Patents

Literature

47results about How to "Reduce the difficulty of excavation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

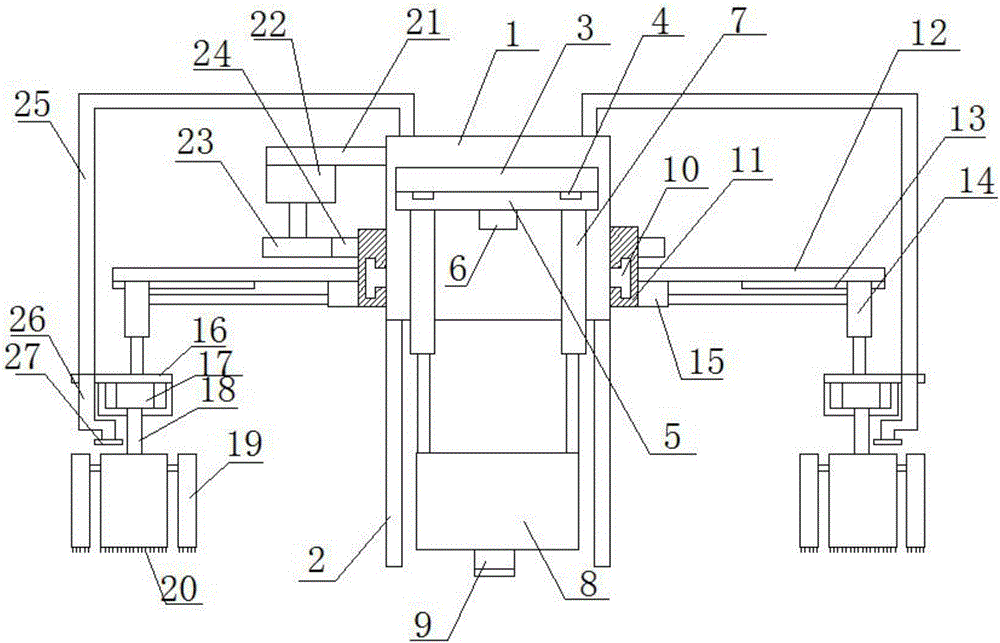

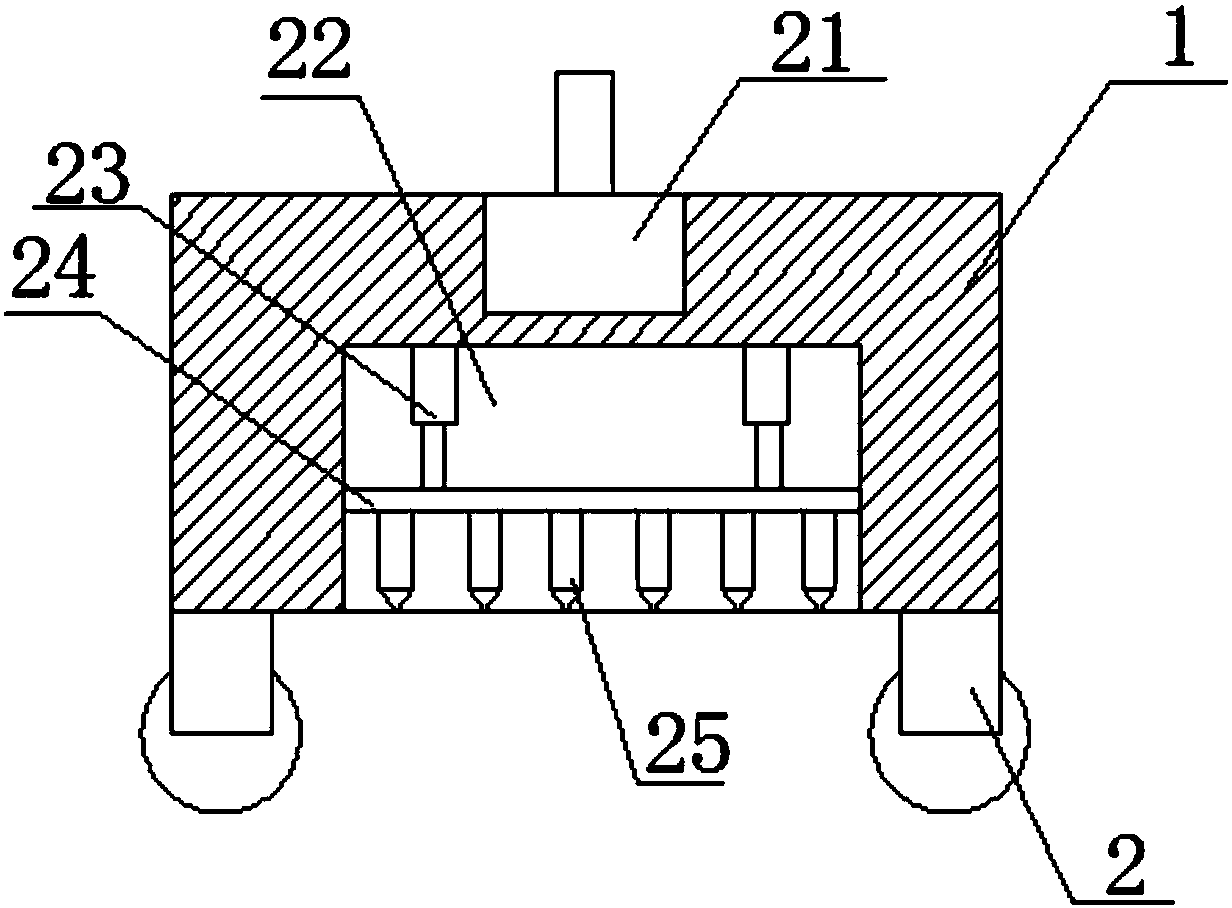

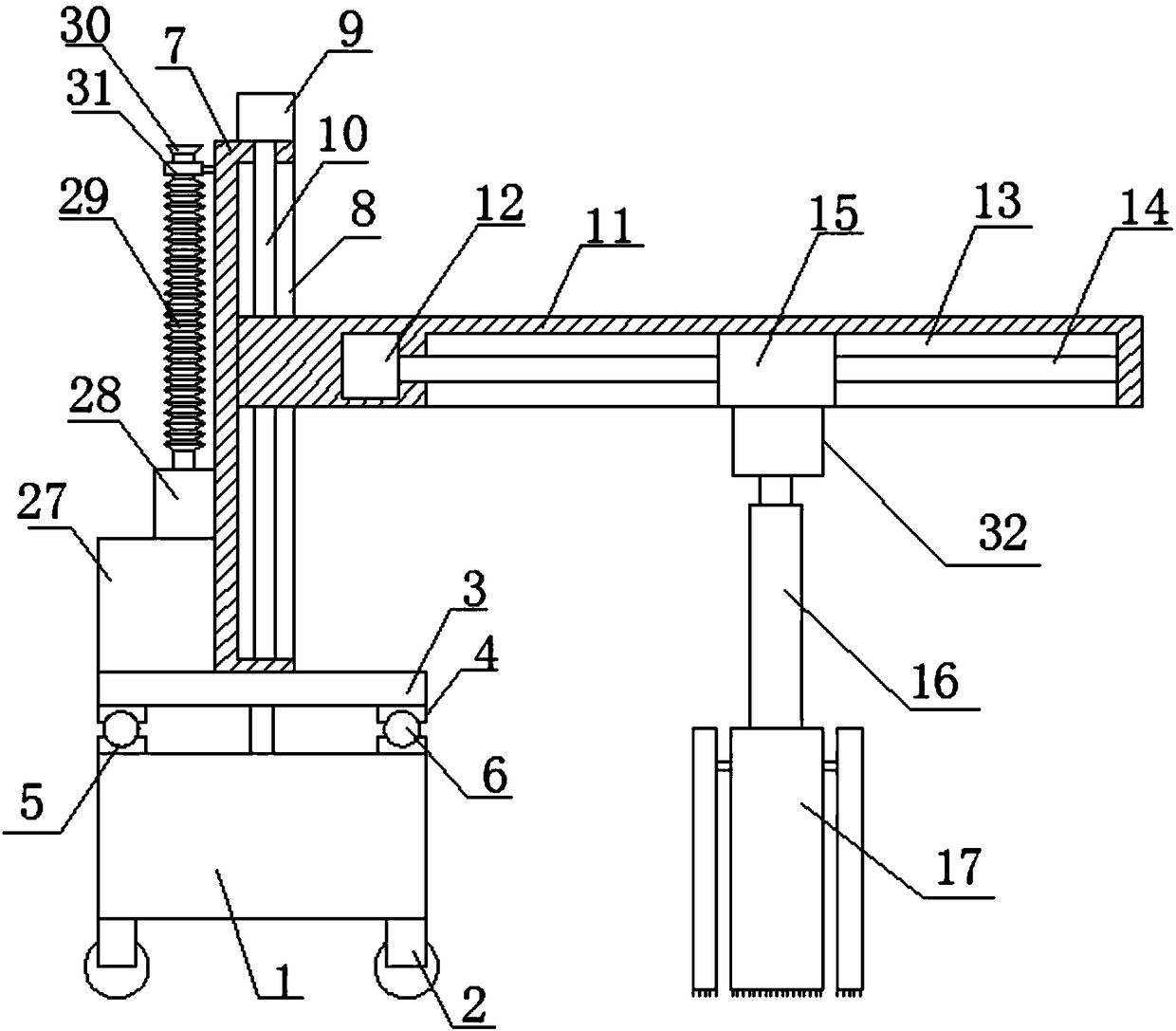

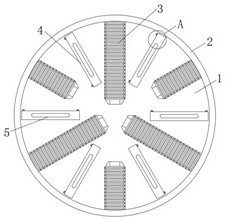

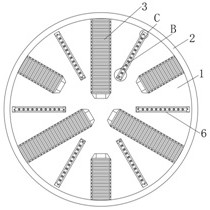

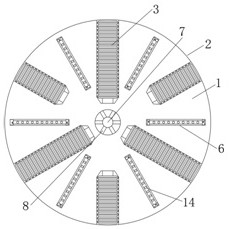

Self-balancing potholing device for tree planting

InactiveCN107172922AExtended service lifeReduce the difficulty of excavationPlantingFurrow making/coveringHydraulic cylinderSlide plate

The invention discloses a self-balancing potholing device for tree planting. The device comprises a machine body, wherein first support plates are arranged at the front side and the rear side of the machine body; first slide rails are arranged on the lower sides of the first support plates; a slide plate is arranged on the first slide rails; a first hydraulic cylinder is arranged at a position, close to the machine body, on the lower sides of the first support plates; the outer end of the first hydraulic cylinder is connected with the rear side of the slide plate; second hydraulic cylinders are arranged on the lower side of the slide plate in an eudipleural way; soil placement boxes are arranged on the lower ends of the second hydraulic cylinders; second support plates are arranged on the outer side of an annular seat in an eudipleural way; second slide rails are arranged on the lower sides of the second support plates; third hydraulic cylinders are arranged on the second slide rails; motor supports are arranged on the lower ends of the third hydraulic cylinders; first motors are arranged in the motor supports; rotary shafts are arranged on the output ends of the first motors; earth cutting devices are arranged on the lower ends of the rotary shafts. The self-balancing potholing device for the tree planting provided by the invention is simple in structure, convenient to use, good in potholing effect, high in efficiency, convenient to plant trees, and long in service life.

Owner:彭利辉

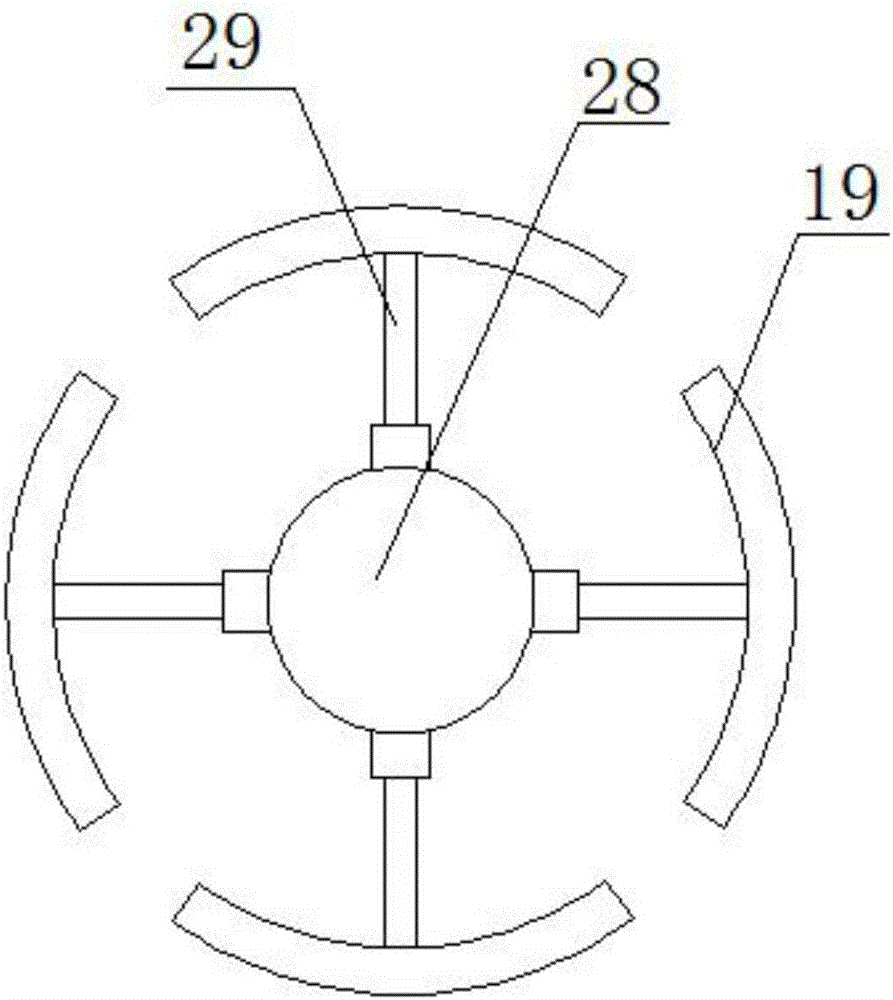

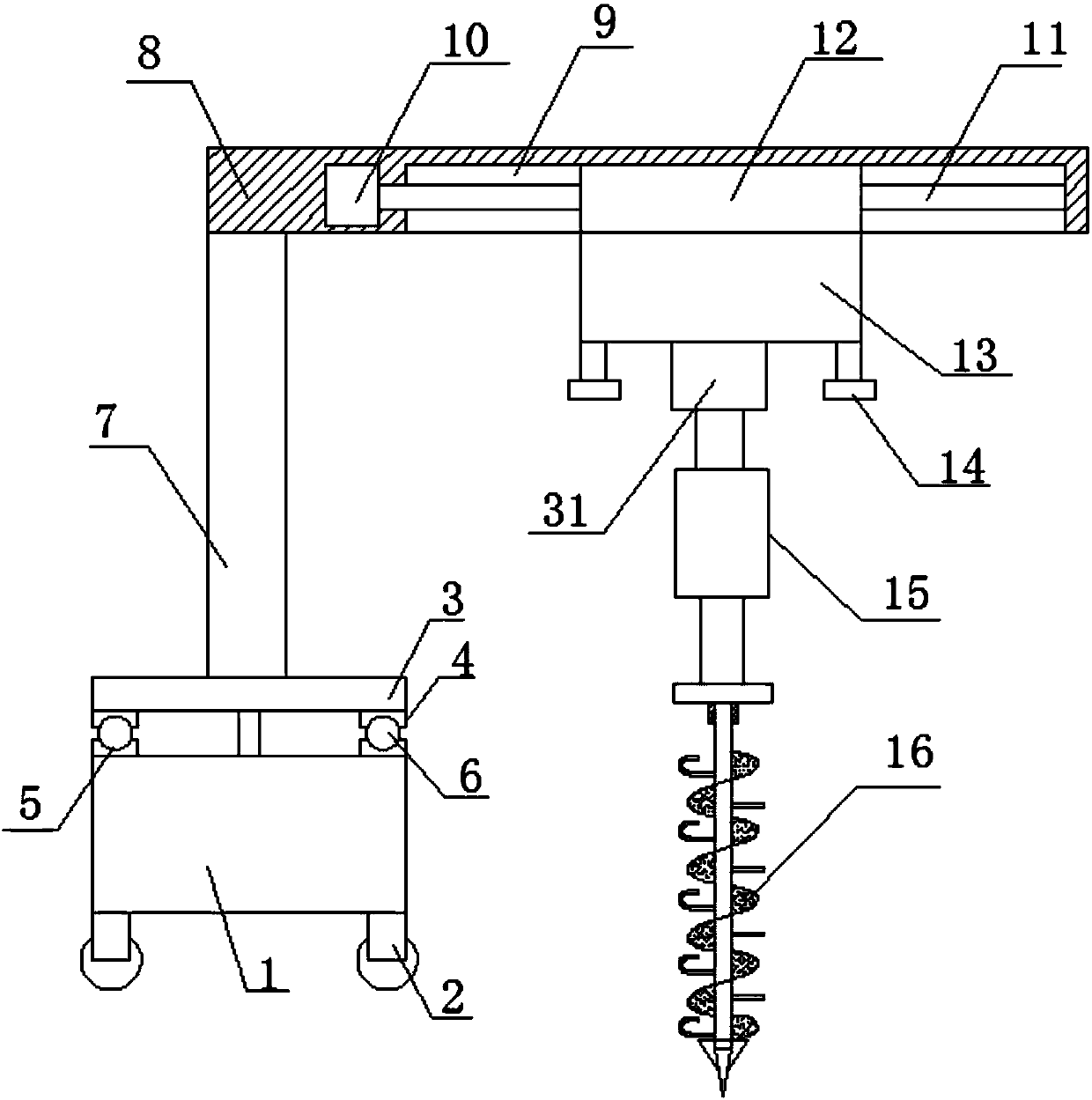

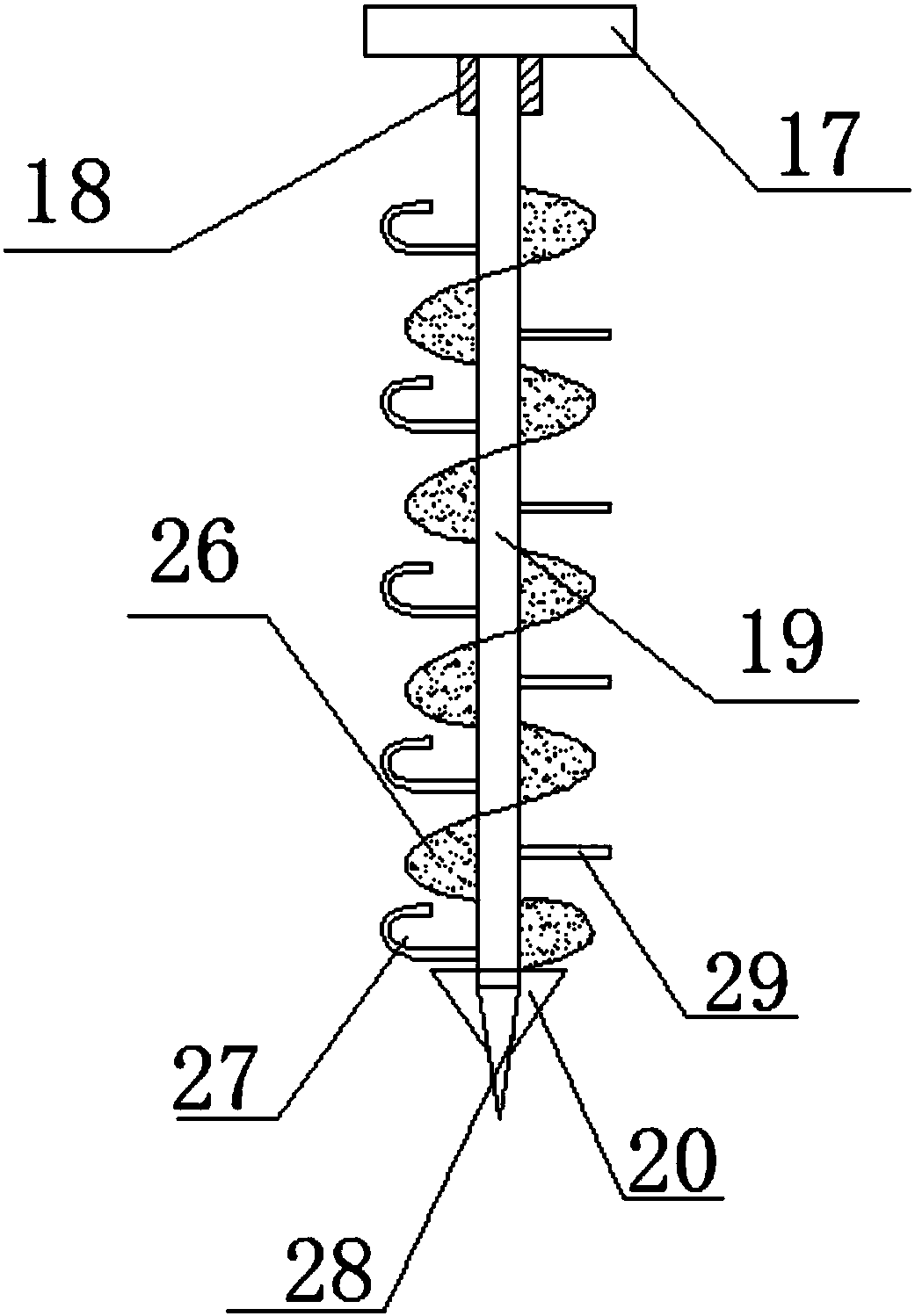

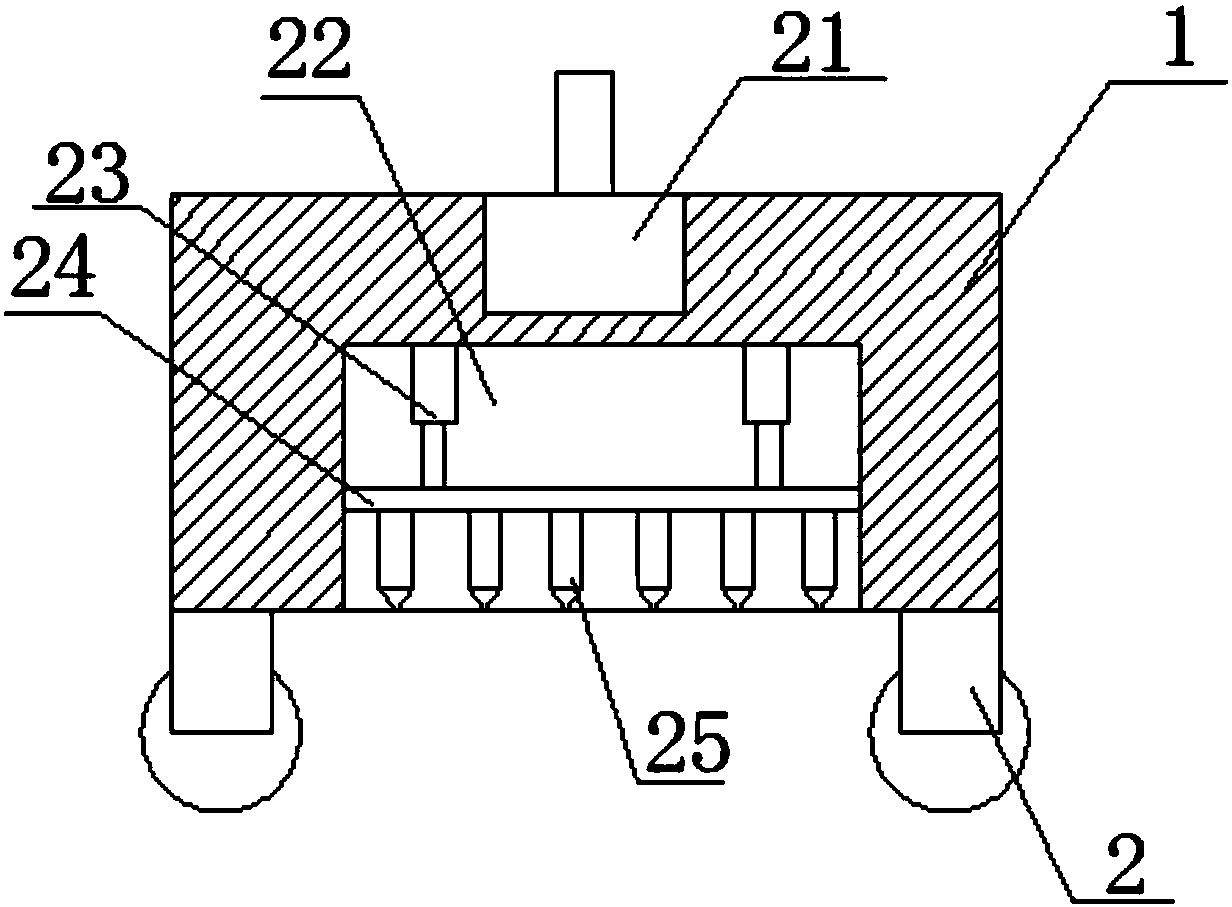

Agricultural planting pit digging device for reducing difficulty

InactiveCN108040544AEasy to moveReduce the difficulty of excavationPlantingCleaning using toolsSpiral bladeEngineering

