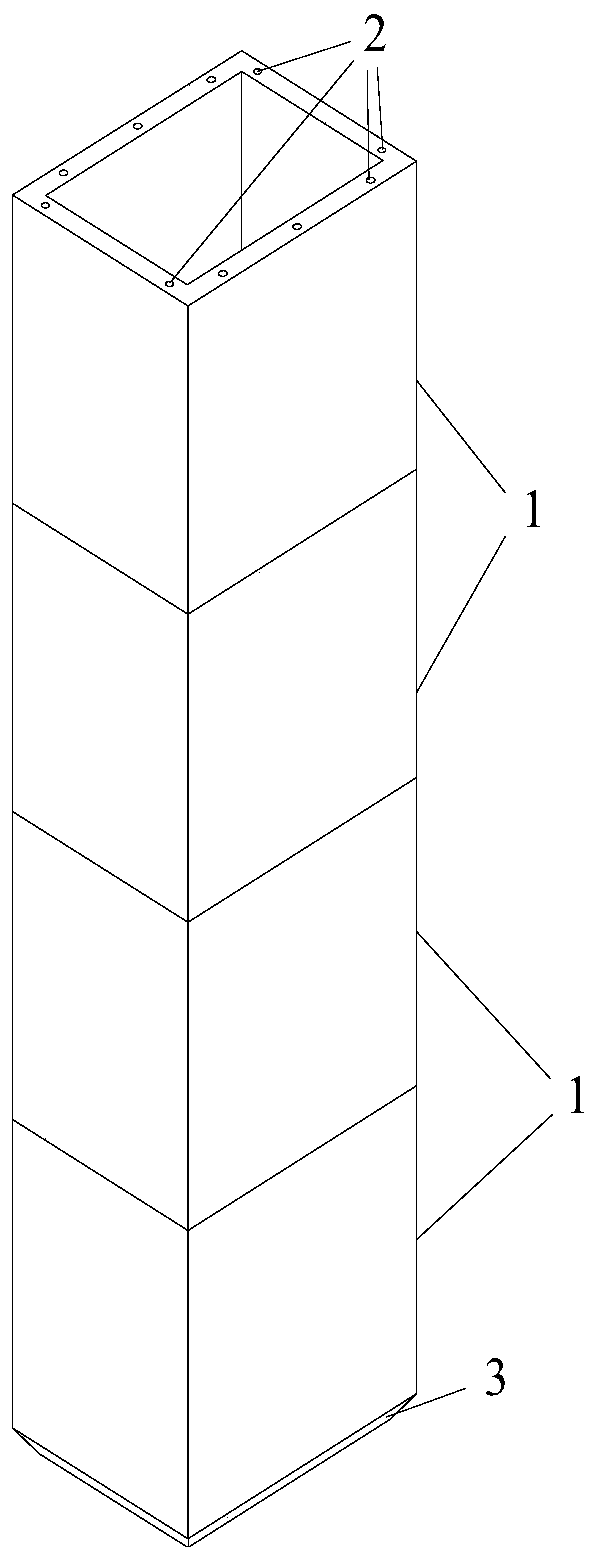

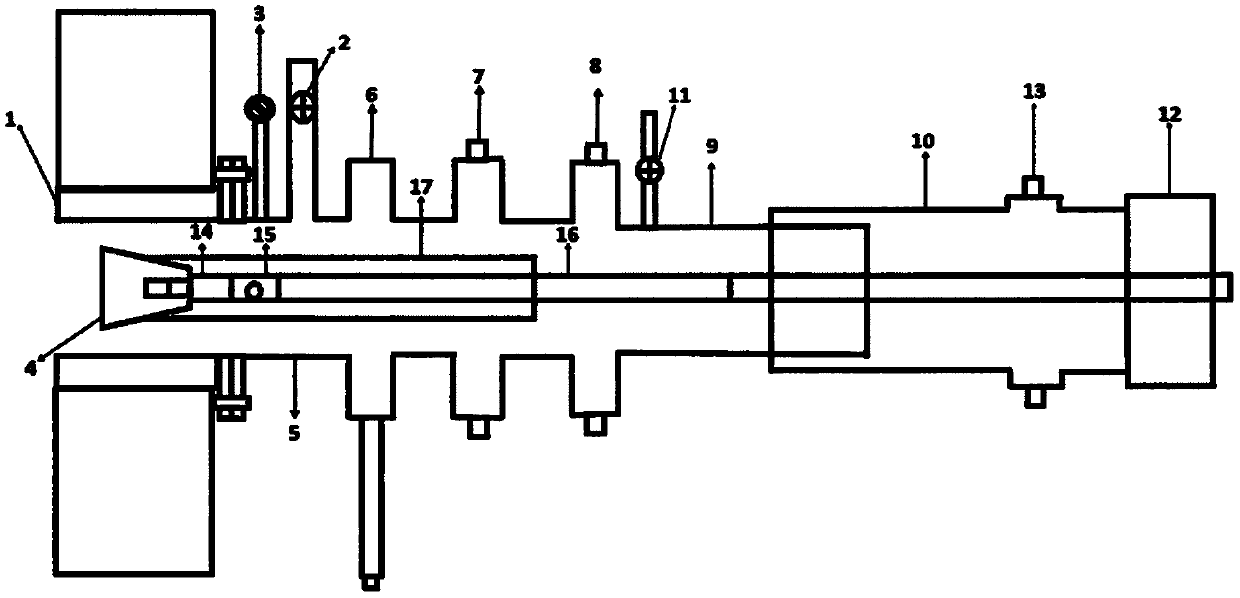

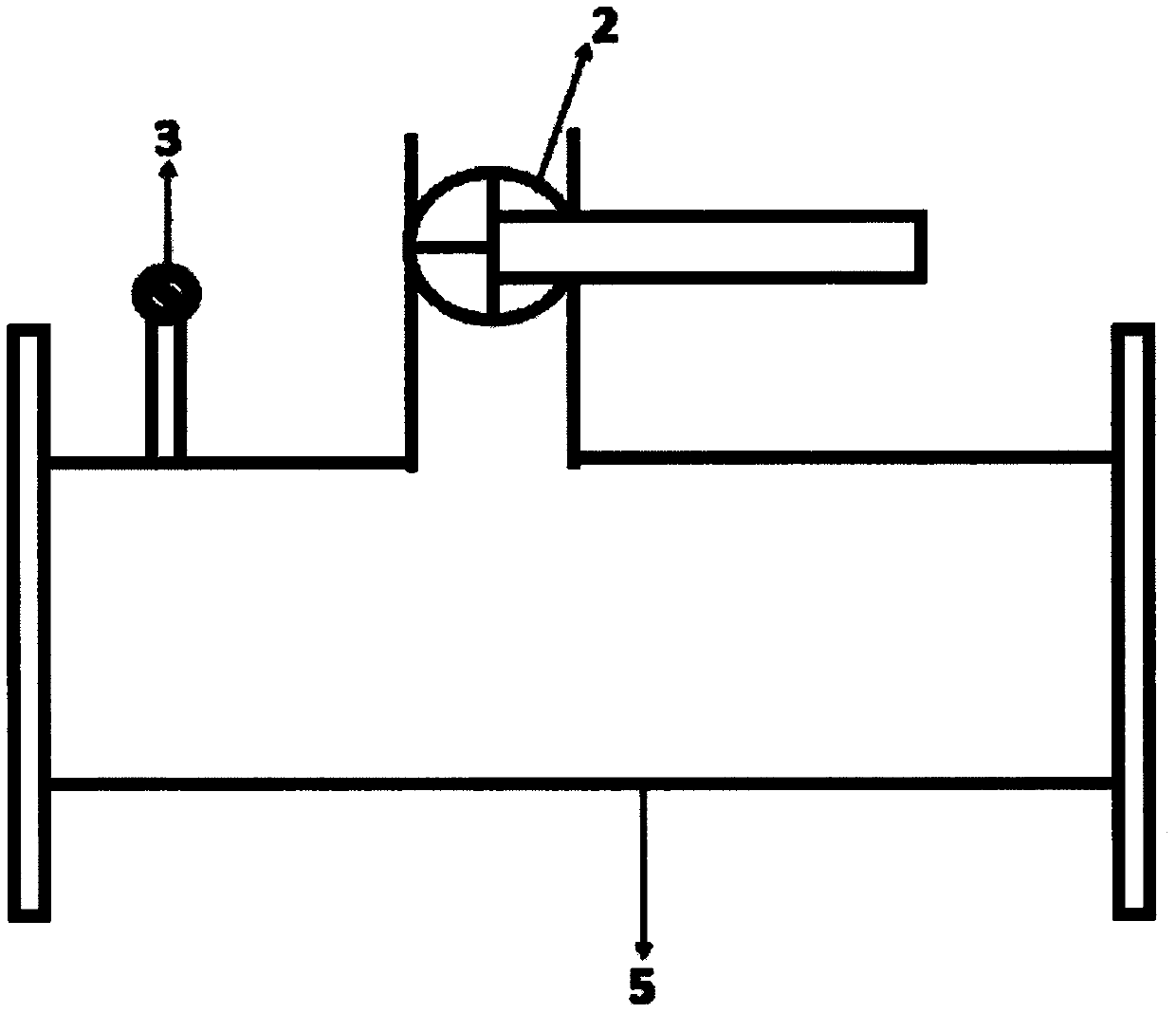

Coal seam drilling hole-collapse preventing lower sleeve device capable of drilling along with drill and drilling method

InactiveCN103114810AAvoid collapsing holesAvoid situations where drilling is uselessDrilling machines and methodsDrill bitPetroleum engineering

