Manual image measuring instrument

An image measuring instrument and image measuring technology, applied in the field of measuring instruments, can solve problems such as inability to adjust, no adjustment device, and large adjustment resistance, and achieve the effects of convenient adjustment operation, reduced measurement error, and guaranteed measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

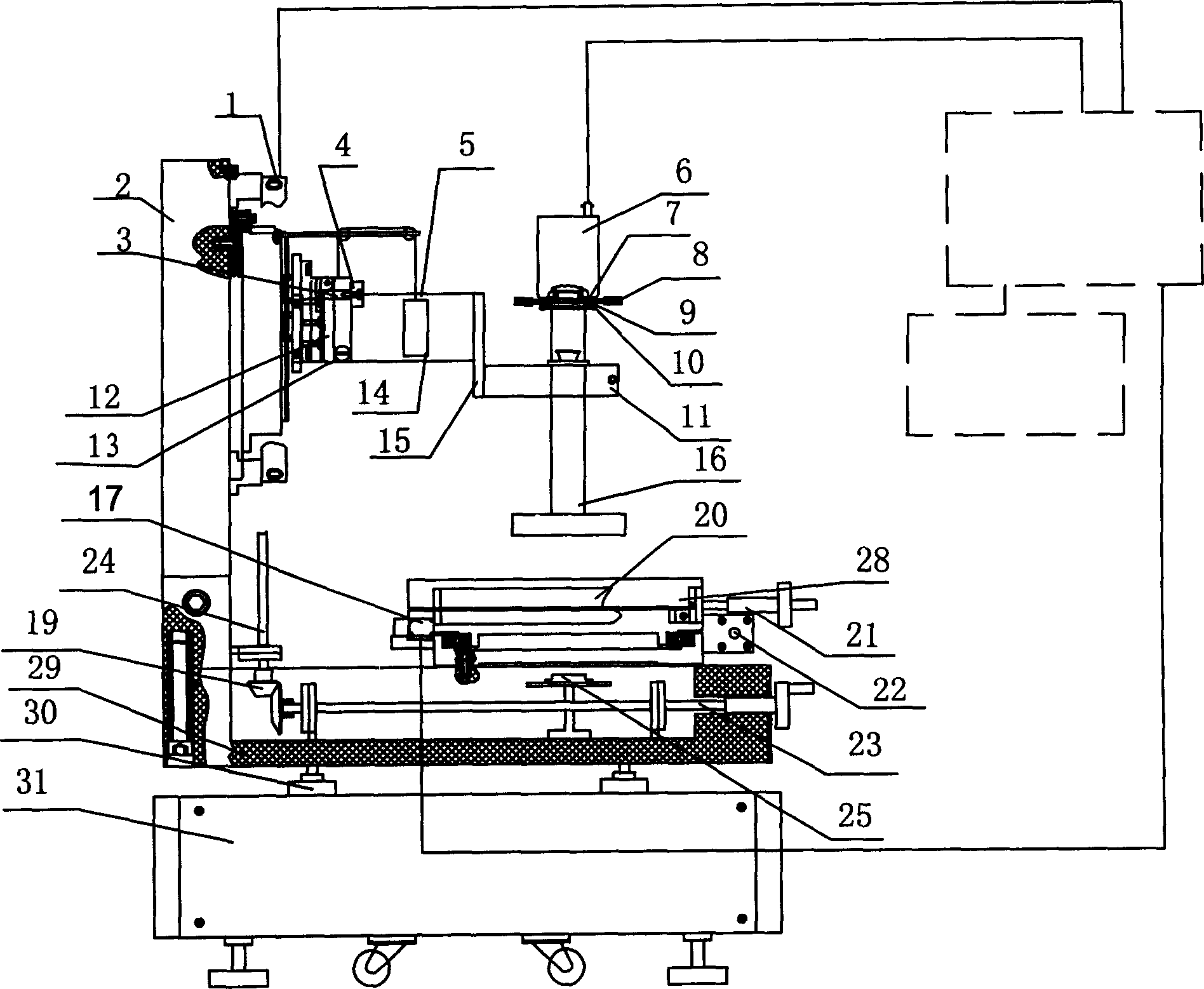

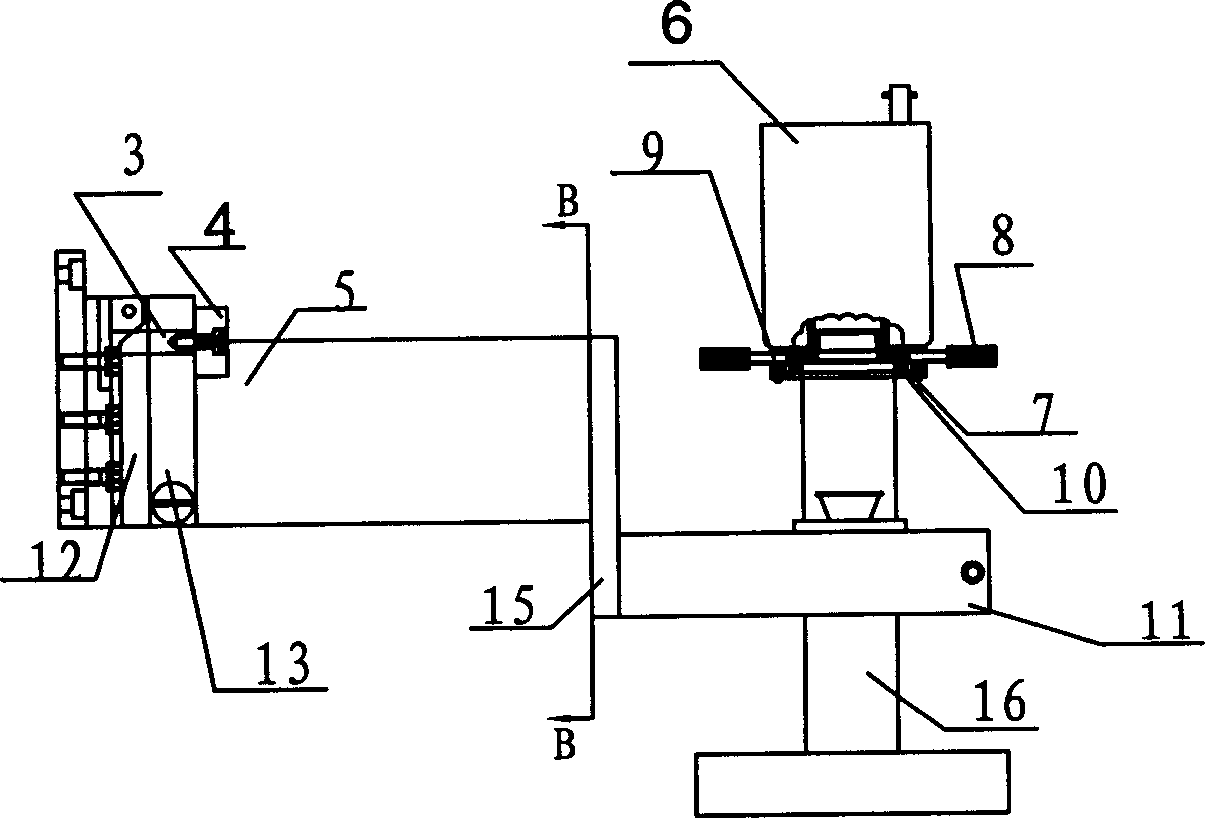

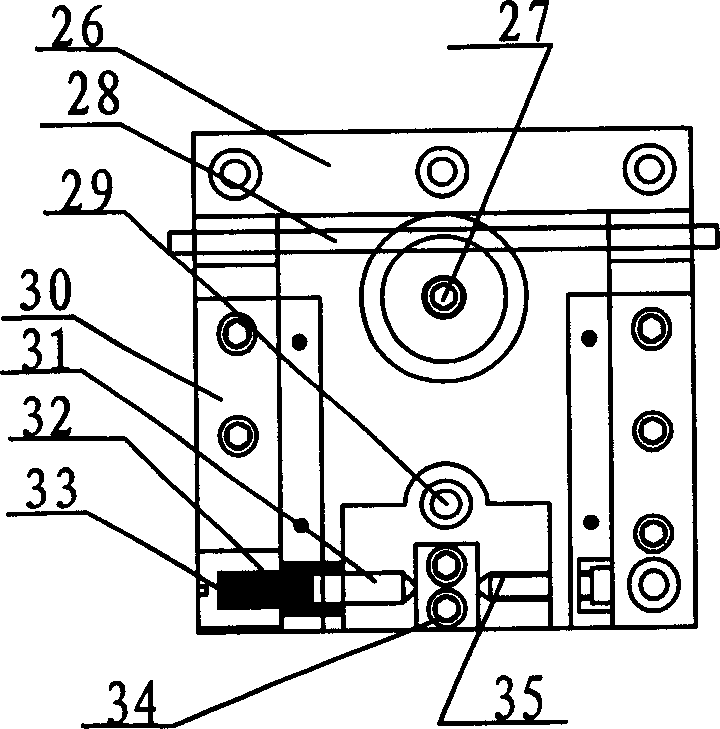

[0017] A preferred embodiment of the present invention is mainly composed of the following parts: imaging system (including: zoom lens, CCD camera and image acquisition card, etc.), lighting system (light source, light source controller), motion system (Z axis / X, Y Workbench), software and auxiliary parts (support seat, adjustment seat, grating ruler, etc.).

[0018] See attached figure 1 As shown: the column 1 and the base 29 are positioned by positioning pins and connected by bolts to form the supporting components of the entire manual image measurement system. The moving parts in the Z-axis direction are fixed on the column by bolts. The CCD camera 6 and the zoom lens 16 are connected through the adjustment device between them and fixed on the camera and the microscope fixed adjustment device through the lens clamp 11, while the camera and the microscope fixed adjustment device are fixed on the z-axis connecting plate with bolts through the connecting base plate superior....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com