Anti-blockage method for bottom hole of mine stope and roadway driving working face

A technology for excavation working face and anti-clogging, which is applied in the direction of earthwork drilling, wellbore/well components, blasting, etc., to avoid safety risks, achieve remarkable results, and simplify the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

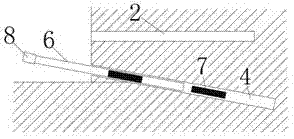

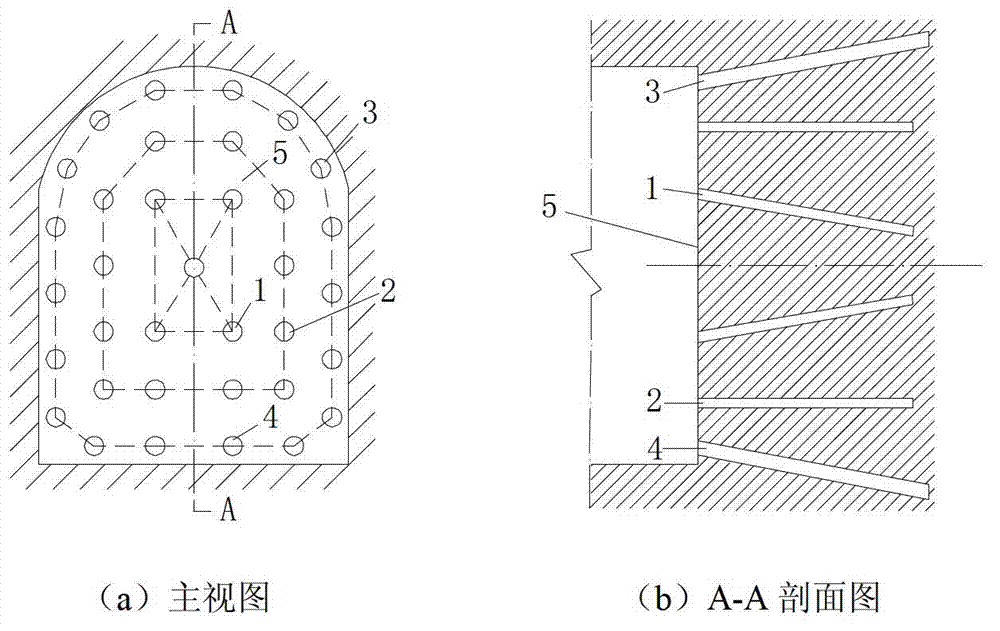

[0021] Here we take the actual application effect of an underground mine in southern my country as an example to illustrate. When the rock drilling preparations are completed, the Boomer282 double-arm rock drilling jumbo is used to drill the bottom hole first; a total of 7 bottom holes are arranged in the designed excavation section, and the drilling depth is 3.5m. When the bottom hole is dug to the design depth, the drill rod is withdrawn , immediately insert the bottom hole tube 6 with an outer diameter of f42mm and a length of 1.5-2.0m into the bottom hole drill hole 4, and the length of the inserted hole is about 1.0-1.5m. If the rock mass is too broken, you can also insert the bottom hole tube deepest hole. The inner and outer walls of the bottom eye tube should be smooth, which not only facilitates the insertion of the bottom eye tube into the blast hole, but also facilitates the smooth delivery of explosive rolls to the bottom of the blast hole through the bottom eye tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com