Drilling machine for road construction

A technology for road construction and drilling machines, which is applied in the direction of rotary drilling machines, drilling equipment and methods, drilling rods, etc., can solve the problem that the drilling machine cannot meet the requirements of road construction, and achieve the protection of the surrounding environment, save time, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

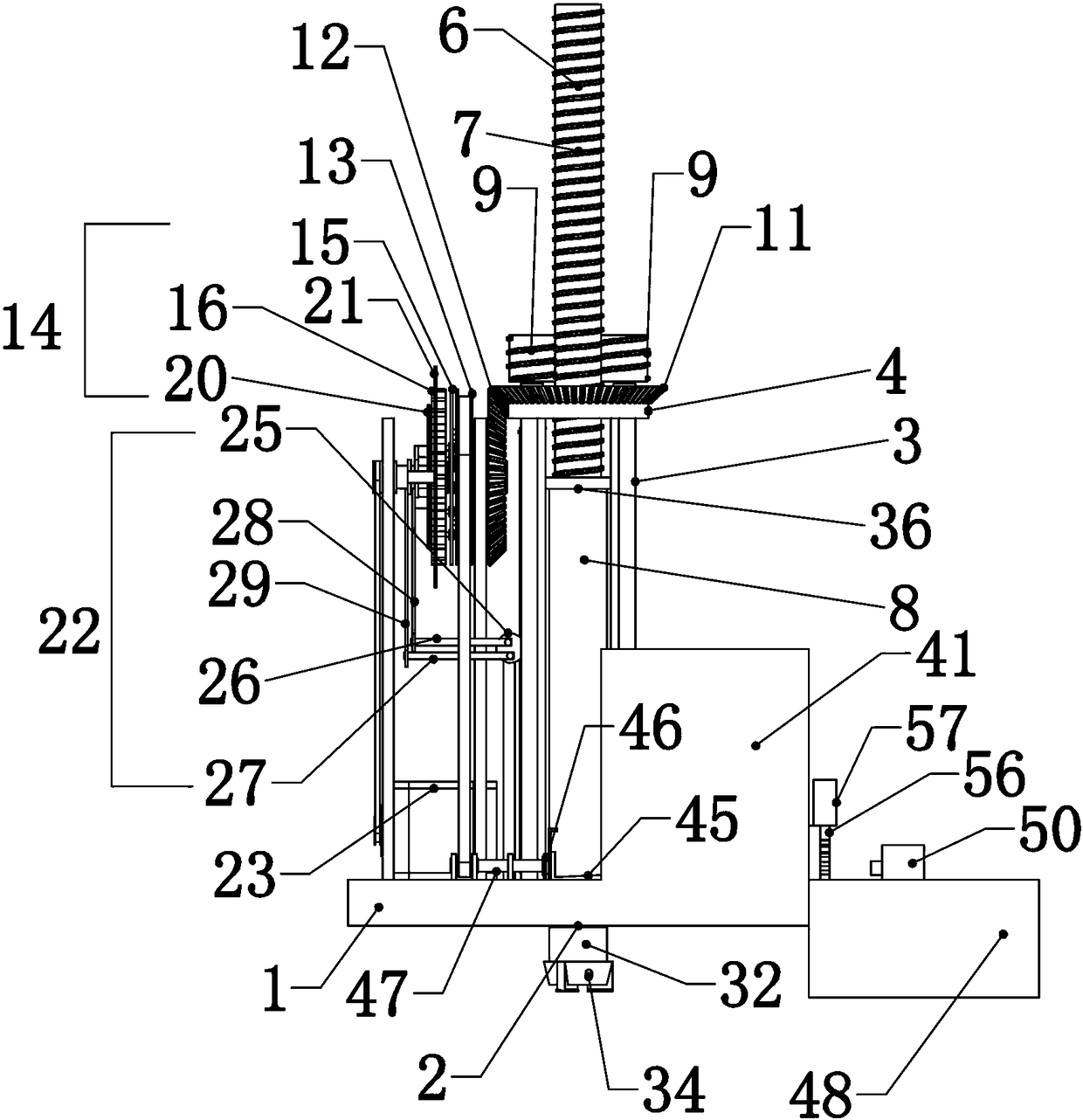

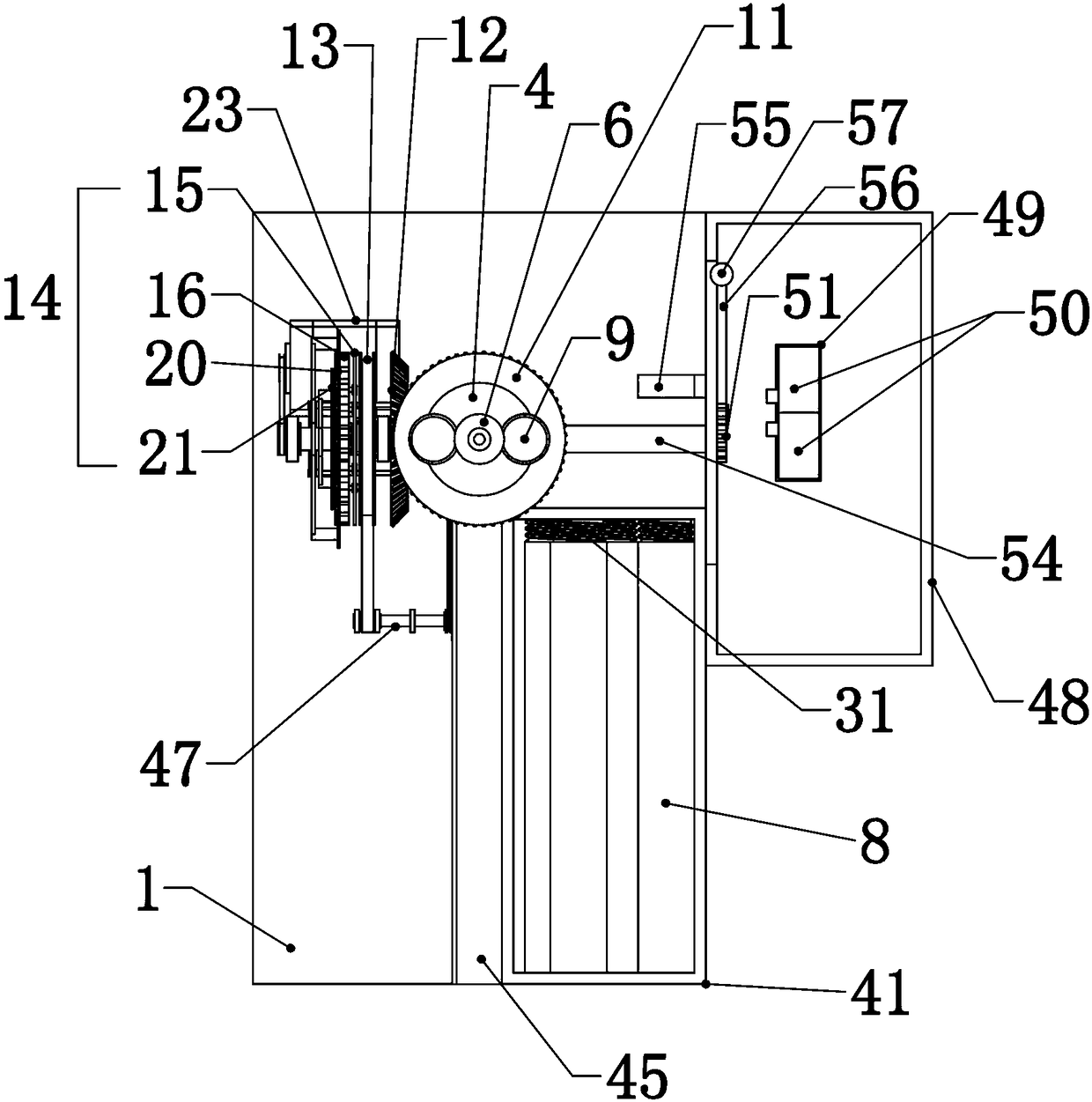

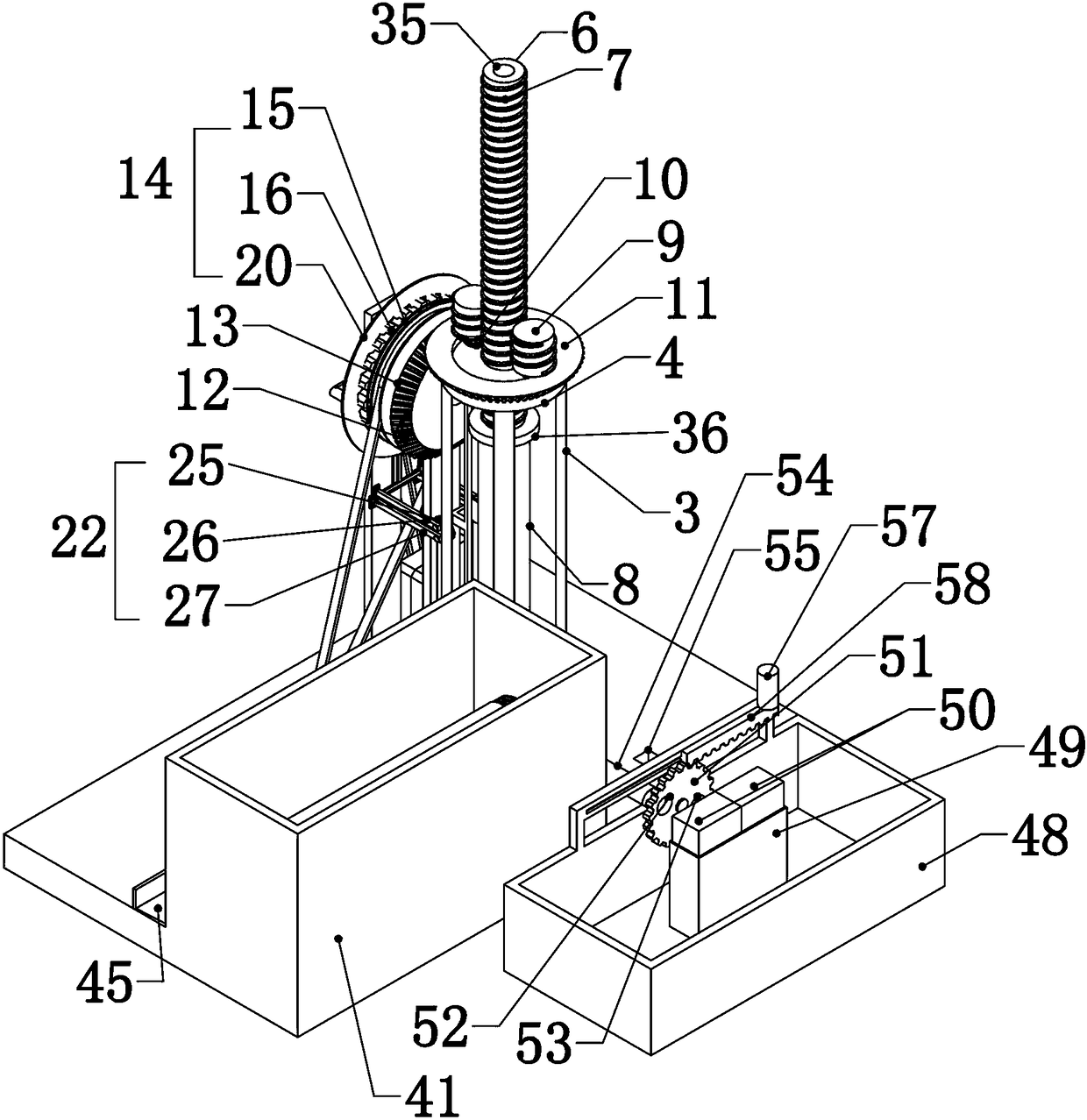

[0050] Embodiment 1, the present invention is a drilling machine for road construction, including a workbench 1, on which a drilling structure, a planetary gear train 14 is used as a drive structure, a drill pipe storage and placement structure, a mud pool and a mud pit. Circulation structure, wherein the drill port structure is used for drilling, the planetary gear train 14 provides driving force for the present invention as a driving structure, and at the same time enables the present invention to realize automatic reversing, and the drill rod storage and placement structure is used for storing drill rods and automatically Drill pipes