Device for measuring flexural rigidity of structural member in high-low temperature environments

A testing device, a technology of bending stiffness, applied in the testing of machine/structural components, measuring devices, elasticity testing, etc., can solve the problem that the laser transmitter cannot be located on the component, follow the three-dimensional displacement of a certain point, and achieve weight The effect of light weight, good real-time performance and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

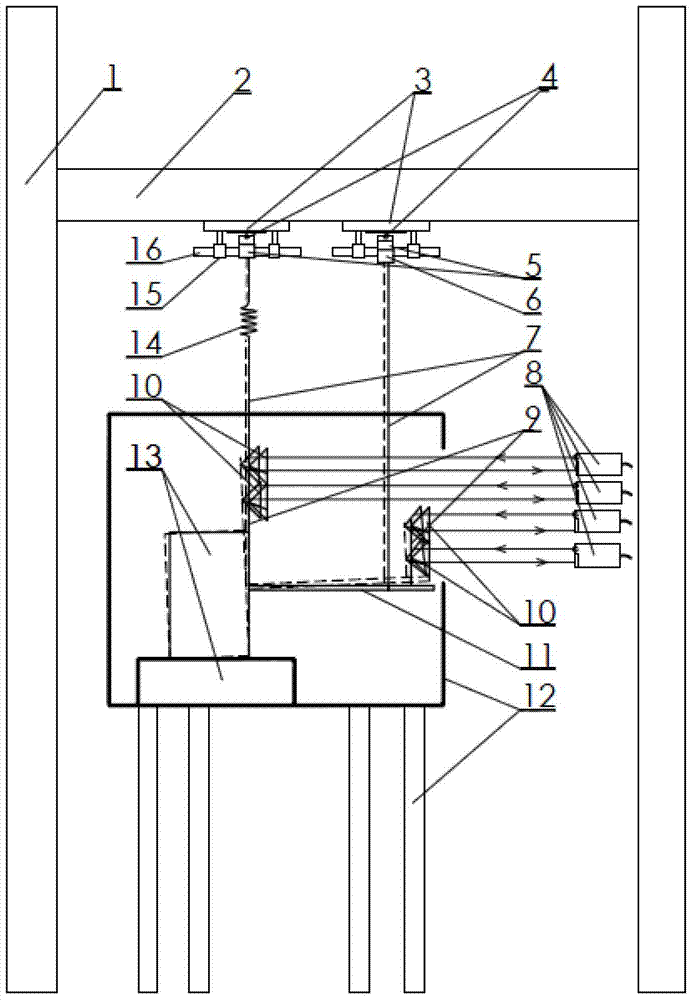

[0029] In conjunction with the accompanying drawings, a device for testing the bending stiffness of structural parts in high and low temperature environments, the test device includes a laser measurement group, an air flotation device, a lifting device 1, a moving beam 2, a high and low temperature resistant pull rope 7, a high and low temperature box etc. The air flotation device includes an air flotation shaft 16 and an air flotation sleeve 5 .

[0030] The lifting device 1 is located outside the high and low temperature chamber, and the moving beam 2 is set on the lifting device 1 and can move up and down.

[0031] The air flotation device has two sets, and the air flotation shaft 16 of the air flotation device is fixed on the moving beam 2 through the air flotation bearing seat 3, and the air flotation sleeve 5 is sleeved on the air flotation shaft 16. A grating displacement sensor 4 and a wireless data transmission module 15 are installed on the air bearing shaft 16 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com