The invention discloses an agricultural planting pit digging device for reducing difficulty. The pit digging device comprises a base. A first motor is embedded in the middle of the upper side of the base. A rotary base is installed at the output end of the first motor. A supporting column is arranged on the upper side of the rotary base. A lifting rack is arranged at the upper end of the right side of the supporting column. An adjusting cavity is formed in the lower side of the lifting frame. A third motor is arranged at the left end of the adjusting cavity. A second threaded rod is arranged at the output end of the third motor. A slide base is arranged on the second threaded rod. A water tank is arranged on the lower side of the slide base. A fourth motor is arranged in the middle of thelower side of the water tank. A telescopic device is arranged at the output end of the fourth motor. A soil digging device is arranged at the lower end of the telescopic device. The soil digging device comprises a driving plate. A connecting base is arranged on the lower side of the driving plate. A drilling stem is arranged on the connecting base. A spiral blade is arranged on the outer side of the drilling stem. A soil drilling tip is arranged at the lower end of the drilling stem. The agricultural planting pit digging device of the structure is good in pit digging effect, high in work efficiency, stable in structure and capable of reducing dust contamination.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

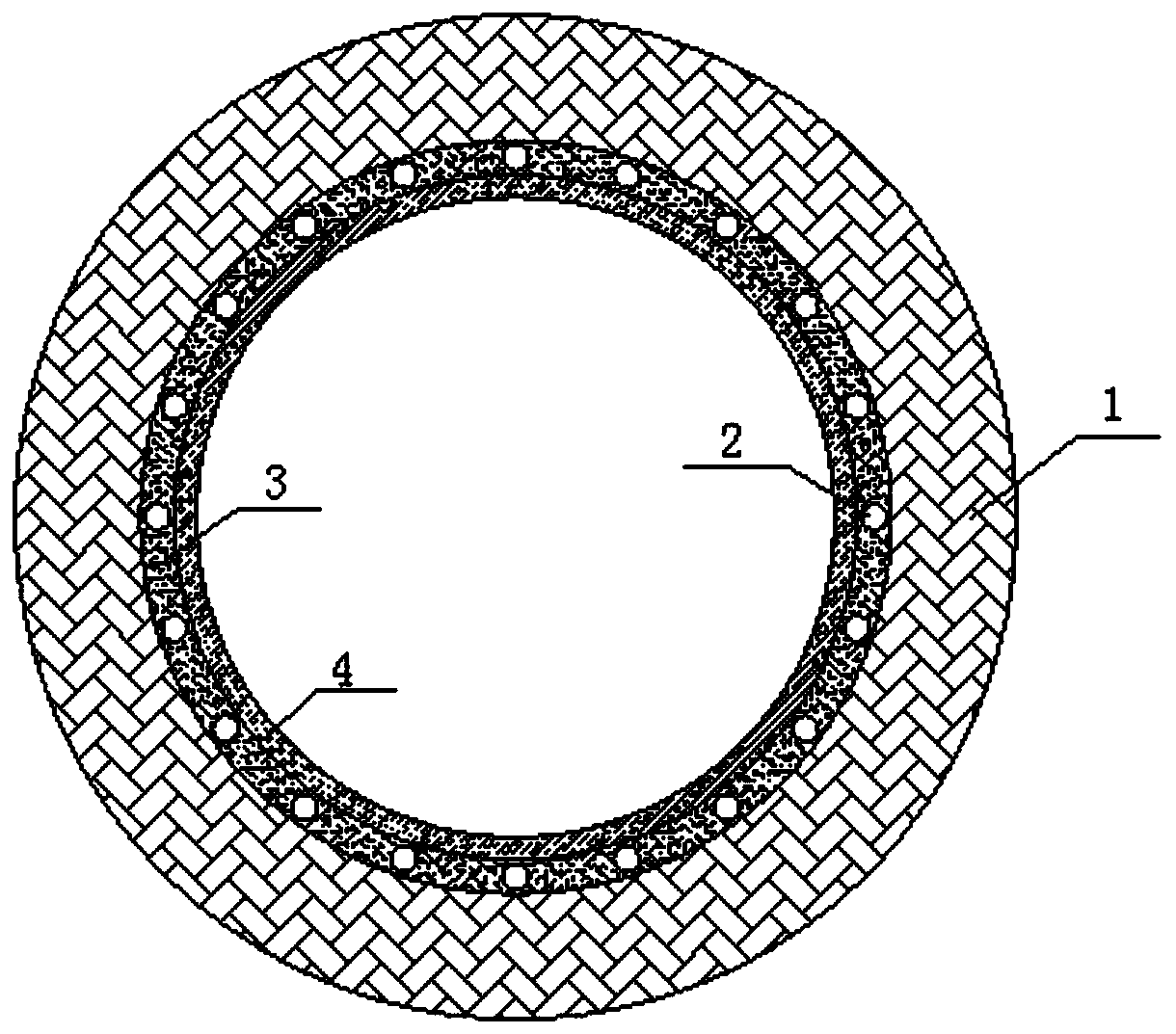

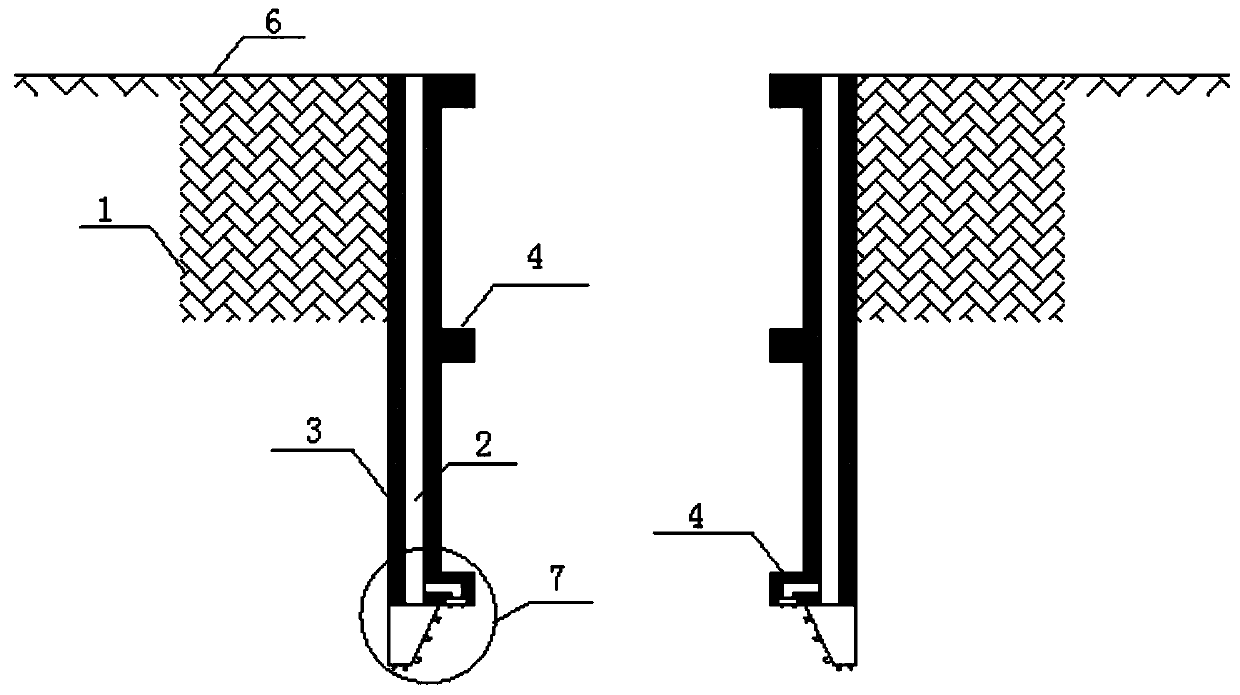

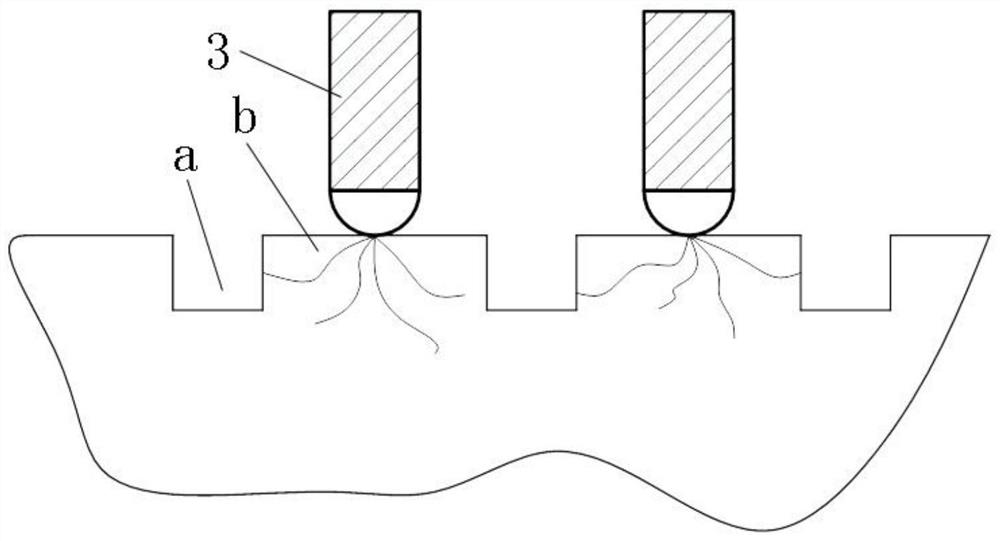

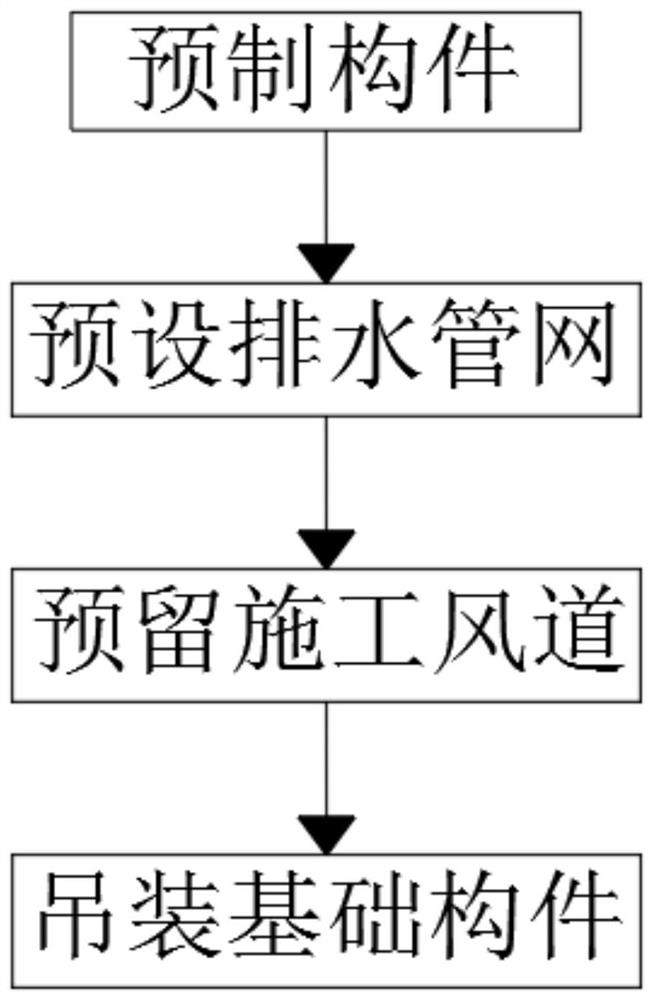

Construction method of deep foundation pit open caisson self-sinking support system

InactiveCN110805053AReduce the difficulty of excavationGuaranteed stabilityCaissonsSupporting systemPipe

The invention discloses a construction method of a deep foundation pit open caisson self-sinking support system. The construction method comprises the following steps that after the pay-off, blade feet made by the cast-in-place are measured, spray heads are pre-buried in the blade feet, a first section ring beam is subjected to cast-in-situ manufacturing, a first section prefabricated open caissonwell body is installed, steel pipes are pre-buried in the open caisson well body, after the open caisson well body is connected with the blade feet, the soil body is cut by water injection and mud isdischarged, and the first section open caisson well body sinks to the designed elevation, after the ring beam is subjected to cast-in-place construction, the next section open caisson well body is installed, the water injection and sinking are carried out by adopting the same method as the first section open caisson well body, all the open caisson well bodies are installed in sequence, so that the open caisson well bodies of all the sections sink in place, and bottom sealing and mud drainage are carried out. According to the construction method of the deep foundation pit open caisson self-sinking support system, the open caissons are assembled in a prefabricated manner, the soil body is converted into the mud to be discharged outwards to enable the open caissons to sink automatically, thesoil pressure and the bottom water pressure at the peripheries are balanced by utilizing the mud in the open caisson, the excavation difficulty is reduced, and the stability in the sinking and excavation process is ensured.