are installed, the mud pool and mud circulation structure are used to provide and store mud for the present invention and complete the switching of mud forward and reverse circulation;

[0051] Described planetary gear train 14 comprises circular back plate 15, and circular back plate 15 is used as the base plate of planetary gear train 14, and ...

Embodiment 2

[0053] Embodiment 2, on the basis of Embodiment 1, the described drilling structure includes a drilling 2, the drilling 2 is a through hole opened on the workbench 1, and the workbench 1 passes through the support column located on the side of the drilling 2 3 is integrally connected with a positioning ring 4, the positioning ring 4 is located directly above the drill hole 2 and coaxial with the drill hole 2, the inner wall of the positioning ring 4 is tapped with a positioning ring thread 5, and the positioning ring 4 has a built-in rotating rod 6, The outer wall of the rotating rod 6 is tapped with a rotating rod thread 7, and the rotating rod 6 and the positioning ring 4 are threadedly engaged. A drive screw 9 is engaged, and its engagement method can be compared to the engagement of male and female screws. The drive screw 9 can drive the rotating rod 6 to rotate. The ring 4 rotates up and down, the lower end of the driving screw 9 is coaxially connected with a driven pinio...

Embodiment 3

[0054] Embodiment three, on the basis of embodiment one, the drill pipe 8 is cylindrical, that is, a cylinder with a through hole inside, the inner wall of the upper end is tapped with a drill pipe internal thread 30, and the outer wall of the lower end is tapped. There are drill pipe external threads 31, and the drill pipe external threads 31 of a plurality of drill pipes 8 can be engaged with the drill pipe internal threads 30, and the drill pipe external threads 31 can be threadedly connected with a drill bit 32, and the drill bit 32 is a diamond drill bit. One-piece drill bit, the whole drill bit has no moving parts, simple structure, high strength, high wear resistance and impact resistance. When drilling in soft and medium hard formations, the diamond drill bit has fast speed, more footage and long life. , stable work, fewer downhole accidents, good well quality, etc., the current drilling rigs and others use this kind of drill bit. The upper end of the drill bit 32 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com