Three-tube communication tower

A communication tower and tower body technology, applied in the field of communication towers, can solve the problems of wasting time and resources, and the tower foundation is arranged in a right-angled triangle, saving construction period and cost, avoiding roof structure transformation, and ensuring the effect of stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below according to the drawings and embodiments.

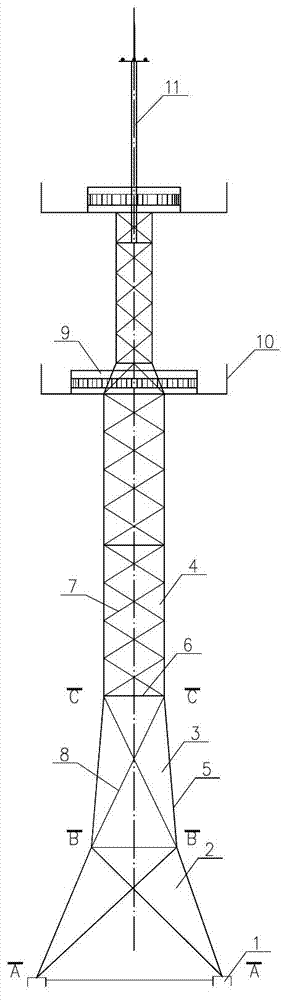

[0019] figure 1 For the structural diagram of the three-pipe communication tower in this implementation case, refer to figure 1 , the present invention, a three-pipe communication tower, including the iron tower foundation 1, the lowermost tower body 2, the middle tower body 3, the uppermost tower body 4, the platform 9, the antenna bracket 10, and the lightning rod 11, wherein the platform 9 is located in the uppermost tower On the top surface of the body 4, the antenna bracket 10 is located on the platform 9, and the lightning rod 11 is located at the top.

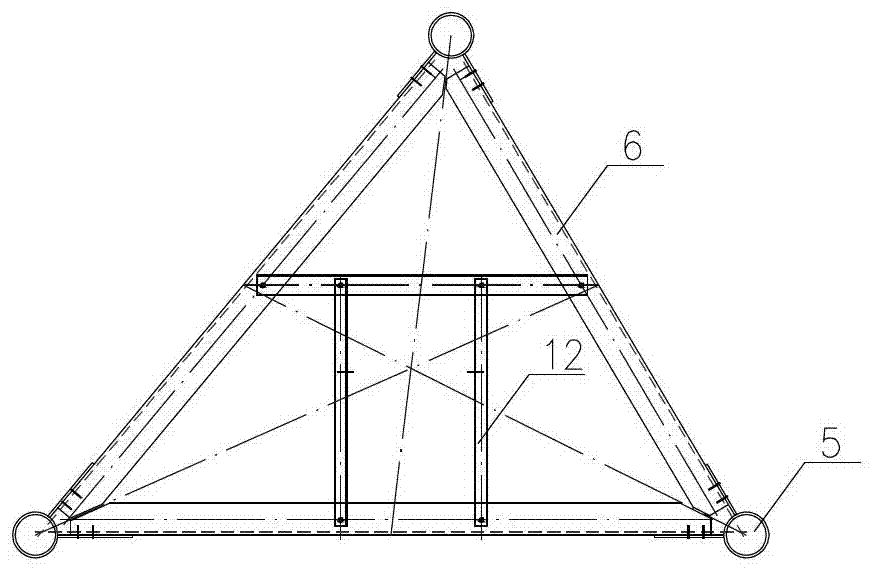

[0020] Wherein, the lowermost section tower body 2, the middle section tower body 3, and the uppermost section tower body 4 are constructed by tower columns 5, inclined bars 7, and cross bars 6.

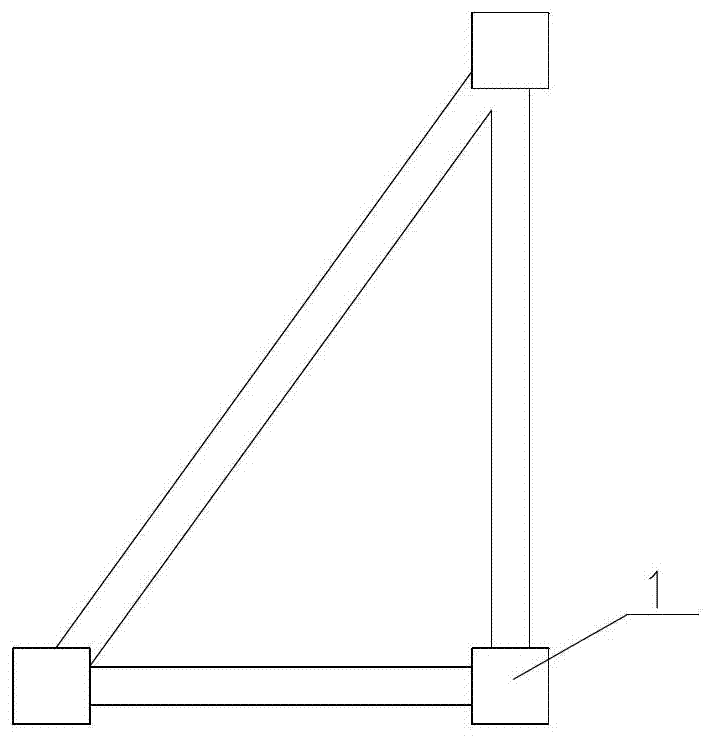

[0021] figure 2 for figure 1 The A—A cross-sectional view of image 3 for figure 1 The B—B cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com