Owner:WUHAN MUNICIPAL CONSTR GROUP

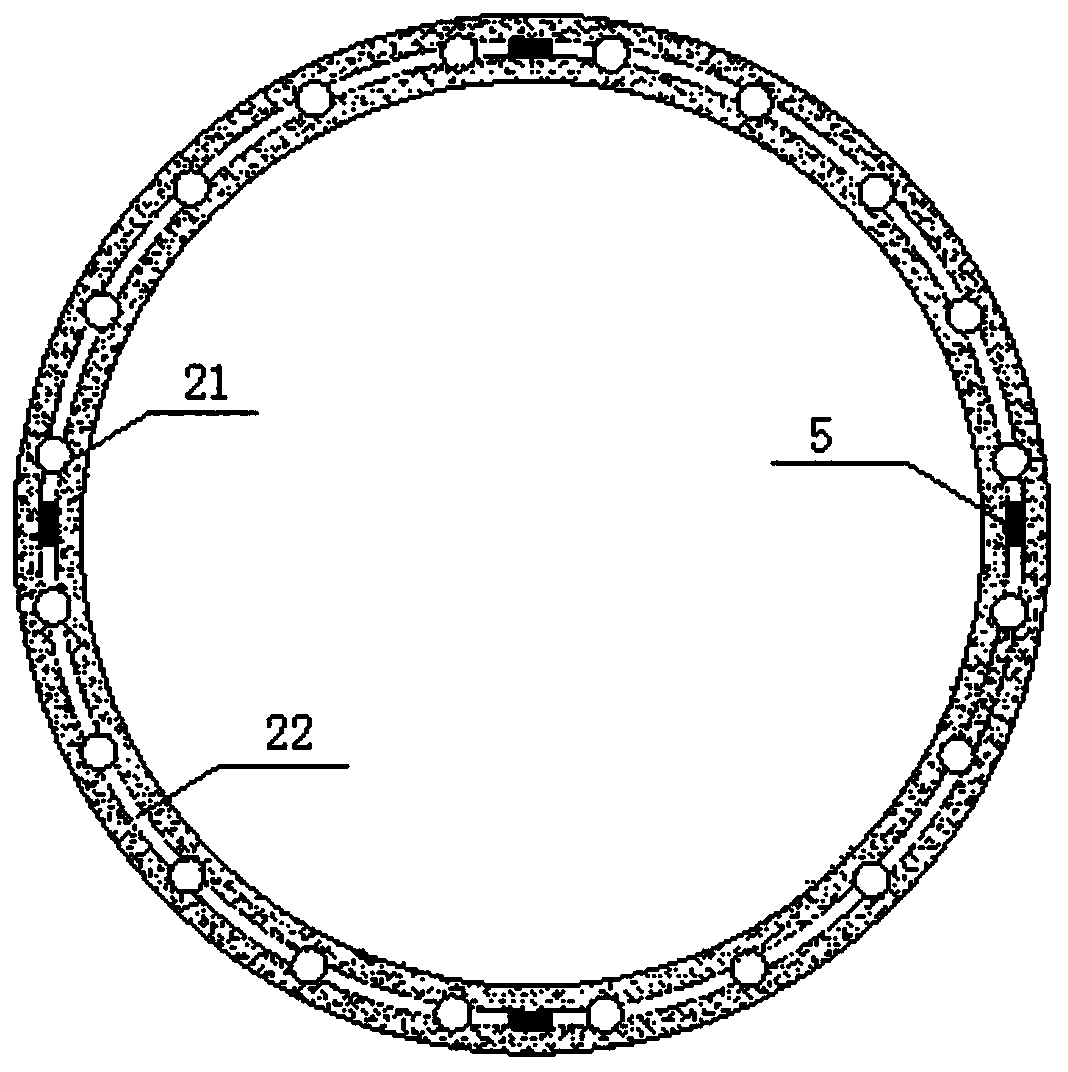

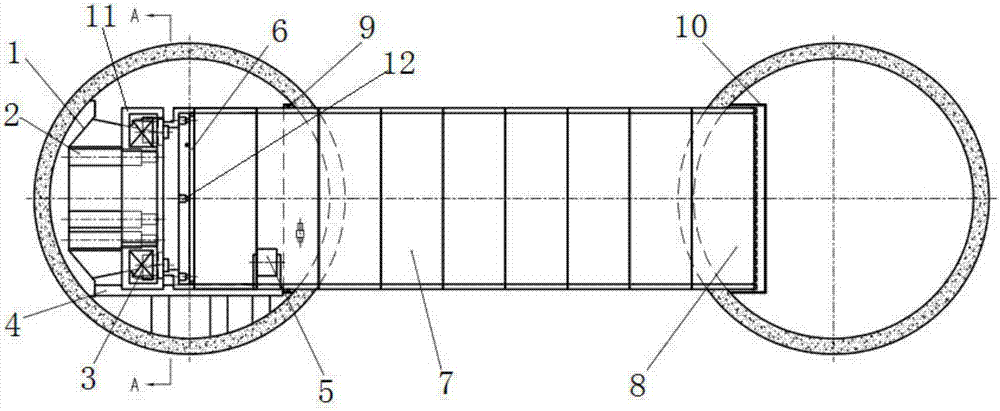

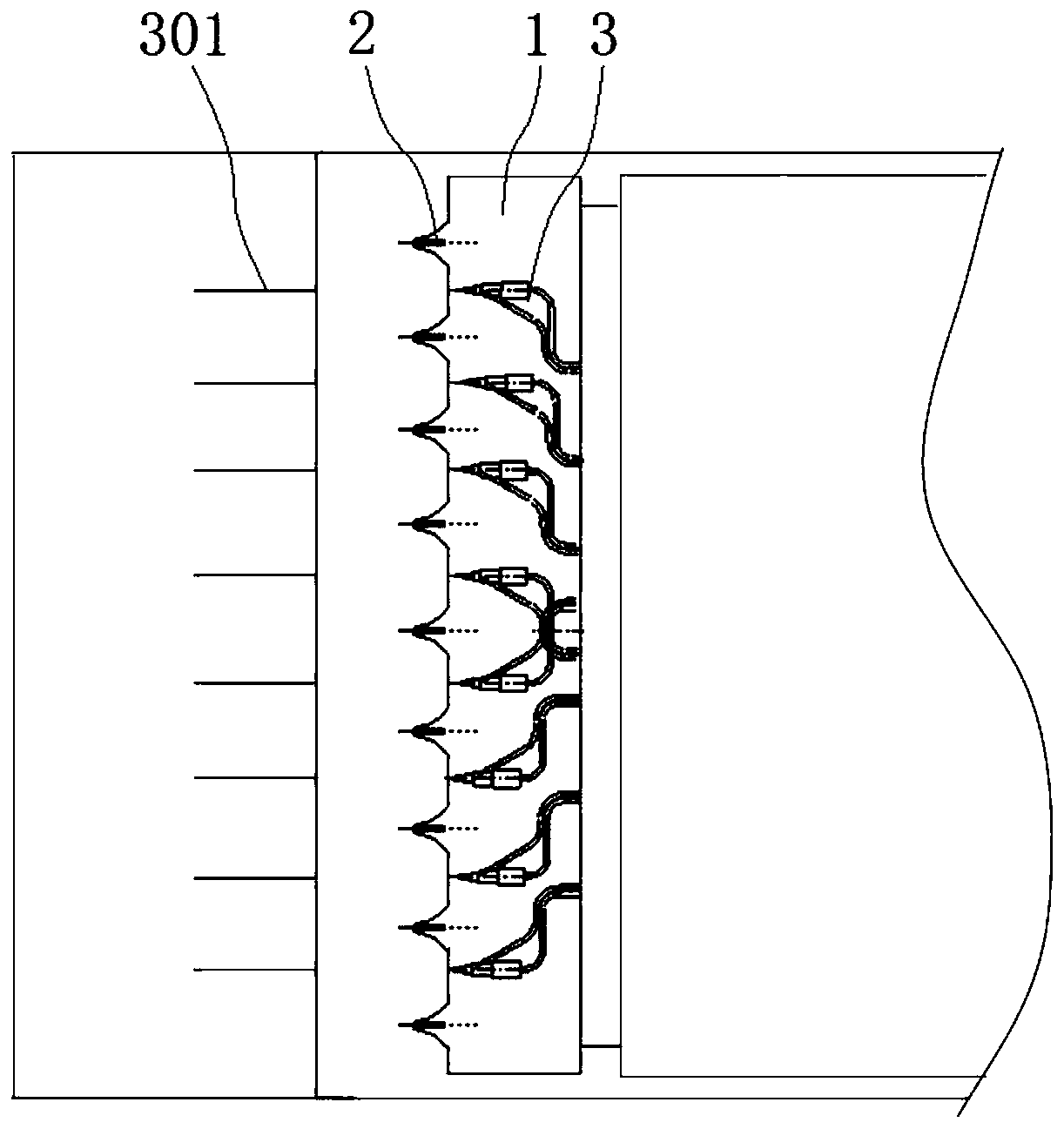

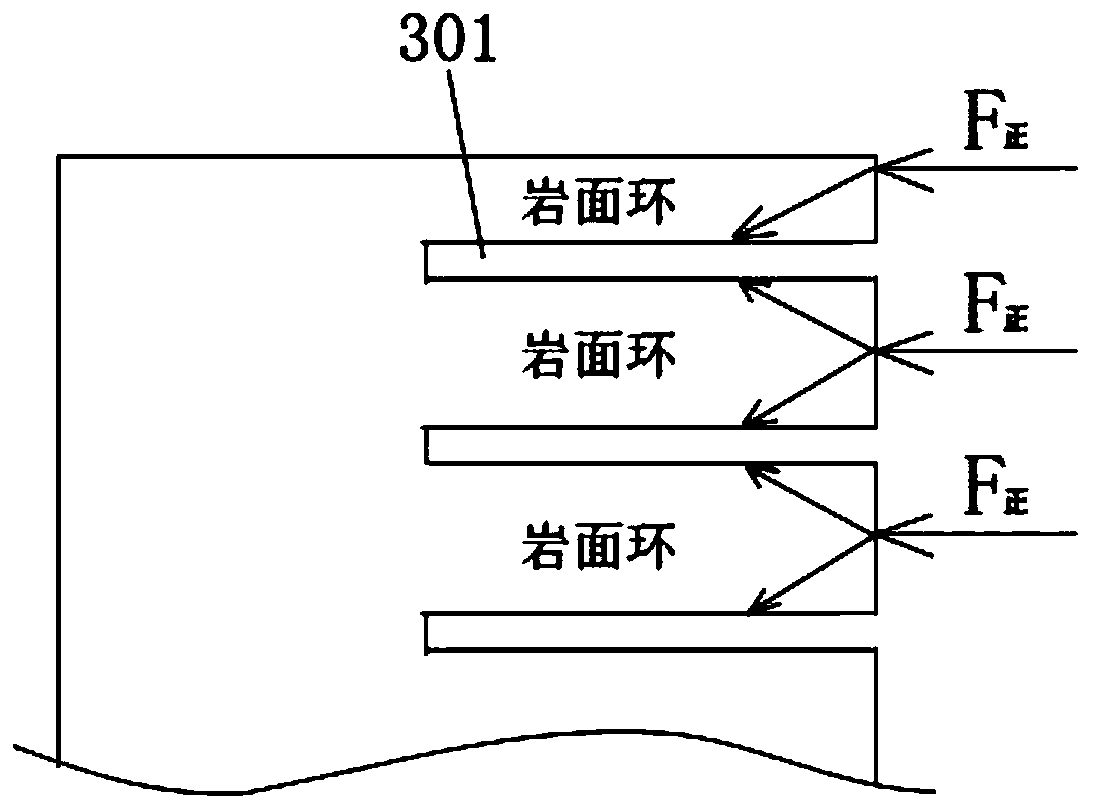

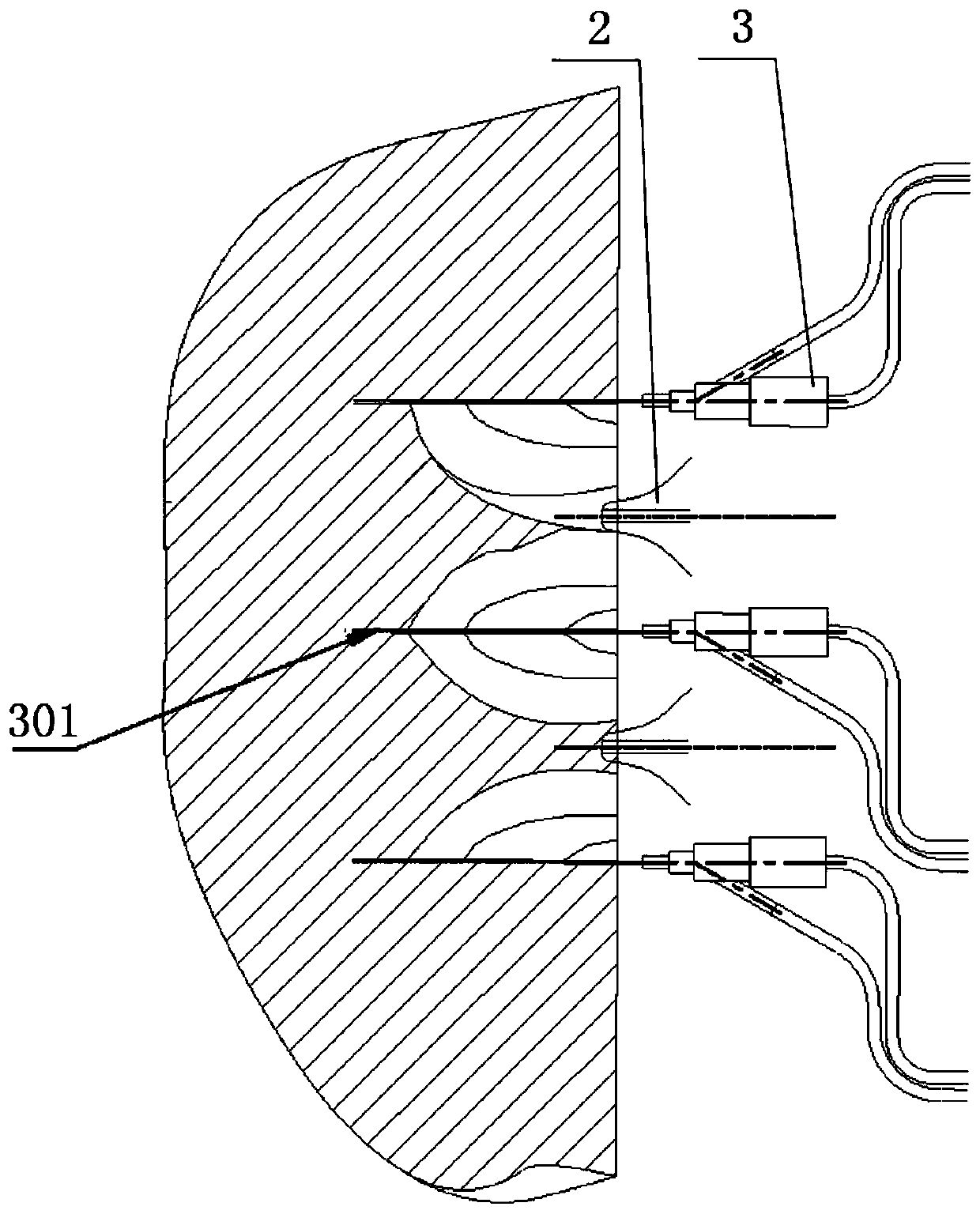

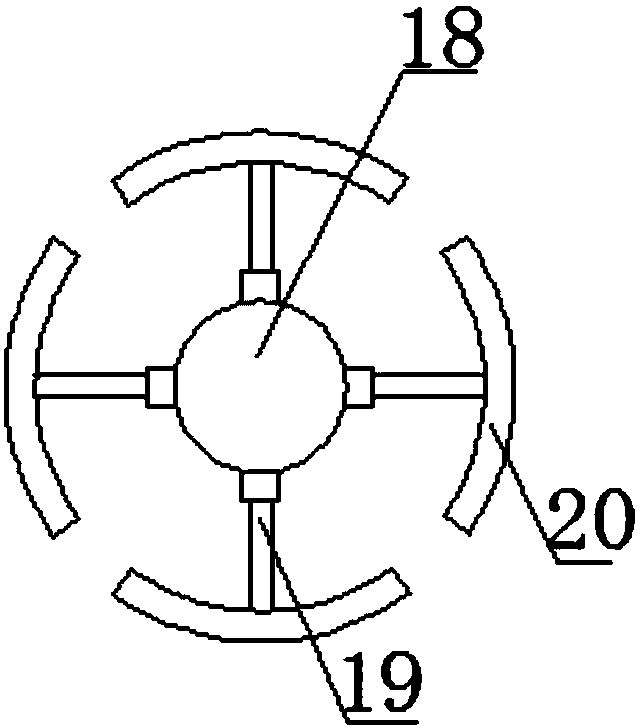

Shield contact channel excavating device

PendingCN107956477AAvoid security issuesReduce the difficulty of excavationTunnelsTunnel wallSoil conditioner

The present invention provides a shield contact channel excavating device, relates to the field of shield construction, and especially relates to a shield contact channel excavating device. The wholesteel pipe ring is driven by a driving device to perform rotational motion, the soil is cut by the steel pipe ring with cutters, and a propulsion oil cylinder is disposed to provide propulsive force to enable the whole pipe ring to excavate forward. A sealing device is equipped with a slurry pipe, the slurry pipe is connected with a slurry pump, and slurry or other soil conditioner is pumped intothe steel pipe ring by the slurry pump to wash muck in the steel pipe ring. Due to the fact that a pressure compartment is formed between the sealing device and an excavating surface, when the pressure in the steel pipe ring is oversized, the slurry in the steel pipe ring enters the gap between the steel pipe ring and a tunnel wall formed by excavation, then a ball valve on an original sending cylinder is opened, and the slurry enters a slurry treatment pool via a pipeline installed on the ball valve. The construction period of excavating a contact channel by the device is largely shortened, and the potential safety hazard of manual excavation in the prior art is avoided.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

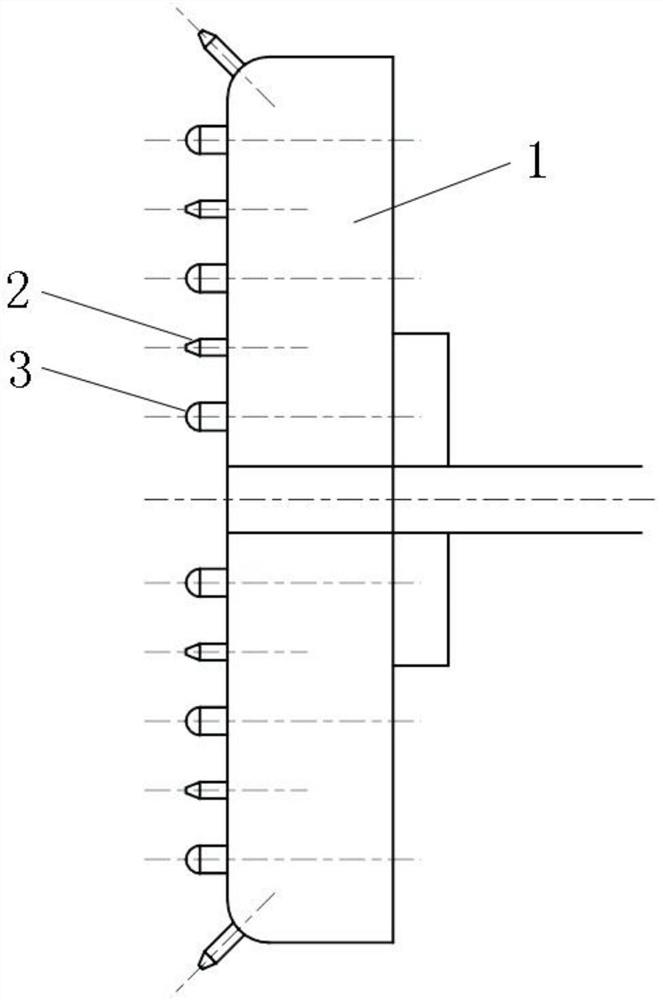

Shield tunneling machine and water jet combined hob rock breaking mechanism thereof

The invention discloses a water jet combined hob rock breaking mechanism, including a cutter disc which is arranged at the front end of a machine body and can feed in the axial direction and rotate inthe circumferential direction, a plurality of layers of hobs arranged on the surface of the cutter disc and distributed in a ring shape, and a jet nozzle arranged on the surface of the cutter disc and between the hobs of the adjacent two layers, and used for cutting a rock face to form several layers of annular cutting slots during the rotation of the cutter disc, and the current depth of the annular cutting seam of each layer is greater than the current cutting depth of the hobs of each layer. According to the water jet combined hob rock breaking mechanism, by use of the annular cutting slots formed by the jet nozzle on the rock surface, the hobs of each layer only needs to overcome the weak shear strength of rocks, rock surface fracture is realized by a shearing failure mode of each layer rock surface ring, the difficulty of tunneling for rocks with high compressive strength is lowered, at the same time, tunneling efficiency is improved and tool wear is reduced. The invention further discloses a shield tunneling machine which has the beneficial effects.

Owner:CHINA RAILWAY CONSTR HEAVY IND

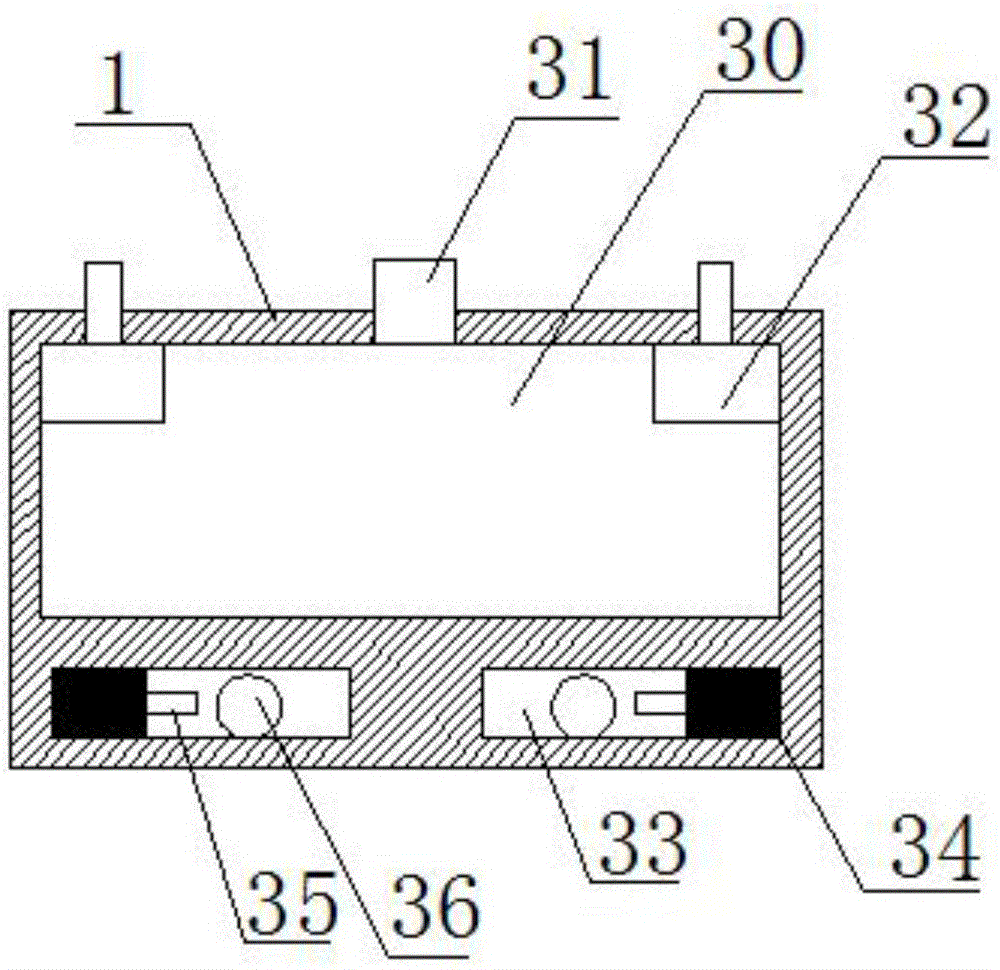

High-working efficiency digging apparatus for agricultural plantation

InactiveCN108156891AReduce the difficulty of excavationReduce pollutionPlantingFurrow making/coveringAgricultural engineeringThreaded rod

The invention discloses a high-working efficiency digging apparatus for agricultural plantation. The apparatus comprises a pedestal, a first motor is embedded in the middle of the upper side of the pedestal, a rotating seat is arranged at the output end of the first motor, a support column is arranged at the upper side of the rotating seat, a lifting chamber is arranged at the right side of the support column, a second motor is arranged at the upper end of the support column, a first threaded rod is arranged at the output end of the second motor, a lifting rack is arranged on the first threaded rod, an adjusting chamber is arranged at the lower side of the lifting rack, a third motor is arranged at the right end of the adjusting chamber, a second threaded rod is arranged at the output endof the third motor, a sliding seat is arranged on the second threaded rod, a fourth motor is arranged at the lower side of the sliding seat, a rotating column is arranged at the output end of the fourth motor, an soil excavating device is arranged at the lower end of the rotating column, and a water tank is arranged at the left part of the upper side of the rotating seat. The apparatus adopting the above structure has the advantages of good digging effect, high working efficiency, stable structure, and reduction of dust pollution.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Composite high-efficiency ultrafine-powder grouting material

ActiveCN107021703ARaw materials are easy to getReasonable design formulaMicrofine cementWork performance

The invention relates to a composite high-efficiency ultrafine-powder grouting material. The material is prepared by fully and evenly stirring the following raw materials in parts by weight: 2500-2700 parts of superfine cement, 241-443 parts of ultrafine composite mineral powder, 18-24 parts of a polycarboxylate superplasticizer, 13-20 parts of inorganic silicon sub-nanometer bead powder, 14-24 parts of an ultrafine complex expansion agent, 0.5-3.5 parts of methyl silicate and 0-1 part of a high-efficiency thickening time control agent. The composite high-efficiency ultrafine-powder grouting material is reasonable in formula, low in production cost, good in working performance, easy in processing, is environment-friendly and free from pollution, thus being wide in application scope.

Owner:GANSU ZHITONG TECH ENG DETECTION CONSULTING CO LTD

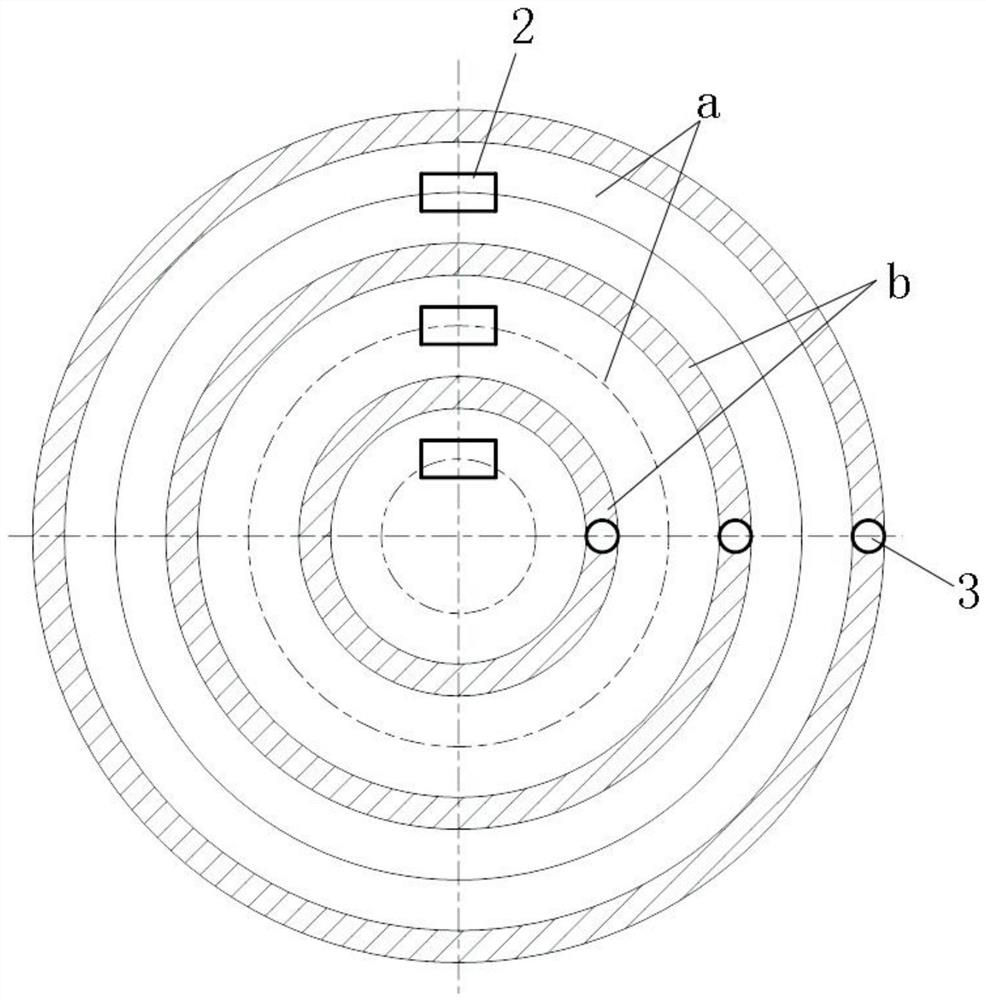

Tunnel boring machine and impact rock breaking cutterhead structure thereof

The invention discloses an impact rock breaking cutterhead structure. The impact rock breaking cutterhead structure comprises a cutterhead body which is arranged at the front end of a machine body andcan feed along the axial direction and rotate along the circumferential direction, impact assemblies arranged on cutterhead body in an axially telescopic mode, distributed in a multi-layer annular mode and used for digging a plurality of layers of annular grooves in a tunnel face along with rotation of the cutterhead body, and rock breaking assemblies arranged on the cutterhead body in an axiallytelescopic mode, distributed in a multi-layer annular mode and used for impacting and breaking annular rock layers located between every two adjacent layers of the annular grooves on the tunnel facealong with rotation of the cutterhead body. Therefore, in the tunneling process, the layers of the annular grooves are formed in a rock surface through the impact assemblies, so that rock breaking assemblies of the layers only need to overcome the weak shear strength of rock, rock surface breaking is achieved through the shear failure mode of the annular rock layers, the tunneling difficulty of rock with large compressive strength is reduced, meanwhile, the tunneling efficiency is improved, and cutter abrasion is reduced. The invention also discloses a tunnel boring machine which has the abovebeneficial effects.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Multifunctional compound grouting material

ActiveCN107337402AZero wasteFlexible adjustment of compatibilityMicrofine cementAluminum magnesium silicate

The invention relates to a multifunctional compound grouting material. The grouting material is prepared from, by weight, 2640-2760 parts of superfine cement, 50-80 parts of modified nanoscale calcium powder, 17-25 part of polycarboxylate superplasticizer, 60-120 parts of superfine steel slag fine powder, 75-120 parts of superfine high-calcium fly ash, 10-20 parts of superfine fluorine gypsum powder, 0.1-0.3 part of secondary nanoscale polymer and 1-3 parts of aluminum magnesium silicate, and the raw materials are evenly stirred to obtain the material. The multifunctional compound grouting material is reasonable in composition, low in production cost, good in working performance, easy to process, environmentally friendly, energy-saving, pollution-free, and wide in application range.

