Drilling device and hole forming method of pre-drilling type lateral pressure test

A technology of side pressure test and drilling device, which is applied in the field of foundation soil survey, construction, and infrastructure engineering, etc. Achieve the effect of shortening the construction period, not easy to disturb, and improving the quality of the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The object of this embodiment is a sandy soil stratum. A pre-drilling type side pressure test hole forming method and drilling device of the present invention are used to carry out a side pressure test. In order to compare the technical effects of the present invention, the side pressure test procedure (YS5224- 2000) the conventional pore-forming method was tested under the same conditions.

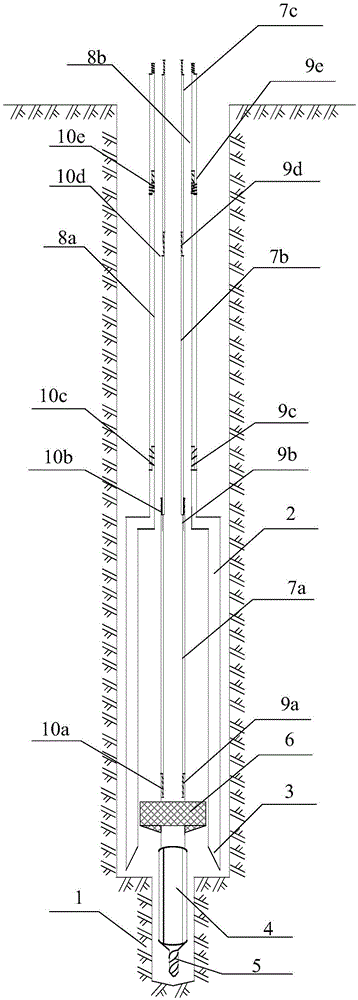

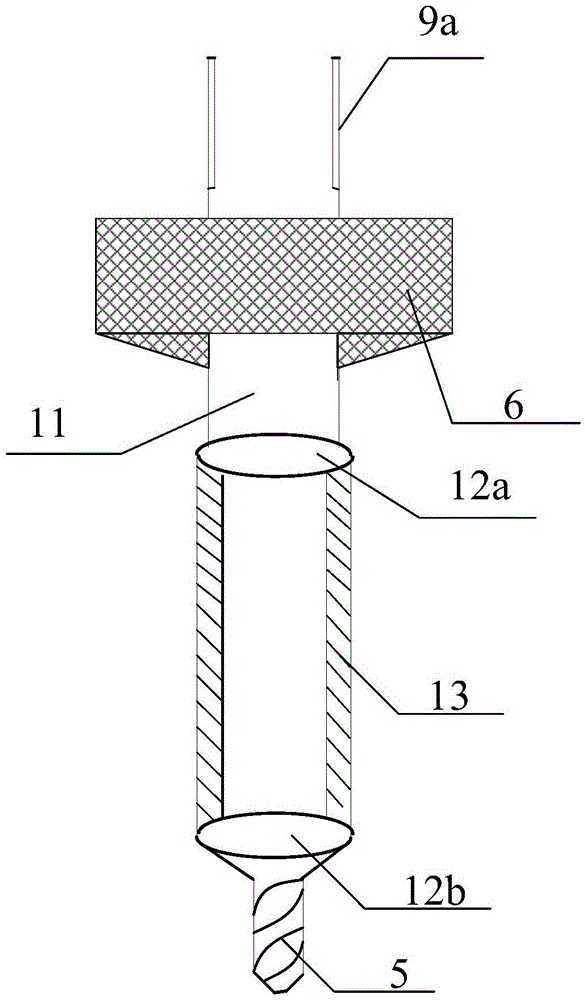

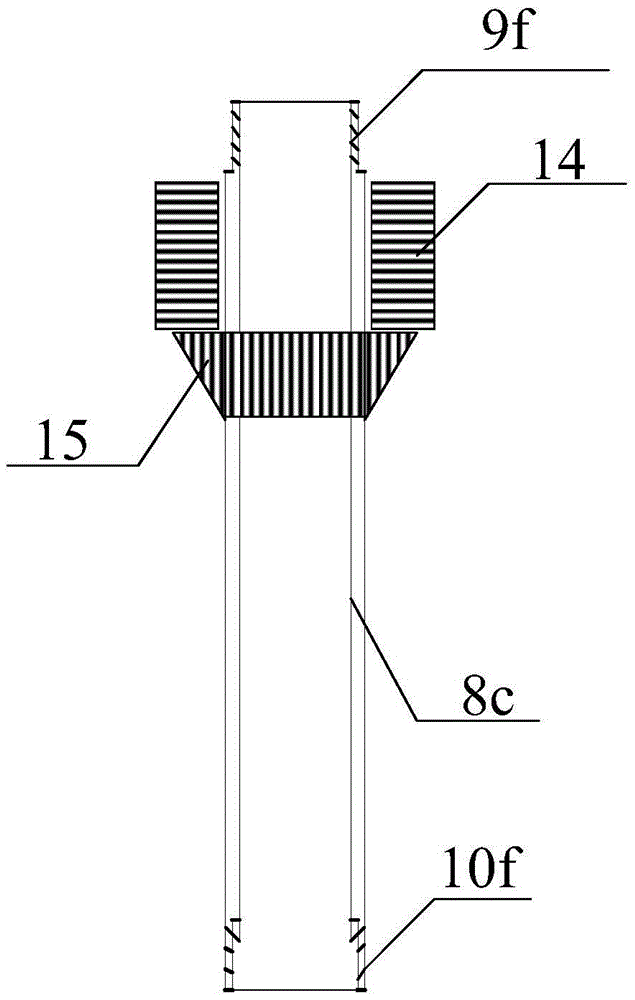

[0041] A kind of drilling device for pre-drilling side pressure test (see Figure 1 to Figure 4 ), which includes ring cutter soil cutter 2, spoon drill 4, drill bit 5, positioner 6, first drill rod 7a, second drill rod 7b, third drill rod 7c, first outer rod 8a, second outer rod 8b, the third outer rod 8c, the connecting rod 11, the first joint 12a, the second joint 12b, the drop weight 14 and the baffle 15.

[0042] Wherein, the top of the drill bit 5 is connected to the lower end of the spoon-shaped drill wall 13 through the second joint 12b, the upper end of the spoon-shaped d...

Embodiment 2

