Shield contact channel excavating device

A technology for connecting passages and shields, which is applied in mining equipment, tunnels, earth-moving drilling, etc., can solve problems such as hidden safety hazards, low work efficiency, slow construction progress, etc., to reduce construction costs, soil improvement, and tunneling. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

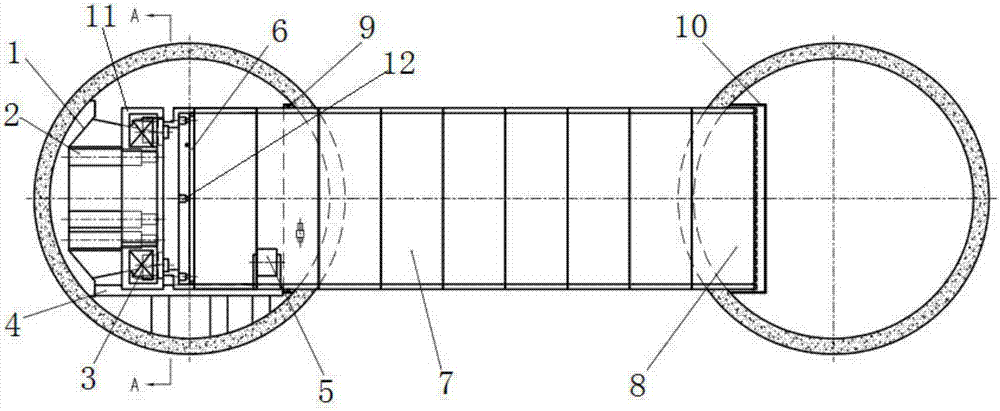

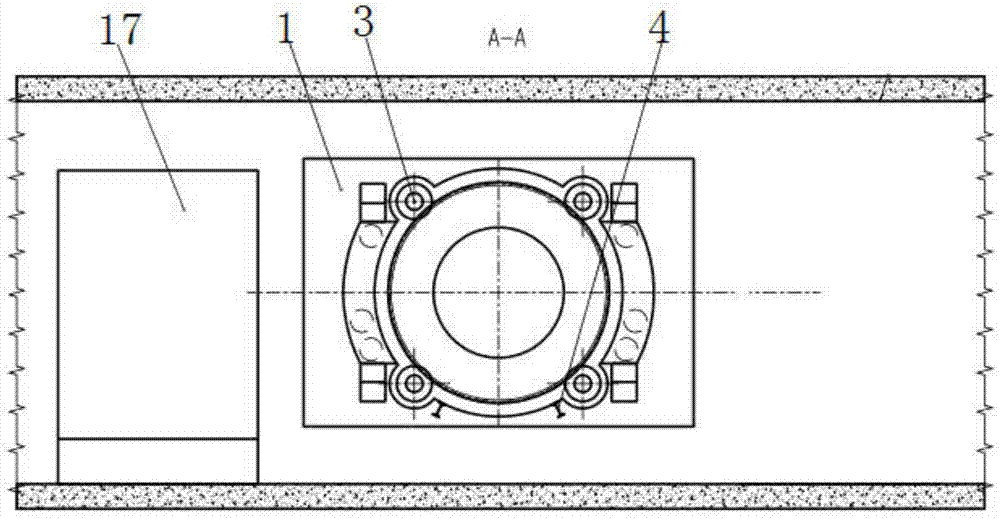

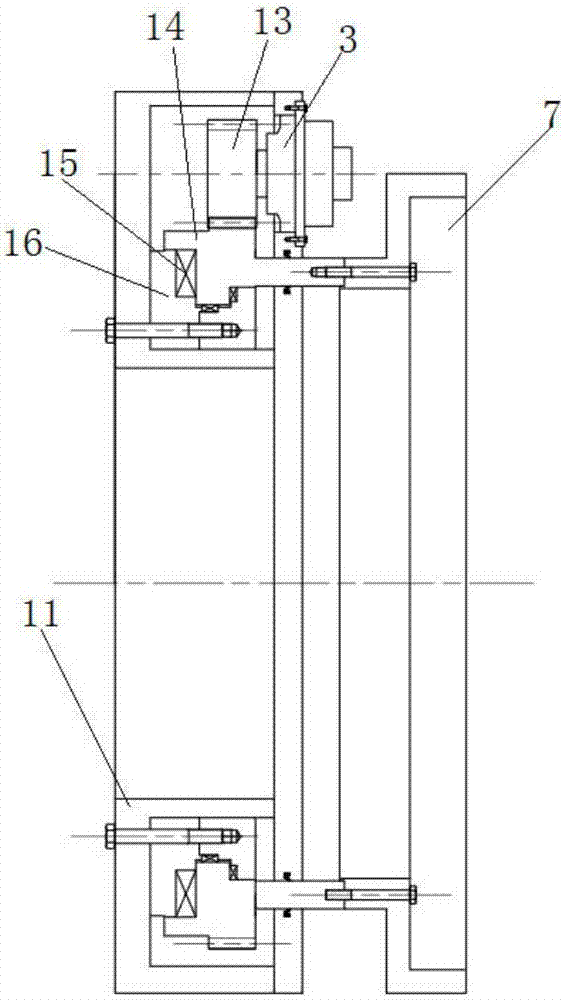

[0018] Such as figure 1 As shown, the present invention includes: a support base 1 installed on the tunnel wall, a plurality of propulsion cylinders 2 vertically installed on the support base 1 along the excavation direction, the piston rod head of the propulsion cylinder 2 is connected with the mounting seat 11, and the mounting seat 11 is a cylindrical shape, and a shaft 16 is installed axially along the mounting seat 11 and is concentric with the mounting seat 11. A bearing 15 is installed on the shaft 16, and a driven gear 14 is installed on the bearing 15. The driven gear 14 is connected to the driving device 3 The driving gear 13 is meshed, the driven gear 14 is connected with the steel pipe ring 7 by bolts, and the steel pipe ring 7 and the mounting seat 11 are seated on the guide rail 4 along the excavation direction, and the guide rail 4 is laid along the exca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com