Owner:GANSU ZHITONG TECH ENG DETECTION CONSULTING CO LTD

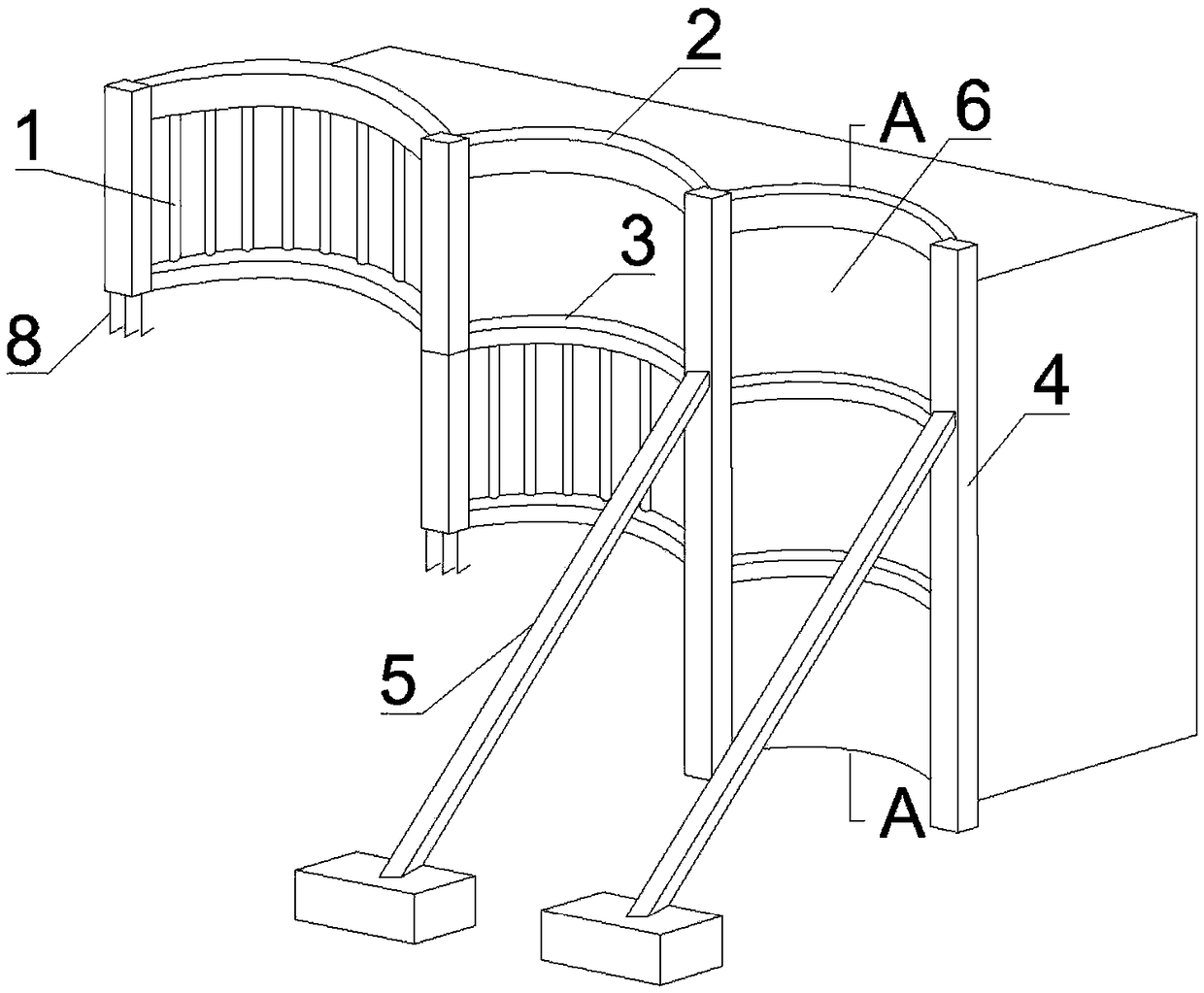

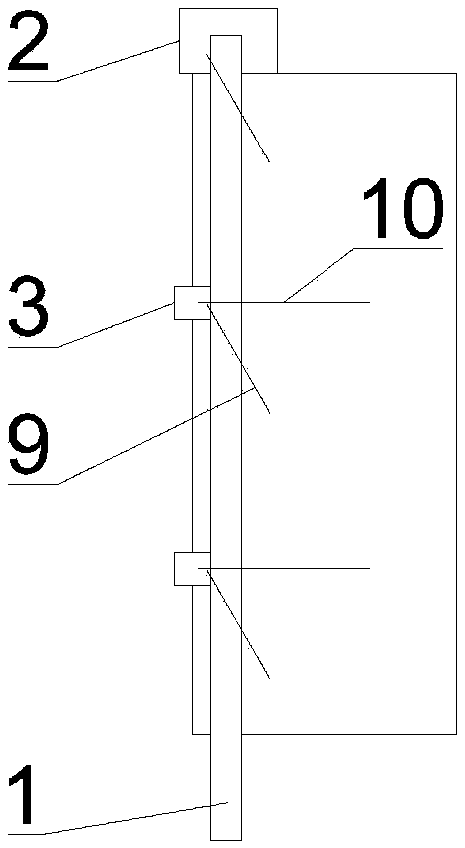

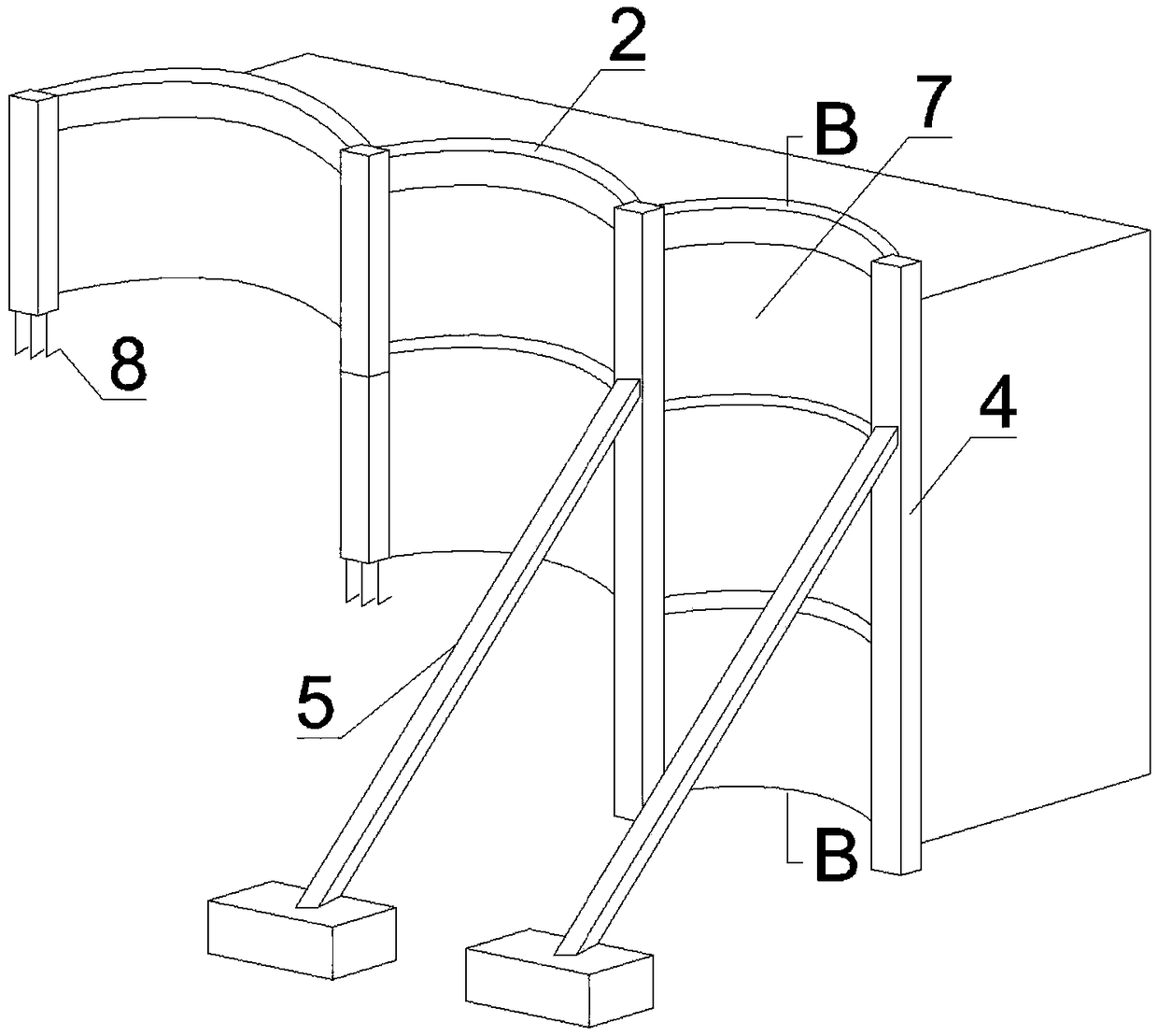

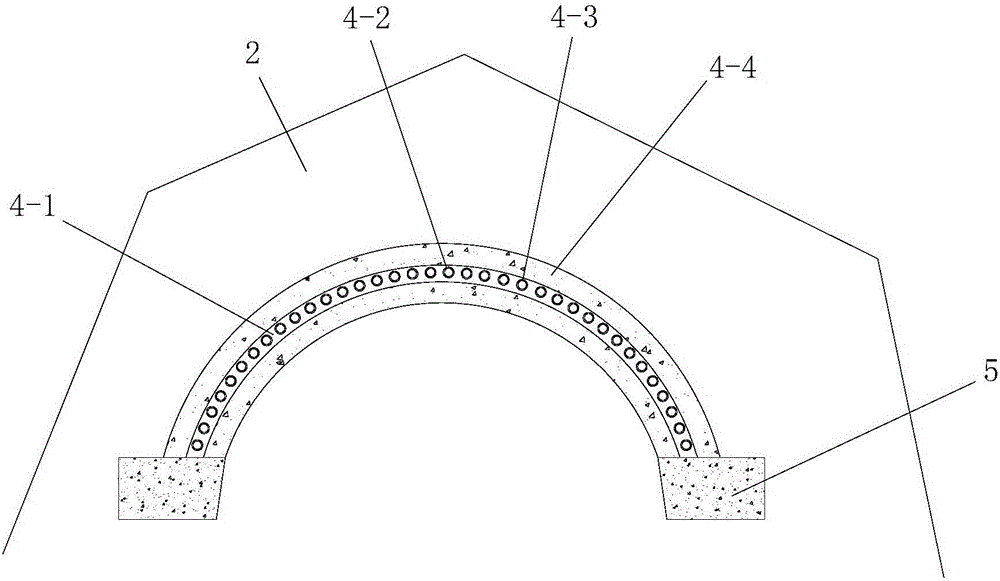

Horizontal-type supporting method for foundation pit of arch shell

The invention discloses a horizontal-type supporting method for a foundation pit of an arch shell and relates to the field of foundation pit supporting. The method comprises the steps that a continuous wall column pile with an orthographic projection curve is constructed at the top of the side wall of the foundation pit, the curve is composed of arcs of multiple circle centers at the same side, and the adjacent ends of every two adjacent arcs are connected; after a corresponding pile top beam is constructed at the top of the wall column pile, multiple digging layers are dug, a corresponding arch rack beam or a corresponding protection panel is constructed on each digging layer, integral buttresses are constructed at the two corresponding ends of each arc, the two adjacent ends of every twoarcs share one integral buttress, a supporting assembly corresponding to each integral buttress is constructed again and effectively supported, and an advanced vertical anchor pipe and an advanced horizontal anchor pipe are constructed on each digging layer. According to the horizontal-type supporting method, the defects of dense supporting of a traditional row pile wall are overcome, the span among the supporting assemblies is increased, and the digging difficulty is lowered.

Owner:ANHUI URBAN CONSTR DESIGN & RES INST

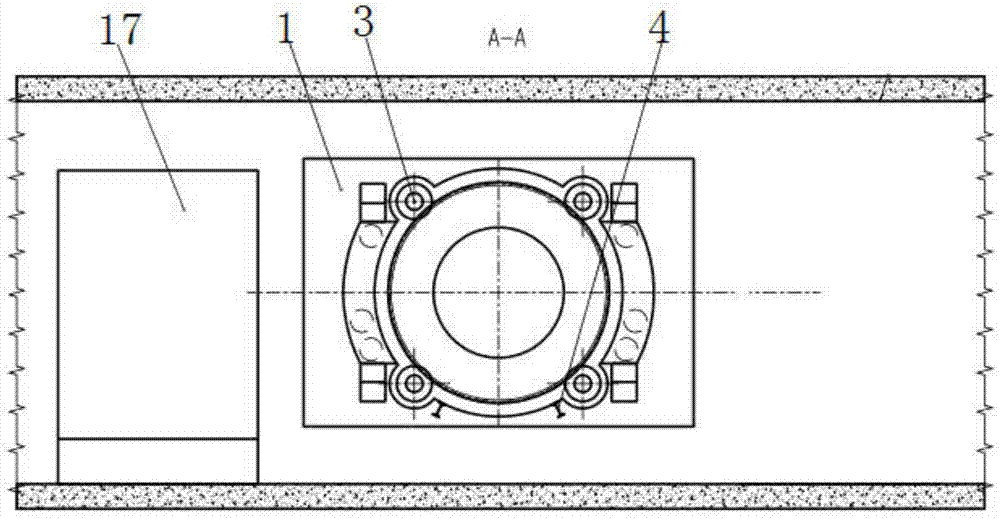

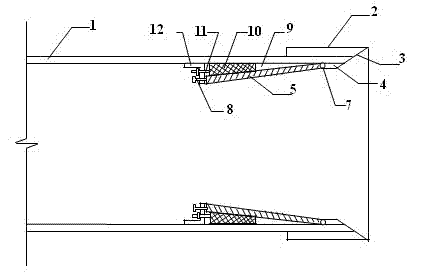

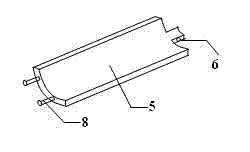

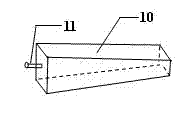

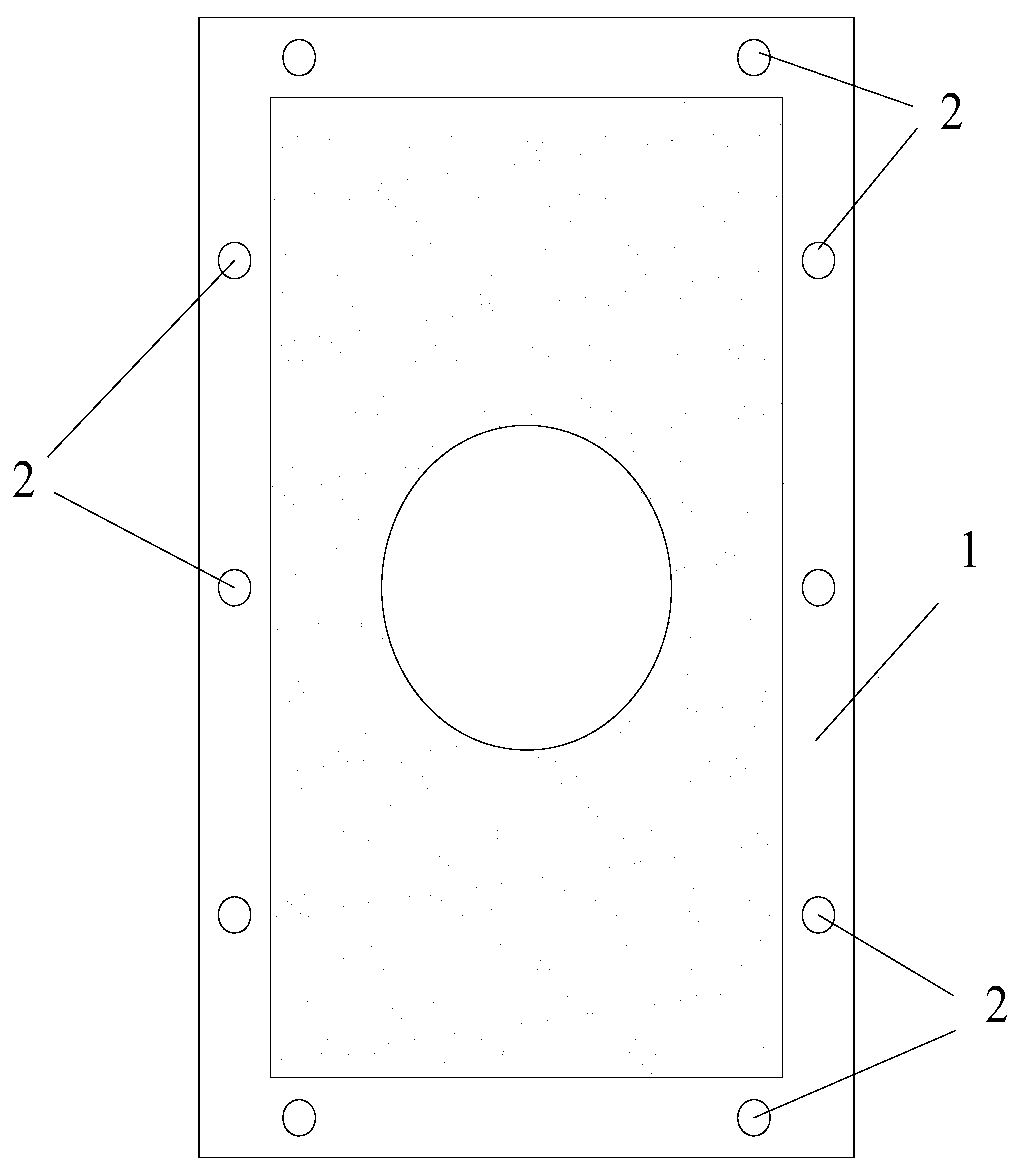

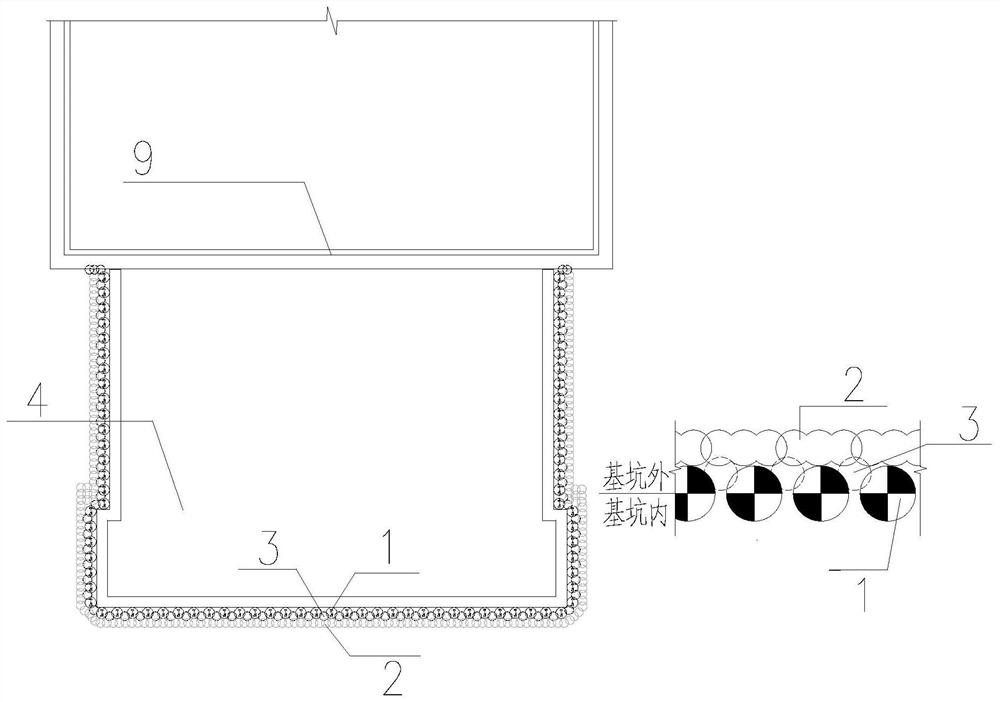

Pushing device of self-compaction reinforcing and anti-seepage pilot pipe and use method thereof

InactiveCN103032629AGuaranteed stabilityReduce the difficulty of excavationPipe laying and repairGeotechnical engineeringWedge shape

The invention discloses a pushing device of a self-compaction reinforcing and anti-seepage pilot pipe and a use method thereof; According to the pushing device of the self-compaction reinforcing and anti-seepage pilot pipe and the use method thereof, compaction plates are arranged on the inner side of the front end of the pilot pipe fully circularly or locally; the compaction plates can rotate around a rotating shaft so as to change angles between the compaction plates and the pilot pipe; wedge-shaped gaps exist between the compaction plates and the pilot pipe, and wedge-shaped rods capable of moving longitudinally along the pilot pipe are arranged in wedge-shaped gaps; screw rods which are welded on the wedge-shaped rods penetrate through screw holes with internal threads in fixed plates; the wedge-shaped rods can move longitudinally along the pilot pipe by screwing nuts on the screw rods; and angles between the compaction plates and the pilot pipes are 1 degrees to 15 degrees. The pushing device of the self-compaction reinforcing and anti-seepage pilot pipe and the use method thereof have the advantages that no water drops when the large-diameter pipe is pushed in a seepage stratum or a soft soil stratum, the soil in the pilot pipe is compacted through the compaction plates so as to achieve the reinforcing and anti-seepage purposes, so that the construction safety is good and the ground surface settlement is easily controlled.

Owner:CENT SOUTH UNIV +1

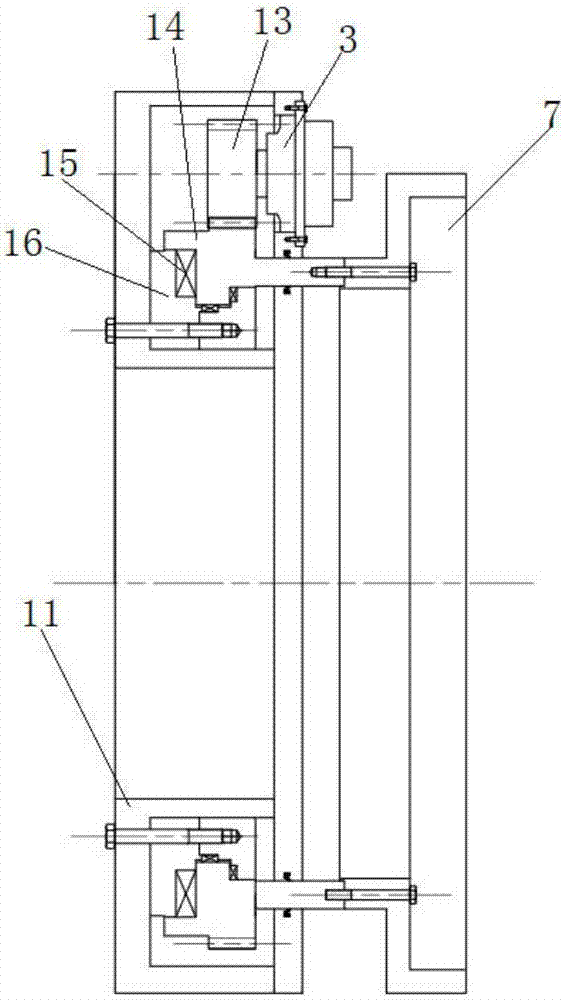

Prefabricated retaining wall and pile hole excavation method

PendingCN110438988ATo meet the needs of hole formationThe settlement process is easyExcavationsBulkheads/pilesLarge sizeInternal stress

The invention discloses a prefabricated retaining wall and a pile hole excavation method. The excavation method comprises the steps that first, guide-hole construction is carried out by using a machinery in an excavation area of a rectangular hole, after the internal opening is carried out, a soil body at the edges and corners of the rectangular hole is disturbed, internal stress is released, thedifficulty of subsequent excavation is greatly reduced, moreover, with the continuous increase of gravity of the prefabricated retaining wall, the settlement process of the prefabricated retaining wall is easier, and construction efficiency is conducive to be improved; and according to the excavation method, excavation of the rectangular hole can be carried out effectively, construction safety isimproved, construction difficulty is reduced, the requirement for forming a large-size rectangular hole is met, at the same time, prefabricated retaining wall structure is effectively installed to avoid the risk of hole collapse, hole digging and the retaining wall can be completed simultaneously, the construction period is conducive to be shortened, energy saving and environment production are achieved, the quality hidden danger of the retaining wall can be avoided effectively, and the excavation method is especially suitable for construction of an anti-slide pile in cold and high altitude areas such as the sichuan-tibet line.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Construction method of steel sheet pile cofferdam

The invention relates to a construction method of a steel sheet pile cofferdam. The construction method comprises the following construction steps that S1, preparatory work before construction is conducted; S2, positioning and measuring are conducted; S3, a guiding frame is constructed; S4, steel sheet piles are constructed; S5, the guiding frame is demounted to provide a space for subsequent construction; S6, inner supports are constructed, specifically, hinged brackets are welded to grooves in the inner sides of the steel sheet piles to serve as a supporting platform, the inner supports arehoisted on the supporting platform, then the three sets of inner supports are sequentially and overall hung and mounted to the designed elevation through a hanging system from top to bottom, and in the hanging process, the hinged brackets are opened and thus embedded in the grooves in the inner sides of the steel sheet piles; S7, water pumping and mud suction are conducted, and a foundation pit isexcavated; S8, underwater bottom sealing construction is conducted; and S9, the cofferdam is demounted. The construction method has the advantages that the construction efficiency is improved, the possibility of deformation and the construction risk in the cofferdam construction process are lowered, and the influence of tidal fluctuation on cofferdam construction is avoided.