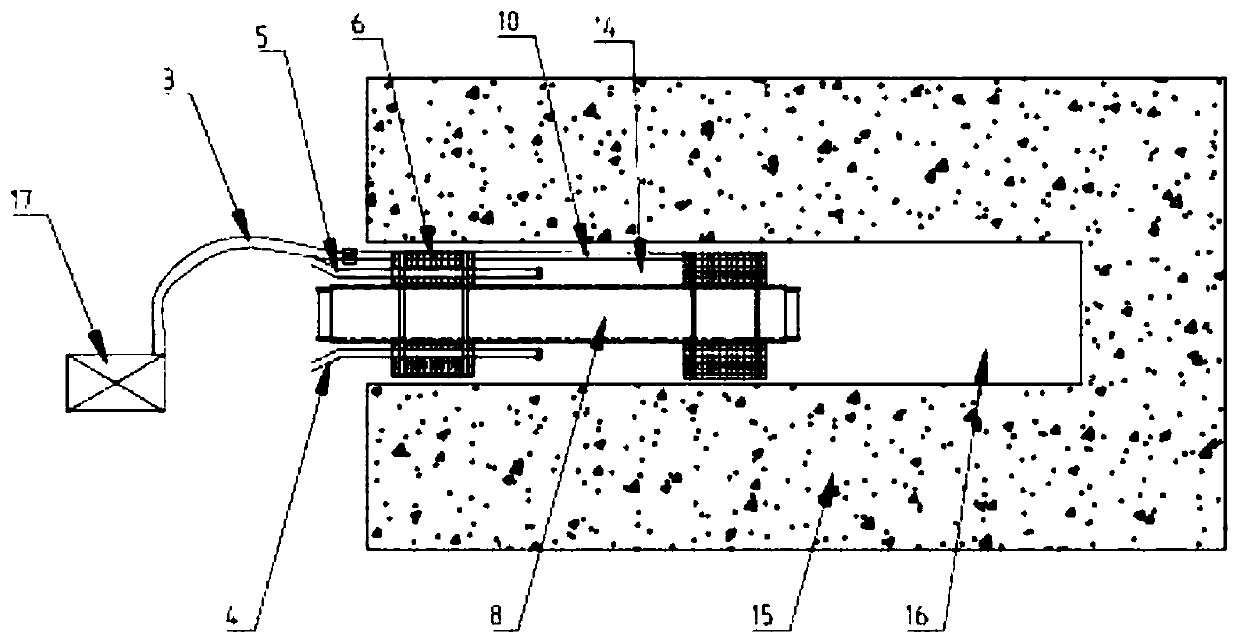

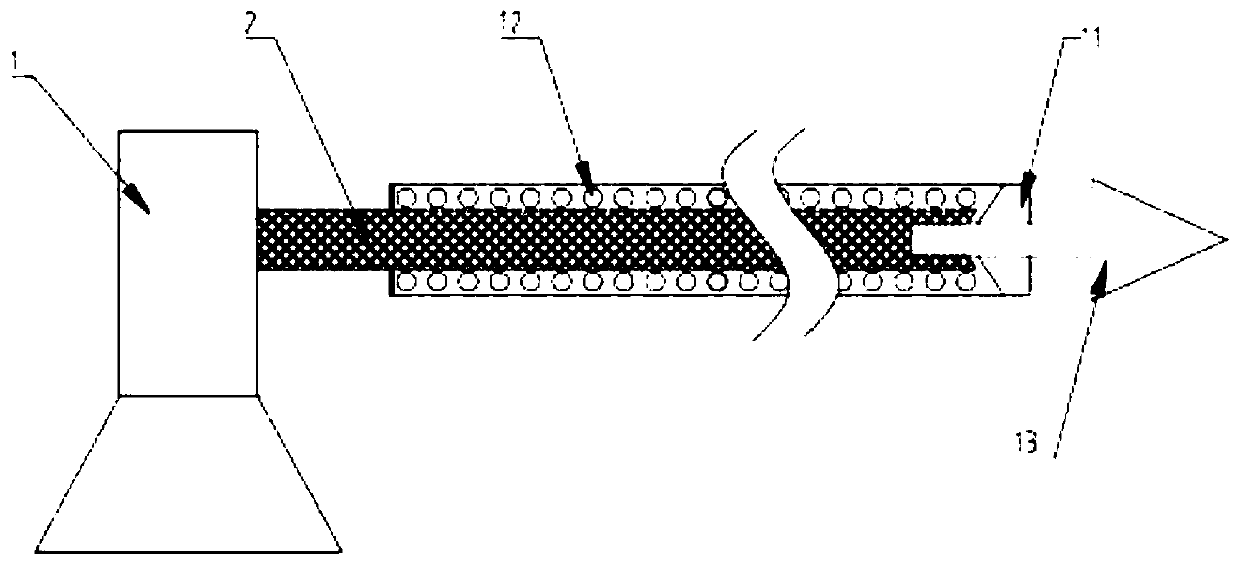

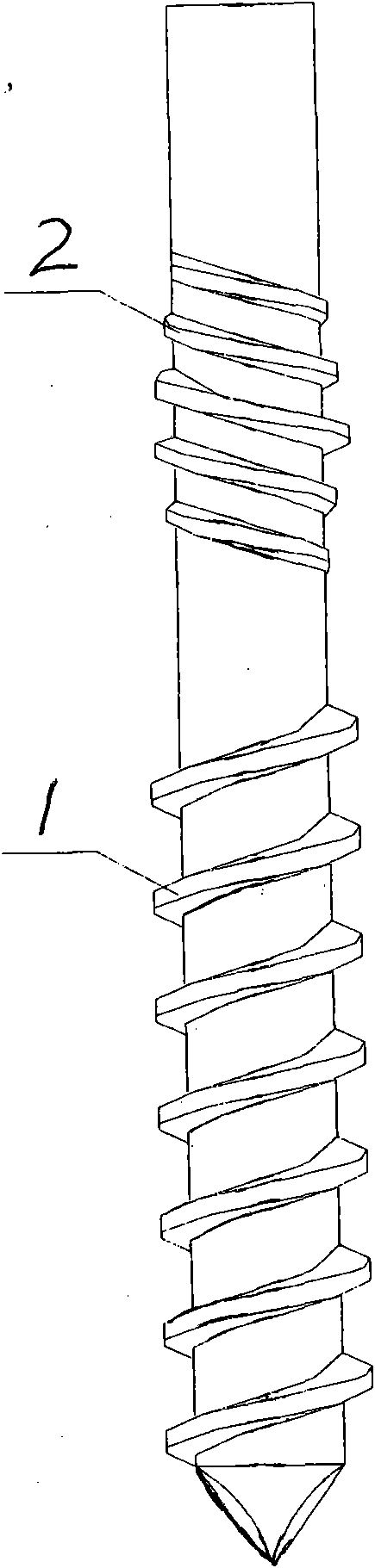

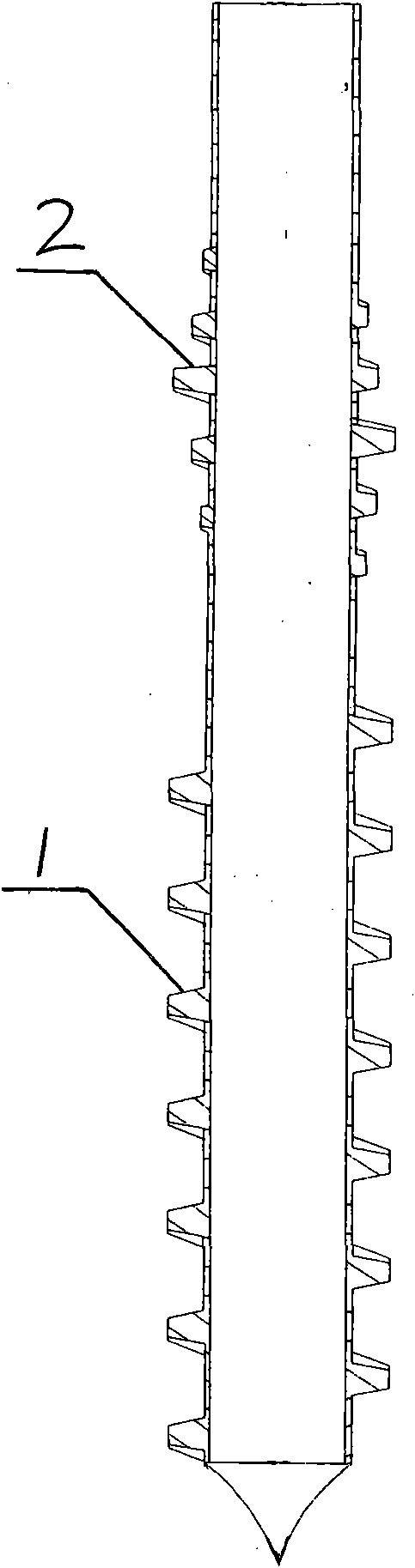

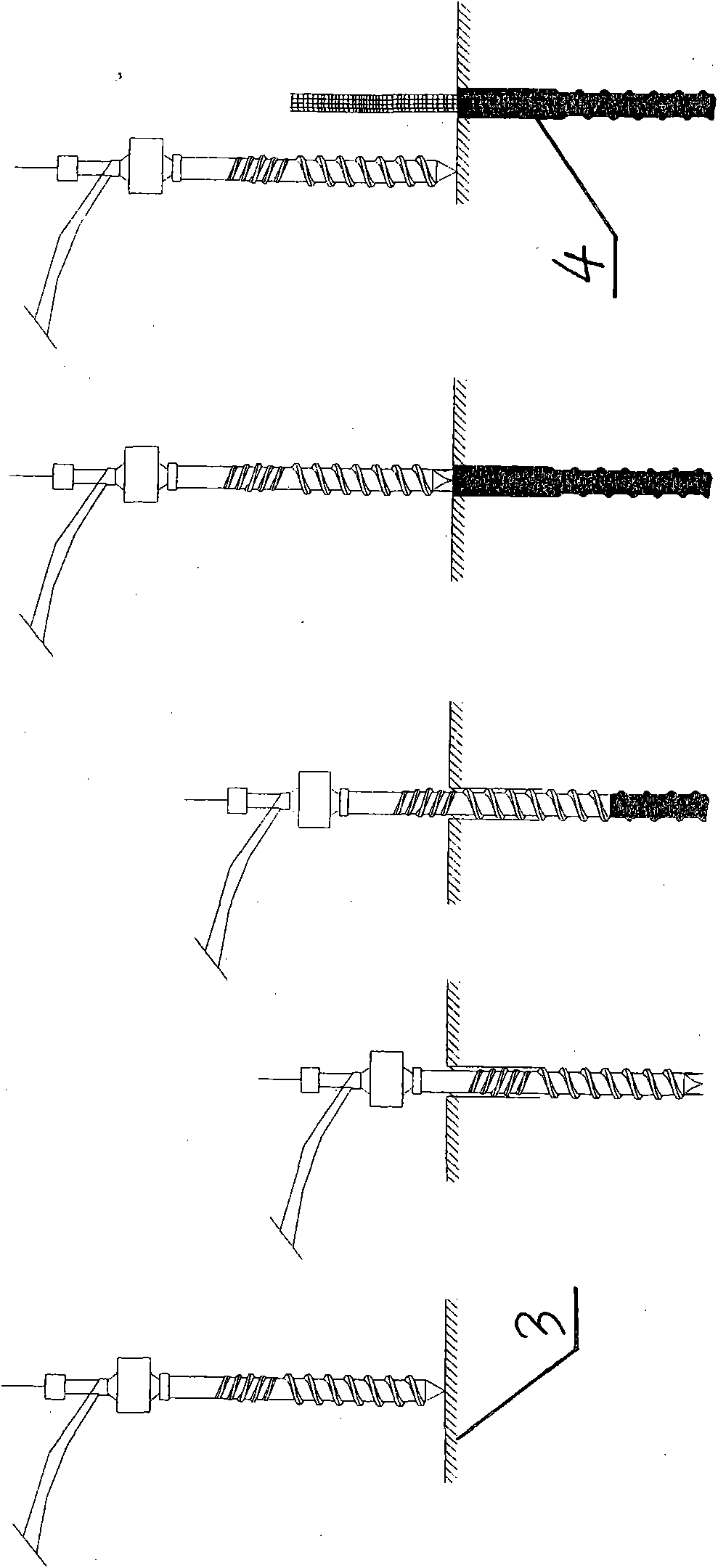

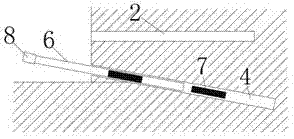

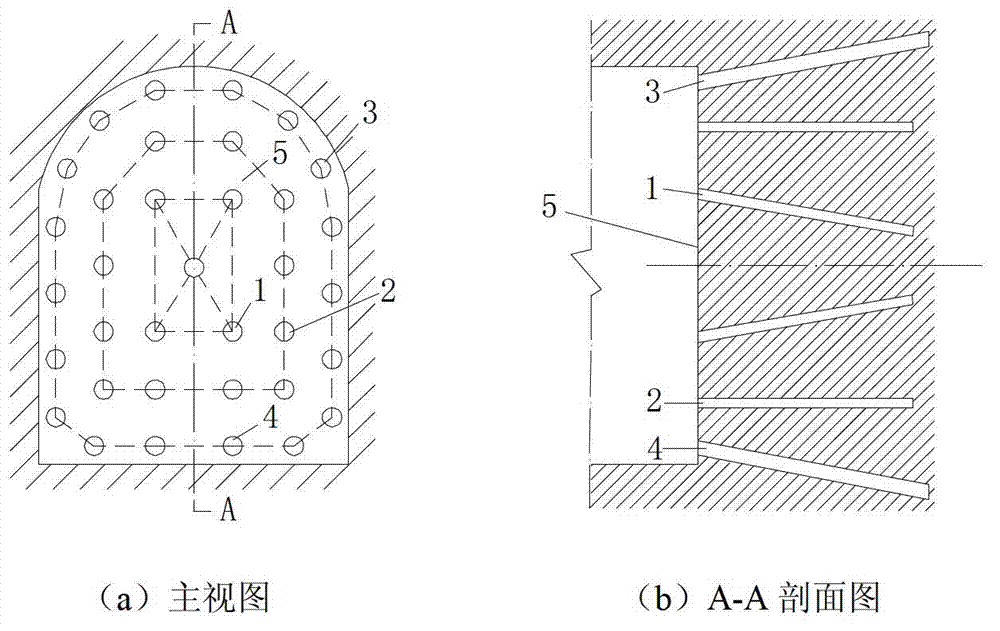

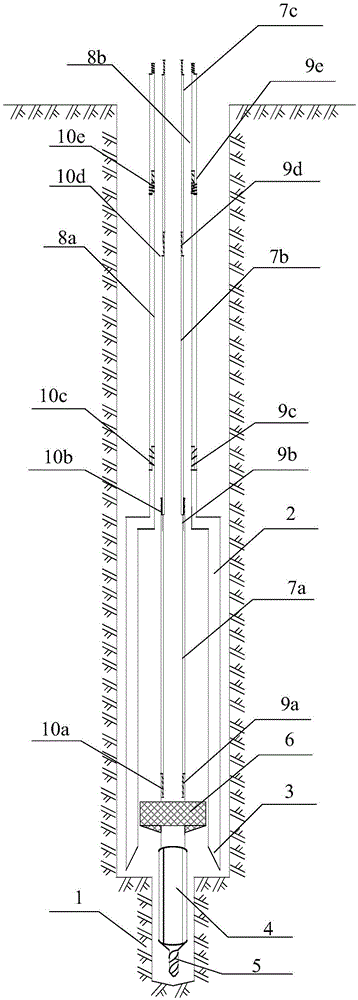

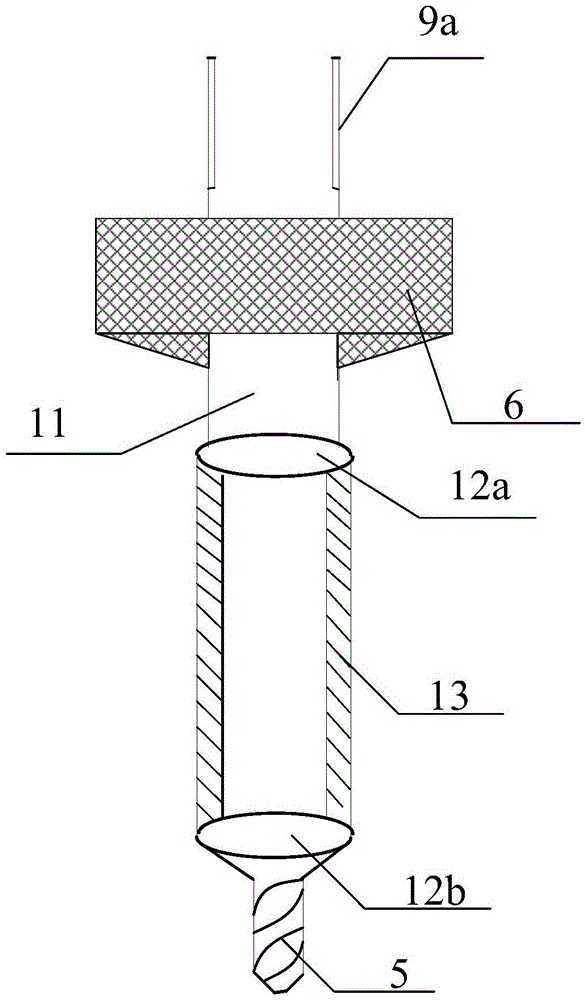

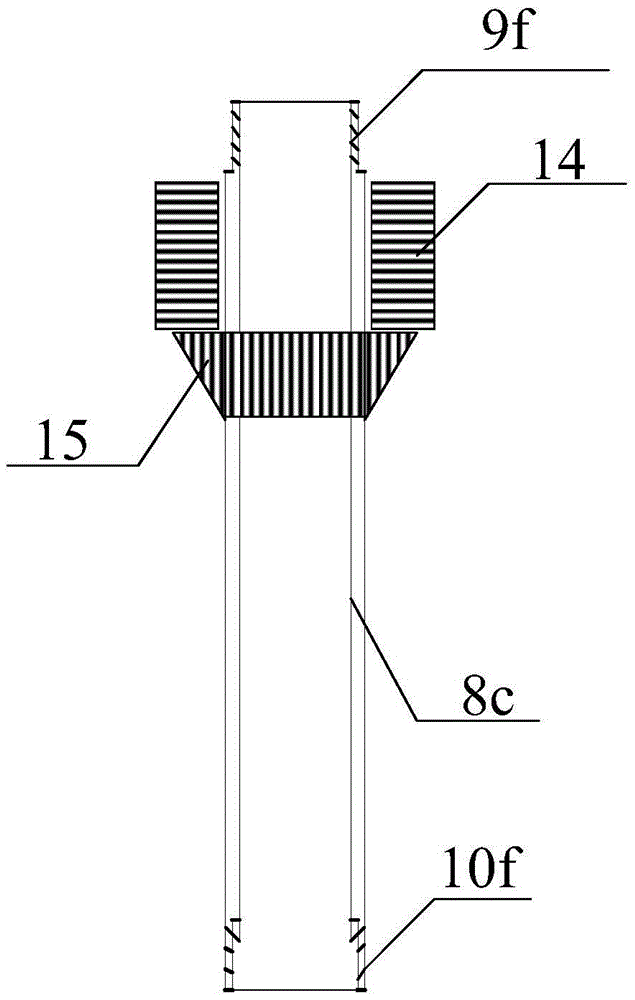

The invention discloses a coal seam drilling hole-collapse preventing lower sleeve device capable of drilling along with a drill and a drilling method. The device is particularly formed by a cavel drill (1), a hose bit (2), a combined propelling device (3), a mesh sleeve (4) and a twisting drill rod (5). According to the coal seam drilling hole-collapse preventing lower sleeve device, in the drilling process of the drill and the drilling process of the twisting drill rod, the combined propelling device (3) is utilized to drive the mesh sleeve (4) and the hose bit (2) to rotate together, and consequently drilling of the twisting drill rod and coal breaking drilling of the hose bit are simultaneously carried out so as to drive the mesh sleeve to drill into a coal hole. When the coal hole reaches a predetermined depth, the twisting drill rod is retreated from the interior of the sleeve, and the mesh sleeve is left in the coal hole. Therefore, the coal seam drilling hole-collapse preventing lower sleeve device plays a role in preventing the coal hole from collapsing and avoids the occurrence of the condition that the drill hole is obsolete.

Owner:CHINA UNIV OF MINING & TECH

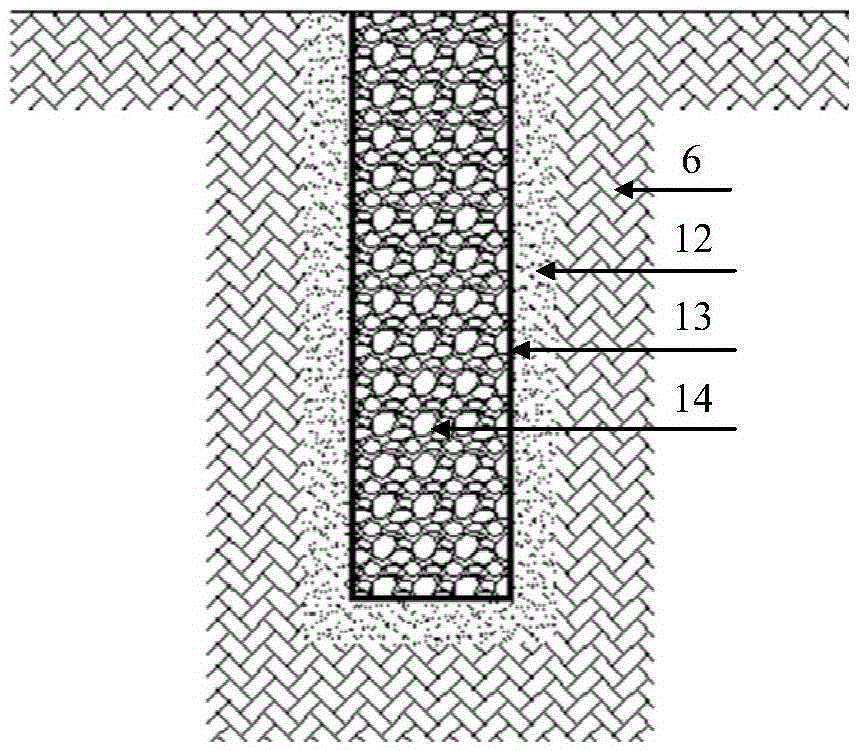

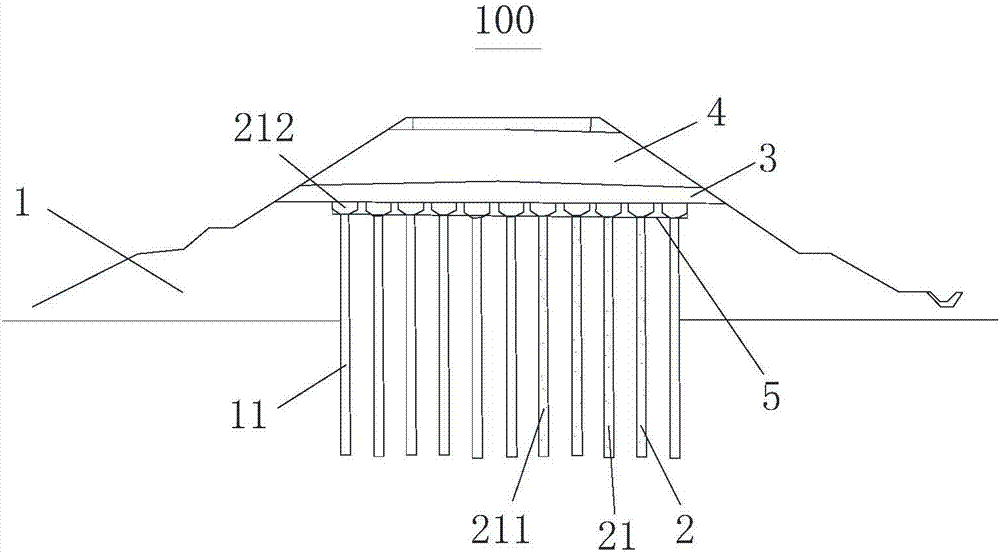

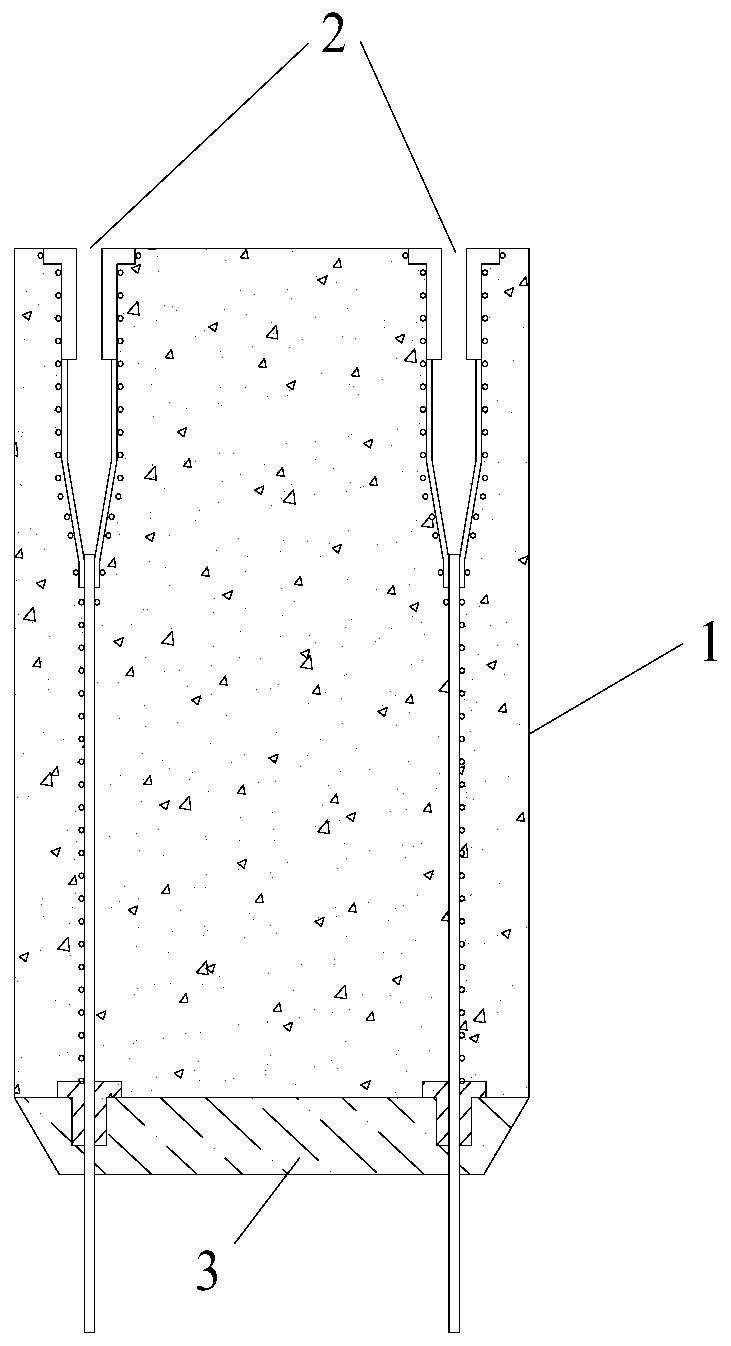

Cast-in-situ bored pile with wall protected through microorganism soil solidification and construction method

ActiveCN105386432AAvoid collapsing holesImprove pile side frictionBulkheads/pilesSoil preservationDrill holeBiology

The invention relates to a cast-in-situ bored pile with the wall protected through microorganism soil solidification and a construction method. The construction method includes the steps that a, a hole is drilled through a drilling rig, and meanwhile microorganism bacterium liquid is injected into the drilled hole and diffused into a foundation around the drilled hole; b, a separation plate is placed into the drilled hole; c, a cementing solution is injected into the drilled hole and diffused into the foundation around the drilled hole and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and soil around the drilled hole is solidified; d, after the separation plate sinks to the bottom of the hole, the separation plate is lifted out; and e, the step a, the step b, the step c and the step d are repeated until hole forming is completed. Mud is not used for protecting the wall in the construction process of the cast-in-situ bored pile with the wall protected through microorganism soil solidification, so that mud cakes and pollution are avoided, and pile side friction resistance is brought into full play; in addition, a microorganism solidified soil layer and a microorganism wall protecting cementing surface are formed by the reinforced soil around the pile and can not only prevent hole collapse but also bear loads in combination with the pile, and therefore the bearing capacity of the single pile is improved.