[0052] A kind of pre-drilling type bypass pressure test drilling device adopted by the second embodiment provided by the present invention is exactly the same as the device adopted in embodiment 1, and the test object is still the sandy soil formation with the same conditions. The drilling method of the pressure test is basically the same as that of Example 1, except that the mud protection wall is not carried out when drilling, the drilling speed of the drill pipe is 90 revolutions per minute, and the drilling stop standard is the lower end of the drill bit 5 or the ring cutter soil cutter 2 simultaneously. When the test depth of side pressure test is 0.5m, stop turning. Embodiment 2 adopts different mud wall protection measures, turning speed, and drilling stop standards from Embodiment 1 to test the influence of these control parameters on the quality of drilling holes and the reliability of side pressure test results.

[0053] The side pressure test curve of embodiment 2 i...

Embodiment 3

[0055] A kind of pre-drilling type lateral pressure test drilling method and drilling device adopted in the third embodiment provided by the present invention are completely the same as those adopted in embodiment 1, but the test object is the silt soil formation with the same conditions. At the same time, the side pressure test was carried out under the same conditions using the conventional pore forming method in the side pressure test procedure (YS5224-2000). To test a kind of pre-drilling type side pressure test drilling method and drilling device of the present invention in the silt soil layer drilling hole forming quality and side pressure test result reliability.

[0056] The side pressure test curve of embodiment 3 sees Figure 7 Shown, utilize a kind of pre-drilling type side pressure test pore forming method of the present invention in comparative example 3, and the side pressure test curve figure that conventional pore forming method obtains can find, adopt conventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com