Owner:北京质诚捷讯水利工程有限公司

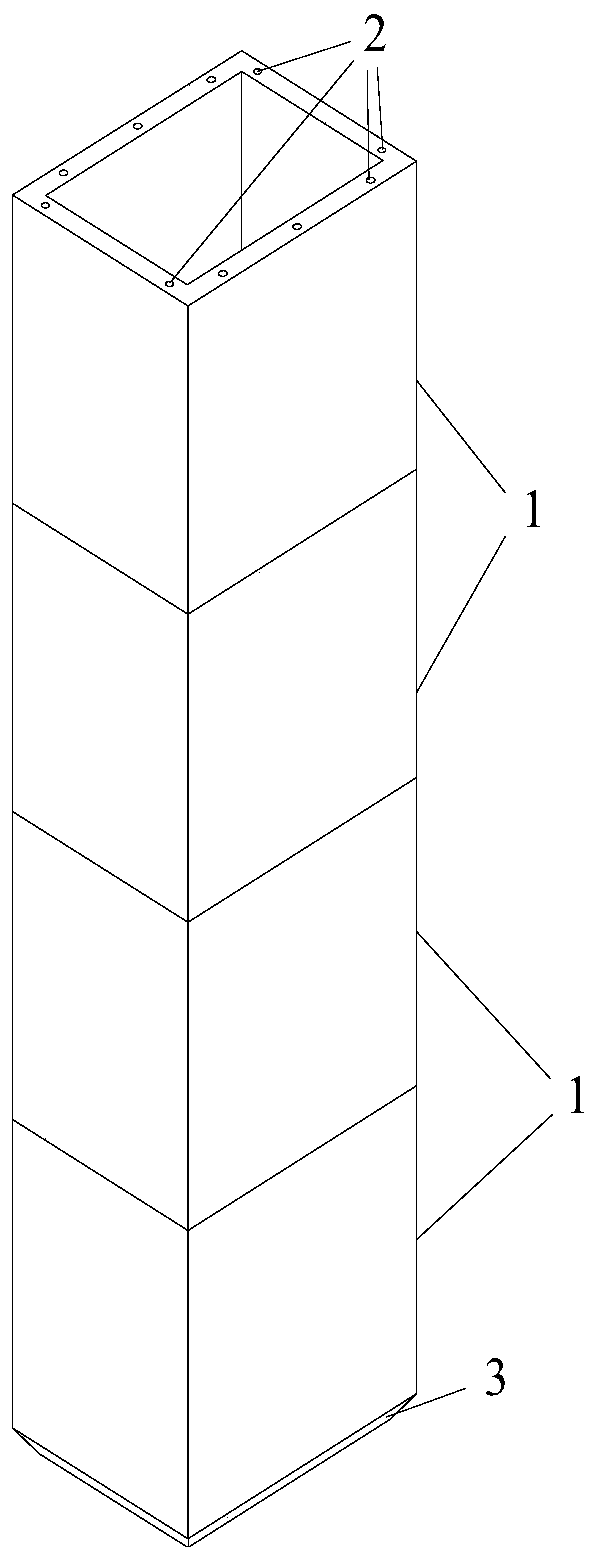

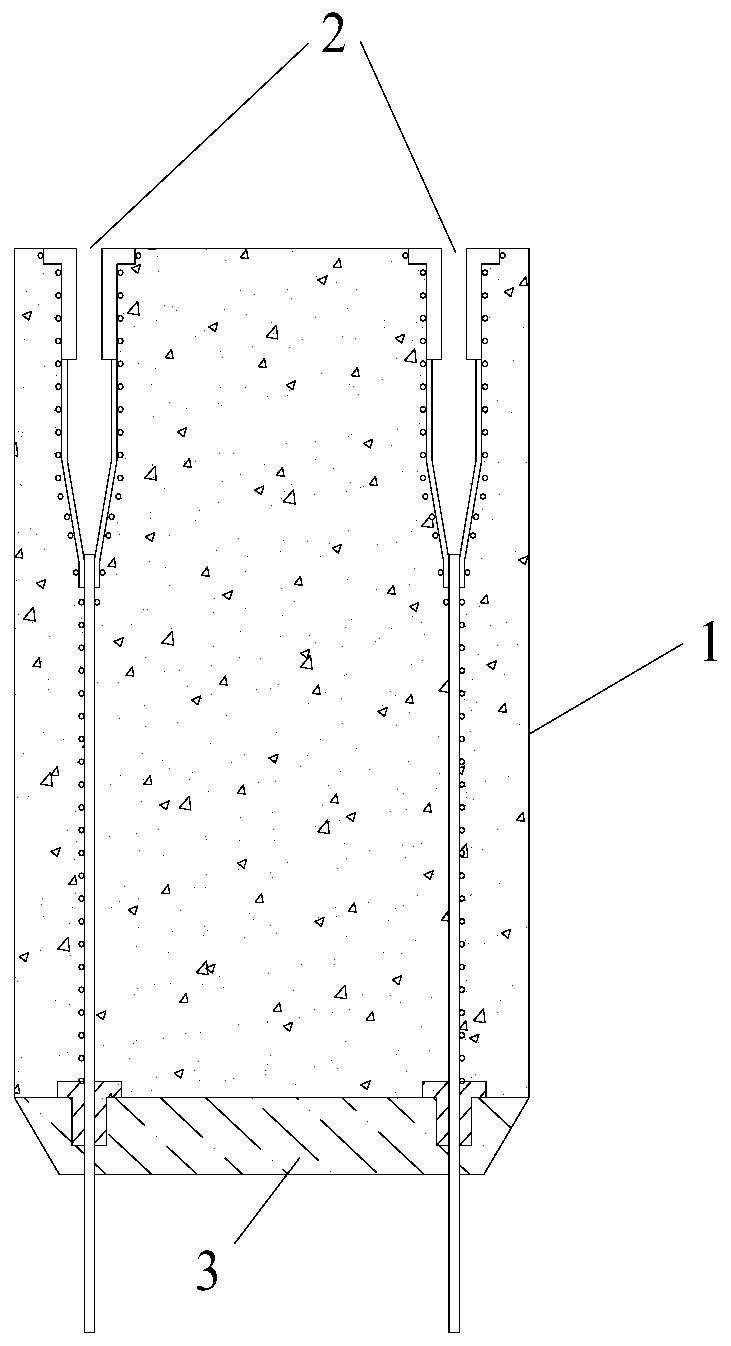

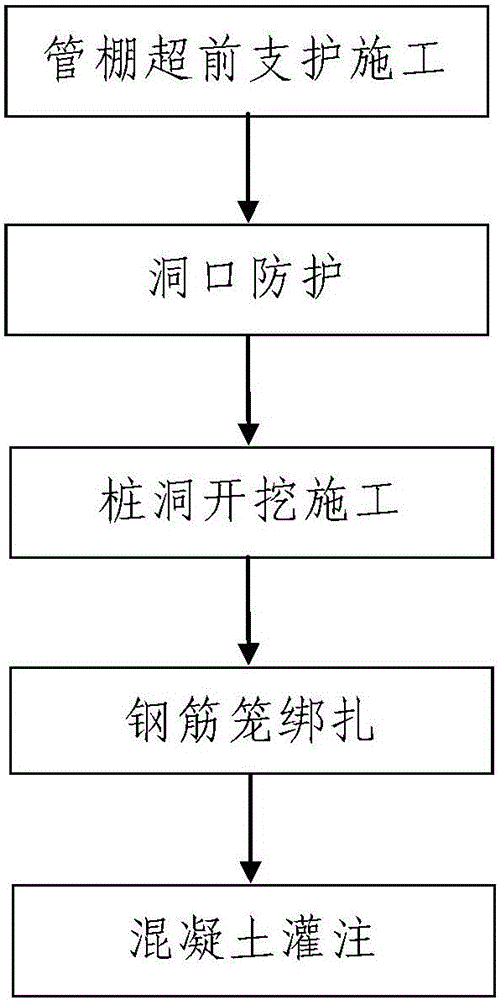

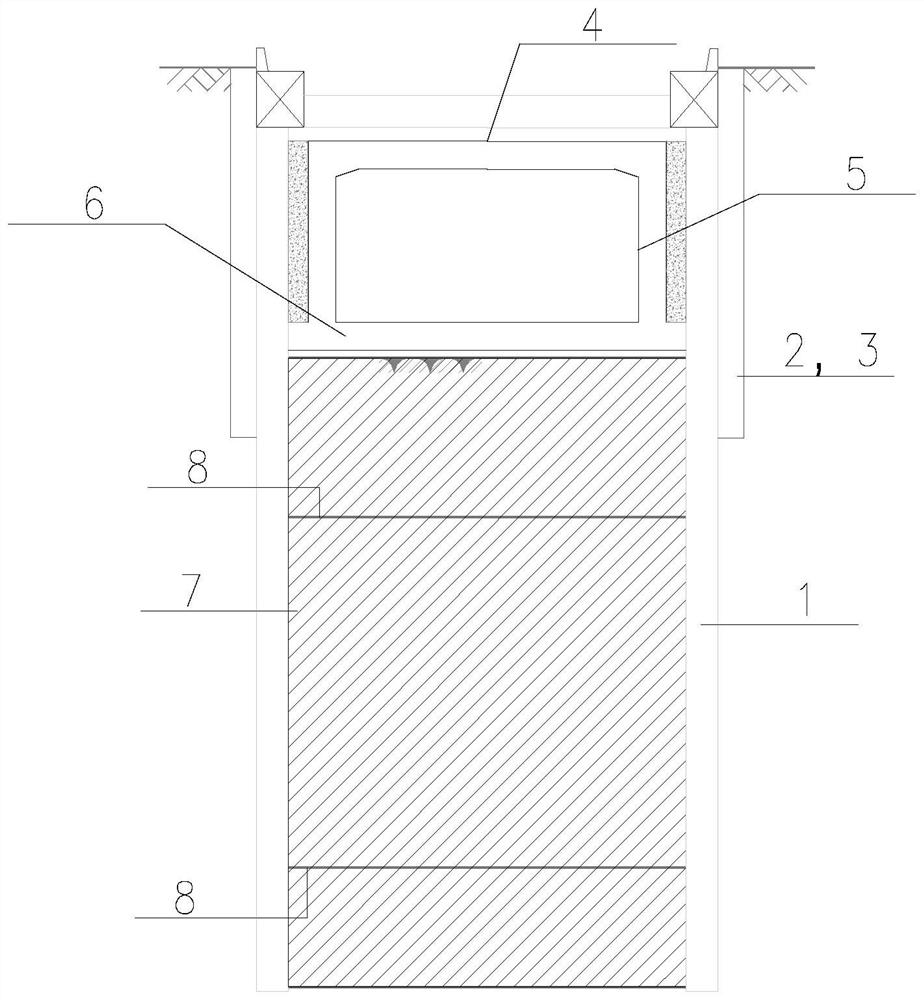

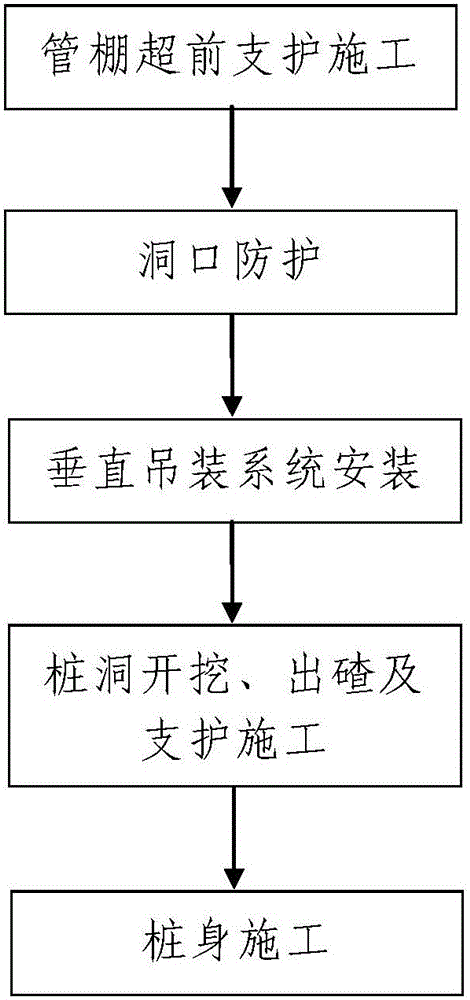

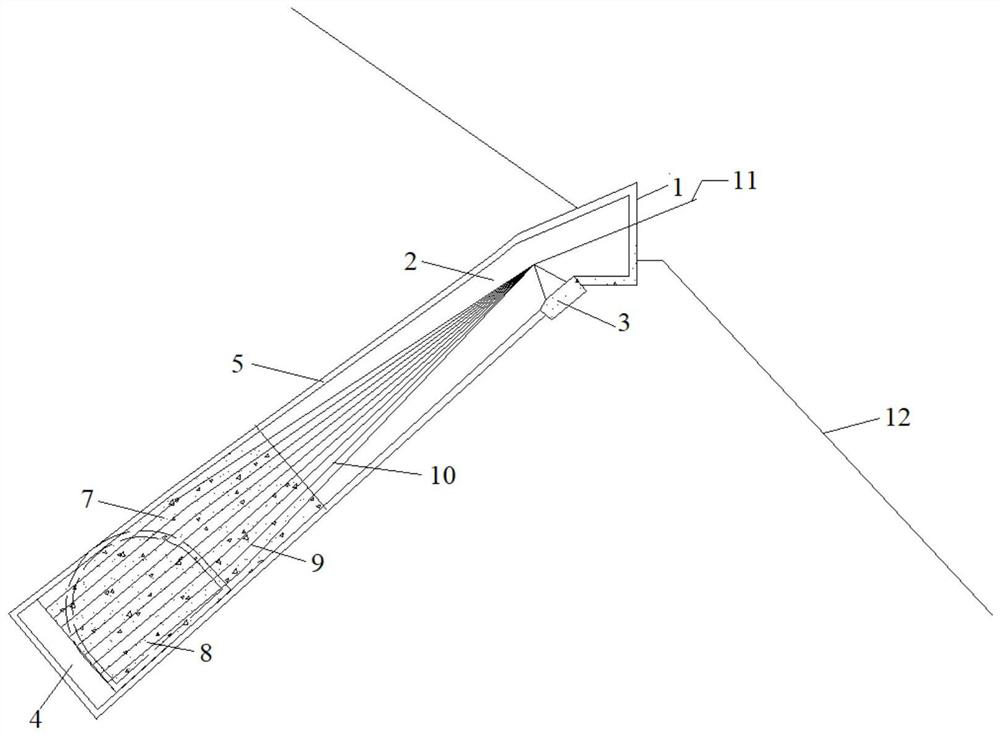

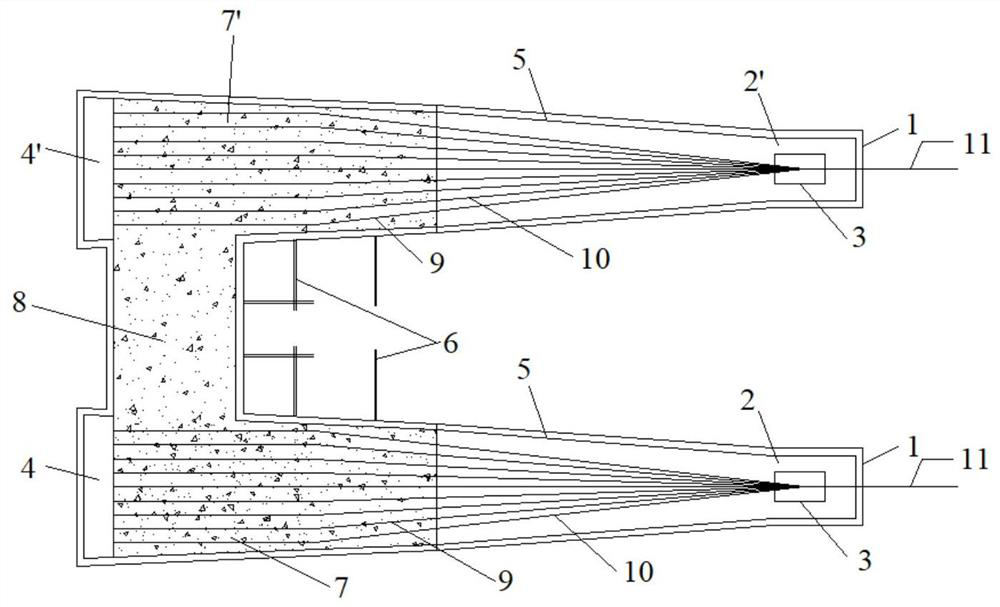

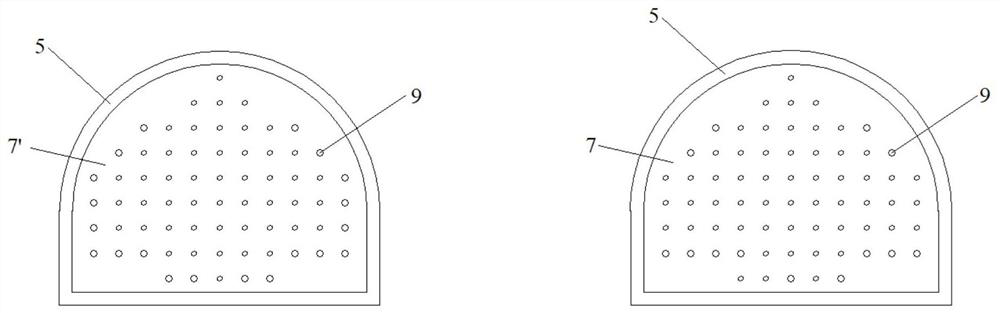

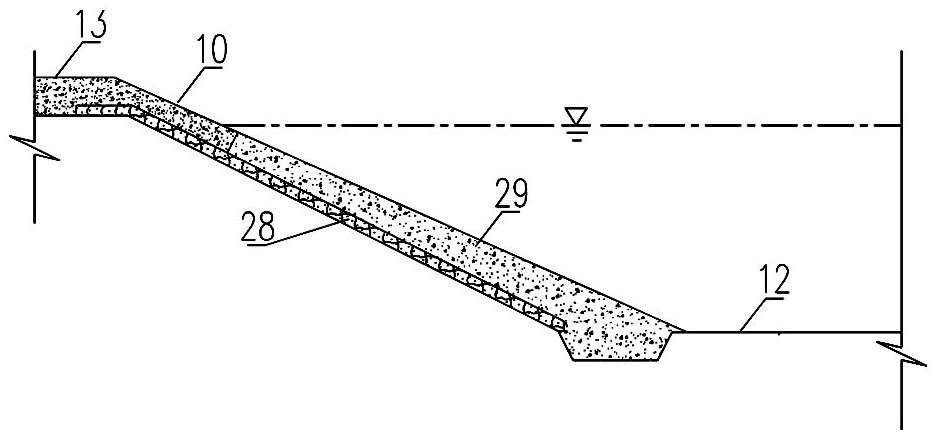

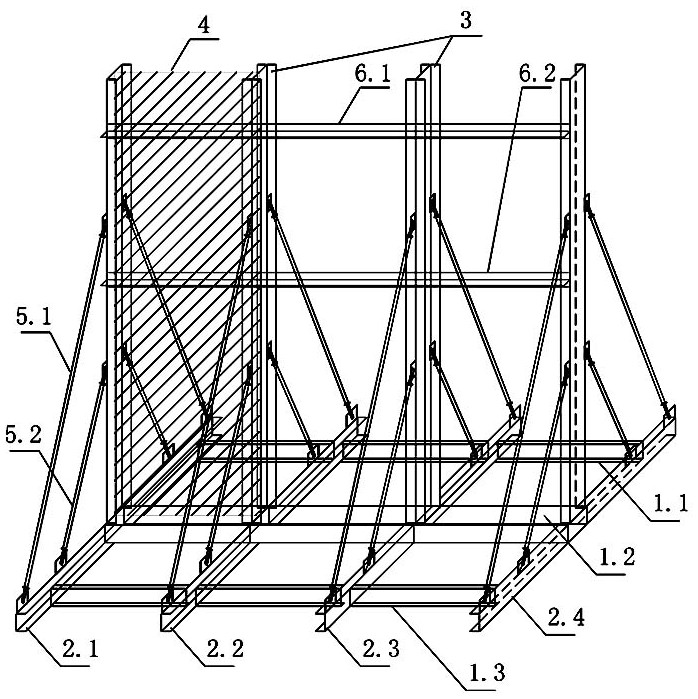

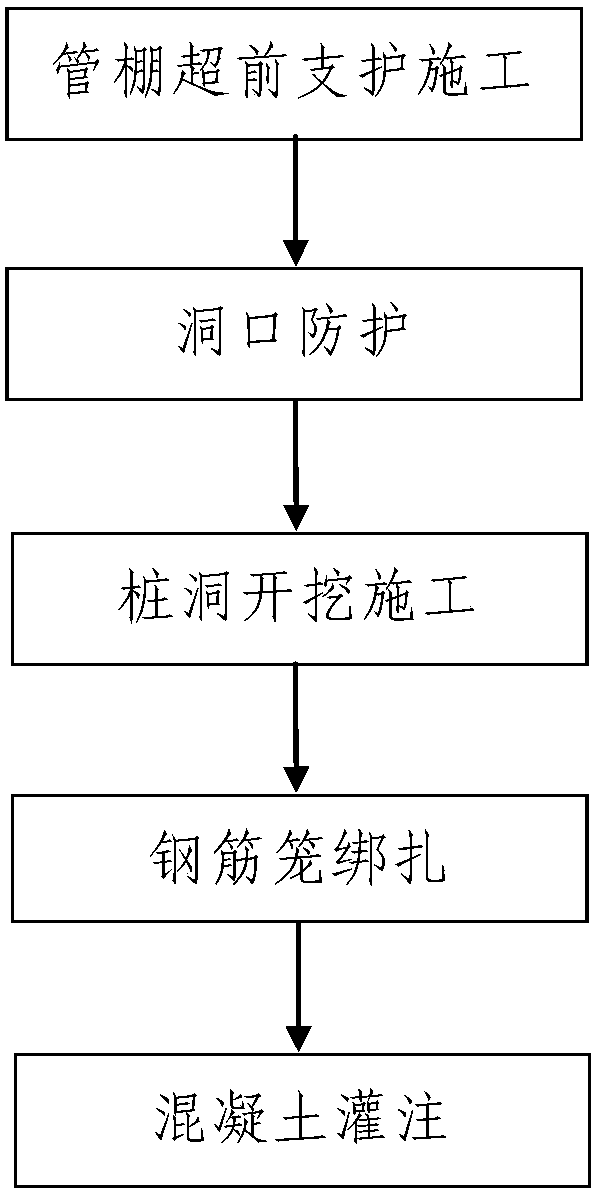

Construction process for superlarge-section and large-dip-angle tunnel type pile foundation