Owner:NANJING FORESTRY UNIV

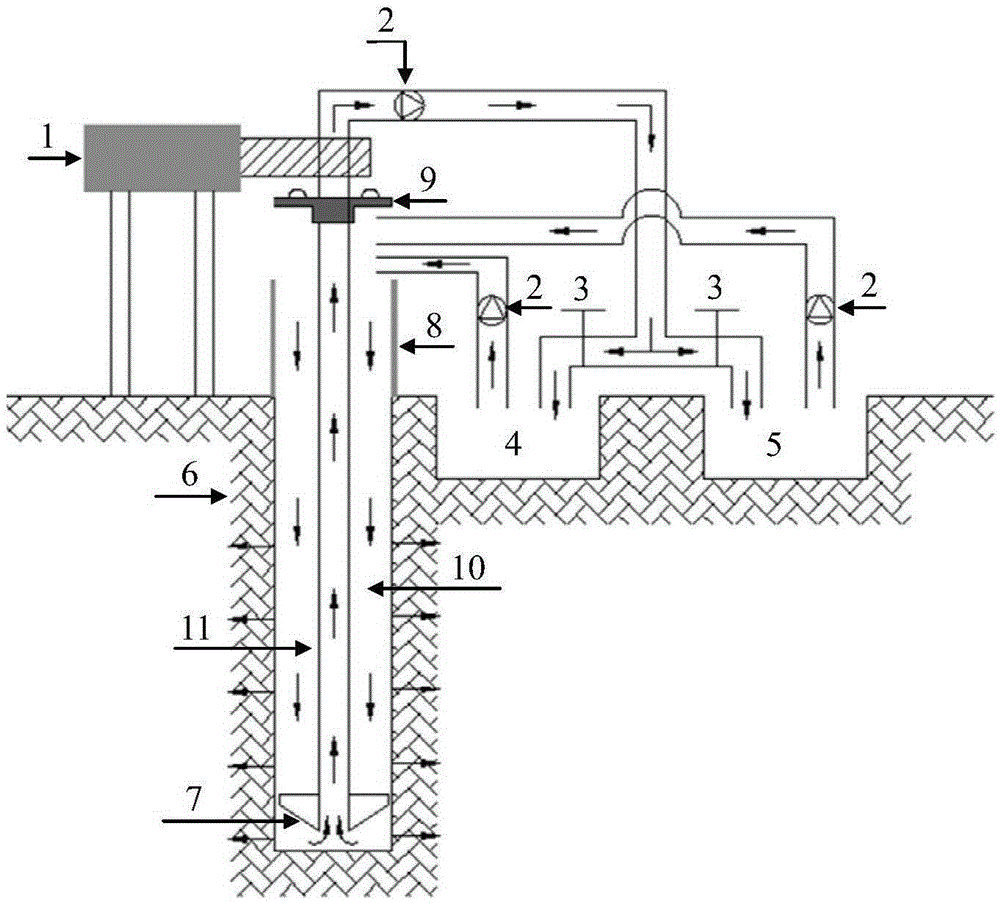

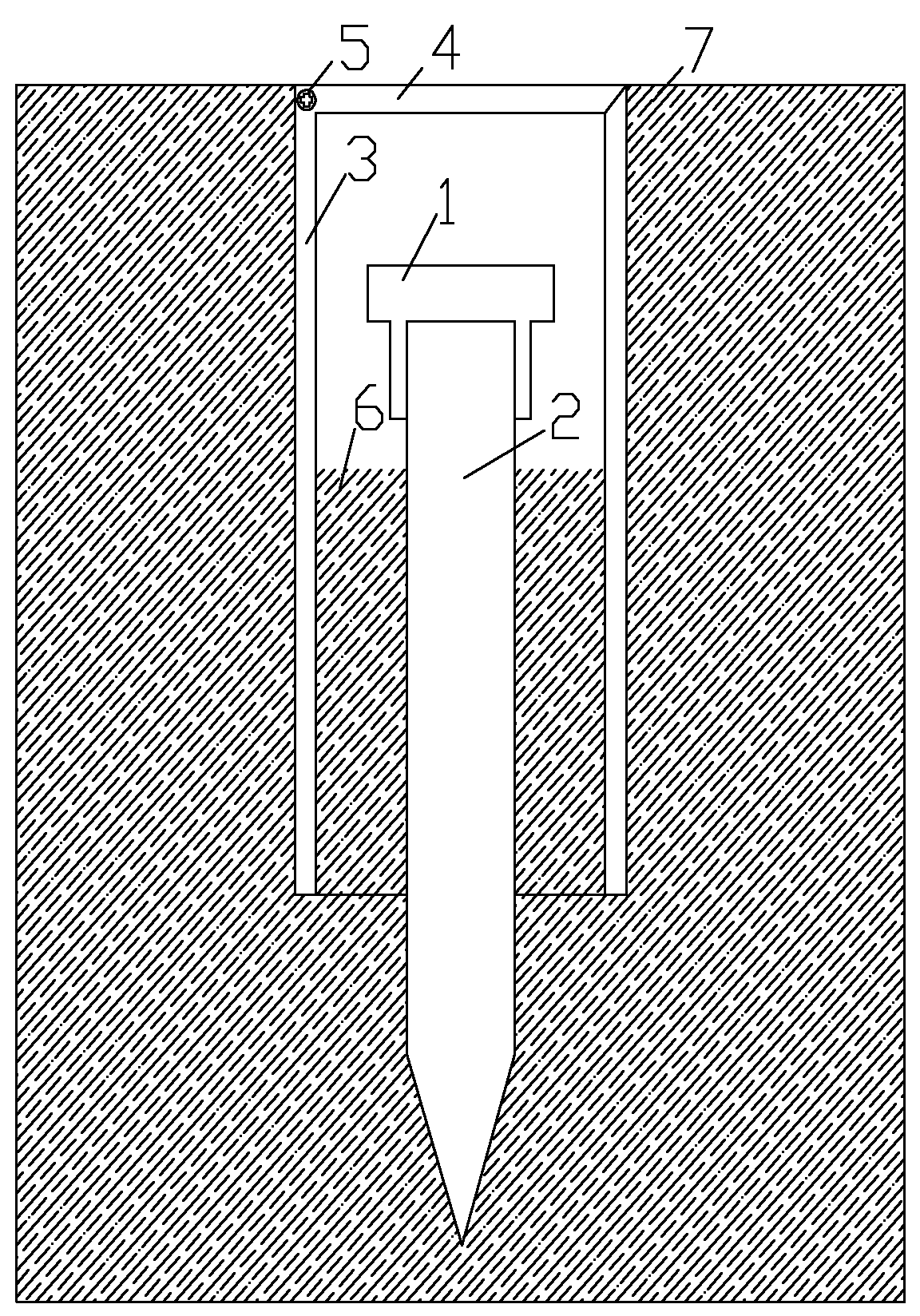

Method for increasing extracting and drilling stability of low-permeability soft coal seam

ActiveCN111021960AAvoid collapsing holesAvoid serious phenomena such as spray holesGas removalSealing/packingThermodynamicsPipe

The invention relates to a method for increasing the extracting and drilling stability of a low-permeability soft coal seam. The method comprises the following steps of (1) sleeving the outer side ofa drill pipe with a telescopic trailing sleeve; (2) deeply drilling into the coal seam; (3) withdrawing the drill pipe and the telescopic trailing sleeve from a drilling cavity after drilling into thespecified depth; (4) putting an anti-collapse pipe in the drilling cavity to the bottom of the drilling cavity; (5) respectively fixing two flexible air bags to both ends of a hole sealing pipe, andconnecting the two flexible air bags through a ventilating pipe; (6) respectively fixing a grouting hose and a return hose to the upper and lower ends of the flexible air bag which is close to the drilling cavity; (7) sleeving the anti-collapse pipe with the hole sealing pipe, and inflating the two flexible air bags, so that the two flexible air bags are tightly abutted with the inner wall of thedrilling cavity; (8) grouting the sealed space between the two flexible air bags; and (9) removing a grouting device after grouting is completed, and tightening the grouting hose and the return hose.According to the method, the extracting and drilling stability is guaranteed, so that the problems of the low hole forming rate and the poor hole sealing effect of the soft coal seam are solved.

Owner:山西潞安矿业集团慈林山煤业有限公司李村煤矿

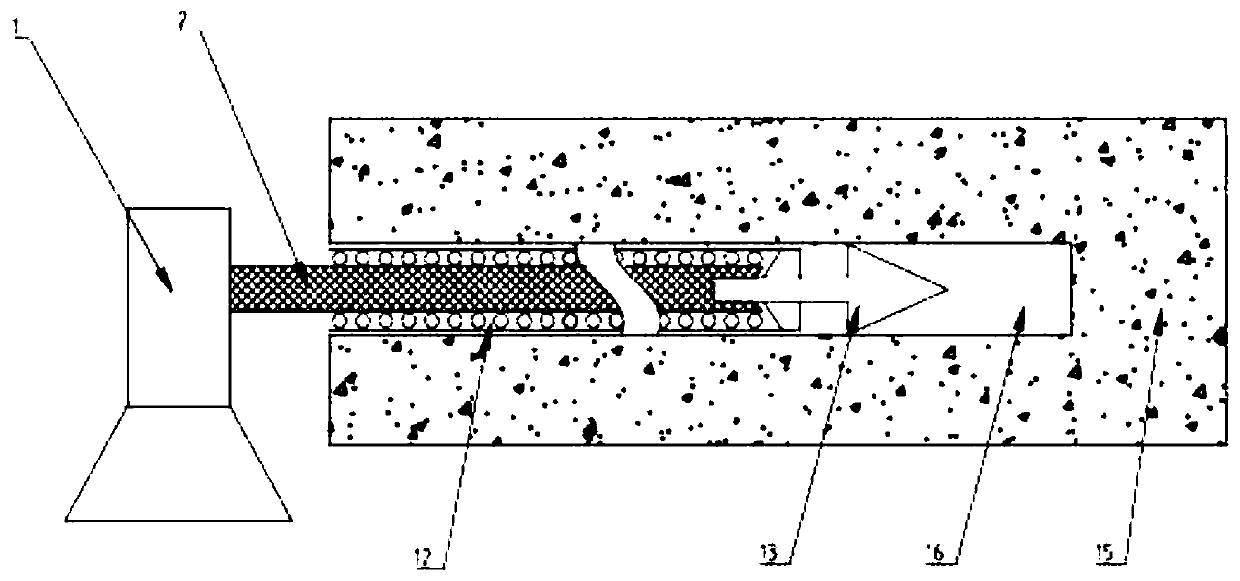

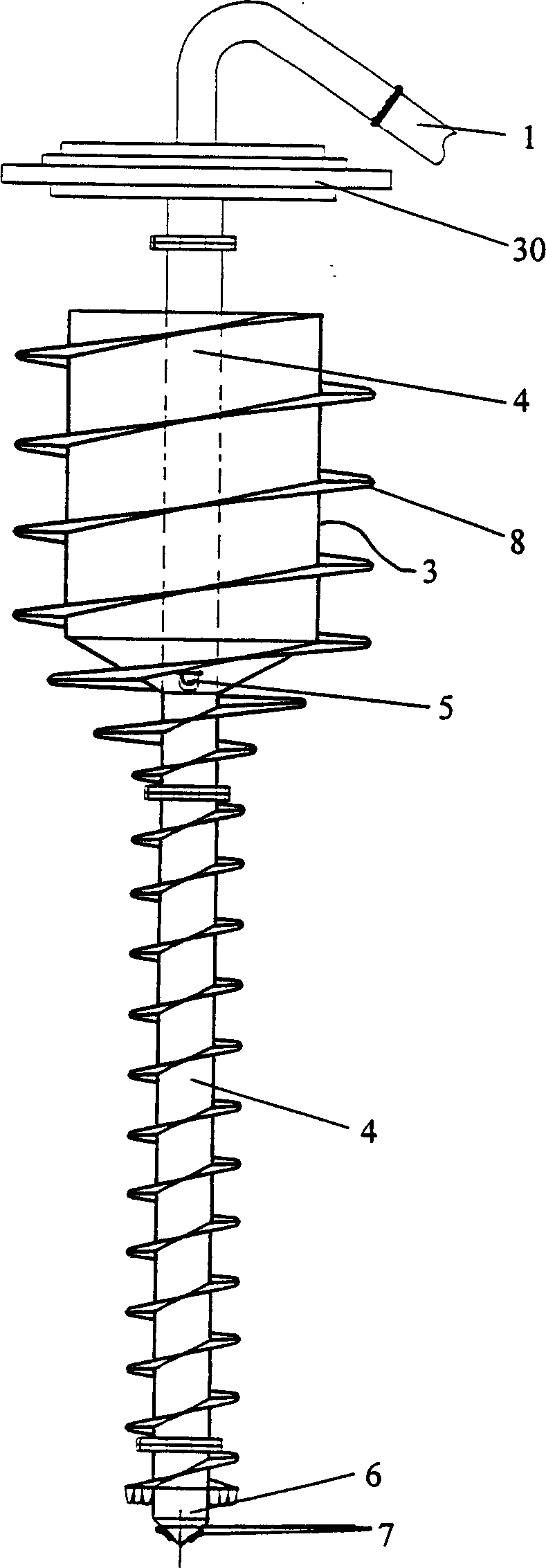

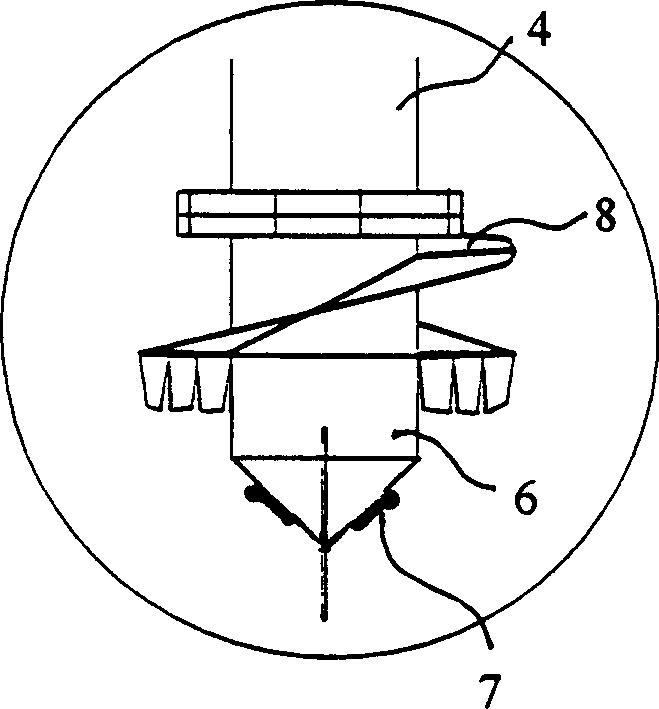

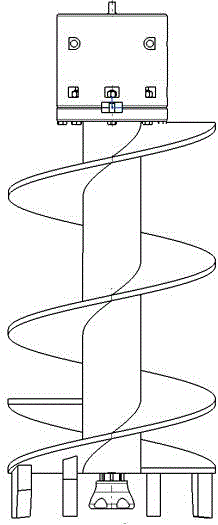

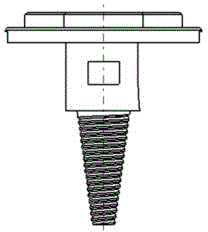

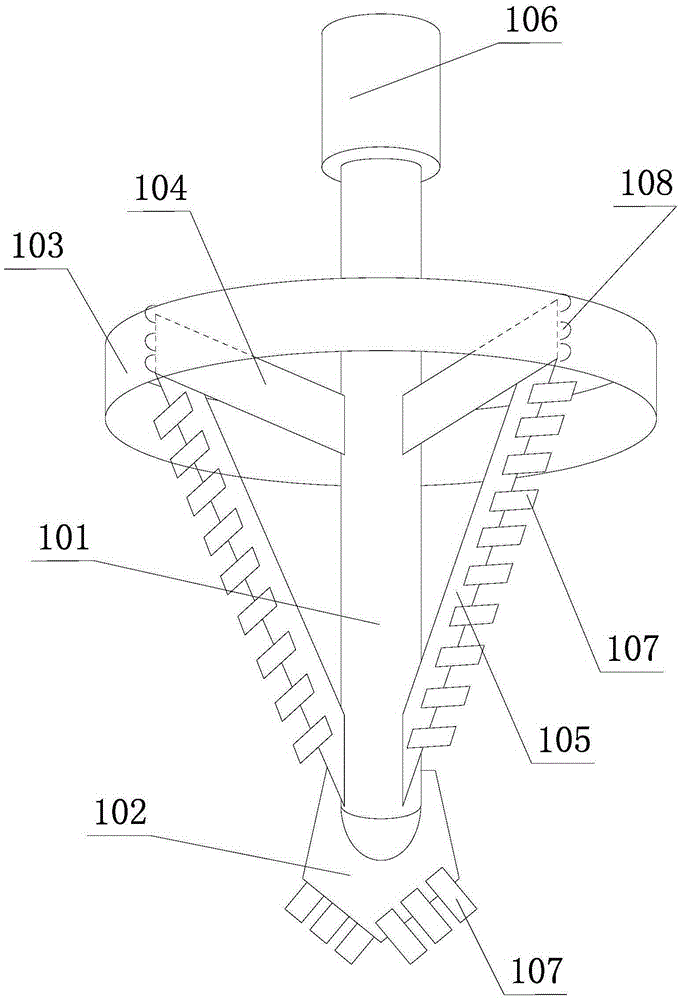

Pile-forming drilling tool for screw pile and pile-forming construction method thereof

InactiveCN101864768ASimplify the construction processSimple and fast operationDrill bitsDrilling rodsReinforced concreteRebar

The invention relates to a pile-forming drilling tool for a screw pile and a pile-forming construction method thereof, wherein forward drilling threads are arranged at the lower part of the pile-forming drilling tool, and backward sweeping threads are detachably arranged on the upper part thereof. The pile-forming construction method comprises the following steps: adopting special screw pile equipment to be assorted with the drilling tool to align with a pile position; utilizing the drilling tool to drill downwards so as to form threaded soil holes to reach the design depth of the pile, and meanwhile utilizing the sweeping threads at the upper part of the drilling tool to extrude and sweep the soil threads to form straight holes which reach the design depth of a straight lever section; lifting up the drilling tool in a rotating mode, and simultaneously concreting to form the thread section and the straight lever section of the pile; and after concreting is completed, placing a reinforcing cage to form the reinforced concrete screw pile. The drilling tool provided by the invention can effectively eliminate part of a threaded soil mass to form the straight holes by adopting forward threads and backward threads, thus achieving the effect of forming screw pile holes by boring at a time and realizing hole-forming and pile-forming of the screw pile at a time; and the pile-forming construction method has simple working procedures, faster speed, reduced construction resistance and no need of taking soil.

Owner:彭桂皎

Anti-blockage method for bottom hole of mine stope and roadway driving working face

InactiveCN102966333AGood effectDoes not affect chargeBlastingBorehole/well accessoriesExplosive AgentsMining engineering

The invention belongs to the field of mining and roadway driving, and relates to an anti-blockage method for a blasting bottom hole of mine stope and roadway driving. The method is characterized in that a mode that a bottom hole tube is inserted is adopted, wherein one end of a tube of a PVC (Polyvinyl Chloride) material or other tube materials is inserted into the bottom hole, and the other end of the tube is exposed in a driving working face; the length of the bottom hole tube in the hole is about 1.0-1.5 m, and the length of the tube exposed outside the hole is about 0.7 m; and the outer end is blocked by using a bottom hole tube cover. Because of the mounting of the bottom hole tube, charging of the bottom hole is not affected by loose gravels falling from the working face during chiseling of upper blast holes even the gravels cover the orifice of the bottom hole since explosive is charged into the bottom of the hole through the bottom hole tube; and the bottom hole tube in the blast hole has effects of supporting the hole wall, preventing the blast hole from collapse and avoiding the safety risk of hurting people by the gravels in a hole digging process. Though the bottom hole tube, the construction process is simplified, the construction efficiency is increased, the charging effect is improved, the blast depth is increased, and the compressive mining cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

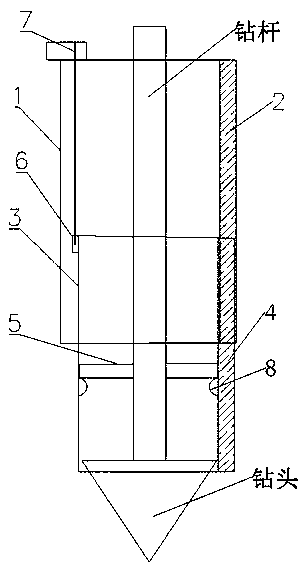

Method for drilling anchor rod hole and anchoring anchor rod in broken roof

The invention provides a method for drilling an anchor rod hole and anchoring an anchor rod in a broken roof. The method includes the following steps that (1) the depth of a drill hole and the length of the anchor rod are determined according to supporting parameters of the anchor rod of broken surrounding rocks, and then two hollow tubular drill rods are connected according to the depth of the drill hole, or a connecting rod is arranged between the threaded ends of the two drill rods in a connected mode to form a combination drill rod; (2) the end, provided with a square inner buckle, of one drill rod is connected with a drill bit in a sleeved mode, and the end, provided with a square inner buckle, of the other drill rod is connected to a drill rig for drilling; (3) the drill rig is dismantled, the drill rods are exposed, and then a cement cartridge is sent to the bottom of a drill rod center hole through the anchor rod; (4) the anchor is pushed into the cement cartridge through the drill rig, the drill rod connected with the drill bit in the sleeved mode is withdrawn, and after 20-30 minutes, an arch supporting plate and a spherical nut are mounted at the end, extending out of the surrounding rocks, of the anchor rod. According to the method, the drill rods and the connecting rod are of a hollow tubular structure, and protective holes of the drill rods and the connecting rod avoid a hole collapse before anchoring the anchor rod; the cement cartridge is used as an anchoring agent, so that the anchoring is prevented from loosing efficacy.

