Automation equipment used for line winding procedure during fishing pole production

An automatic equipment and winding technology, applied in fishing rods, fishing, applications, etc., can solve the problems of inaccurate winding position, low degree of automation, and dependence on skilled workers, so as to ensure winding quality, high degree of automation and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Referring to the accompanying drawings, the present invention will be further described in detail with specific embodiments.

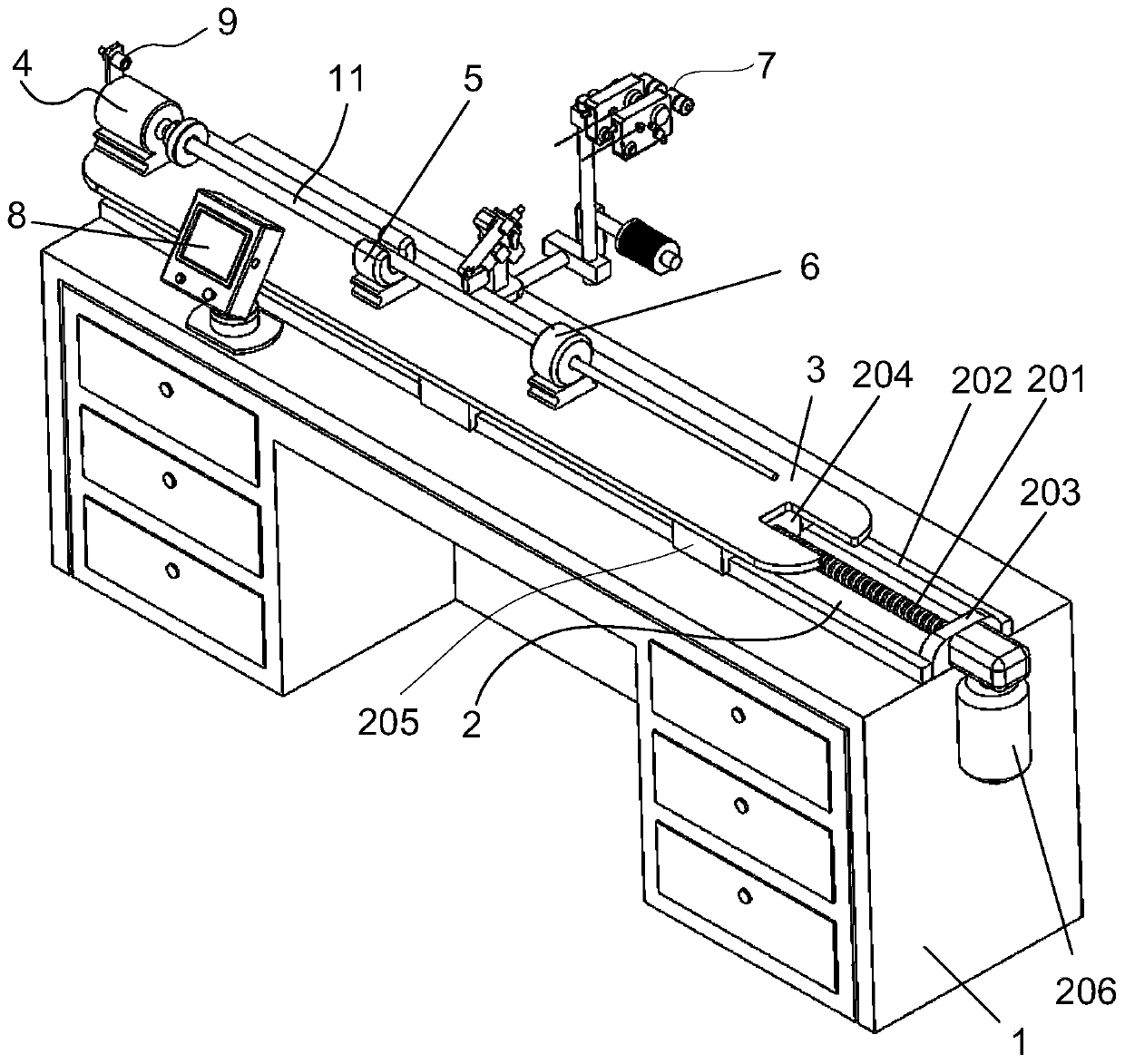

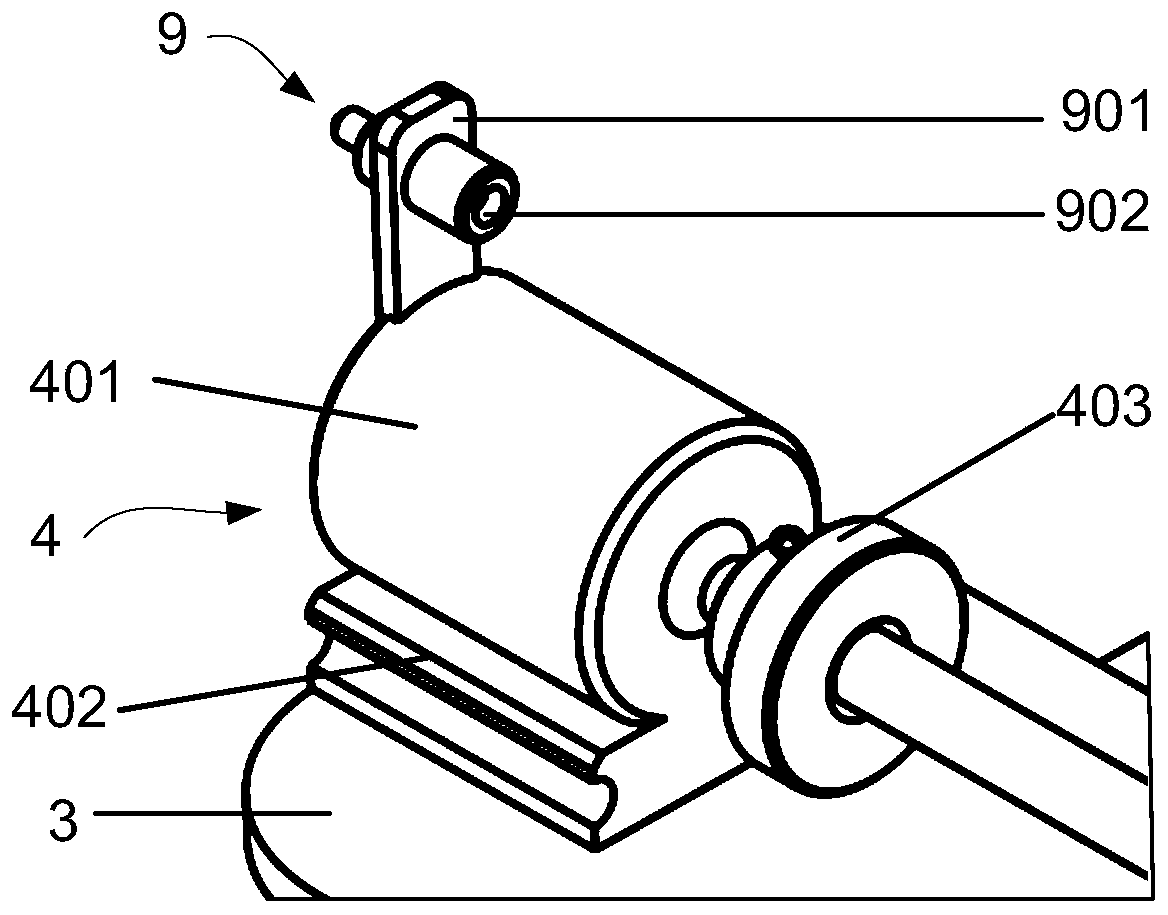

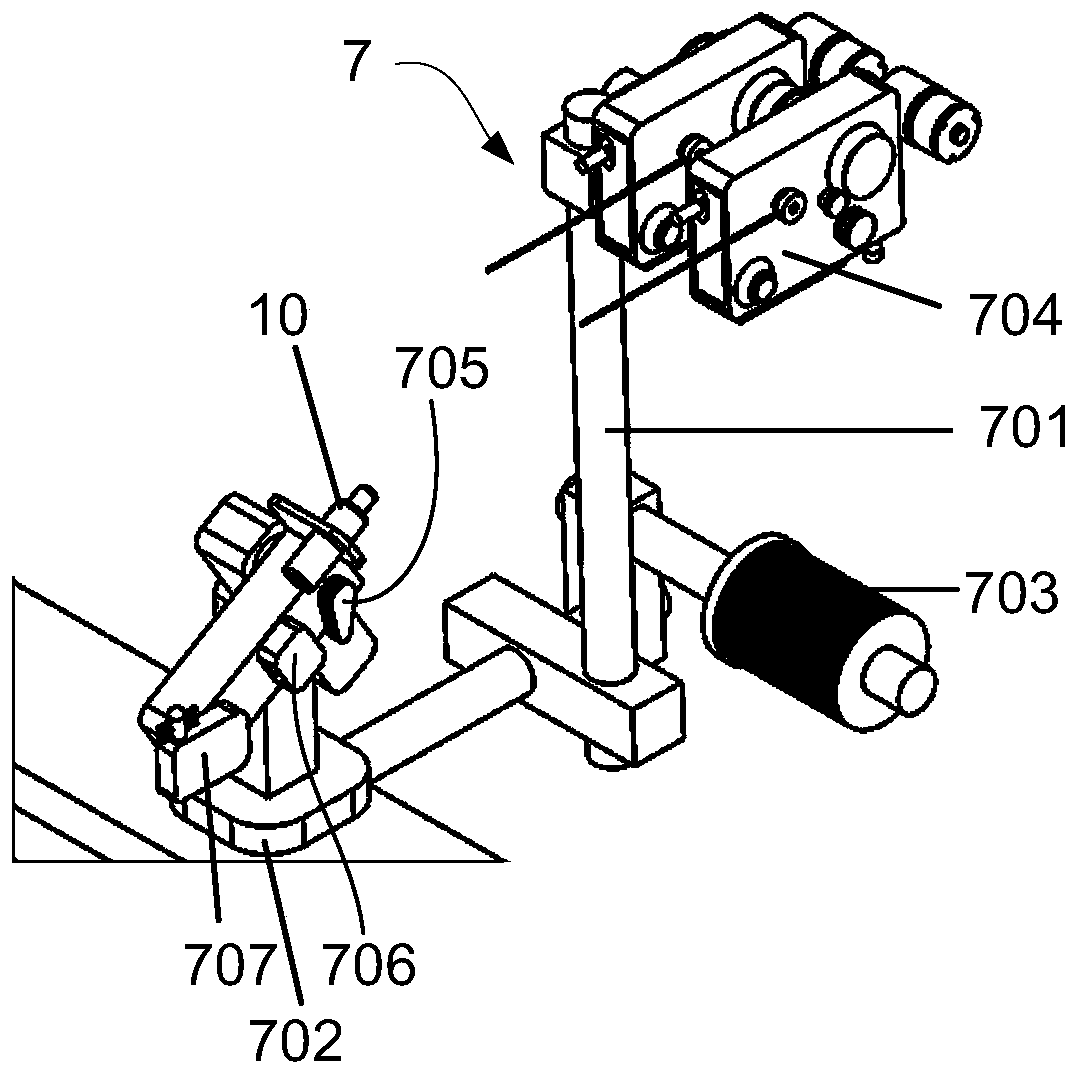

[0029] like Figure 1-3 As shown, the automatic winding equipment includes a base 1, a control panel 8, a translation mechanism 2, a sliding table 3, a rotation drive mechanism 4, an axial laser positioning device 9, a support seat 6, a wire feeding mechanism 7, and a radial laser positioner 10 . The control panel 8 is used to control the translation mechanism 2, the rotation drive mechanism 4, the axial laser positioning device 9, the radial laser positioner 10 and other components to work.

[0030] A translation mechanism 2 is installed above the base 1 . The translation mechanism 2 includes a ball screw 201 , a guide rail 202 , a screw support 203 , a nut seat 204 , a slider 205 , and a translation drive motor 206 . The ball screw 201 is connected to the base 1 through the screw support 203, the output shaft of the translation drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com