ActiveCN105970992AThe process steps are simpleReasonable designFoundation engineeringReinforced concreteRebar

The invention discloses a construction process for a supperlarge-section and large-dip-angle tunnel type pile foundation. The pile foundation to be constructed is a reinforced concrete pile. A pile hole of the reinforced concrete pile is a superlarge-section large-dip-angle tunnel hole. In construction of the pile foundation to be constructed, the process comprises the steps of firstly, pile hole construction, i.e., 101, advanced pipe shed support construction is conducted at the top of the pile hole, 102, hole mouth protection is conducted and a hole mouth support structure is constructed at a hole mouth of the pile hole, and 103, pile hole excavation construction is conducted, a full section excavation method is adopted for the pile hole excavation with a plurality of construction segments arranged from top to bottom, and a full section support structure is adopted for supporting; and secondly, pile body construction, i.e., the pile body of the reinforced concrete pile is constructed, and the construction process comprises the two steps of reinforcing cage binding and concrete spouting. The construction process for the supperlarge-section and large-dip-angle tunnel type pile foundation is simple in step, reasonable in design, low in investment cost, simple and easy to construct, good in use effect and capable of easily and fast completing the construction process of the tunnel type pile foundation, and the construction process is easy to control.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

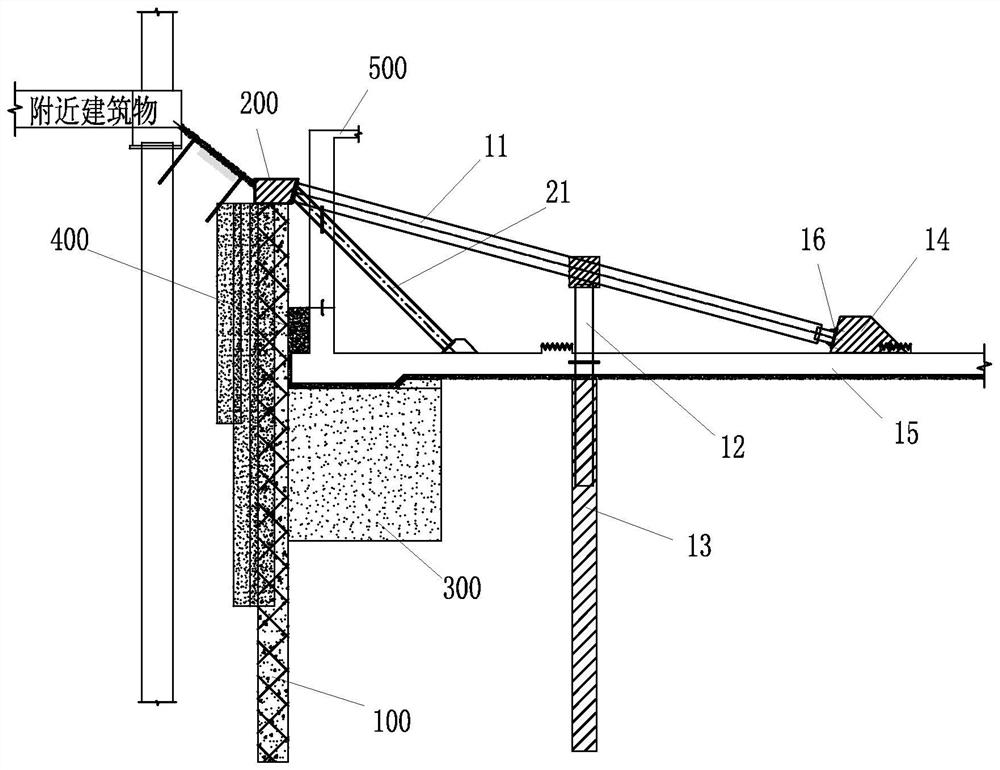

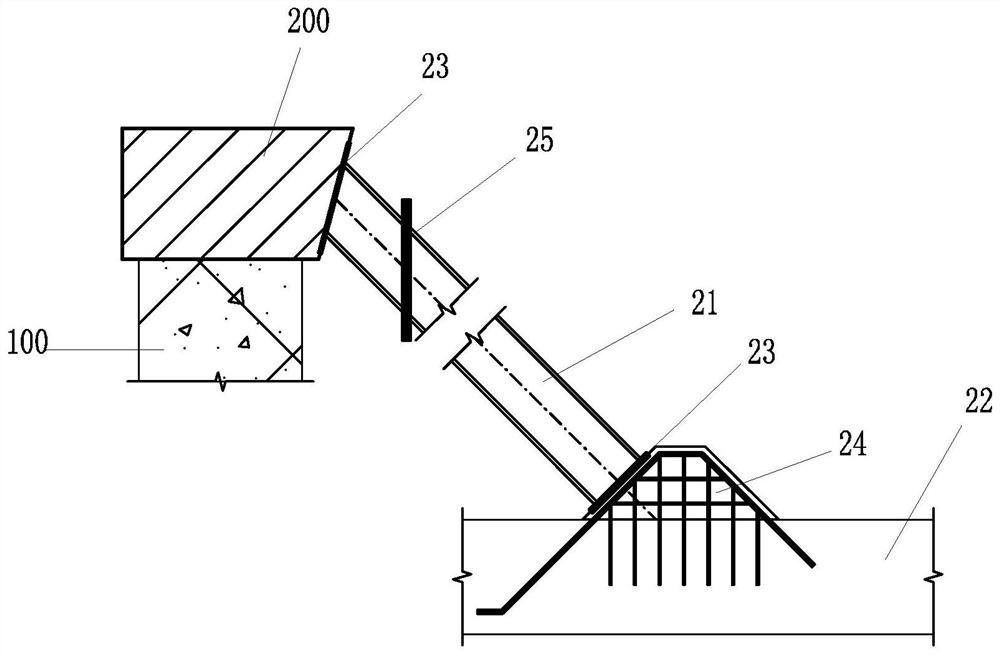

Foundation pit inclined support system and foundation pit inner support construction method

PendingCN113463650AReduce relevanceFast constructionExcavationsSupporting systemArchitectural engineering

The invention discloses a foundation pit inclined support system and a foundation pit inner support construction method. The foundation pit inclined support system comprises a side wall enclosure structure of a foundation pit, a top beam connected with the side wall enclosure structure, a steel pipe inclined strut and a bracket, wherein the bracket is fixedly arranged on a foundation pit bottom plate, the steel pipe inclined strut is arranged between the side wall enclosure structure and the foundation pit bottom plate in an inclined strut mode, one end of the steel pipe inclined strut is fixedly connected with the top beam, and the other end of the steel pipe inclined strut is fixedly connected with the bracket. The foundation pit inner support construction method is based on the foundation pit inclined support system and comprises the following steps of (1) mounting a long type inclined strut; (2) excavating reserved soil and constructing a residual bottom plate; (3) mounting a short type replacement support and removing the long type inclined strut; and (4) constructing a main body structure and removing the short type inclined strut. The foundation pit inclined support system and the foundation pit inner support construction method have the advantages that supporting materials can be recycled, so that the supporting rigidity is increased; and the support construction period is short, the reserved soil excavation difficulty is reduced, the construction cost is reduced, and the construction safety is improved.

Owner:中铁一局集团厦门建设工程有限公司 +1

Construction method for boring of extra large diameter pile foundation in dangerous landform region of mountainous area

InactiveCN108193671AReduce the difficulty of digging holesSolve measurement difficultiesBulkheads/pilesEngineeringAerial photography

The invention discloses a construction method for boring of an extra large diameter pile foundation in a dangerous landform region of a mountainous area. According to the method, aerial photography with an unmanned aerial vehicle, the BIM technology and a digital map are used, so that the problem that measurement of the dangerous landform construction region of the mountainous area is difficult iseffectively solved, and more accurate and visual data are provided for onsite construction planning; and then a small rotary drilling rig is used for drilling a plurality of reasonably-arranged smallholes at first, backfilling is carried out, then manual hole digging is conducted, and slag removing and boring are carried out. A feasible technological means is provided for boring of the moderately weathered rock large diameter pile foundation which has high environment protection requirements, cannot allow blasting method excavation, does not have a large equipment entering condition and hashigh excavation difficulty. In addition, manual excavation difficulty is reduced, the manual excavation speed of the pile foundation under the special environment is increased, and the boring qualityof the pile foundation is guaranteed.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

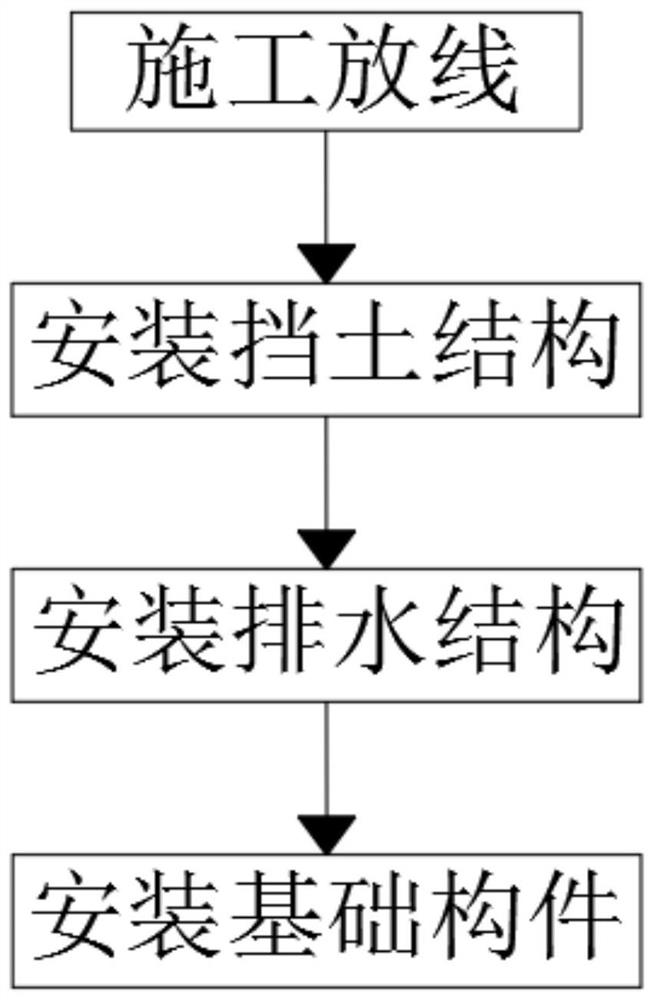

Construction method of underground structure of municipal building

InactiveCN113463684AReduce the difficulty of excavationImprove construction efficiencyArtificial islandsExcavationsArchitectural engineeringRebar

The invention discloses a construction method of an underground structure of a municipal building. The construction method comprises the following steps: conducting setting-out, specifically, conducting setting-out on a construction site according to a construction drawing; punching, specifically, punching on the edge of an excavated foundation pit; installing a soil retaining structure, specifically, inserting a reinforcement cage into a hole site, pouring concrete, forming soil retaining columns; excavating, specifically, in the process of foundation pit excavating, continuously installing the soil retaining structure, and connecting and reinforcing the multiple soil retaining columns; installing drainage structures, specifically, arranging the drainage structures in soil layers of different depths in a graded mode, and the multiple drainage structures communicate with one another; and installing foundation components, specifically, installing the foundation components in the foundation pit according to construction requirements. The foundation pit excavation environment is controlled through the soil retaining structure, the stability of the construction environment is guaranteed through the drainage structures, the quality of the components is guaranteed through the prefabricated foundation components, meanwhile, the construction efficiency is improved, the construction period is shortened, a construction plan can be smoothly completed, the benefits of a construction party are guaranteed, and the working intensity of constructors is reduced.

Owner:丁超超

Water jet cutter for cutter head of shield tunneling machine

PendingCN112796774AIncrease moisture contentWill not reduce bearing capacityTunnelsTool bitWater use

The invention belongs to the technical field of shield tunneling machines, and discloses a water jet cutter for a cutter head of a shield tunneling machine. The water jet cutter comprises a cutter head and a water supply assembly, wherein the water supply assembly is used for conveying water; a hobbing cutter is arranged at one side of the cutter head; a blocking cover is arranged on the circumferential surface of the cutter head in a sleeving way; an installing groove is formed in one side, near the hobbing cutter, of the cutter head; a water outlet pipe is arranged inside the installing groove; a water spraying head is arranged on the circumferential surface of the water outlet pipe; the water supply assembly comprises a main pipe; the main pipe is arranged inside the cutter head; and a water inlet pipe is arranged at one side of the main pipe. The front side of the cutter head is shielded through the blocking cover, so that the water sprayed out from the water spraying head cannot directly flow into soil under the shield tunneling machine; the water can drive the broken soil body to enter a soil water cabin; the too high water content of the soil in front of the shield tunneling machine cannot be easily caused; the soil bearing force cannot be reduced; the soil layer collapse cannot be easily caused; and the safety guarantee during the construction is improved.

Owner:扬州赛欧德马沁机械制造有限公司

Underground station end well front upper part air-shaft-containing structure and undercrossing construction method thereof

ActiveCN114541408AQuality assuranceWon't breakExcavationsBulkheads/pilesArchitectural engineeringStructural engineering

The invention provides an underground station end well front upper portion air-containing shaft structure and an underneath pass construction method thereof. The underneath pass construction method comprises the following steps that S1, the ground is leveled; s2, an enclosure structure is arranged on the periphery of the air shaft; s3, soil body reinforcement is conducted within the range of the enclosure structure, and the air shaft excavation area and the shield area are covered with a soil body reinforcement area in the vertical direction; s4, an air shaft structure foundation pit is excavated, segmented and layered excavation is conducted from top to bottom, supporting is conducted firstly, then excavation is conducted, and bottom sealing is conducted immediately after the foundation pit is excavated; after the air shaft foundation pit is excavated, air shaft structure main body construction is immediately started, and base bottom plate treatment, side wall and top plate construction and connector construction are conducted; and S5, after the soil body reinforcement area meets the design strength requirement, subway tunnel shield construction is conducted, secondary grouting is matched in the shield construction process, and secondary grouting is conducted outside the duct piece so that it can be ensured that grouting behind the duct piece wall is dense. Disturbance generated by shield crossing cannot damage the air shaft structure, and the quality of the air shaft structure is protected.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

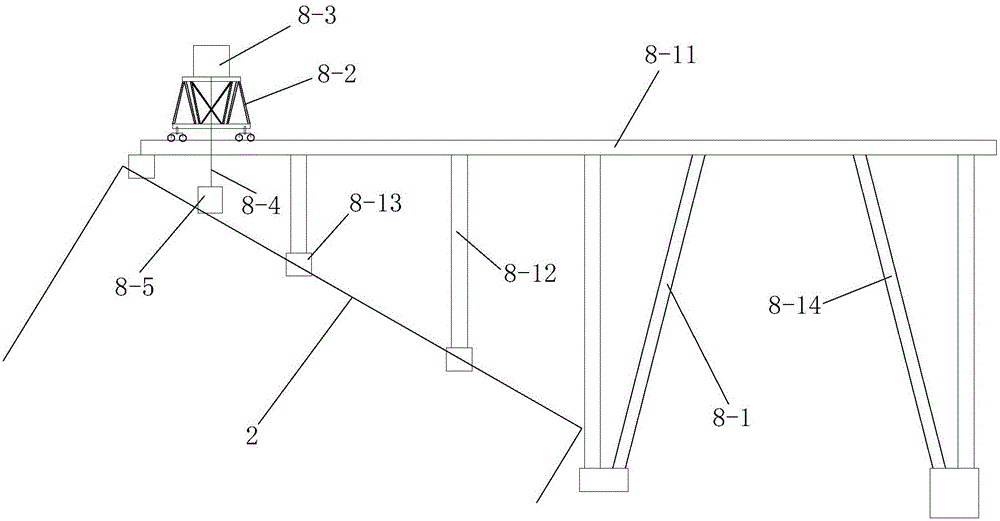

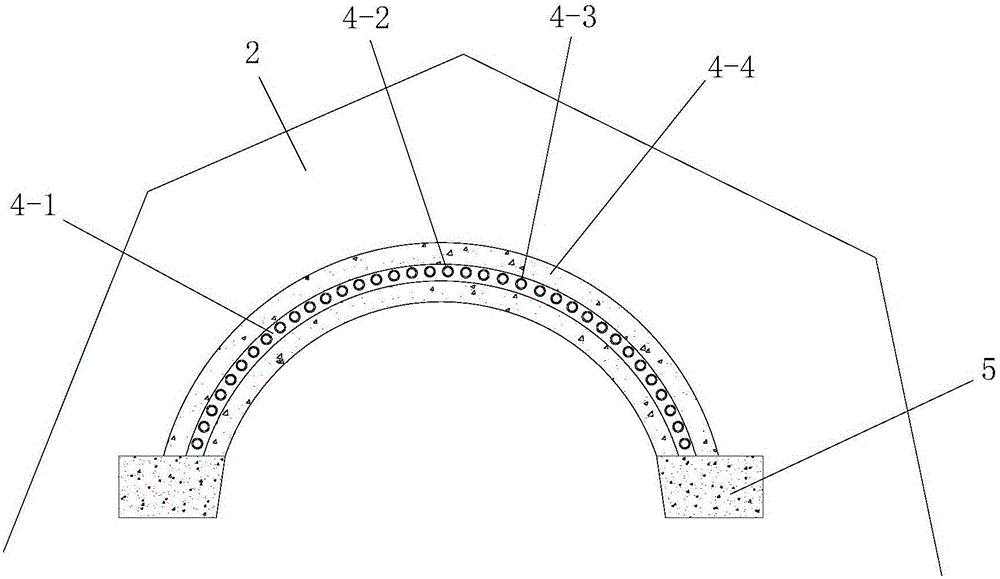

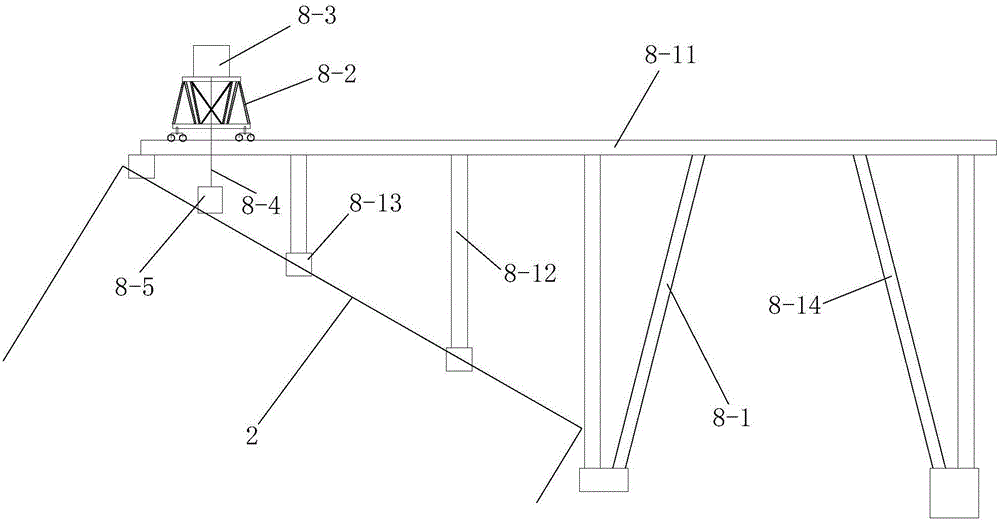

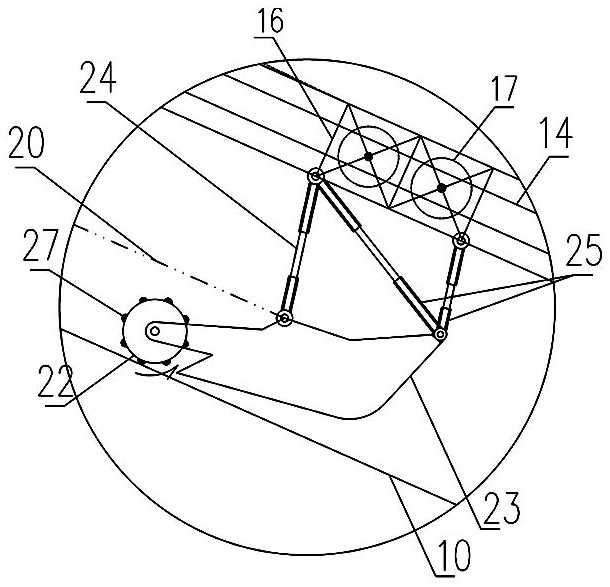

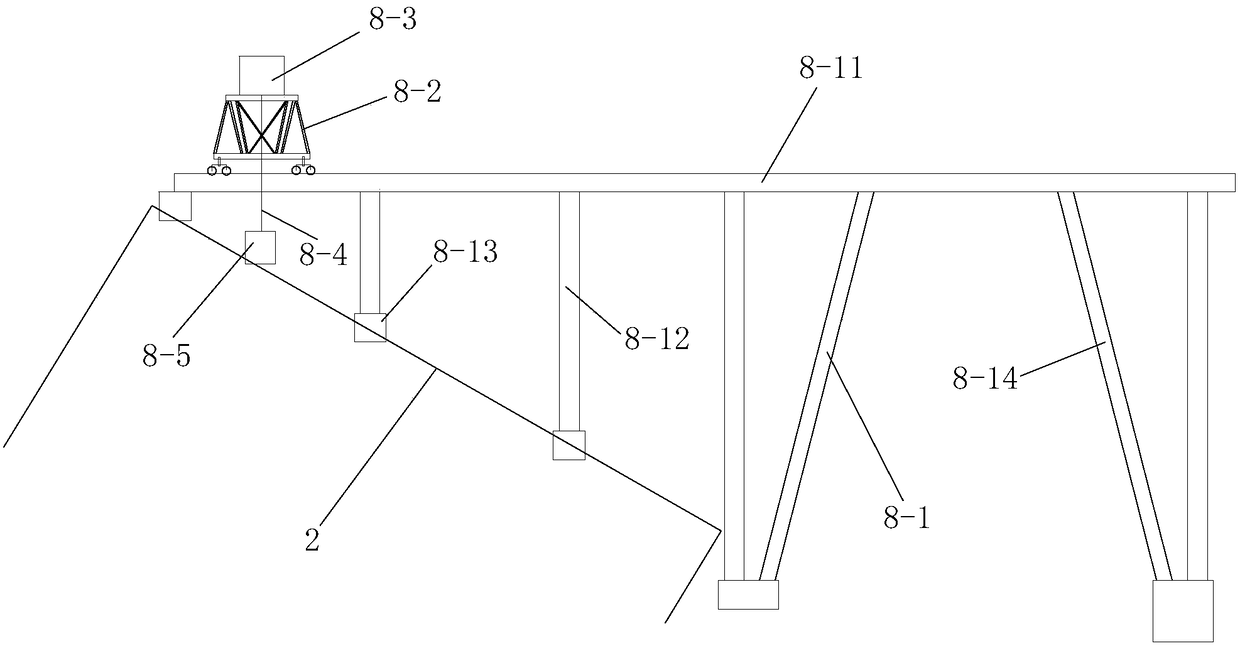

Ultralarge section inclined single-pile foundation construction process based on vertical lifting system