Owner:阜宁县龙创科技服务有限公司

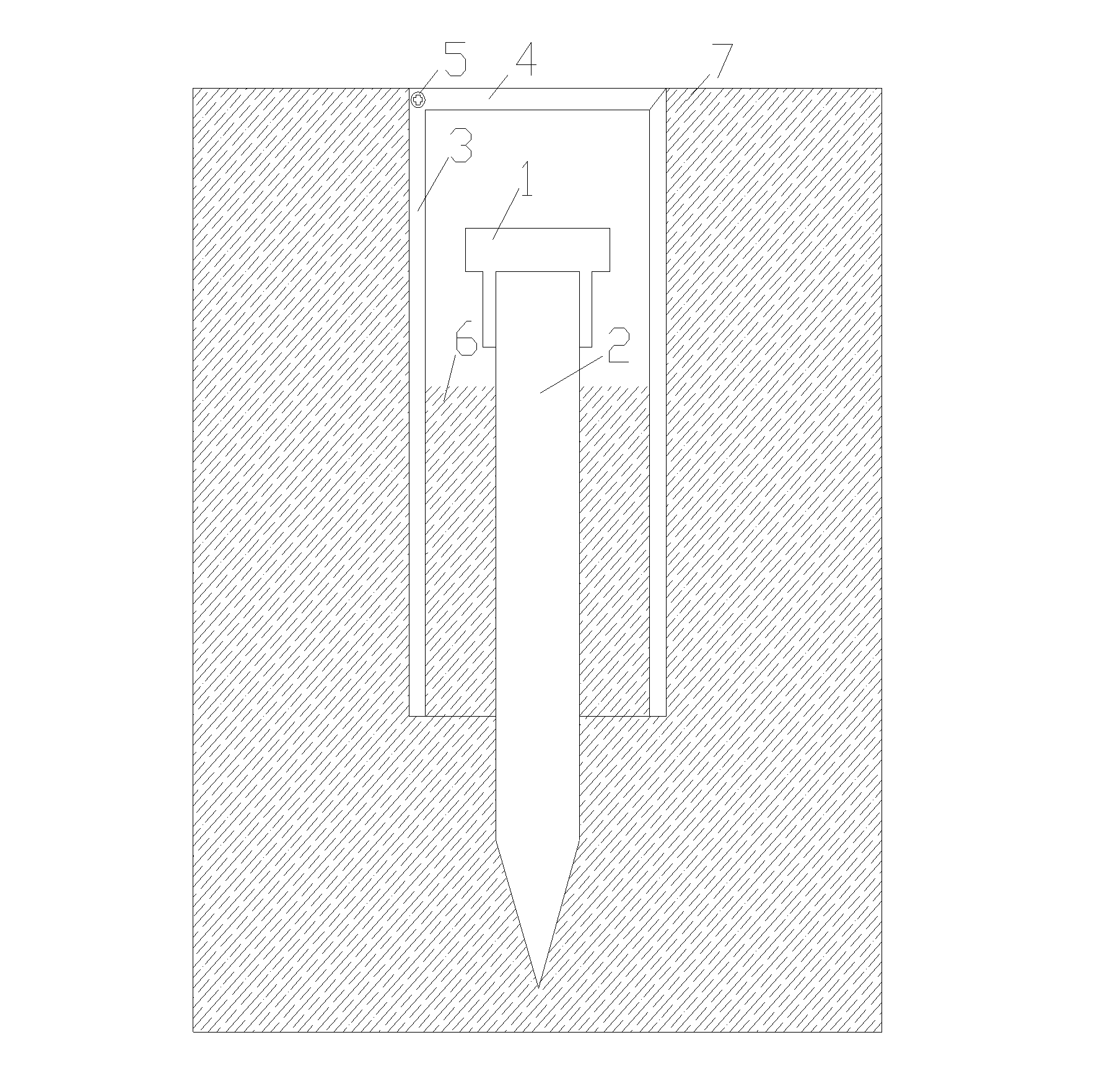

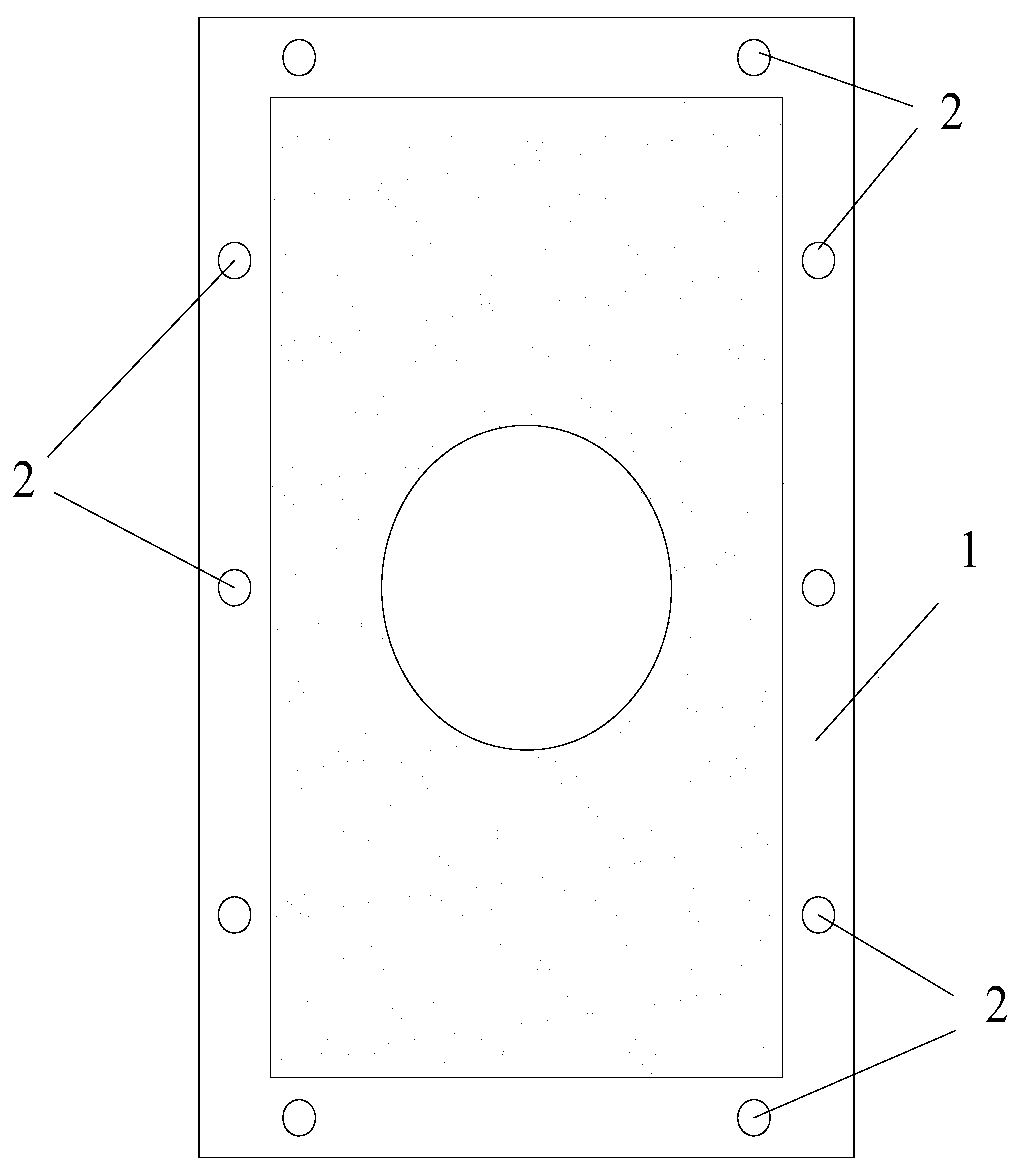

Pavement settlement point arrangement apparatus in monitor measurement and burying method

InactiveCN102494678ARelieve stressPrevent shrinkageMeasuring points markingManufactured materialRoad surface

The invention relates to a pavement settlement point arrangement apparatus in monitor measurement. The apparatus comprises measuring point steel bar inserted link, a measuring point screw thread cap, a retaining wall sleeve and a protection cover. One end of the measuring point steel bar inserted link is conical drilling head, and the other end of the measuring point steel bar inserted link is a smooth plane and connected with the measuring point screw thread cap through screw thread; and the retaining wall sleeve is arranged outside the measuring point steel bar inserted link, and an upper end of the retaining wall sleeve is provided with the protection cover. The invention also discloses a burying method of the apparatus. The conical end of the measuring point steel bar inserted link has a smaller radius to facilitate break of a soil layer; for usage, the conical end is inserted into a rock-soil layer of the pavement, and the other end is rotatably connected with the measuring pointscrew thread cap through the screw thread; and the retaining wall sleeve is arranged outside the measuring point steel bar inserted link and filled with fragmented dinas. The invention has advantagesof low manufacture material cost, simple burying method and little error, etc.

Owner:SHANDONG UNIV

Method for repeated hole sealing on gas extraction drilling hole by rotary jet grouting and solidifying

ActiveCN105041264AHinder deformationDrain concentration dropsGas removalSealing/packingHigh concentrationHigh pressure

The invention relates to a method for repeated hole sealing on a gas extraction drilling hole by rotary jet grouting and solidifying. Rotary jet grouting and solidifying materials are uniformly sprayed on a drilling hole wall surface by high-pressure rotary jet grouting equipment and can permeate in cracks of coal masses well, after being solidified, the rotary jet grouting and solidifying materials can be tightly combined to the coal masses and have high strength, cracks surrounding a large drilling hole can be sealed, and the hole can be fixed. A gas extraction tube with a bag is plugged into the drilling hole, and the rotary jet grouting and solidifying materials are injected into the bag by a liquid injector. After the rotary jet grouting and solidifying materials are solidified, the gas extraction tube is used for extracting gas, and first-time hole sealing for the drilling hole is finished. If gas extraction concentration is reduced to 30%, the large drilling hole can be sealed and solidified by the high-pressure rotary jet grouting equipment again, and the hole sealing frequency is not limited so as to continuously extract high-concentration gas. The drilling hole can be repeatedly sealed by rotary jet grouting and solidifying, deformation of the drilling hole is avoided, gas extracting concentration is increased, and the service life of the drilling hole is prolonged.

Owner:CHINA UNIV OF MINING & TECH

Drilling machine for road construction

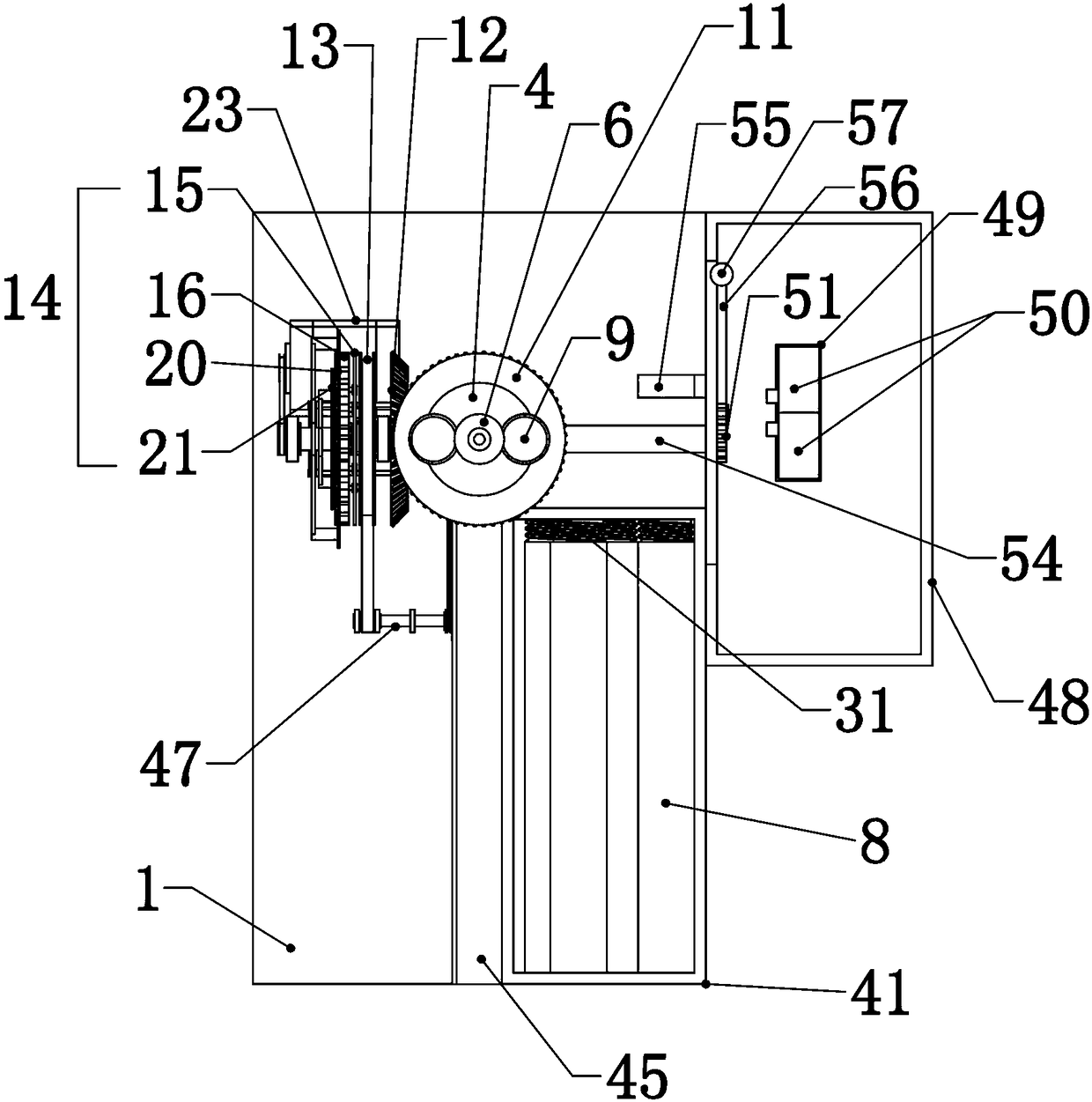

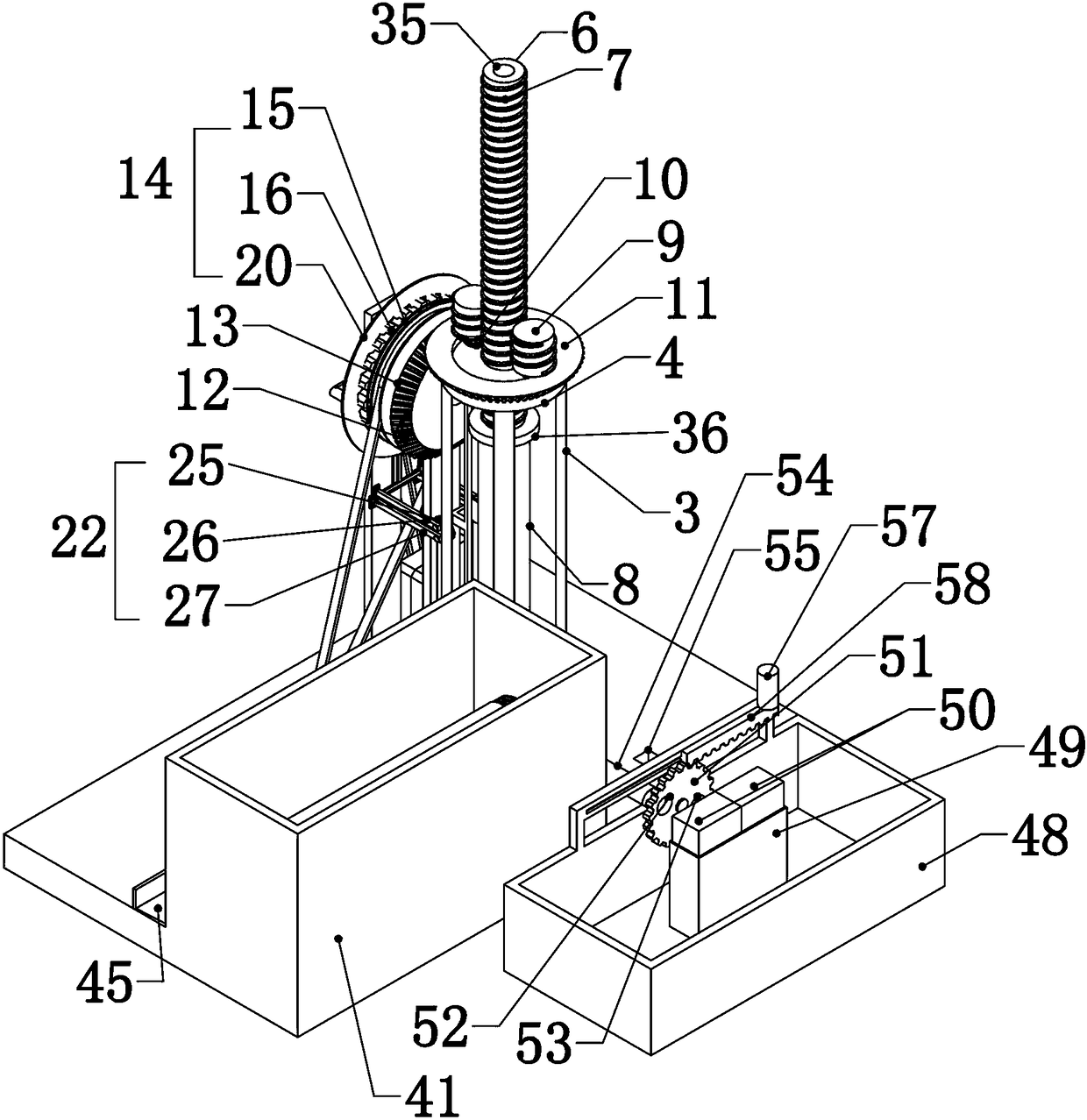

ActiveCN108505949AReduce labor intensityFully automatedDrilling rodsConstructionsControl systemEngineering

The invention relates to a drilling machine for road construction. The problem that an existing drilling machine cannot change directions and replace rods automatically is effectively solved. According to the technical scheme, the drilling machine comprises a workbench, a drill hole is formed in the workbench, the workbench is integrally connected with a locating circular ring by a supporting column located near the drill hole, and a locating circular ring thread is arranged on the inner wall of the locating circular ring in a tapping mode. A rotating rod is arranged in the locating circular ring, a rotating rod thread is arranged on the outer wall of the rotating rod in a tapping mode, the rotating rod meshes with the locating circular ring in a threaded mode, and a drill rod is connectedto the lower end of the rotating rod in a threaded mode. A driving screw is arranged next to the drill rod in a threaded and meshing mode, the rotating rod can drive the locating circular ring to move rotatably up and down in the locating circular ring, a driven small gear is integrally and coaxially connected to the lower end of the driving screw, and a driving gear ring is arranged outside thedriven small gear in a meshing mode. A helical tooth is arranged outside the driving gear ring, a driven helical gear is arranged next to the driving gear ring in a meshing mode, a driven belt pulleyis integrally connected to the driven helical gear, a planetary gear train is in pin joint with the driven belt pulley, and the planetary gear train is controlled by a control system. The drilling machine for the road construction improves the efficiency of construction work.

Owner:刘国胜

Slurry for cross-sea bridge drilling pile drill construction and pulp making method

The invention discloses slurry used for the drilling construction of a sea-spanning bridge drilling pile, which comprises the following components: 13.5 to 16.6 percent of sea mud, 81 to 83 percent of seawater, 0.15 to 0.2 percent of slurry admixture, 1 to 3 percent of swell soil, as well as 0.4 to 0.5 percent of calcined soda; wherein, the percentage is the weight percentage; the preparing method of the slurry is as follows: the slurry admixture and the calcined soda are uniformly stirred to form the comprehensive material of the slurry admixture and the calcined soda; then after the swell soil is added into a stirring machine, the comprehensive material of the slurry admixture and the calcined soda is added and stirred uniformly; then the sea mud is added; the stirring machine is adjusted to a low-speed gear; the seawater is slowly added simultaneously when stirring; slow speed stirring is carried out for 3 to 5 minutes at first, then high speed stirring is carried out for 10 to 15 minutes, thus leading various materials to be completely decomposed and molten.

