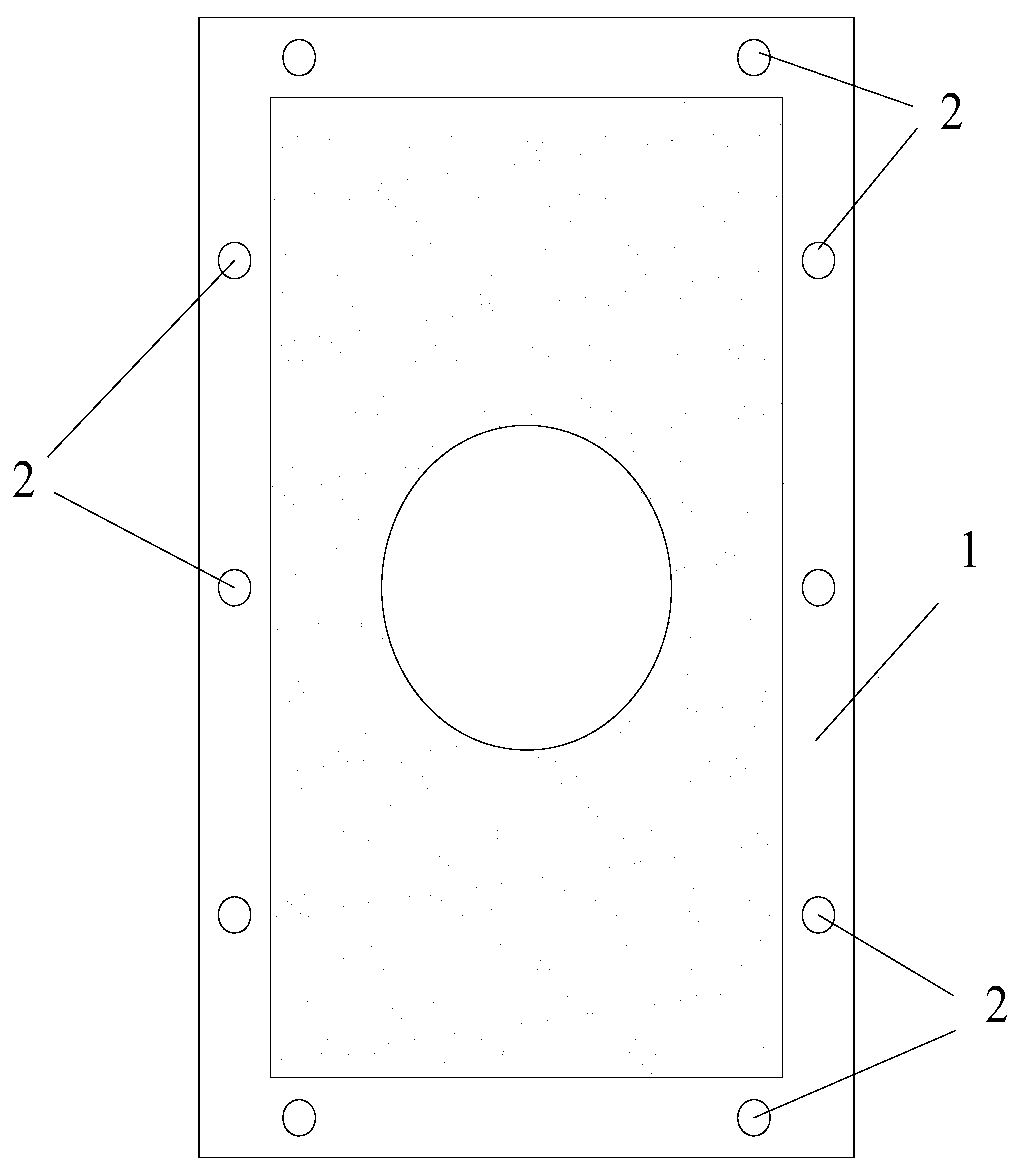

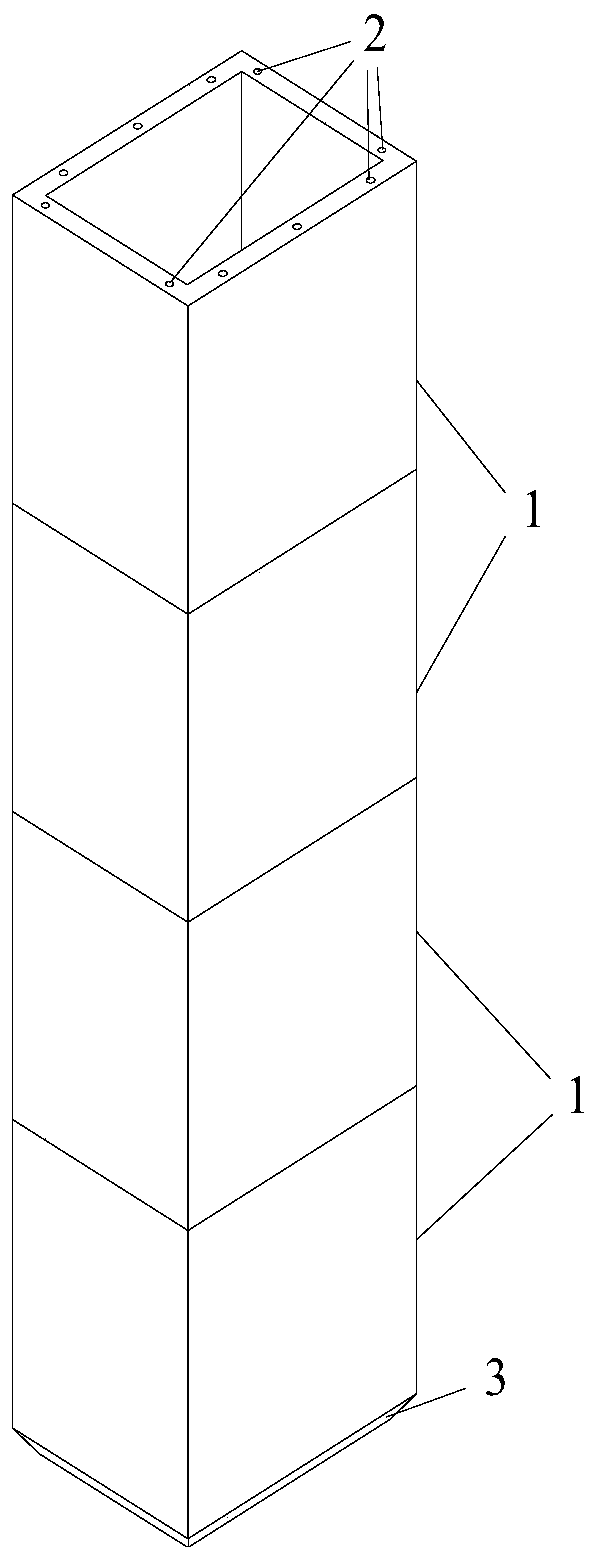

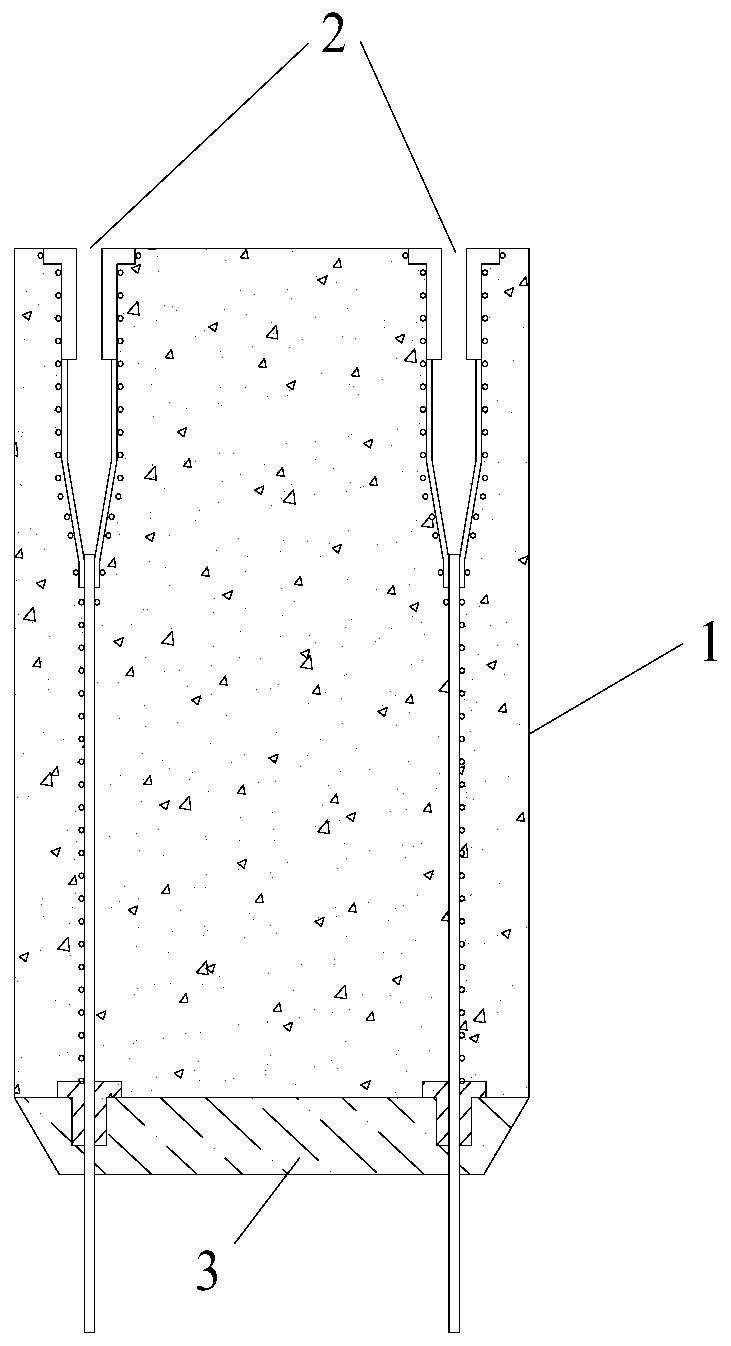

Prefabricated retaining wall and pile hole excavation method

A pile hole and earthwork technology, used in excavation, sheet pile walls, construction, etc., can solve the problems of large rectangular hole section size, high risk of manual hole digging, poor forming quality, etc., to ensure the forming size and hole quality, The effect of reducing manual participation and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of pile hole excavation method of the present invention comprises the following steps:

[0037] a. Construction lofting, fixed pile hole position;

[0038] b. Use machinery to lead the hole to the depth of the design elevation, and clear and transport the earthwork for the hole;

[0039] c. To sink the prefabricated retaining wall, first position the prefabricated retaining wall section 1 of the first section, then press the upper opening of the prefabricated retaining wall section 1 of the first section to a place 10cm-50cm above the natural ground, and then excavate the The earth in the prefabricated retaining wall shall be cleared and transported;

[0040] d. After connecting the prefabricated wall section 1 of the next section to the top of the prefabricated wall section 1 of the previous section, press the upper opening of the prefabricated wall section 1 of the next section to be higher than the natural ground 10cm-50cm, and then excavate the earth in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com