The invention discloses a ultralarge section inclined single-pile foundation construction process based on a vertical lifting system. A constructed ultralarge section inclined single-pile foundation is a reinforced concrete pile, and is provided with a reinforcement cage inside; the ultralarge section inclined single-pile foundation is constructed by the following steps: (1) the advance support construction is performed for a pipe roof; (2) hole opening protection: a hole opening support structure is constructed in a hole opening of a pile hole; (3) the vertical lifting system is installed; (4) the excavation, the slag discharge and the support construction are performed for the pile hole. The pile hole is excavated by multiple construction sections from top to bottom through a full-section excavation method; the slag discharge is synchronized in the excavation process; and the wall protection construction is respectively performed for pile hole sections excavated by all the construction sections; and (5) pile body construction: the reinforcement cage is bound and concrete is filled. The process is simple in steps, reasonable in design, low in investment cost, convenient for construction and excellent in use effect, can simply and quickly finish the construction process of the ultralarge section inclined single-pile foundation, and is easy to control the construction process.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

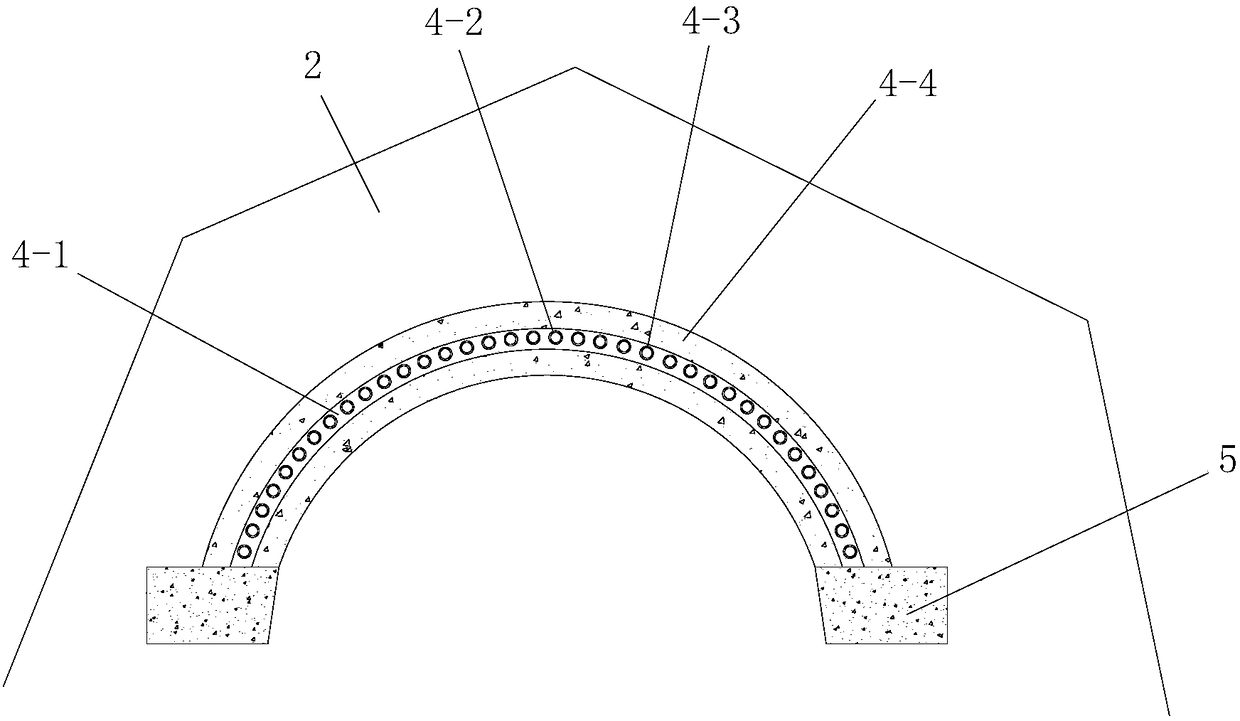

Composite tunnel anchor

PendingCN111705658AScale upSmall scaleBridge structural detailsStructural engineeringGeotechnical engineering

Owner:CHINA MAJOR BRIDGE ENERGINEERING

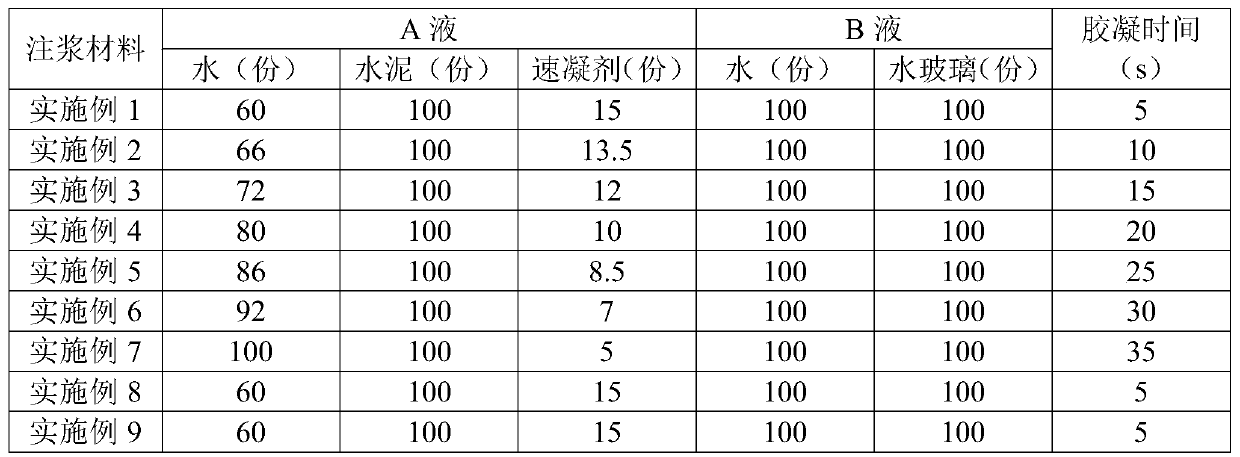

Collapsible loess composite grouting material as well as preparation method and application thereof

PendingCN111470837AFast solidificationThe setting time is easy to adjustSoil preservationSoil scienceCement slurry

The invention discloses a collapsible loess composite grouting material, which comprises a liquid A and a liquid B. The liquid A and the liquid B are independently stored and mixed in use. The liquidA comprises following components in parts by weight: 60-100 parts of water, 100 parts of cement and 5-15 parts of an accelerator. The liquid B comprises the following components in parts by weight: 100 parts of water and 100 parts of water glass. The grouting material has the advantages that the solidification speed is quick, the solidification time is easy to control, the permeability is good, and the impermeability is good. The grouting material is suitable for solidification of tunnel full-section water-rich collapsible loess, collapsible loess foundation treatment of newly-built buildingsor equipment foundations and collapsible loess foundation treatment of buildings or equipment foundations with differential settlement. The invention also discloses a preparation method of the collapsible loess composite grouting material. The preparation method comprises the following steps: fully stirring 60-100 parts of water and 100 parts of cement to form cement slurry, adding 5-15 parts of an accelerator into the cement slurry to form a liquid A; and uniformly stirring 100 parts of water and 100 parts of water glass to form a liquid B. When the collapsible loess composite grouting material is used, the liquid A and the liquid B are mixed to obtain the collapsible loess composite grouting material.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

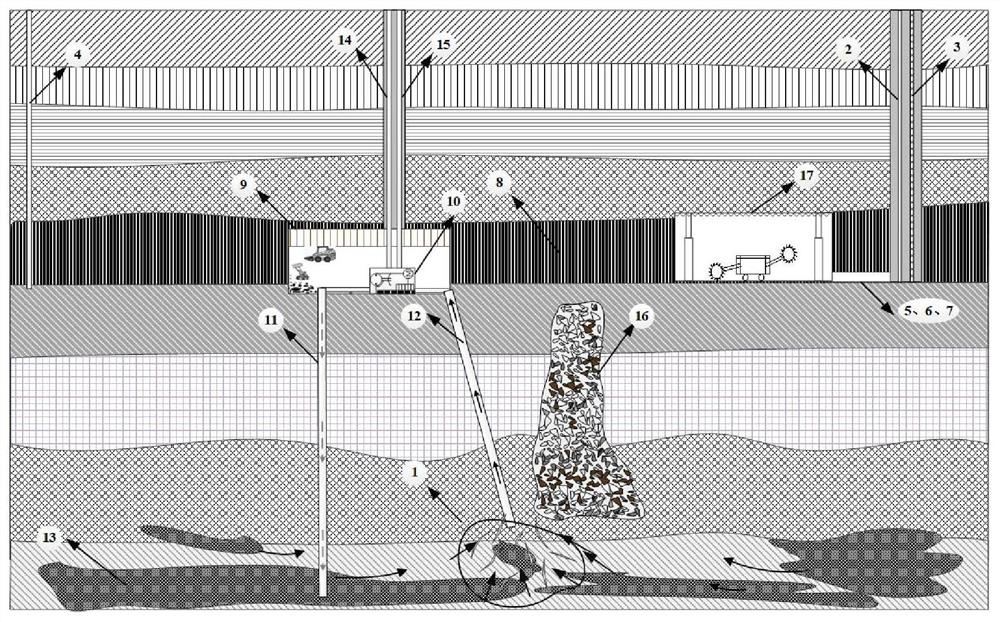

Coal-geothermal water collaborative mining method based on subsidence column water guide channel

ActiveCN111577279BRealize collaborative miningImprove liquidityUnderground miningFluid removalWell drillingGeothermal water

The invention discloses a coal-geothermal water collaborative mining method based on a water guiding channel of a collapsed column. While mining coal, the water guiding channel between the collapsed column and a geothermal reservoir is fully utilized as a geothermal water collection area. Geothermal mining. After the mining of the working face, a heat exchange station is established in the roadway formed along the goaf and in the chamber, and geothermal wells are excavated through the drilling chamber. The water returns to the pipe, and the ends of the two are separated by a certain distance. The geothermal water is extracted to the heat exchange station through the geothermal water pumping pipeline, and the heat energy is extracted and transported to the ground for use; after the heat is extracted, it is reinjected into the geothermal reservoir through the tail water reinjection pipeline to control the stability of the rock formation and realize the geothermal energy. Sustainable extraction of hot water. At the same time, coal mining can be carried out at the same time on the next working face, realizing the coordinated mining of coal-geothermal water. The mining method of the invention has the advantages of high resource utilization rate, low geothermal water mining cost, and turning the water guide channel around the collapsed column from harm to benefit.

Owner:CHINA UNIV OF MINING & TECH

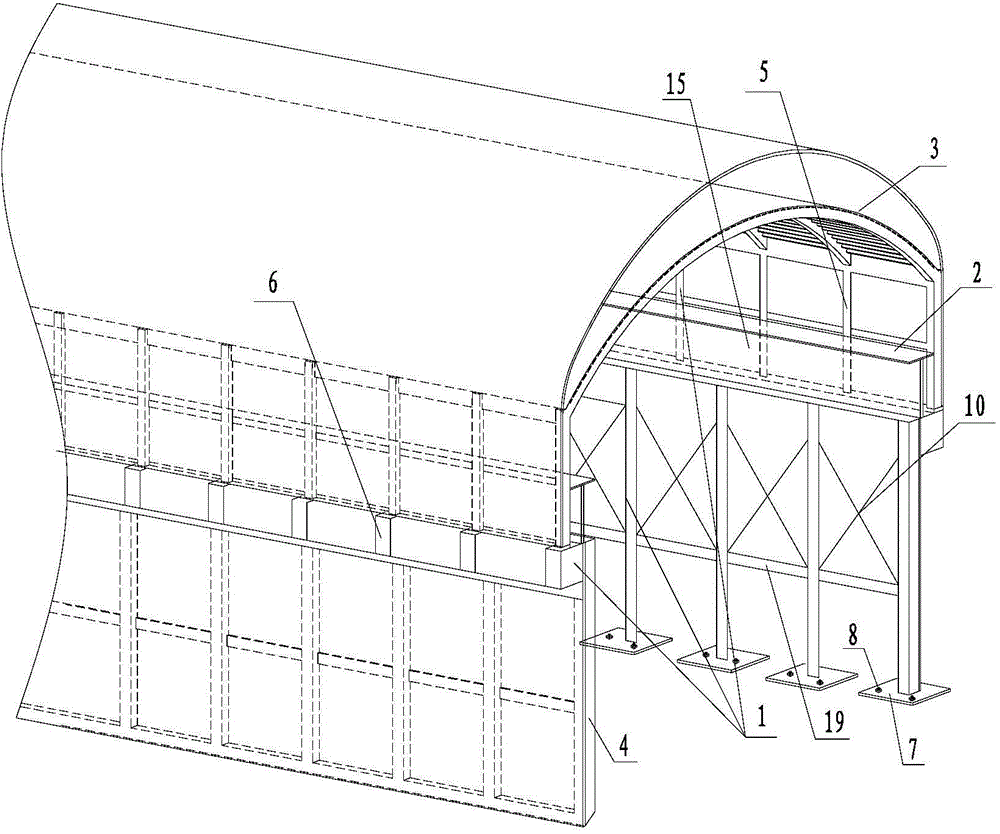

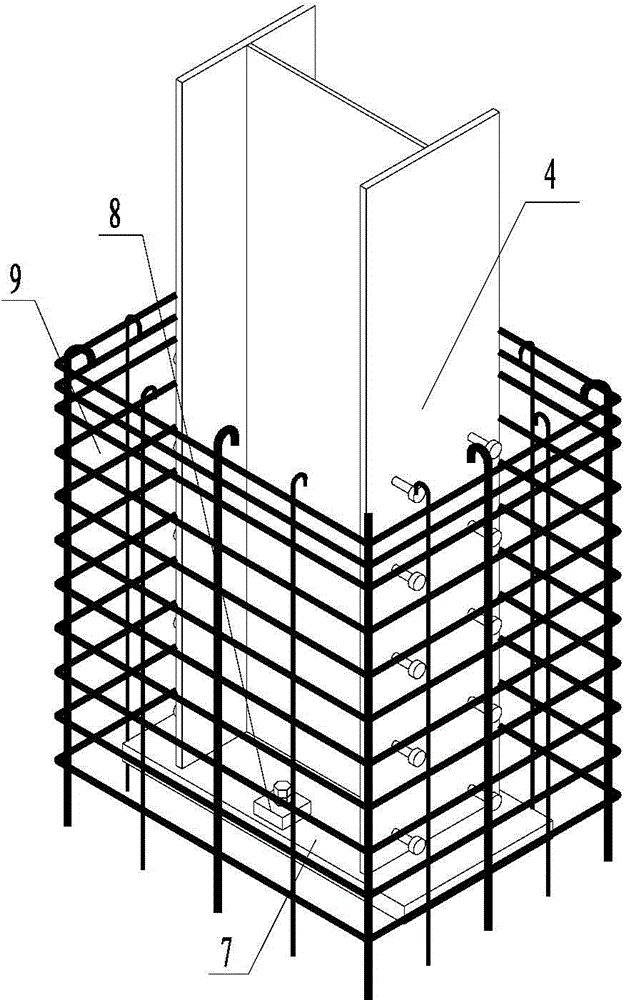

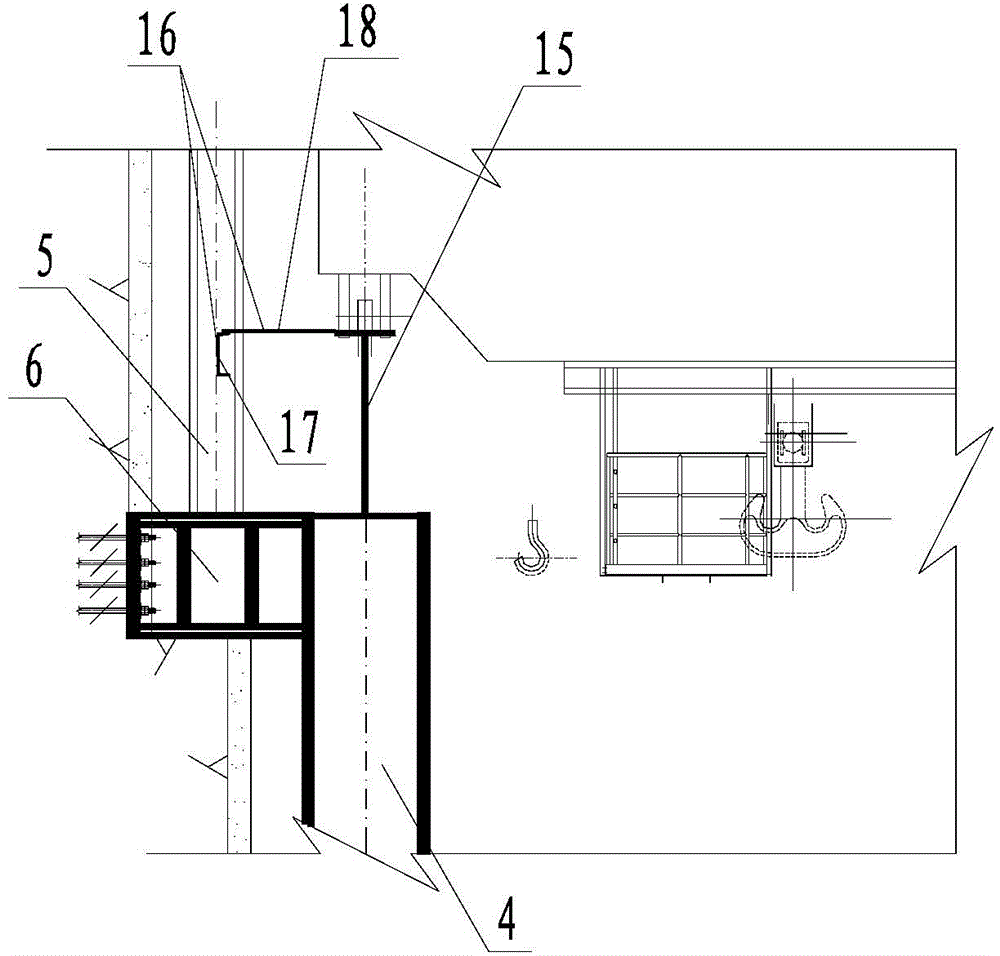

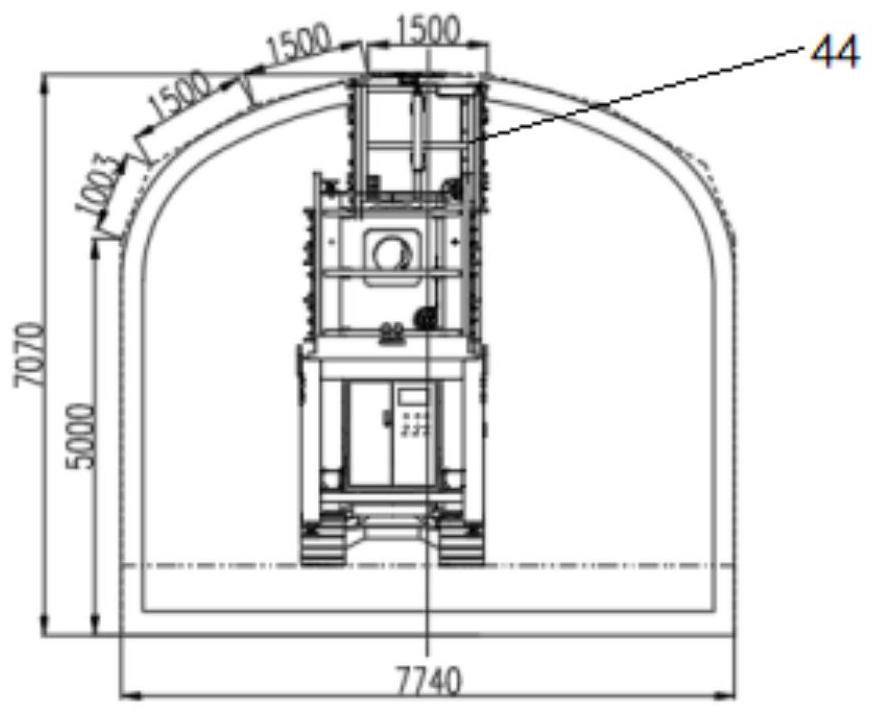

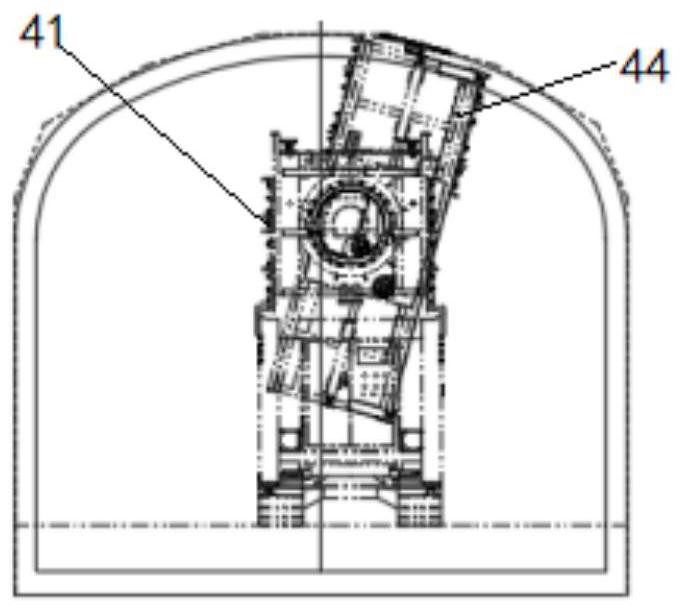

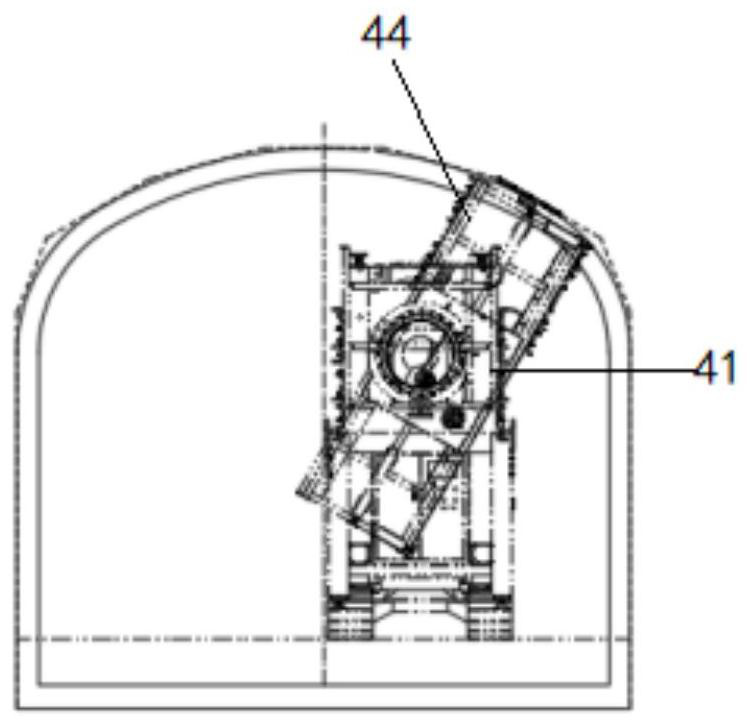

Workshop structure for position above generator layer of underground powerhouse of hydropower station

ActiveCN104532805AReduce the difficulty of excavationReduced excavation workloadFinal product manufactureWater-power plantsProtective systemHydropower engineering

The invention discloses a workshop structure for the position above a generator layer of an underground powerhouse of a hydropower station, and belongs to the technical field of design and manufacturing of ancillary facilities of water conservancy and hydropower engineering. The workshop structure for the position above the generator layer of the underground powerhouse of the hydropower station is small in excavation difficulty and small in mutual interference degree of a building process and other kinds of construction work. The workshop structure comprises a steel framework system, a rail system and a protection system; the rail system is fixedly arranged on the upper middle portion of the steel framework system; the protection system is connected to the outer side of the steel framework system in a covering manner; and the workshop structure is fixedly connected with an external civil engineering foundation through the steel framework system.