Owner:ROAD AND BRIDGE CONSTRUCTION

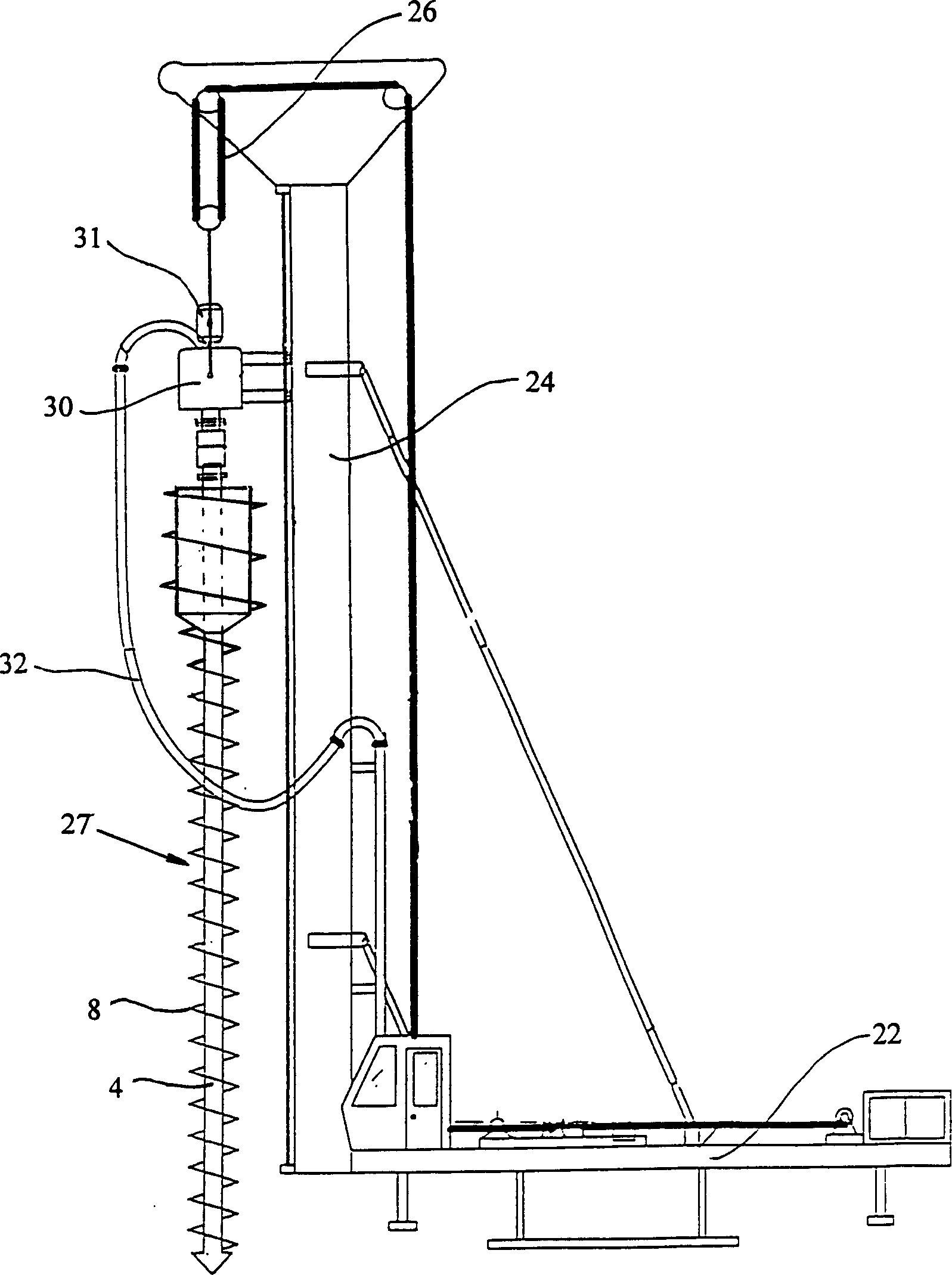

Earth auger of making concrete pile

InactiveCN1540129AIncreased compactionAvoid collapsing holesRotary drillingRotary-drilling machinesGeotechnical engineeringDrill bit

A spiral drilling machine for forming concrete pile has a drilling tool, which is composed of a hollow drilling rod with spiral blades, a drill bit with discharge outlet and arranged at lower end of said hollow drilling rod, and an external pipe coaxially connected to the upper part of said hollow drilling rod in sealed mode. Said spiral blades are fixed to the external surface of said external pipe.

Owner:何庆林

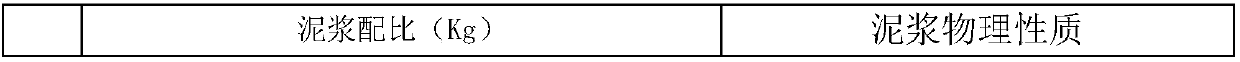

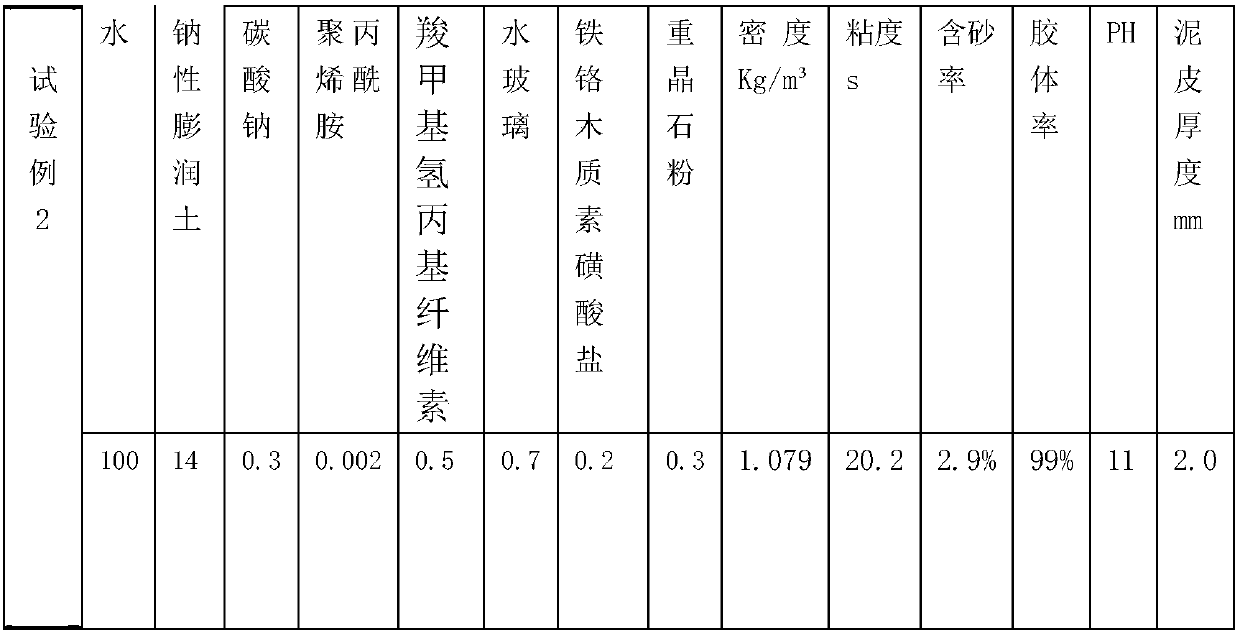

Alluvial plain karst developing district drilling pile formation wall protection mud and preparation method thereof

InactiveCN107739597AReduce construction riskMake up for technical defects in drillingDrilling compositionSodium BentoniteKarst

The invention discloses alluvial plain karst developing district drilling pile formation wall protection mud which is prepared from the components in parts by mass: 100 parts of water, 6-10 parts of clay, 5-14 parts of sodium bentonite, 0.2-0.3 part of sodium carbonate, 0.002-0.005 part of polyacrylamide, 0.5-0.6 part of carboxymethyl hydroxypropyl cellulose, 0.6-0.9 part of water glass, 0.1-0.3 part of ferric chromium lignin sulfonate, 0.1-0.3 part of barite powder and 0.25-0.5 part of potassium humate. The mud prepared by the invention is suitable for an alluvial plain karst developing district drilling pile formation technology and lowers the probability of occurrence of safety accidents of drilling pile formation. A result of interaction of the mud and a stratum is changed by changingthe performance index of the mud, so that the safety coefficient of construction is increased, and the technical defect of drilling a complex strata is made up.

Owner:SHENYANG POLYTECHNIC UNIV

Cast-in-place pile synchronous casing hole-forming constructing method

InactiveCN103015408ASolve the problem of collapse and stickingSolve the problem of verticality skewDrilling rodsBorehole drivesSlurryPollution

The invention belongs to the technical field of building engineering and particularly relates to a cast-in-place pile synchronous casing hole-forming constructing method. The method comprises the following steps of 1, pile position lofting; 2, synchronous follow-up installation; 3, pile machine positioning; and 4, hole forming and hole cleaning. The cast-in-place pile synchronous casing hole-forming constructing method has the beneficial effects that when the stratum has giant-grained soil layers such as erratic boulder, rock block and pebbles, the problems of verticality deflection and drill clamping through rock caving can be effectively solved, the construction speed is high, and the cost is low; for strata such as loose backfill soil and sand layers, the occurrence of pile body hole collapse phenomena can be effectively controlled, and the concrete cost is effectively reduced; the slurry making wall protection is not needed, a synchronous follow-up steel sleeve can effectively prevent the hole collapse, meanwhile, the synchronous follow-up steel sleeve can be embedded into the rock layer in time, an effect of preventing underground water from leaking into the pile holes is realized, and no water exists in the holes after the hole forming; and the method has the characteristics that the construction quality is reliable, the hole forming speed is high, the hole forming rate is high, the adaptability is high, and the like, the noise is low, the pollution is little, and the environment is protected.

Owner:SHANDONG WANXIN CONSTR

Drilling device and hole forming method of pre-drilling type lateral pressure test

ActiveCN105568951AMake sure the center of gravity coincidesGuaranteed to be verticalIn situ soil foundationEarth surfaceAdverse effect

The invention provides a drilling device of a pre-drilling type lateral pressure test. The drilling device comprises a cutting ring soil miller, a spoon-type drill, a drill bit, a locator, drilling rods, outer rods, a connecting rod and a baffle. A hole forming method for carrying out the pre-drilling type lateral pressure test through the device comprises the steps that 1, an instrument is assembled, wherein the drill bit and the wall of the spoon-type drill are connected, the wall of the spoon-type drill is connected with the connecting rod, and the connecting rod is connected with the drilling rods; 2, drilling is carried out, wherein drilling is stopped when the locator is in contact with the ground surface, the center of the cutting ring soil miller is aligned to the locator to be vertically pressed into the underground, the baffle is arranged on the corresponding outer rod at the upper end of the cutting ring soil miller, and the cutting ring soil miller is vertically pressed into soil by pressing the baffle through the gravity of a drilling machine or hammering the baffle through a heavy hammer; 3, testing is carried out; and 4, drilling continues to be carried out, and the lateral pressure test of different depths in the same drilled hole is carried out. The device is simple in structure, detachable, convenient to manufacture and maintain, safe, stable, easy to operate, low in manufacturing cost, high in drilling speed and high in hole forming quality, the construction period can be remarkably shortened, and the adverse effect of hole collapse and hole shrinkage to the result of the lateral pressure test is eliminated.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Construction method for quicksand layer pile foundation

The invention discloses a construction method for a quicksand layer pile foundation. The construction method comprises the following steps that S10 the depth of a quicksand layer around the pile portion is surveyed, the length of the quicksand layer capable of penetrating through a steel pile casing is determined according to the survey result, and the steel pile casing is prefabricated; S20 the whole steel pile casing is embedded in the pile portion with the adoption of a vibratory hammer; S30 a pore is drilled and formed in the steel pile casing, a reinforcement cage is installed in a pore after the pore is formed, and the reinforcement cage is positioned on the pore opening after the reinforcement cage is installed; and S40 a conduit is installed and fixed in the pore, concrete is injected into the pore through the conduit after the pore is cleaned up, the steel pile casing is lifted immediately after the concrete is injected to the top face of the steel pile casing, the lifting time of the steel pile casing is controlled in the initial set time of the concrete, and the concrete sets and forms the pile foundation after the steel pile casing is lifted out totally. According to the construction method for the quicksand layer pile foundation, the quicksand layer pile pore can be prevented from collapsing effectively, and sand layer loss and the exceeding square amount of the concrete in the pore are controlled well, so that the use amount of the concrete is reduced, mud treatment and discharging are decreased, the mud is prevented from polluting the environment, the construction cost is reduced, the construction period is short, and the benefit is high.

Owner:CHINA RAILWAY PORT & CHANNEL ENG GRP +1

Drilled grouting pile composite roadbed structure and construction method thereof

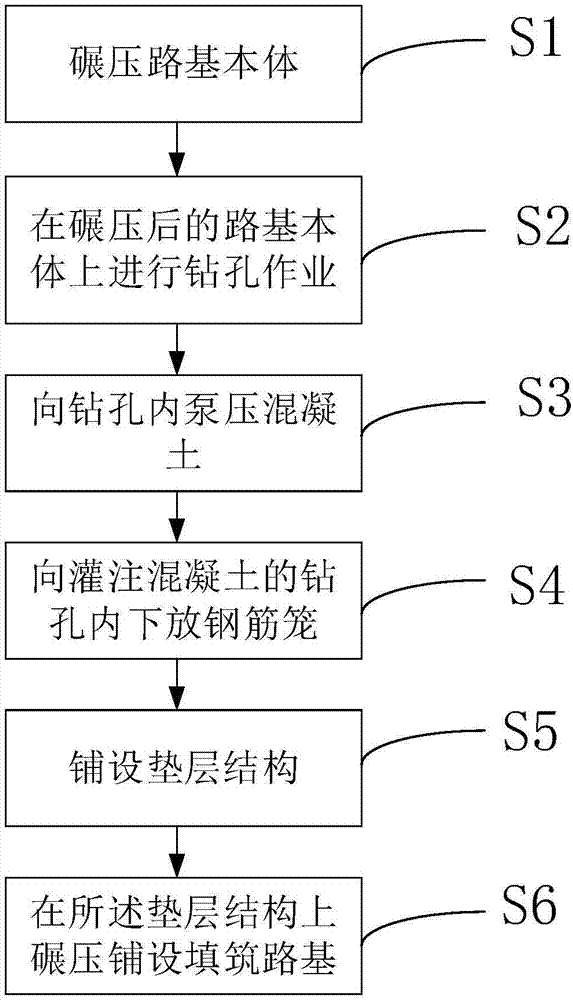

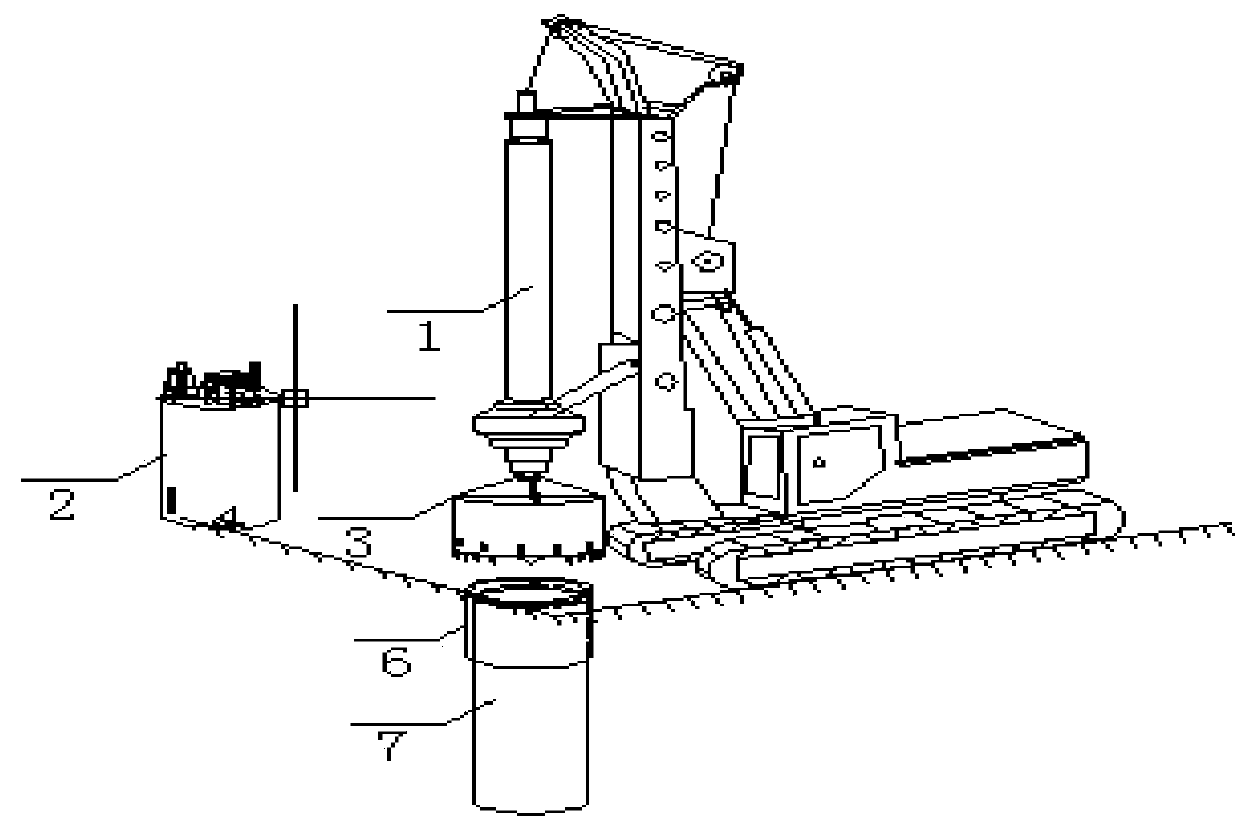

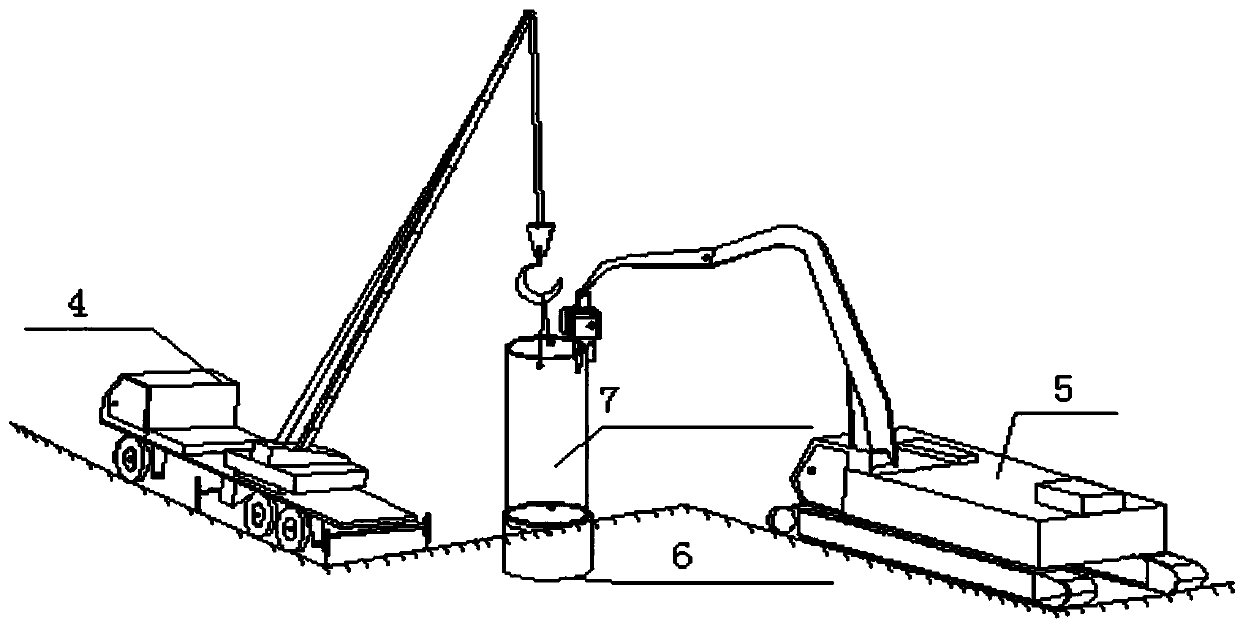

InactiveCN106968147AImprove construction efficiencyImprove efficacyRoadwaysBulkheads/pilesEngineeringComposite structure

The invention relates to the technical field of roadbed reinforcement, and discloses a composite roadbed structure of bored piles and a construction method thereof. A borehole in the rock formation; a reinforcement body disposed in the borehole; a cushion structure disposed on the upper surface of the reinforcement body; and a filling roadbed disposed on the upper surface of the cushion structure, the method comprising : rolling the basic body of the road; carrying out the drilling operation on the road basic body after rolling; pumping concrete into the borehole; lowering the reinforcement cage into the borehole poured with concrete; laying the cushion structure; on the cushion structure Rolling and laying to fill the roadbed. The bored pile composite subgrade structure has the advantages of preventing post-construction settlement and improving bearing capacity.

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

Rotary drilling dry-excavation method for cast-in-situ bored piles of viaduct bridges by adopting double steel protection canisters

InactiveCN107587504AReduce mud dischargeImprove safety and civilized constructionBulkheads/pilesStructural engineeringSlurry

The invention discloses a rotary drilling dry-excavation method for cast-in-situ bored piles of viaduct bridges by adopting double steel protection canisters. Hole-opening steel protection canisters are arranged on a long protection canister of the pile body, and an outer protection canister protects a hole opening to effectively insulate surface water and make the hole opening stable; an inner protection canister insulates underground water, protects a hole wall and prevents the hole wall from collapsing, and by adopting the double protection canisters to protect the wall and replace a traditional method for using slurry to protect the wall, the slurry emission is reduced; by adopting a vibration hammer and a hoisting crane to hoist the steel protection canisters in the process of pouringconcrete, it can be ensured that the steel protection canisters can be recycled. In all, the method has the advantages that preparation of the slurry and circular protection of the wall are not required during punching, the time for pile formation is shortened, the working efficiency is improved, and the purposes of saving time and cost and improving quality are achieved.

