Alluvial plain karst developing district drilling pile formation wall protection mud and preparation method thereof

A development zone and mud technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems that mud cannot be applied, has no innovation, and limits the application range of drilling and pile technology, so as to prevent hole collapse and reduce Unnecessary losses and the effect of reducing the probability of pile foundation construction accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of drilling and pile-forming mud in the karst development area of the alluvial plain:

[0031] The raw material components of the mud and the mass percentages of each component in the total raw material are as follows:

[0032] Water: clay: sodium carbonate: polyacrylamide: carboxymethylhydropropyl cellulose: water glass: iron chromium lignosulfonate: barite powder=100 parts: 10 parts: 0.25 parts: 0.03 parts: 0.5 parts: 0.9 parts: 0.1 parts: 0.2 parts.

[0033] Step 1. Weigh water, clay, sodium carbonate, polyacrylamide, carboxymethyl hydroxypropyl cellulose, water glass, iron chromium lignosulfonate, potassium humate, and barite powder according to the test plan, and place them in a cool and ventilated place. place.

[0034] Step 2. Heat an appropriate amount of water to 50°C, then pour the weighed polyacrylamide, carboxymethyl hydroxypropyl cellulose, and water glass into water, stir for three hours with a mixer, and store the mixed liquid i...

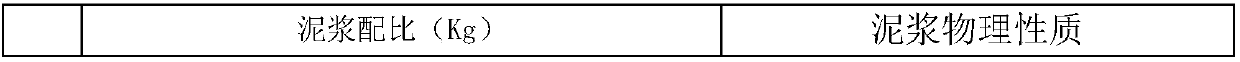

Embodiment 2

[0040] Embodiment 2: method is the same as embodiment 1

[0041]

[0042]

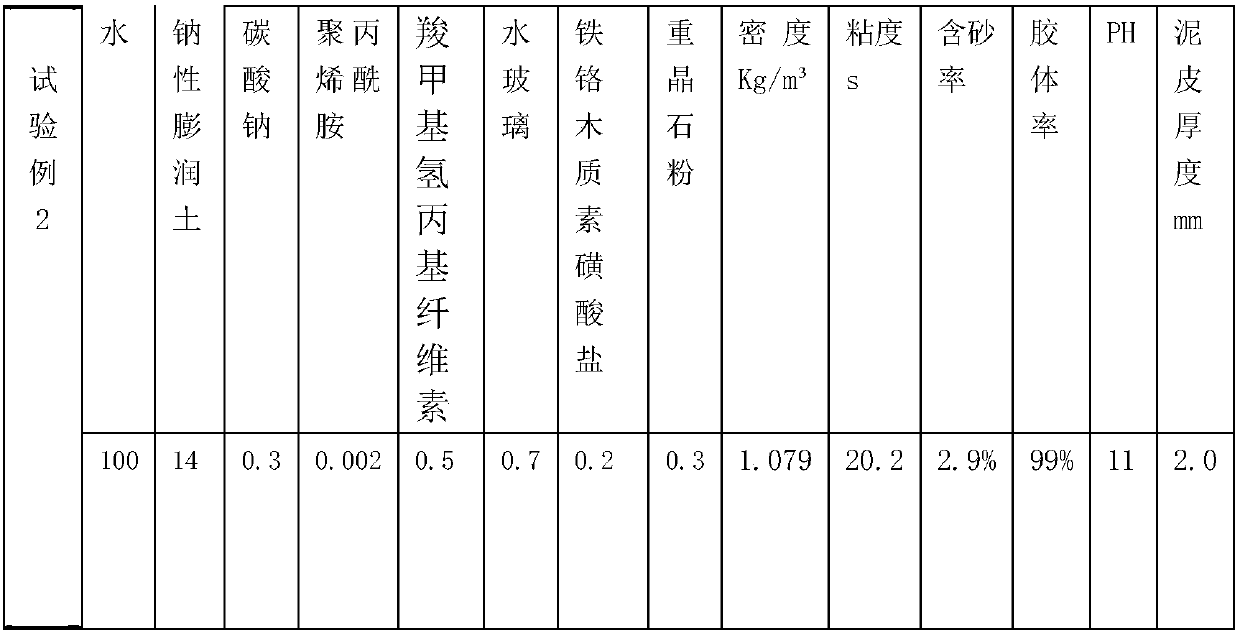

Embodiment 3

[0043] Embodiment 3: specific method is the same as embodiment 1

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| colloid rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com