Method for increasing extracting and drilling stability of low-permeability soft coal seam

A soft coal seam, drainage drilling technology, applied in the direction of drilling equipment and methods, drilling equipment, mining equipment, etc., can solve the problems of low porosity rate and poor sealing effect of soft coal seams, and achieve wide practicability and application Foreground, enhance effect, design rational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention is mainly aimed at low-permeable soft coal seams, especially high-gas soft coal seams with a firmness coefficient less than 0.5, and solves the problems of low drilling porosity and poor sealing effect, and improves the extraction of low-permeable soft coal seams through the following steps Drilling stability, as follows:

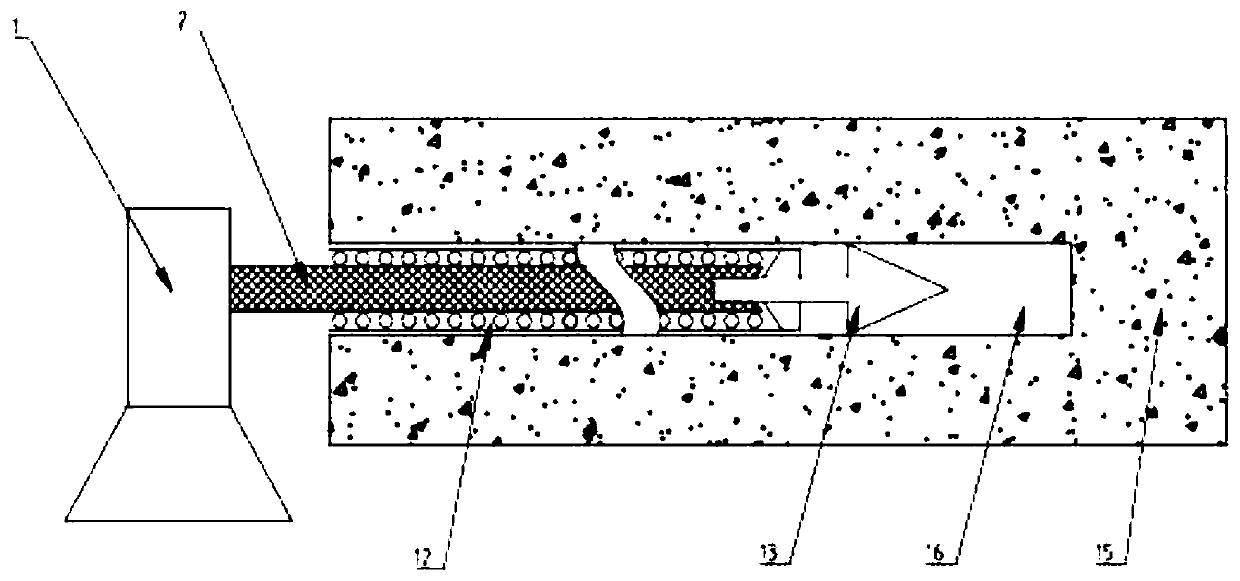

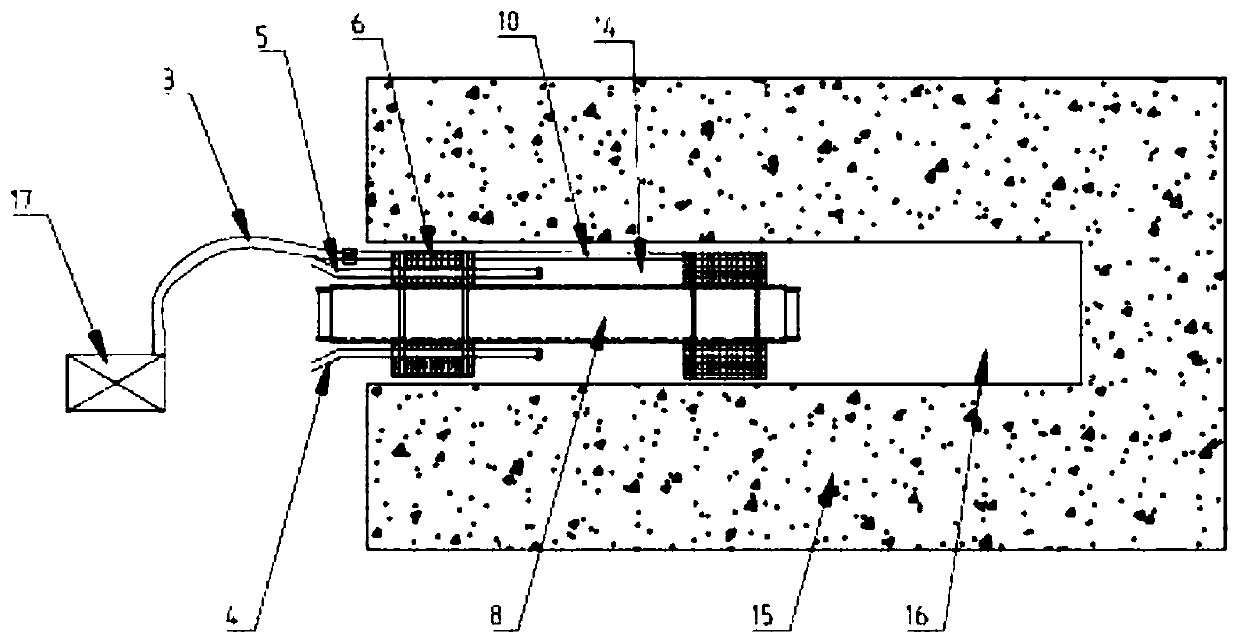

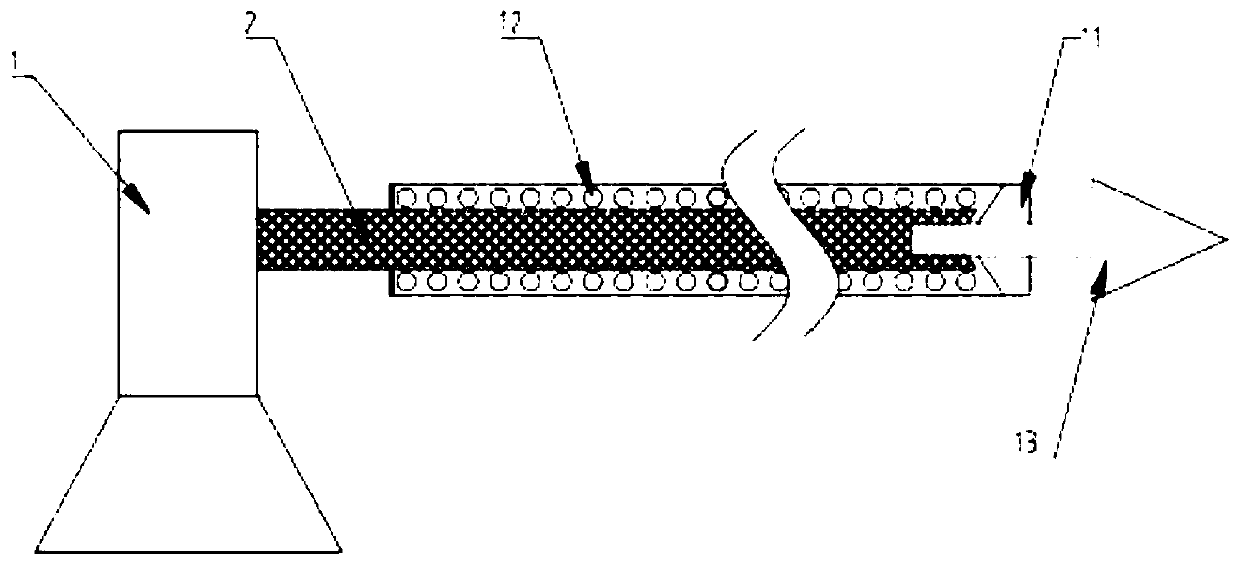

[0043] see first figure 1 and image 3 , figure 1 and image 3 It is a schematic diagram of the drilling device and the drilling stage, and the drilling rod 2 is connected with the drilling machine 1 .

[0044] Step 1: A retractable dragging casing 12 is sleeved on the outside of the drill rod 2, and a drill bit 13 is threadedly connected to the head of the drill rod 2. Drill bits 13 of different sizes can be replaced according to drilling requirements. The drill bit 13 is connected with the retractable drag The movable sleeves 12 are connected by joint sleeve ratchets 11 . When the drill bit 13 drills forward, it can drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com