Owner:CHINA MCC17 GRP

Drilling process for surveying land pebble-filled limestone cave

ActiveCN109667537AShorten the construction periodReduce processing costsDrilling rodsDrilling casingsCoringCave

The invention relates to a drilling process for surveying a land pebble-filled limestone cave. Different from a traditional process, the drilling process for surveying the land pebble-filled limestonecave comprises the process steps of (a) measuring a hole position, then adopting a first drilling tool to start drilling, and protecting a wall for a hole drilled at the upper end of a rock base plane after drilling to the rock base plane; (b) then drilling a limestone cave layer top plate surface, cleaning the hole to be below a limestone cave layer bottom plate surface, then lift-drilling, andrecording the distance between the limestone cave layer top plate surface and the limestone cave layer bottom plate surface; (c) configuring a core barrel with a drill bit according to the distance instep (b) so as to form a second drilling tool, then using the second drilling tool to drill the limestone cave layer bottom plate surface, and keeping the core barrel with the drill bit in the drilled hole so as to protect the wall, wherein the wall protecting range is at least from the limestone cave layer top plate surface to the limestone cave layer bottom plate surface; (d) adopting a third drilling tool with the diameter being smaller than the inner diameter of the core barrel for drilling and coring in the core barrel to a designed hole depth; and (f) after finishing drilling and coring, taking the core barrel out. The drilling process for surveying the land pebble-filled limestone cave involved in the invention has high construction efficiency.

Owner:HUBEI CENT SOUTH EXPLORATION & FOUND ENG

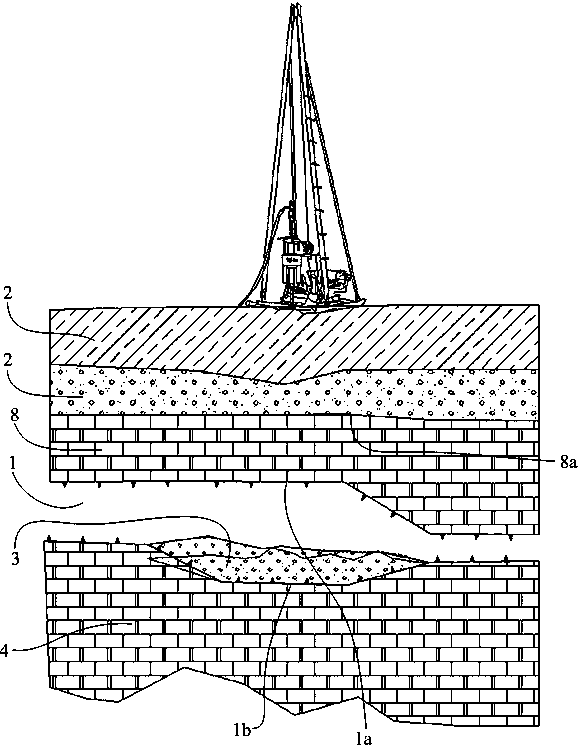

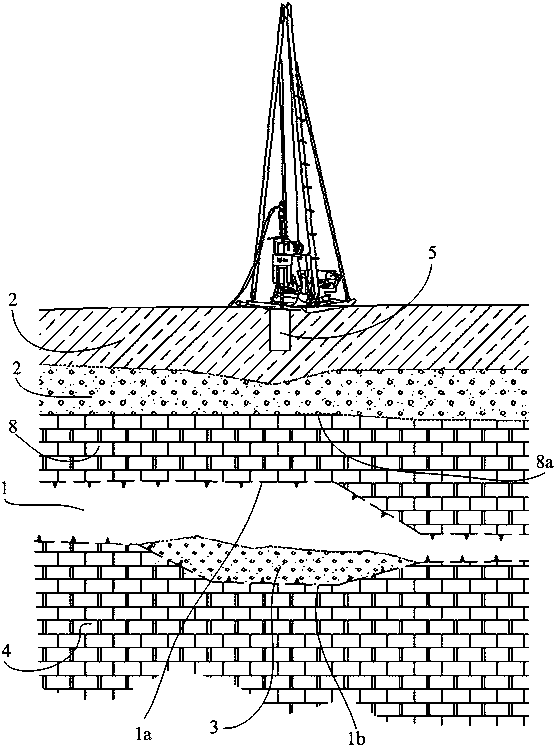

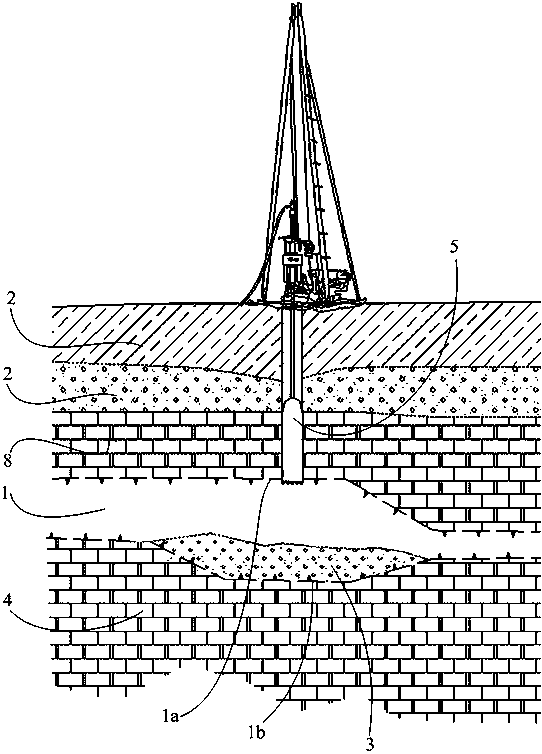

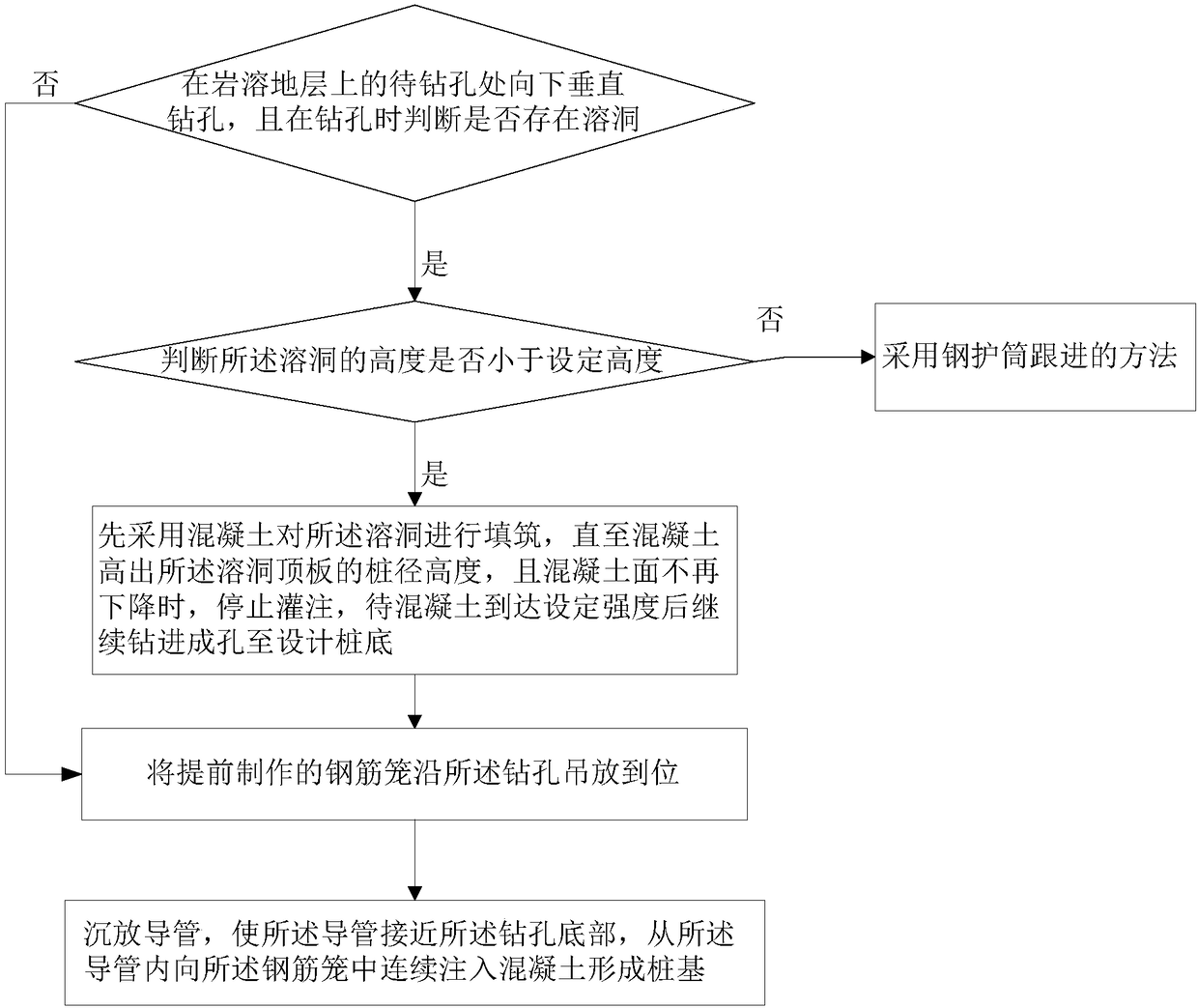

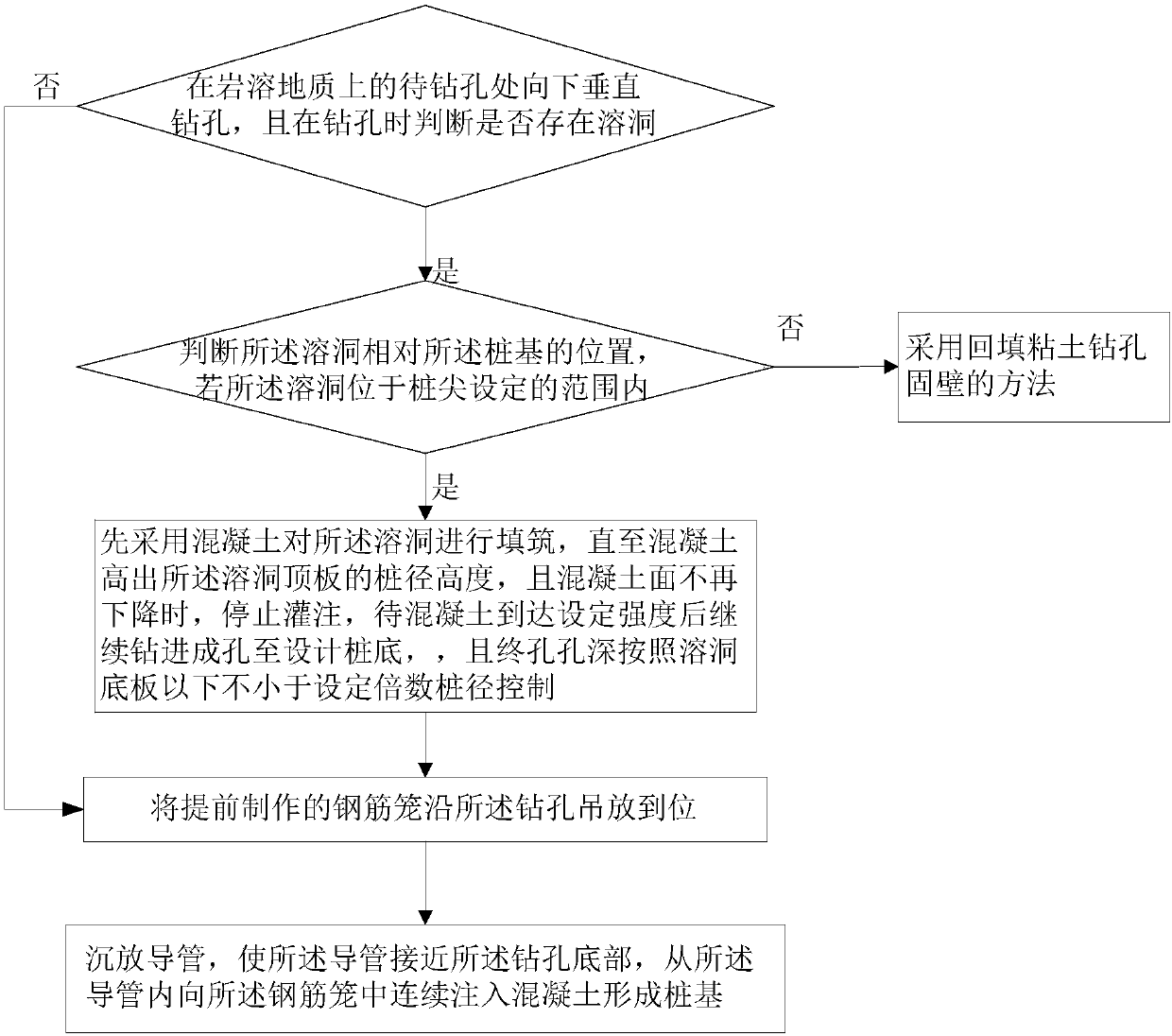

Construction method of karst stratum pile foundation

The invention relates to a construction method of a karst stratum pile foundation. A place to be drilled on a karst stratum is downwards and vertically drilled; existence of a karst cave is judged during drilling; if so, the height of the karst cave is continuously judged; when the height of the karst cave is lower than a set height, concrete is adopted to fill the karst cave; if the height of thekarst cave is higher than the set height, a steel protecting cylinder followup method is adopted; a reinforcement cage manufactured beforehand is lifted in place along a drilled hole; a guide pipe issunk to approach the bottom of the drilled hole; concrete is continuously injected from the guide pipe into the reinforcement cage to form a pile foundation. The construction method of the karst stratum pile foundation can prevent the hole collapse phenomenon in the construction process, and is simple in construction and low in cost.

Owner:CCCC THIRD HARBOR ENG

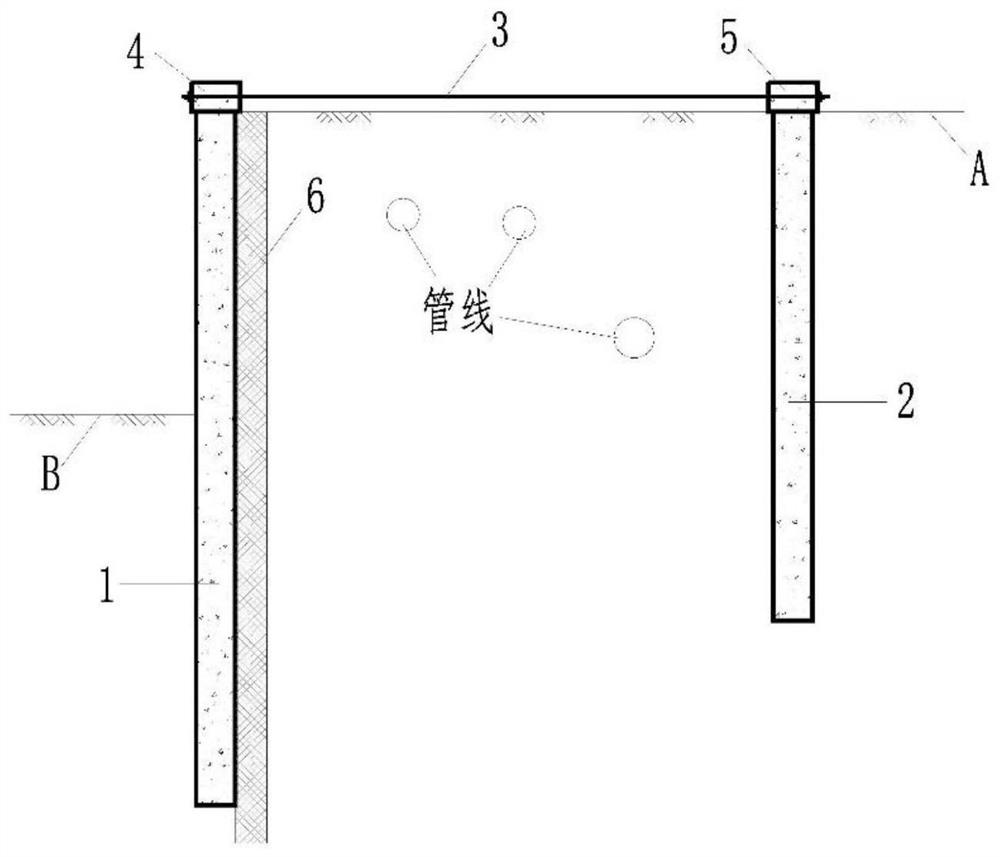

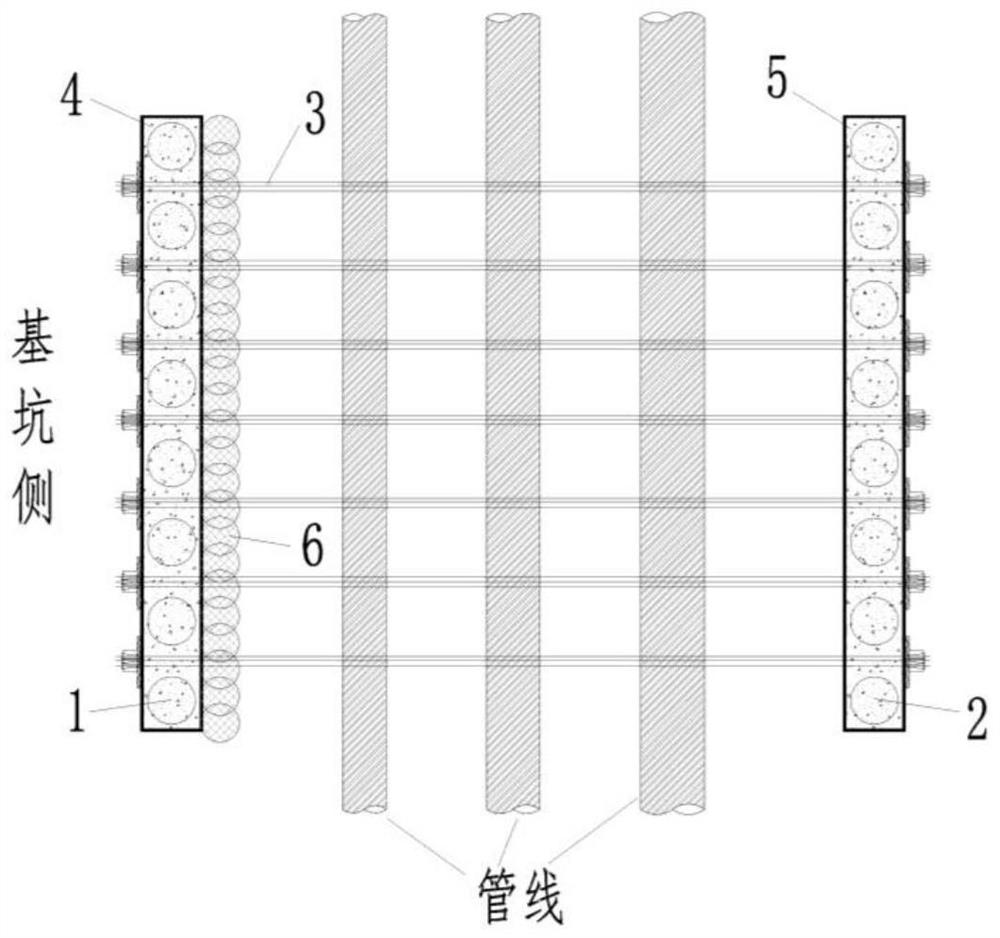

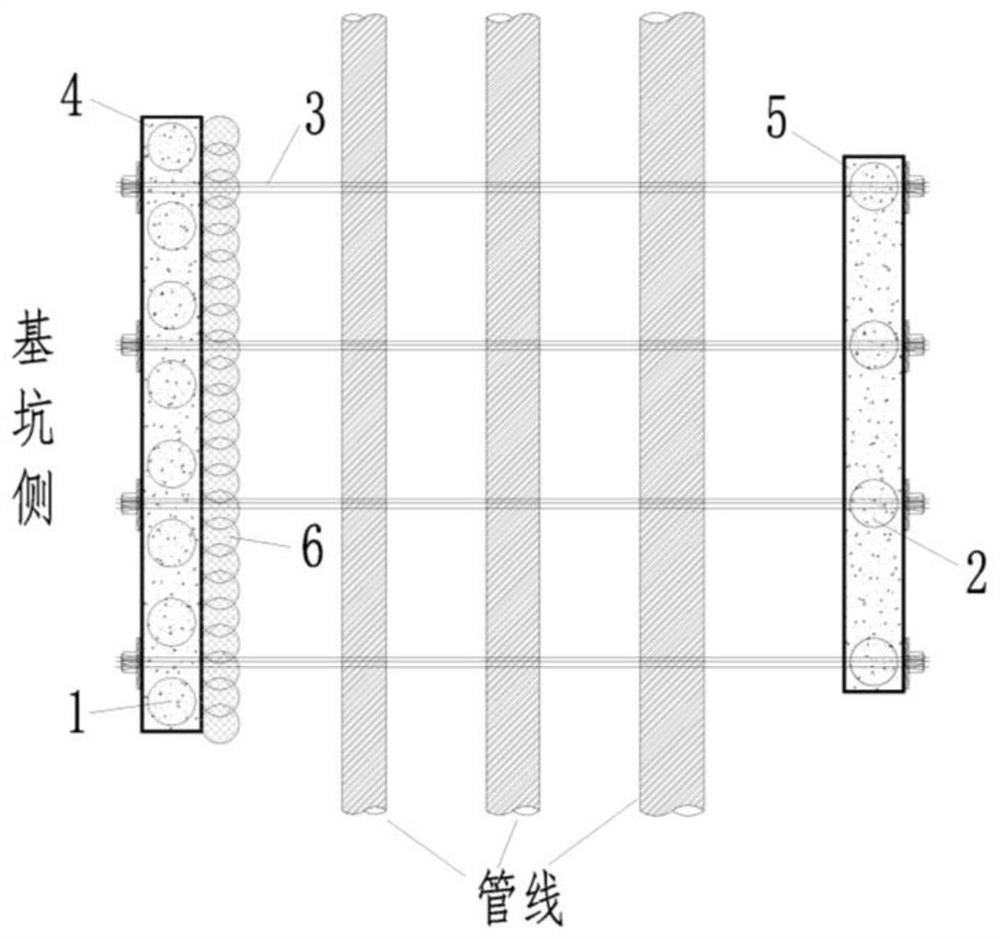

Anchoring type supporting system based on horizontal anchor cables and counter-force piles and construction method thereof