Owner:POWERCHINA CHENGDU ENG

Construction method of non-blasting chain saw cutting machine

ActiveCN113431595AReduce overmining and underminingReduce labor intensityTunnelsArchitectural engineeringWire cutting

The invention provides a construction method of a non-blasting chain saw cutting machine. The construction method specifically comprises the following steps that a crawler walking mechanism and a moving mechanism of the chain saw cutting machine are used for driving a cutting chain saw to move to a proper position for cutting a tunnel face; the cutting chain saw carries out grid type cutting and fitting arc cutting on the tunnel face; and after cutting is completed, stone separation is carried out through a full saw cutting method or a hydraulic fracturing rock breaking method. According to the construction method, grid type cutting can be carried out on the tunnel face, and tunnel excavation and tunneling are carried out by adopting the hydraulic fracturing rock breaking method or the full saw cutting method to cut the section after cutting, so that the whole is broken up into parts, the excavation difficulty is reduced, the influence on a stratum is reduced, the labor intensity of workers is reduced, the over-excavation and under-excavation amount of the tunnel is reduced, the construction cost is reduced, and the like.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

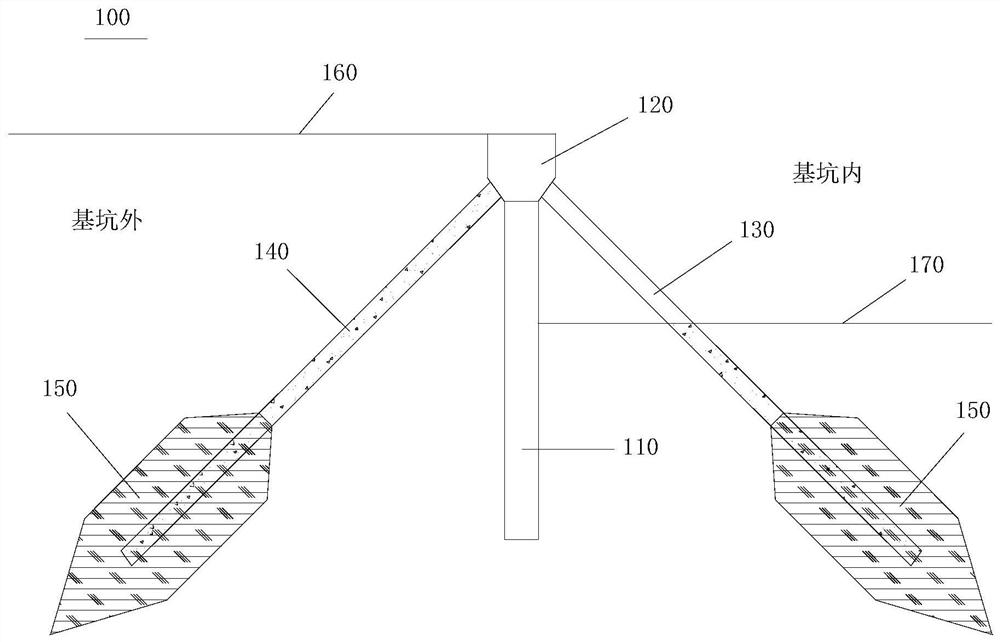

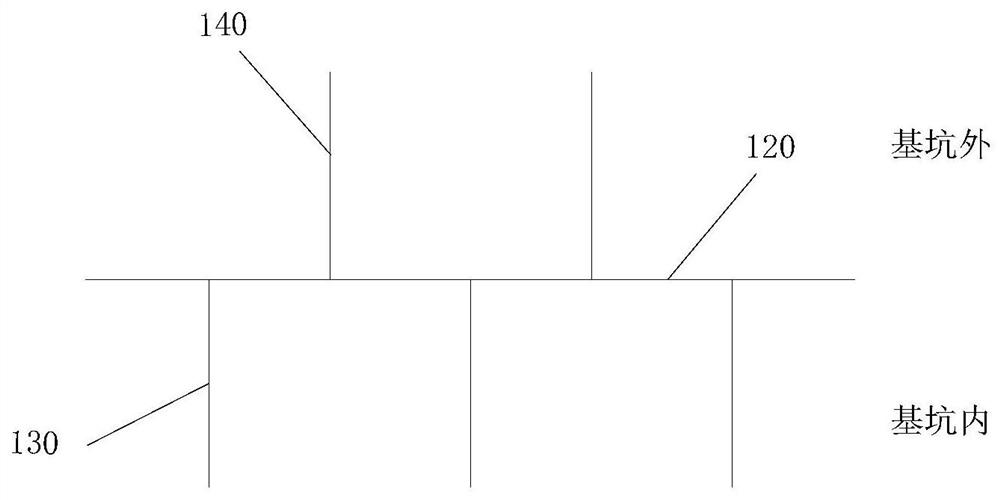

Front-supporting and rear-pulling type foundation pit support system and construction method thereof

InactiveCN113653064AReduce layout densityImprove reliabilityExcavationsBulkheads/pilesSupporting systemPipe

The invention discloses a front-supporting and rear-pulling type foundation pit support system and a construction method thereof. The foundation pit support system comprises a support pile, a capping beam, a front-supporting type grouting steel pipe pile, and a rear-pulling type grouting steel pipe pile; the support pile is vertically constructed in a soil body to form a foundation pit support; the capping beam is arranged on the support pile; the front-supporting type grouting steel pipe pile is obliquely buried in the soil body in a foundation pit, the front-supporting type grouting steel pipe pile is anchored on the capping beam, and grout is injected into a pipe section, below the elevation of the bottom of the foundation pit, of the front-supporting type grouting steel pipe pile; and the rear-pulling type grouting steel pipe pile is obliquely buried in a soil body outside the foundation pit, the rear-pulling type grouting steel pipe pile is anchored on the capping beam, grout is injected into the whole rear-pulling type grouting steel pipe pile, and the rear-pulling type grouting steel pipe pile and the front-supporting type grouting steel pipe pile are alternately distributed. According to the system and the construction method thereof, the arrangement density of the front-supporting type grouting steel pipe piles in the length direction of the support pile can be reduced, the reliability, stability, safety and overall strength of the support system are improved, and the excavation difficulty of earth beside the foundation pit is reduced.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

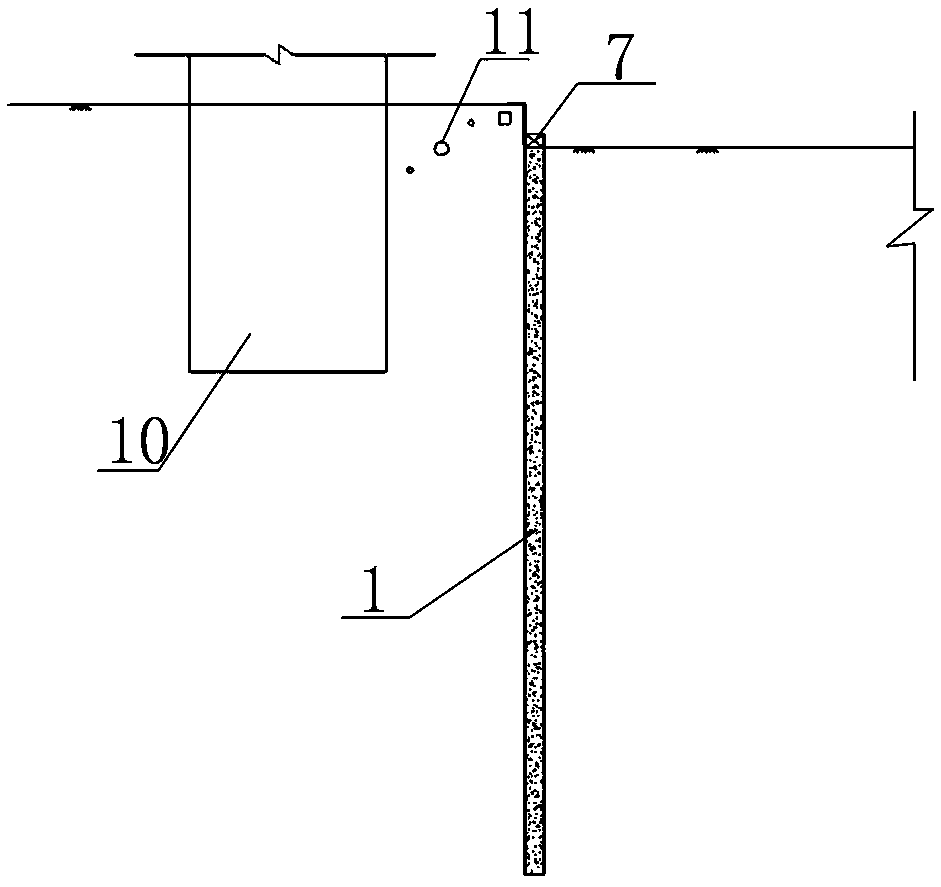

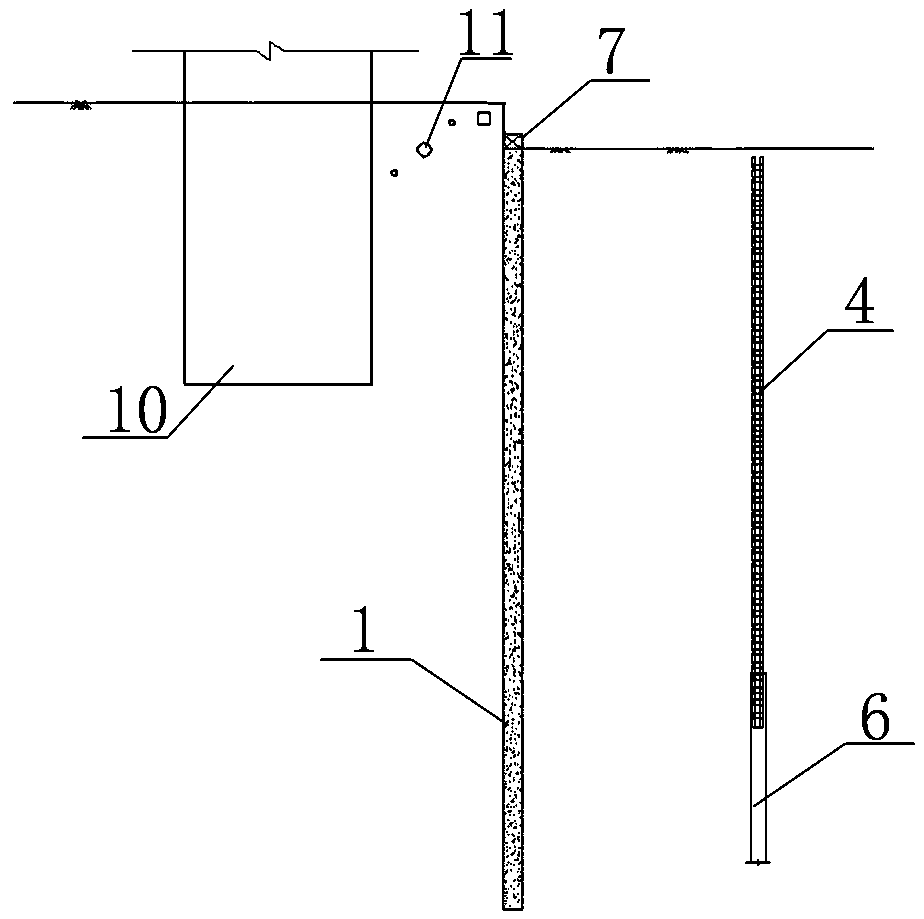

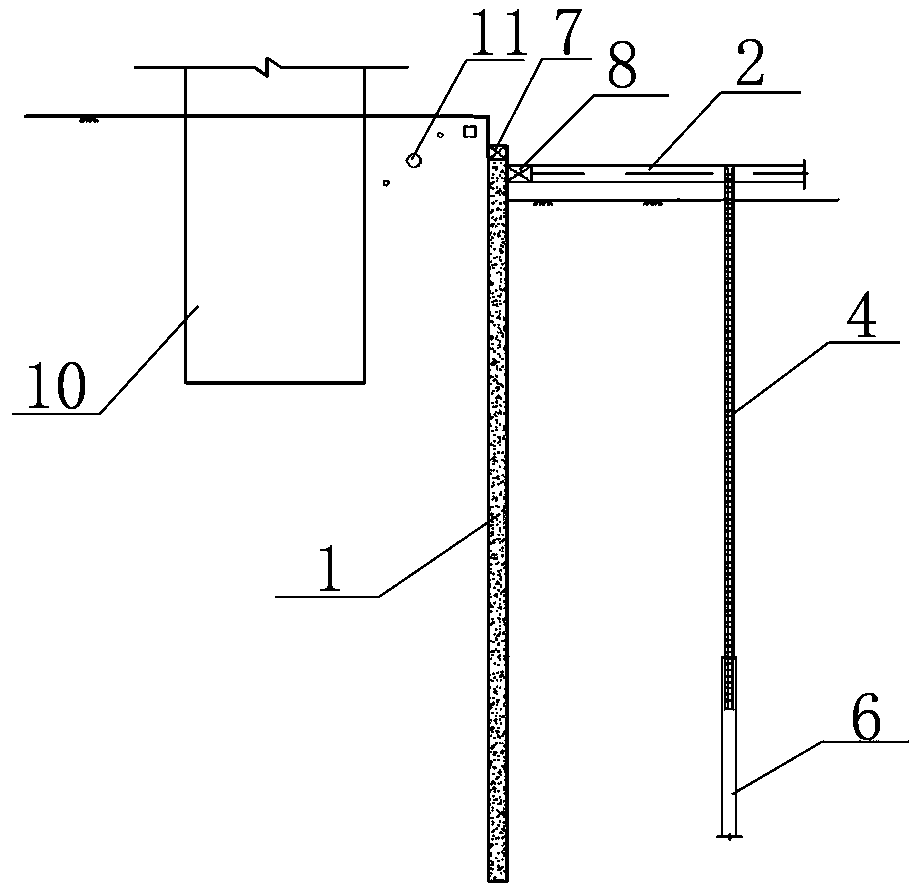

Top-rigid-and-bottom-flexible deep foundation pit supporting system and construction method thereof

PendingCN109403348AGood stabilityReduce pit deformationExcavationsBulkheads/pilesUnderground pipelineLine tubing

The invention relates to a top-rigid-and-bottom-flexible deep foundation pit supporting system and a construction method thereof. The top-rigid-and-bottom-flexible deep foundation pit supporting system comprises vertical shoring members, rigid supporting members and flexible pulling anchor members; at least two rows of rigid supporting members are arranged in the vertical direction at interval; each row of rigid supporting members are arranged vertically and horizontally in the same horizontal plane in a crossed manner; the at least two rows of flexible pulling anchor members are arranged; thedistance between the flexible pulling anchor members on the bottommost row and the bottom of a foundation pit is not less than 2 m, and the distance between the flexible pulling anchor members on thetopmost row and the rigid supporting members on the bottommost row is 2 m to 4 m; and one ends of the flexible pulling anchor members are connected to the vertical shoring members, and the other endsof the flexible pulling anchor members are anchored into soil bodies at the backs of the flexible pulling anchor members. The top-rigid-and-bottom-flexible deep foundation pit supporting system and the construction method solve the technical problem about the construction condition that an underground structure and an underground pipeline of an existing building (structure) on the periphery avoidthe flexible pulling anchor members within a certain depth, and solve the technical problems that when a full rigid supporting structure is adopted, earth excavation is inconvenient, the constructionprogress is slow, materials are wasted, and the cost is high.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Underwater construction method suitable for repairing large-scale water delivery channels without stopping water

ActiveCN110541397BDoes not affect water delivery capacityFull benefitMechanical machines/dredgersArtificial water canalsMarine engineeringWater flow

The invention discloses an underwater construction method suitable for repairing large-scale water delivery channels without stopping water. The first step is to set up an underwater steel fence to enclose the repair area to form a still water area, so that the inside and outside of the steel fence The water pressure is balanced and the water flow is still; the second step, underwater soil excavation: in the still water area enclosed by the steel fence, use the underwater excavation device to excavate the repair area from bottom to top along the slope ; After the excavation of a repair station is completed, move the underwater excavation device to another repair station for excavation until the repair area is completely excavated; the third step, in the repair area after excavation Inside, the underwater restoration is done by pouring underwater formwork concrete or / and underwater non-dispersible concrete. The invention adopts the assembled steel enclosure to form the still water area, which reduces the difficulty of underwater construction and avoids the pollution of the water quality of the channel by the underwater construction. The underwater excavation mechanical device greatly improves the efficiency and accuracy of underwater soil excavation, and reduces the difficulty of underwater soil excavation.

Owner:中国南水北调集团中线有限公司 +2

Construction Technology of Tunnel Type Pile Foundation with Super Large Section and Large Dip Angle

ActiveCN105970992BThe process steps are simpleReasonable designFoundation engineeringReinforced concreteRebar

The invention discloses a construction technology of super large section and large inclination tunnel type pile foundation. The pile foundation to be constructed is a reinforced concrete pile, and the pile hole of the reinforced concrete pile is a super large section and large inclination angle tunnel hole; when constructing the constructed pile foundation, the steps include: : One, pile hole construction, process is as follows: 101, pipe shed advance support construction: carry out pipe shed advance support construction to pile hole top; Hole excavation construction: adopt the full-section excavation method to excavate the pile hole in multiple construction sections from top to bottom, and use the full-section support structure for support; 2. Pile body construction: the reinforcement of reinforced concrete piles The construction of the pile body includes two steps of steel cage binding and concrete pouring. The invention has the advantages of simple process steps, reasonable design, low investment cost, simple construction, good use effect, simple and rapid completion of the construction process of the tunnel type pile foundation, and the construction process is easy to control.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

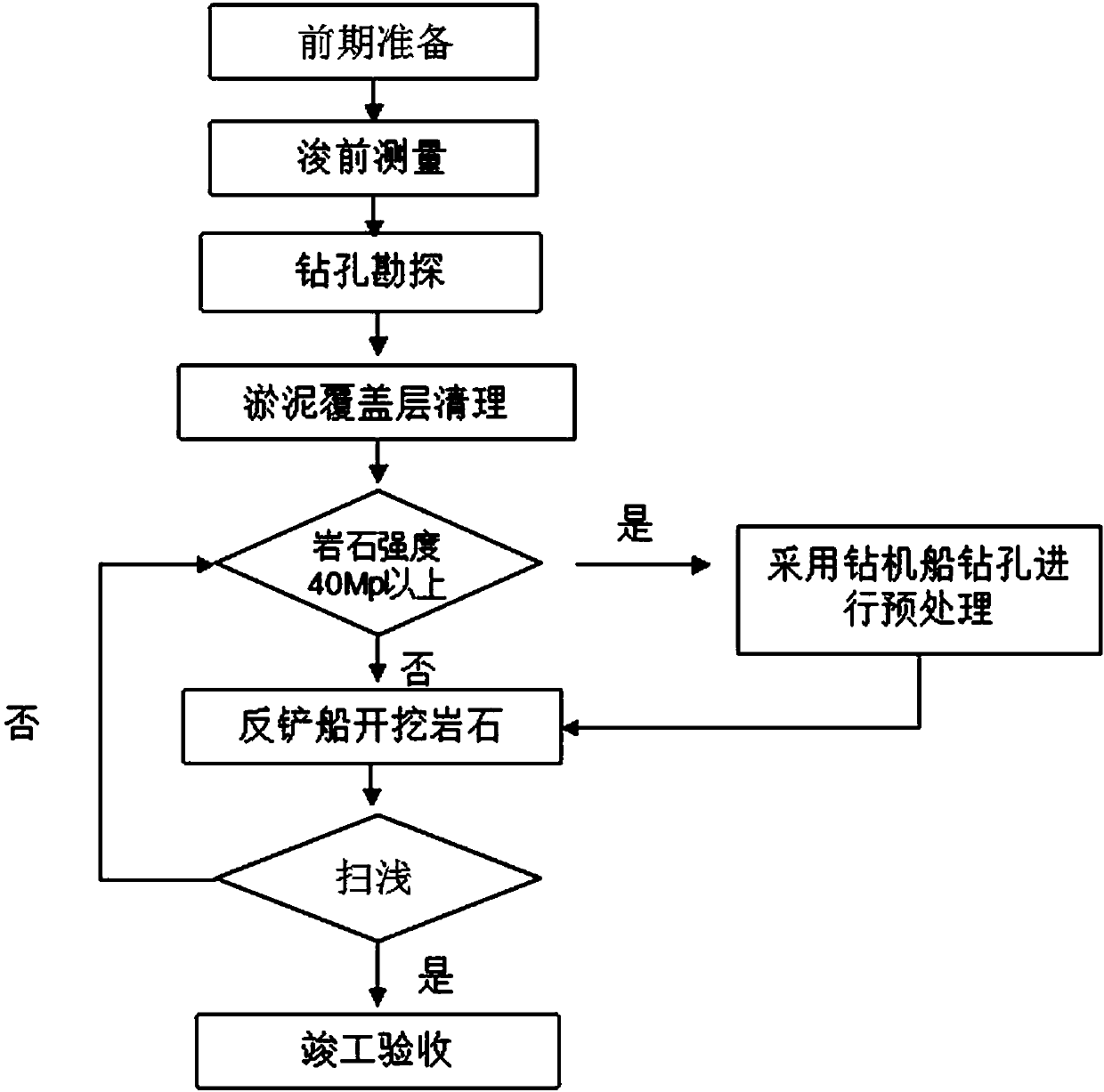

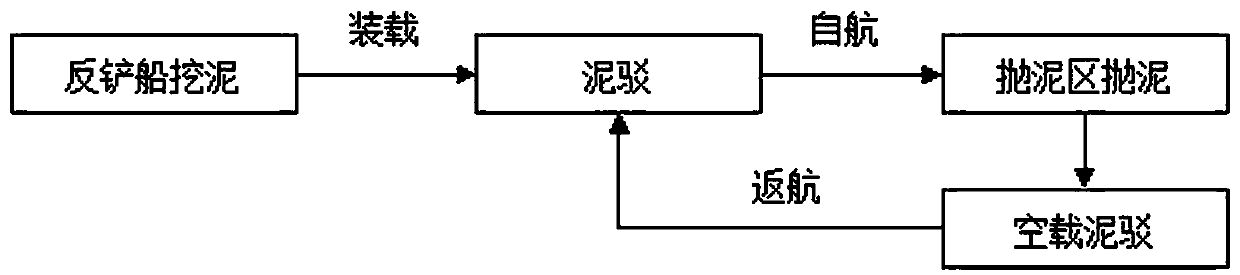

A joint rock excavation construction method of a backhoe dredger and a drilling rig ship

ActiveCN105421286BAvoid the influence of surrounding rocksIncrease Difficulty of DiggingSoil-shifting machines/dredgersStream regulationEcological environmentSludge

The invention discloses a combined rock excavation construction method using a backhoe dredger and a drill ship. The combined rock excavation construction method is characterized by comprising the following steps of making early-stage preparations for construction, making a scheme, cleaning away a sludge covering layer, conducting drilling treatment, excavating rock through the backhoe dredger, conducting shallow spot dredging and conducting inspection and acceptance when a project is completed. According to the combined rock excavation construction method, the requirement for fairway construction is met, the influence on the ecological environment is also reduced, construction efficiency is improved, potential safety hazards are reduced, the national sustainable development strategy is satisfied, and the popularization range is broad.

Owner:中交天航南方交通建设有限公司 +5

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com