Bearing strip of fastener arranged according sequence for fastener driving tool

A fastener driving and fastener technology, applied in the direction of threaded fasteners, nailing tools, manufacturing tools, etc., can solve the problems of bending fasteners, rebounding and twisting of fasteners, etc., and achieve a simple design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

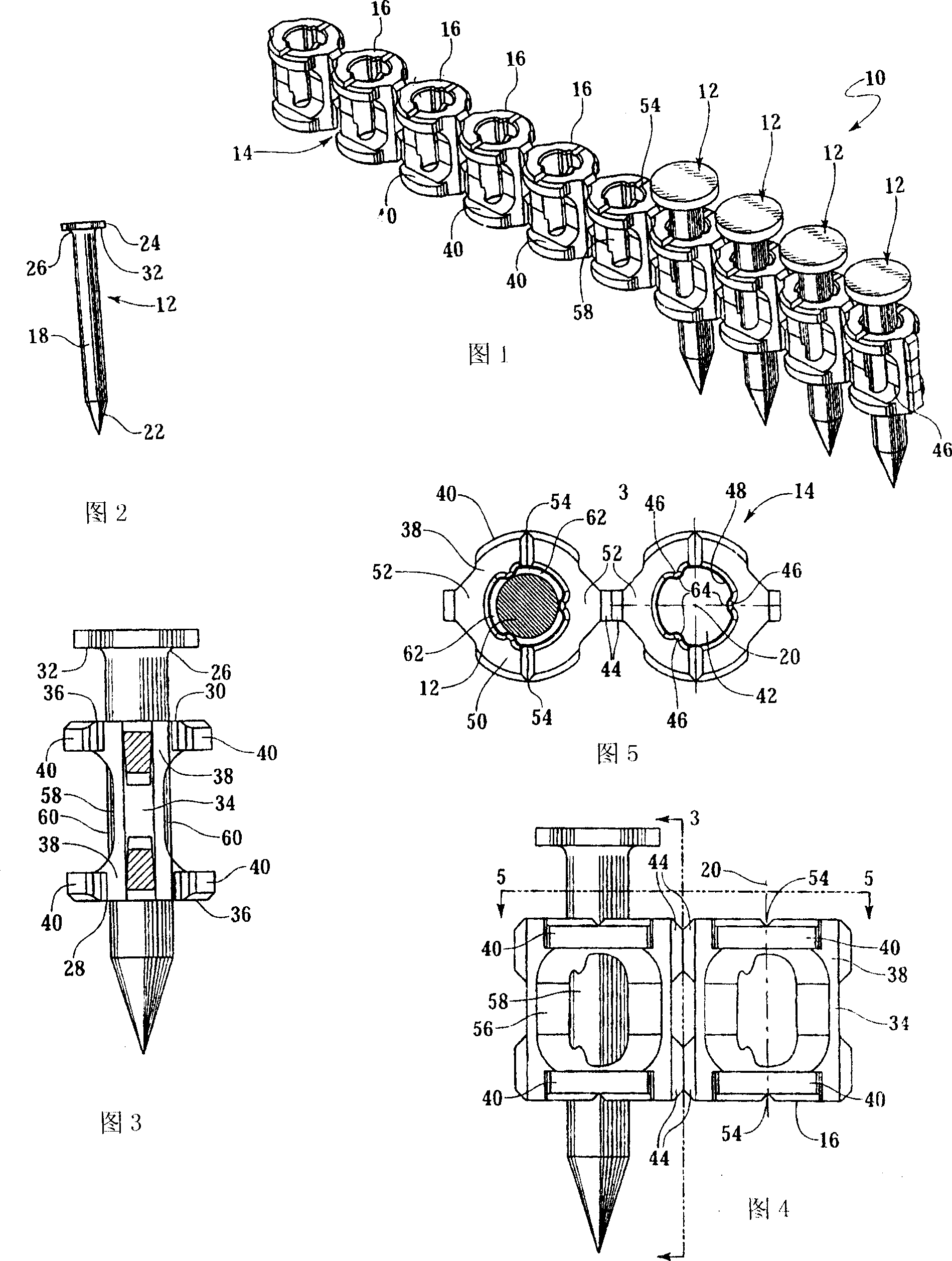

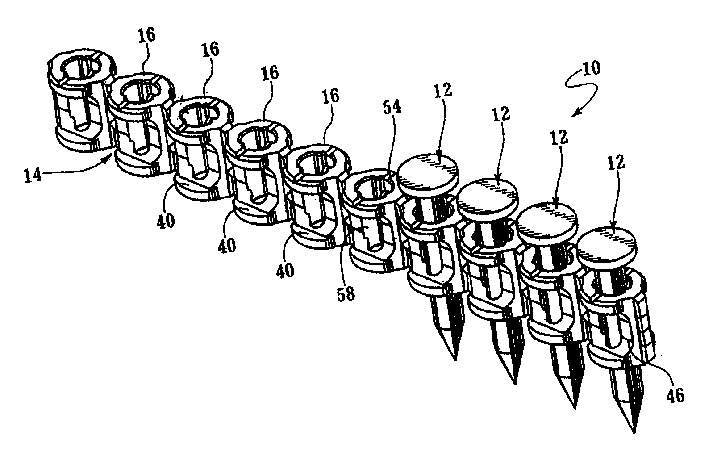

[0017] Referring now to FIG. 1, there is shown a novel and improved carrier bar 10 for sequentially arraying fasteners 12 for use in a fastener driving tool. Carrier bar 10 can be used in many types of fastener driving tools, but is preferably used in explosive powder actuated tools. Each carrier bar 10 includes a carrier 14 having a plurality of sleeves 16 each clamping an associated fastener 12 . Each sleeve 16 is also new and improved, and the invention is not limited to multiple sleeves 16 clamping multiple fasteners 12 .

[0018] Each fastener 12 includes an elongated shank 18 and each sleeve 16 helps grip the shank 18 of the associated fastener 12 to keep the fastener 12 centered in the bore 42 of the sleeve 16 and correctly oriented so that the fastener 12 is aligned with a central axis 20 passing through the sleeve 16 .

[0019] A representative fastener 12 is shown in FIG. 2 . Each fastener 12 is a tack, which may be made of hardened steel. Each fastener 12 is des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com