InactiveCN113529738AIncrease stiffnessImprove anti-overturn performanceExcavationsSupporting systemLine tubing

The invention belongs to the technical field of foundation pit engineering, and discloses an anchoring type supporting system based on horizontal anchor cables and counter-force piles and a construction method thereof. The supporting system is composed of supporting piles, the counter-force piles, a supporting pile crown beam, a counter-force pile crown beam and the horizontal anchor cables, wherein the supporting piles are constructed on the side wall of a foundation pit, the supporting pile crown beam is poured on the tops of the supporting piles, the counter-force piles are constructed on a foundation pit outside soil body, the counter-force pile crown beam is poured on the tops of the counter-force piles, and the supporting piles and the counter-force piles are connected into a whole through the horizontal anchor cables penetrating through the supporting pile crown beam and the counter-force pile crown beam. According to the anchoring type supporting system based on horizontal anchor cables and counter-force piles and the construction method thereof, the rigidity and the overturning resistance of single-row supporting piles can be improved, deformation of the foundation pit is effectively controlled, and the defects that a traditional cantilever pile structure is low in overall rigidity and cannot meet the deformation control requirement easily are overcome; and meanwhile, the technical problems that underground pipelines around the foundation pit are complex, land use is limited, and conventional oblique anchor cables cannot be adopted are solved by using the horizontal inhaul cables, and a new thought and a new method are provided for a municipal foundation pit supporting structure.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

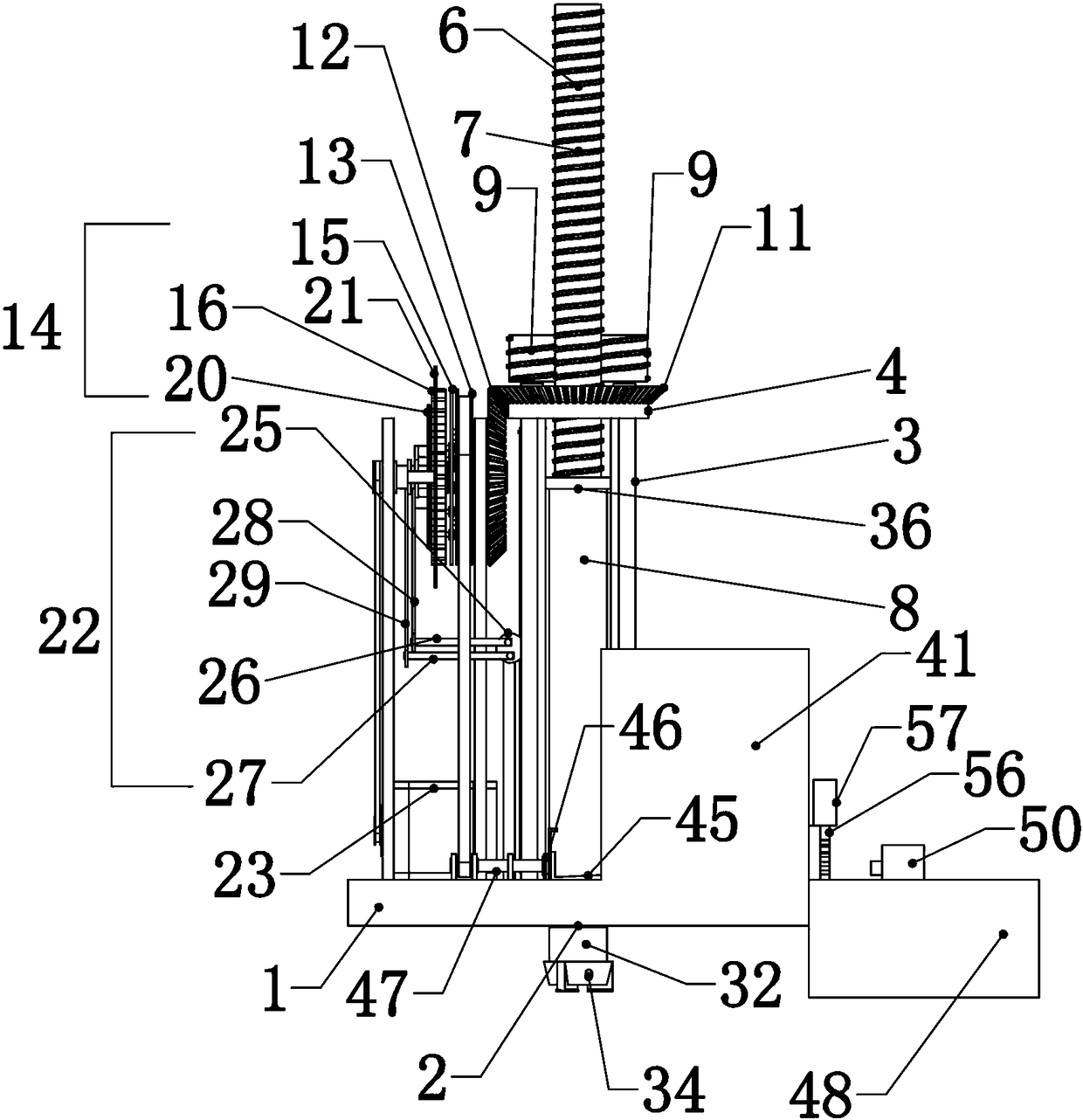

Long screw pile machine

ActiveCN104533284APlay a role in coolingImprove adaptabilityDrill bitsDrilling rodsEngineeringWater pipe

The invention discloses a long screw pile machine. The machine is characterized in that a central through hole is formed in a screw bit, a down-hole hammer stretching out of a drill is arranged in the central through hole of the screw bit and is connected with a tapered threaded rod on a flange through a tapered threaded hole in the upper end of a handle to achieve location. A limit plate is arranged between the down-hole hammer handle and the screw bit through hole. An air through pipe and a water through pipe are arranged on the flange, an inlet of the air through pipe is communicated with an air guide pipe in a screw drill rod and a screw bit joint, an outlet of the air through pipe is communicated with an air inlet pipe in the down-hole hammer handle, an inlet of the water through pipe is communicated with a water guide pipe in the screw drill rod and the screw drill joint, an outlet of the water through pipe is connected with a water injection pipe, an outlet of the water injection pipe is formed in a lower port of the screw drill central through hole, and the air guide pipe and the water guide pipe in the screw drill rod and the screw drill joint are communicated with an air pipe and a water pipe on a power head. The machine has the advantages of being novel in structure, simple to operate, high in work efficiency, long in service life, wide in application range and the like.

Owner:WEIHAI HYDRAULIC & GEOTECHN ENG

Telescopic pile casing for offshore wind power single pile rock-socketed construction and operation method

InactiveCN109778849ASmooth and smooth removalPrevent collapseBulkheads/pilesOffshore wind powerDrill bit

The invention provides a telescopic pile casing for offshore wind power single pile rock-socketed construction and an operation method. The telescopic pile casing comprises an outer pile casing, an outer pile casing guide rail, an inner pile casing, an inner pile casing guide rail, an inner pile casing follow-up device, an inner pile casing lifting lug, a jack and an inner pile casing limiting ring. The inner pile casing moves in the outer pile casing through the guide rail. A propelling device installed on a drill rod presses the inner pile casing downwards through the limiting ring welded tothe inner pile casing, so that the inner pile casing follows along with a drill bit, and hole collapse can be effectively prevented and controlled. The inner pile casing is connected with the jack ofa platform through a steel wire rope and is used for mounting, lifting and dismounting the inner pile casing. The construction method is used for aspects of offshore wind power single pile rock embedding, side wall grouting, single pile implanting and the like, and has the advantages of preventing hole collapse, accelerating the construction progress, being convenient to dismantle, being reusable, reducing cost, improving benefits and the like.

Owner:CCCC FIRST HARBOR ENG

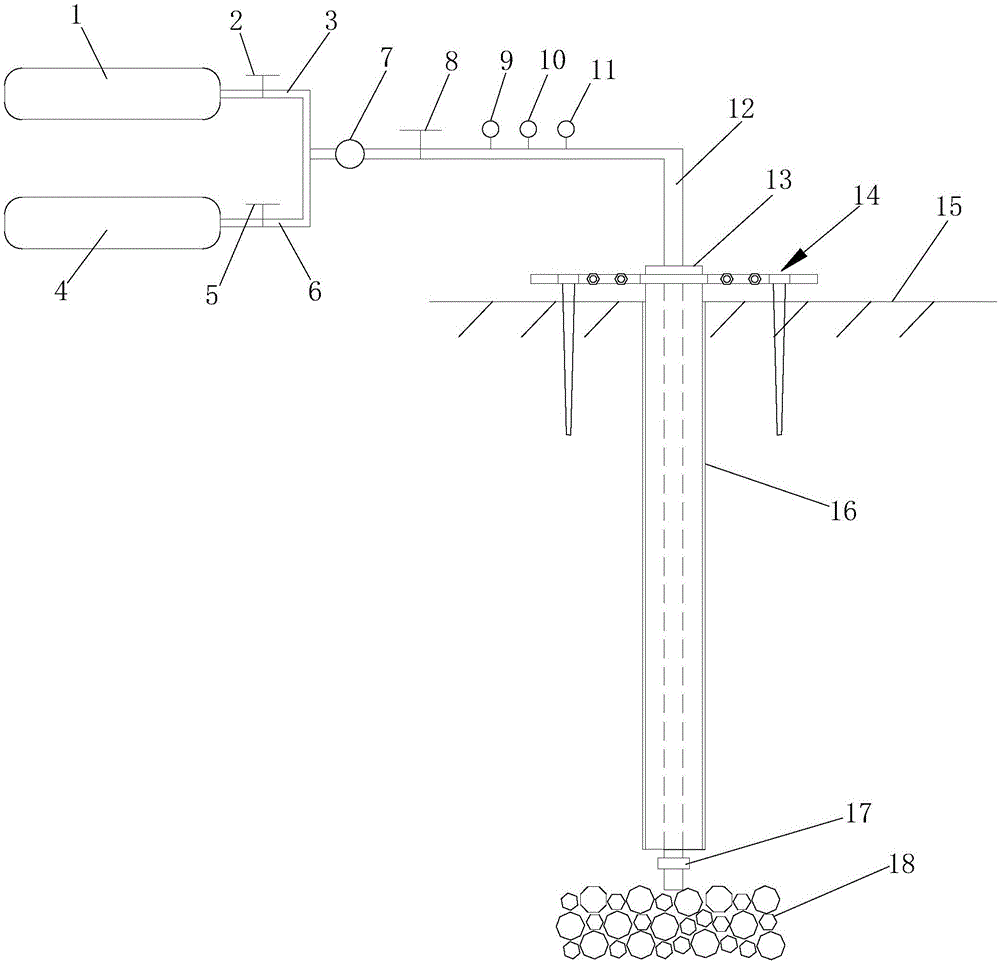

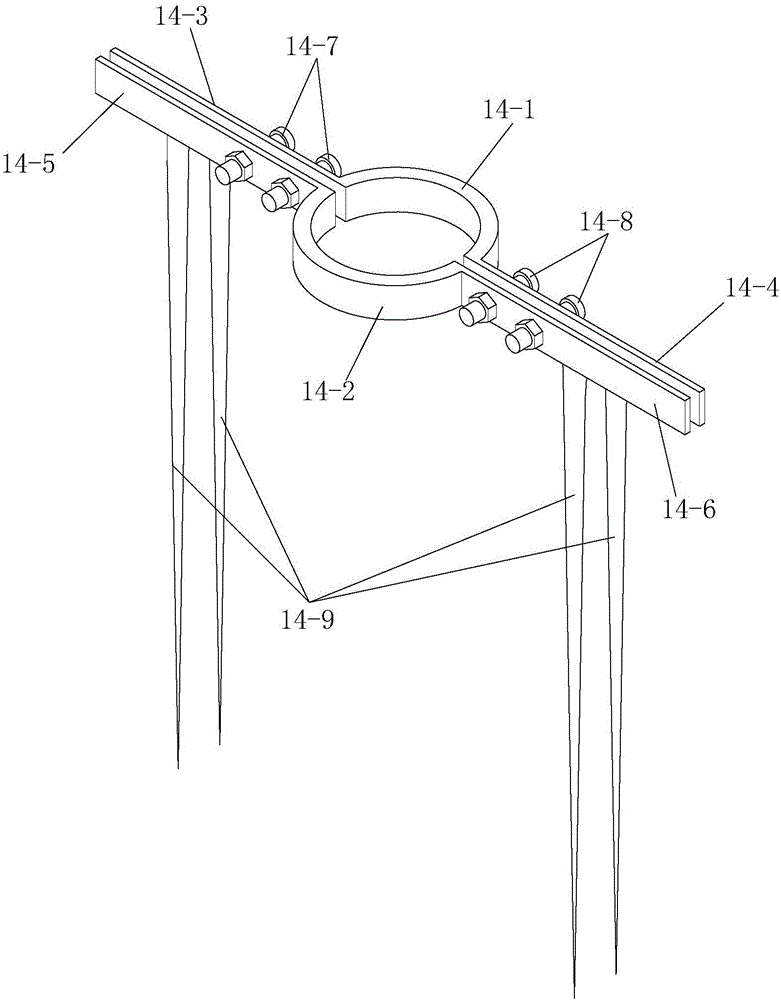

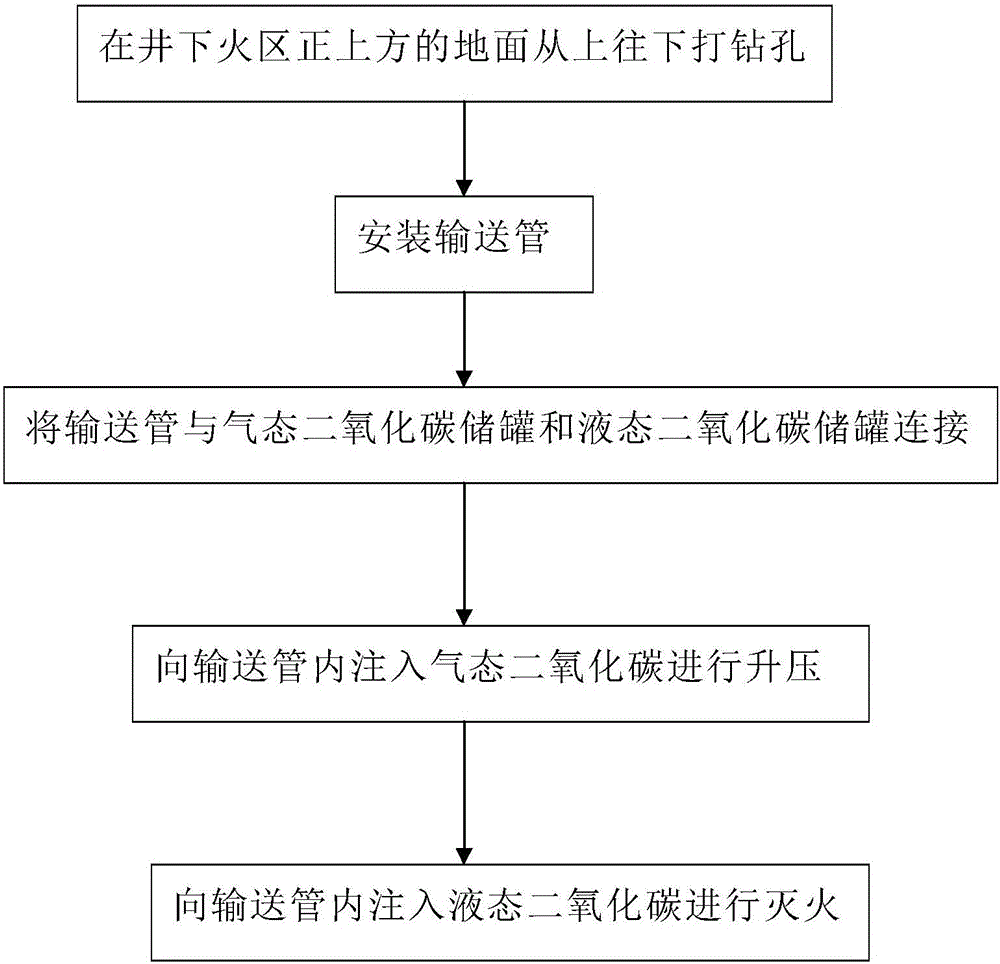

Device and method for transmitting liquid carbon dioxide used for firefighting by means of surface drilling

InactiveCN106247168ASimple structureNovel and reasonable designPipe supportsFire rescueLiquid carbonPiezometer

The present invention discloses a device for transmitting liquid carbon dioxide used for fire fight by means of surface drilling. The device comprises a gaseous carbon dioxide storage tank, a liquid carbon dioxide storage tank, and a transmission tube; the transmission tube is disposed in a drill hole extending downwards from a ground surface; an upper end of the transmission tube is provided with a pressure maintaining valve; a lower end of the transmission tube is provided with a pressure control valve; a piezometer is disposed on the transmission tube; the upper end of the transmission tube is communicated with the gaseous carbon dioxide storage tank through a first connection tube; and the upper end of the transmission tube is communicated with the liquid carbon dioxide storage tank through a second connection tube. The transmission device can achieve direct transmission of the liquid carbon dioxide. The present invention further discloses a method for transmitting liquid carbon dioxide. The method comprises the following steps: drilling the drill hole downwards from the ground surface right above a fire area in a well; mounting the transmission tube; connecting the transmission tube to the gaseous carbon dioxide storage tank and the liquid carbon dioxide storage tank; injecting gaseous carbon dioxide in the transmission tube for boosting the pressure; and injecting liquid carbon dioxide in the transmission tube for firefighting. The transmitting method is easy to operate and is effective.

Owner:XIAN UNIV OF SCI & TECH

Construction method of bored pile in karst geological region

The invention relates to a construction method of a bored pile in a karst geological region. The construction method comprises the steps that a hole is vertically drilled downwards in a to-be-drilledposition in the karst geological region, and whether a karst cave exists or not is judged in the drilling process, if yes, the position of the karst cave relative to a pile foundation is judged, and if the karst cave is located within a set range of a pile point, the karst cave is filled with concrete; if the karst cave is not located within the set range of the pile point, the drilled hole is backfilled with clay so as to reinforce the wall; a reinforcement cage manufactured in advance is hoisted to the proper position along the drilled hole; and a guide pipe sinks to approach the bottom of the drilled hole, and concrete is continuously injected into the reinforcement cage from the guide pipe, so that the pile foundation is formed. By adoption of the construction method of the bored pilein the karst geological region, hole collapses can be avoided in the construction process; and construction is simple, and the cost is low.

Owner:CCCC THIRD HARBOR ENG

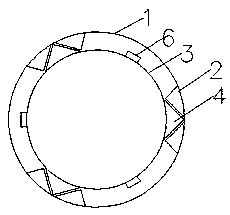

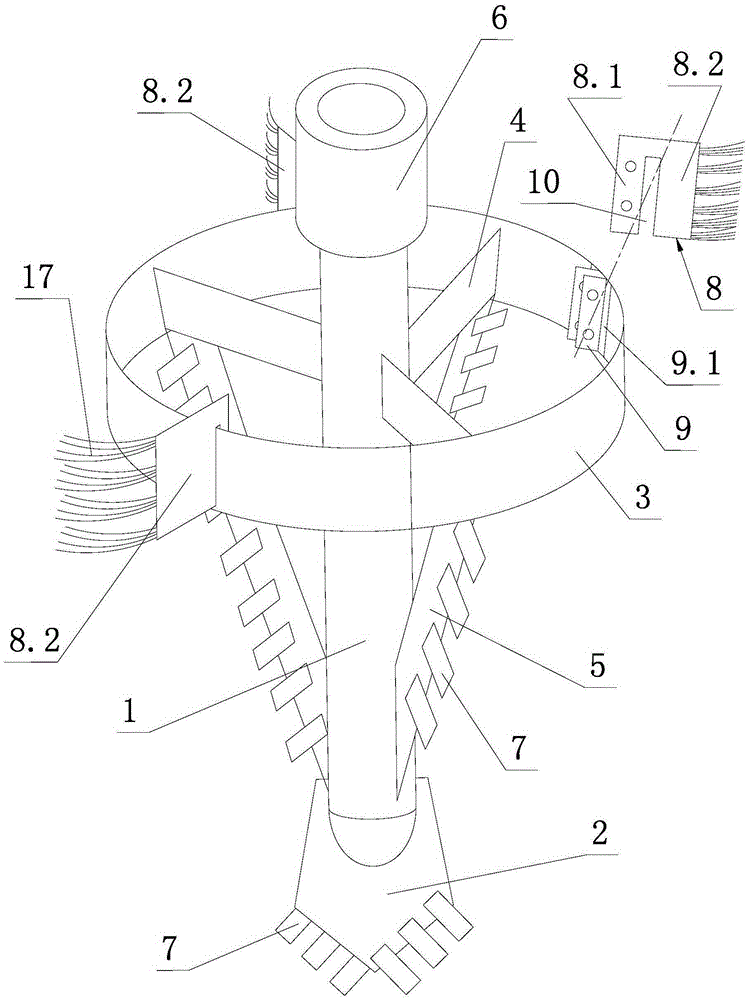

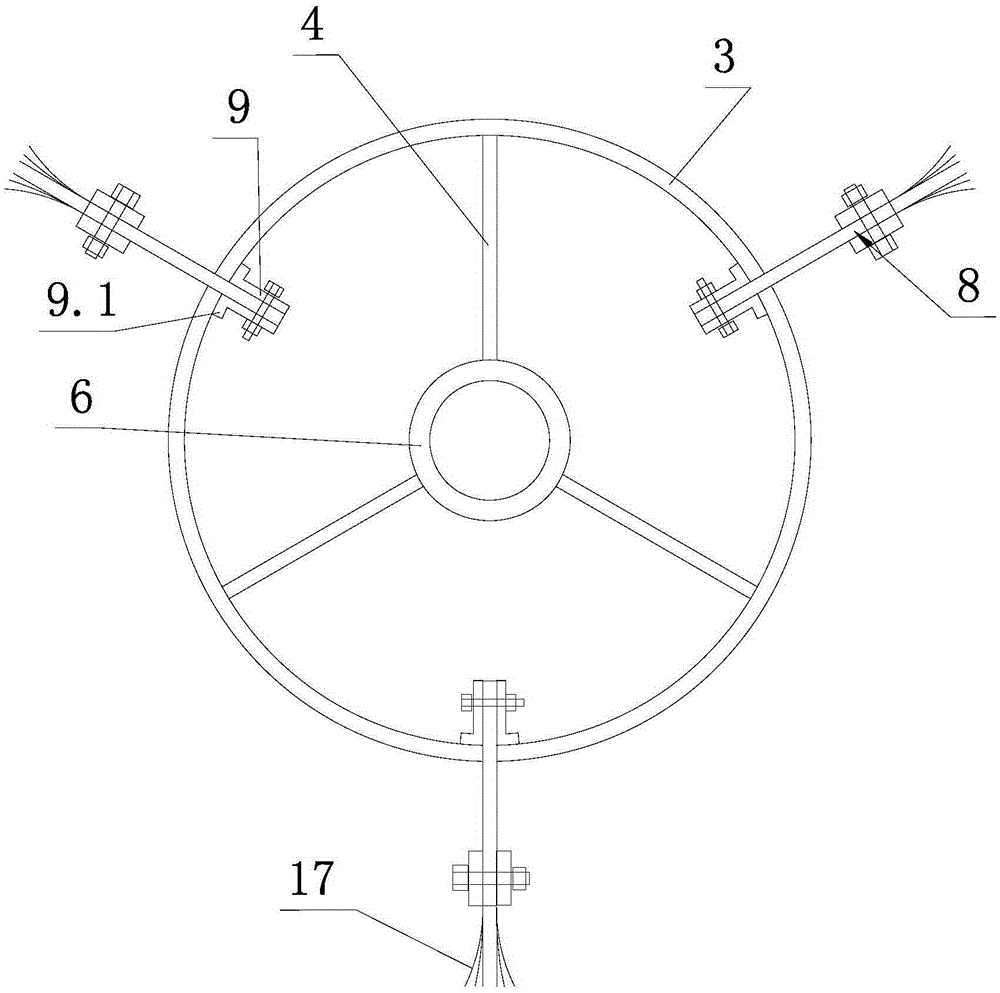

Drill bit for constructing bored piles and construction method using same

ActiveCN105317382AAvoid wear and tearLow costEarth drilling toolsDrill bitsStructural engineeringSmall hole

The invention discloses a drill bit for constructing bored piles and a construction method using the drill bit. The drill bit is provided with a mud scraping assembly and a detachable rib protecting block. The mud scraping assembly comprises a mud scraping plate (8) and installing plates (9), and the installing plates (9) are welded to the circumferential face of the inner circle of a block ring (3). A steel brush (17) is arranged on the outer side of the mud scraping plate (8). The mud scraping plate (8) is hung on the block ring (3) through a first clamping groove (10). An installing part (8.1) of the mud scraping plate (8) is located between the two installing plates (9) of the same set, and the installing part (8.1) of the mud scraping plate (8) and the installing plates (9) on the two sides are fixed in a threaded connection mode. The method is characterized in that in the drilling process, the mud scraping plate (8) is firstly installed on the block ring (3) so that a large hole with the size matched with that of a pile casing can be drilled, then the mud scraping plate (8) is taken down, and the rib protective block is installed so that a small hole with the size matched with the designed size of the bored piles can be drilled. By means of the drill bit and the construction method, sand soil between the pile casing and the pile holes can be effectively removed in a drilling mode.

Owner:浙江易通特种基础工程股份有限公司

Prefabricated retaining wall and pile hole excavation method

PendingCN110438988ATo meet the needs of hole formationThe settlement process is easyExcavationsBulkheads/pilesLarge sizeInternal stress

The invention discloses a prefabricated retaining wall and a pile hole excavation method. The excavation method comprises the steps that first, guide-hole construction is carried out by using a machinery in an excavation area of a rectangular hole, after the internal opening is carried out, a soil body at the edges and corners of the rectangular hole is disturbed, internal stress is released, thedifficulty of subsequent excavation is greatly reduced, moreover, with the continuous increase of gravity of the prefabricated retaining wall, the settlement process of the prefabricated retaining wall is easier, and construction efficiency is conducive to be improved; and according to the excavation method, excavation of the rectangular hole can be carried out effectively, construction safety isimproved, construction difficulty is reduced, the requirement for forming a large-size rectangular hole is met, at the same time, prefabricated retaining wall structure is effectively installed to avoid the risk of hole collapse, hole digging and the retaining wall can be completed simultaneously, the construction period is conducive to be shortened, energy saving and environment production are achieved, the quality hidden danger of the retaining wall can be avoided effectively, and the excavation method is especially suitable for construction of an anti-slide pile in cold and high altitude areas such as the sichuan-tibet line.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Construction method for forming holes on soil nail wall by water punching

The invention relates to a construction method for forming holes on a soil nail wall by water punching. The construction method comprises the following steps of: firstly ejecting side slope concrete, then ejecting high-pressure water to form soil nail holes, inserting soil nail reinforcing bars or using slurry injection anchor pipe as soil nails, and then injecting slurry through slurry injection pipes or the slurry injection anchor pipes to finally form the soil nails. The method is suitable for powdery sand soil layers, fine-sand-mingled silty clay layers and other soil layers in which holes are easily formed by water punching, had the advantage of reducing technical interval of soil excavation, and is suitable for project which has short time limit and is in urgent need of lower-layer soil excavation and deep-foundation pit structure construction.

Owner:北京建工一建工程建设有限公司

Device and method for improving roadway base plate anchor rod anchor cable pore-forming efficiency and anchoring performance

InactiveCN103410542AImprove pore forming efficiencyImprove the anchoring effectAnchoring boltsSlurryDrilling machines

The invention discloses a device and a method for improving pore-forming efficiency and anchoring performance of a roadway base plate anchor rod anchor cable. The device comprises a special drill rod, a connecting rod and a rod taking device. The special drill rod is successively utilized to perform twice drilling operations and reserved in a hole after the operations of the special drill rod are finished, then a common drill rod is inserted into the inner cavity of the special drill rod to continue to perform drilling till the designed depth is reached, the common drill rod is taken out, an anchoring agent is placed into the hole, an anchor rod or the anchor cable is installed, and finally the special drill rod is taken out through the rod taking device. When the device and the method are adopted to perform drilling and installation of the anchor rod or the anchor cable, the special drill rod is always reserved in the hole so that hole collapse can be effectively prevented. The smooth mud return of an anchor rod anchor cable drilling machine is ensured in the drilling process, water in mud is prevented from entering a loose fractured rock mass at the shallow portion of a base plate, accordingly rock soil is prevented from depositing at the drilling bottom, and borer clamping is avoided. The device for improving the pore-forming efficiency and the anchoring performance of the roadway base plate anchor rod anchor cable is simple in structure and convenient to use, the drilling rate reaches to 100%, the anchoring effects of the anchor rod and the anchor cable are good, the borer clamping is effectively prevented in the drilling process, and the construction efficiency is improved remarkably.

Owner:CHINA UNIV OF MINING & TECH

Grouting and post-grouting consolidation technology for prefabricated piles by full-casing construction method

The invention relates to a grouting and post-grouting consolidation technology for prefabricated piles by a full-casing construction method. The grouting and post-grouting consolidation technology isapplicable to the technical fields of foundation and ocean engineering. The background technology is that at present, in the technical fields of foundation and ocean engineering, cast-in-situ bored piles in rivers, lakes and the sea have long period and high cost due to links such as cofferdam island building. The grouting and post-grouting consolidation technology can remarkably overcome the defects mentioned above. According to the main content, after holes are formed by the full-casing construction method, cement slurry or mortar is poured into the boreholes while casings are hoisted so asto prevent the underwater boreholes from collapsing; before the cement slurry or mortar is solidified, the prefabricated piles made according to the design requirements are driven (sunk) into the boreholes by using a pile driver to the design elevation or are directly put into the borehole bottoms through the casings after the holes are formed, the cement slurry or mortar is poured, and then the casings are hoisted; and meanwhile, reserved grouting pipes in the prefabricated piles are used to inject grout to the pile bottoms and pile sides, the grout can be cement slurry, mortar and chemical grout, and finally the prefabricated piles and the stratum around the boreholes are tightly cemented and fixed together.

Owner:高永光 +1

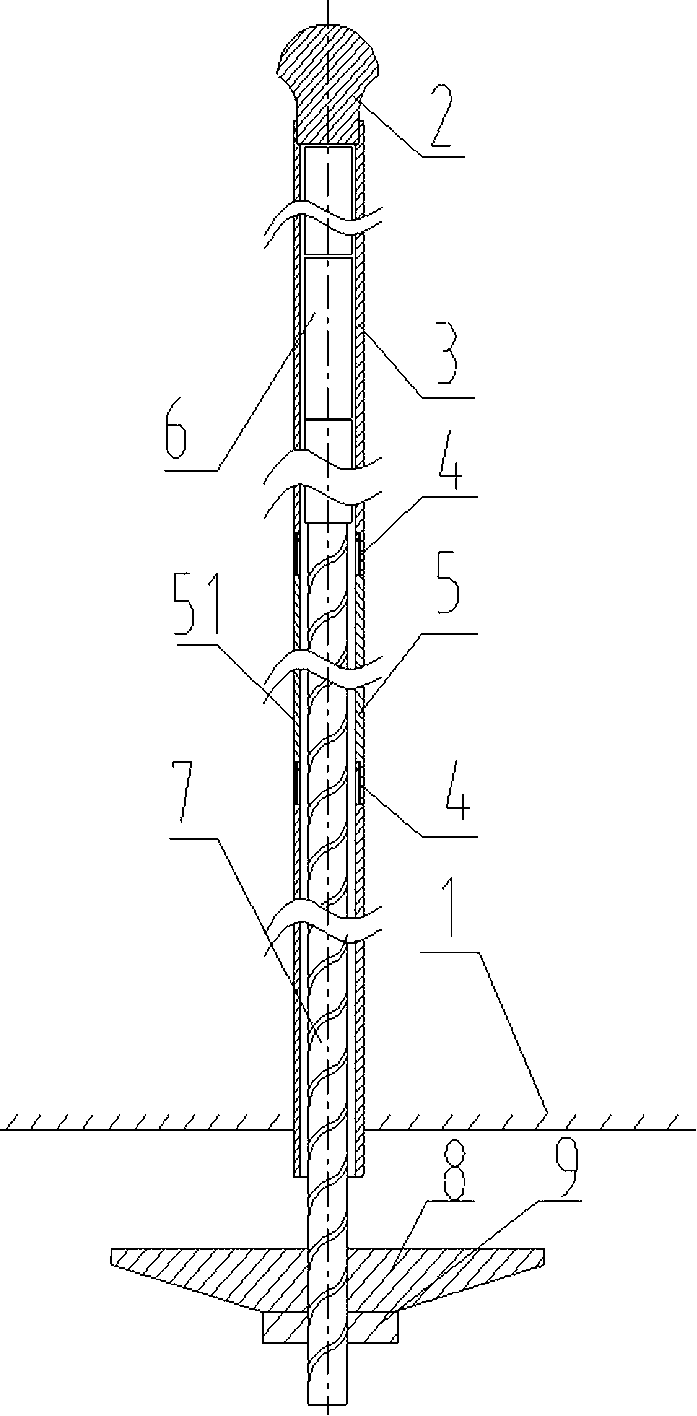

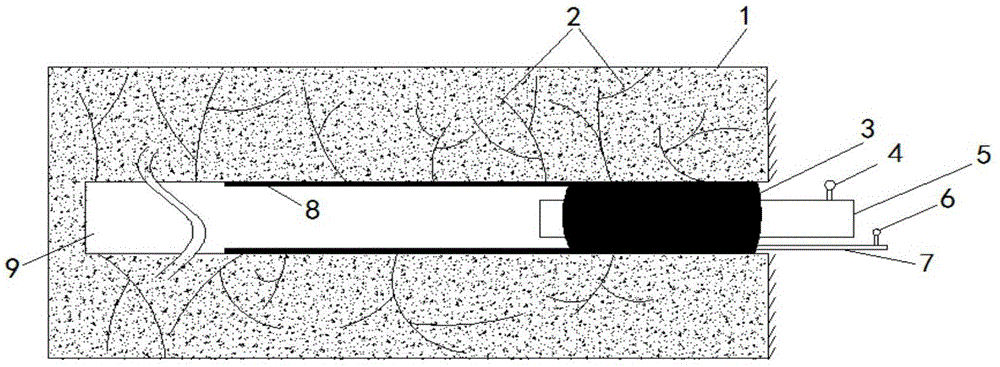

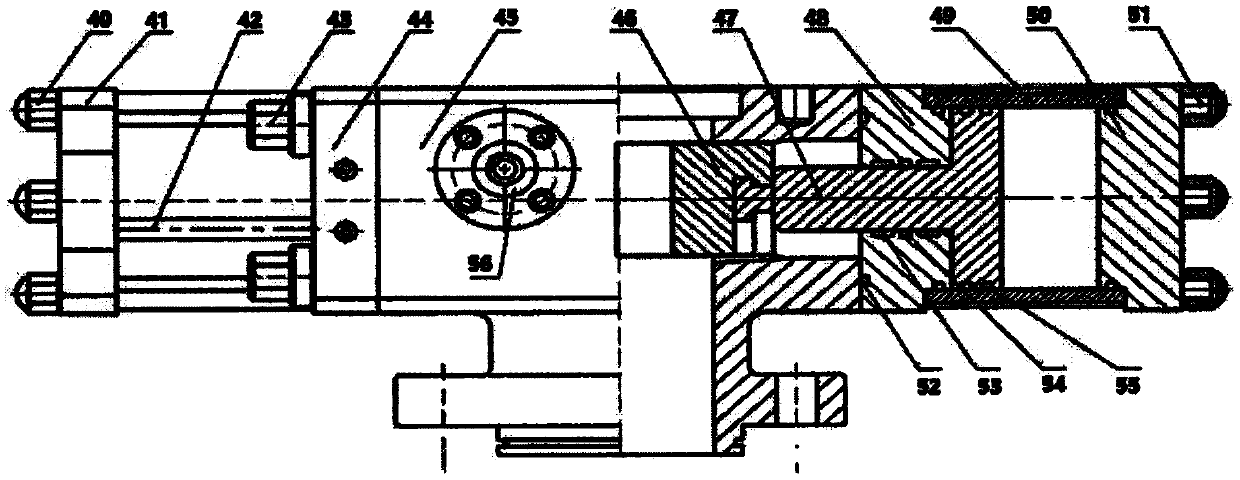

Liner tube feeding device and liner tube feeding method for horizontal drill hole under pressure

PendingCN111206877AEliminate blocking of horizontal boreholesPlay a supporting roleDirectional drillingSealing/packingBlowout preventerScrew thread

The invention relates to a liner tube feeding device and a liner tube feeding method for a horizontal drill hole under pressure. The liner tube feeding device comprise a plurality of liner tubes, a plurality of drill rods and an orifice pressure-maintaining device for the horizontal drill hole, wherein matched screw threads are arranged at the two ends of the liner tubes; the inner diameter of each liner tube is larger than the outer diameter of each drill rod; the orifice pressure-maintaining device is provided with a liner tube channel suitable for the liner tubes to insert and penetrate through, and comprises a three-way pipe short section, a gate valve, a first liner tube clamper, a blowout preventer, a first barrel, a second barrel, a second liner tube clamper and a ring-shaped sealerconnected sequentially from front to back; the first barrel is in threaded connection with the second barrel; and a screw-thread buckle type between the first barrel and the second barrel is the sameas a screw-thread buckle type between the two liner tubes in threaded connection. Through the liner tube feeding device and the liner tube feeding method for the horizontal drill hole under pressureprovided by the invention, the liner tubes can be sequentially connected and fed into the horizontal drill hole under pressure, and the liner tubes located in the drill hole can completely eradicate the occurrence of the phenomenon that collapsing holes block the drill hole, so that the long-time safety and unobstruction of a gas production channel of the drill hole is ensured, and the continuousstability of the coalbed gas extraction rate is ensured.

Owner:张海轩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com