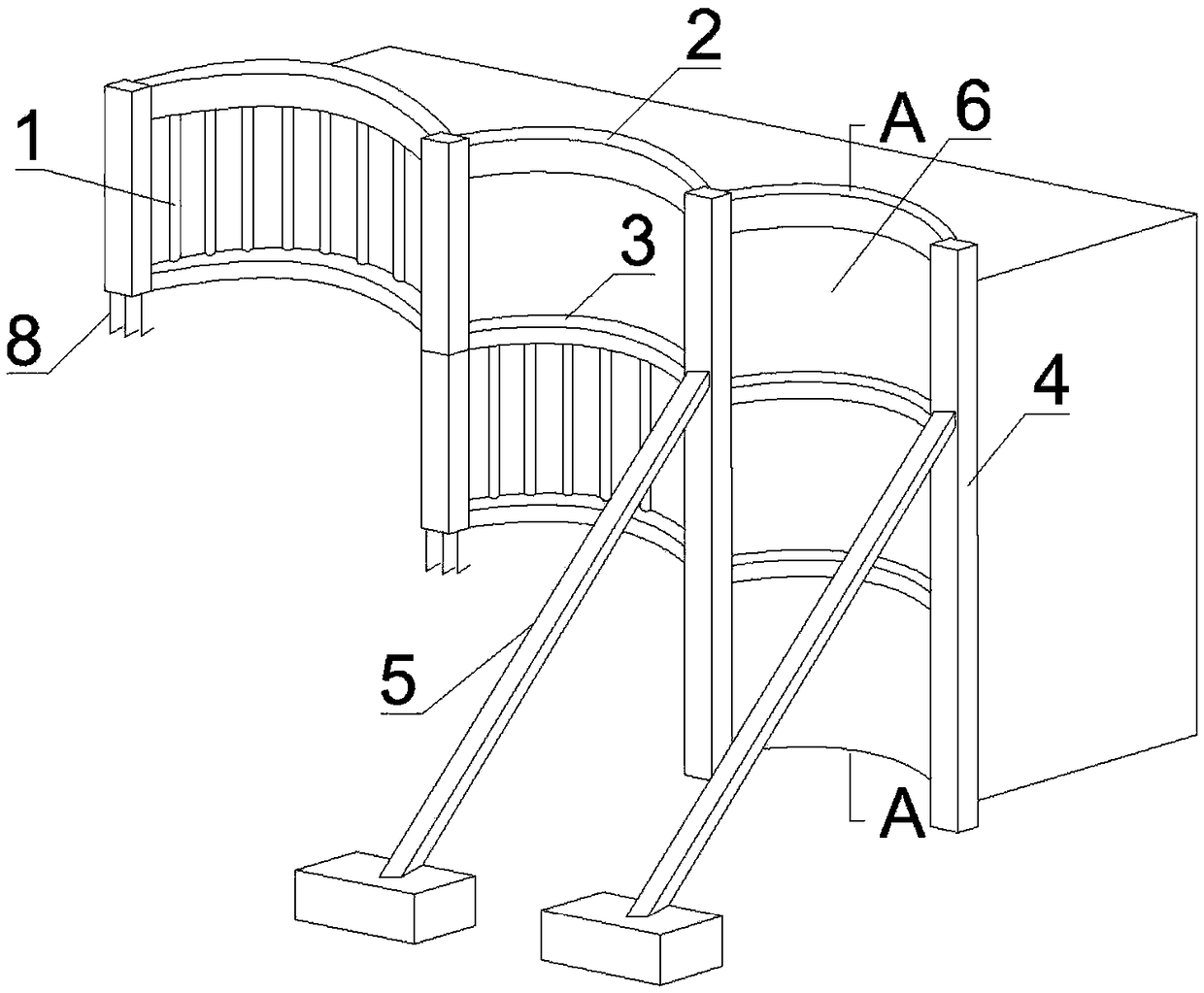

Horizontal-type supporting method for foundation pit of arch shell

A technology of foundation pit support and arch shell foundation, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of dense support spacing and low excavation efficiency, and achieves the advantages of easy quality, reduced excavation difficulty and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

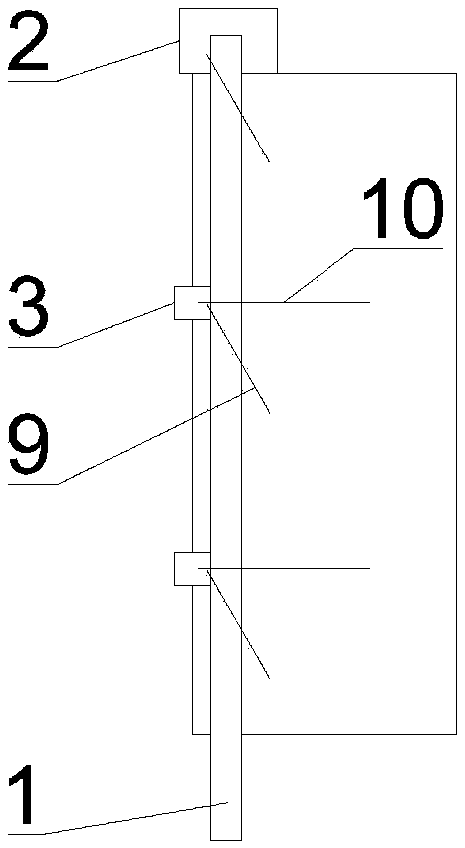

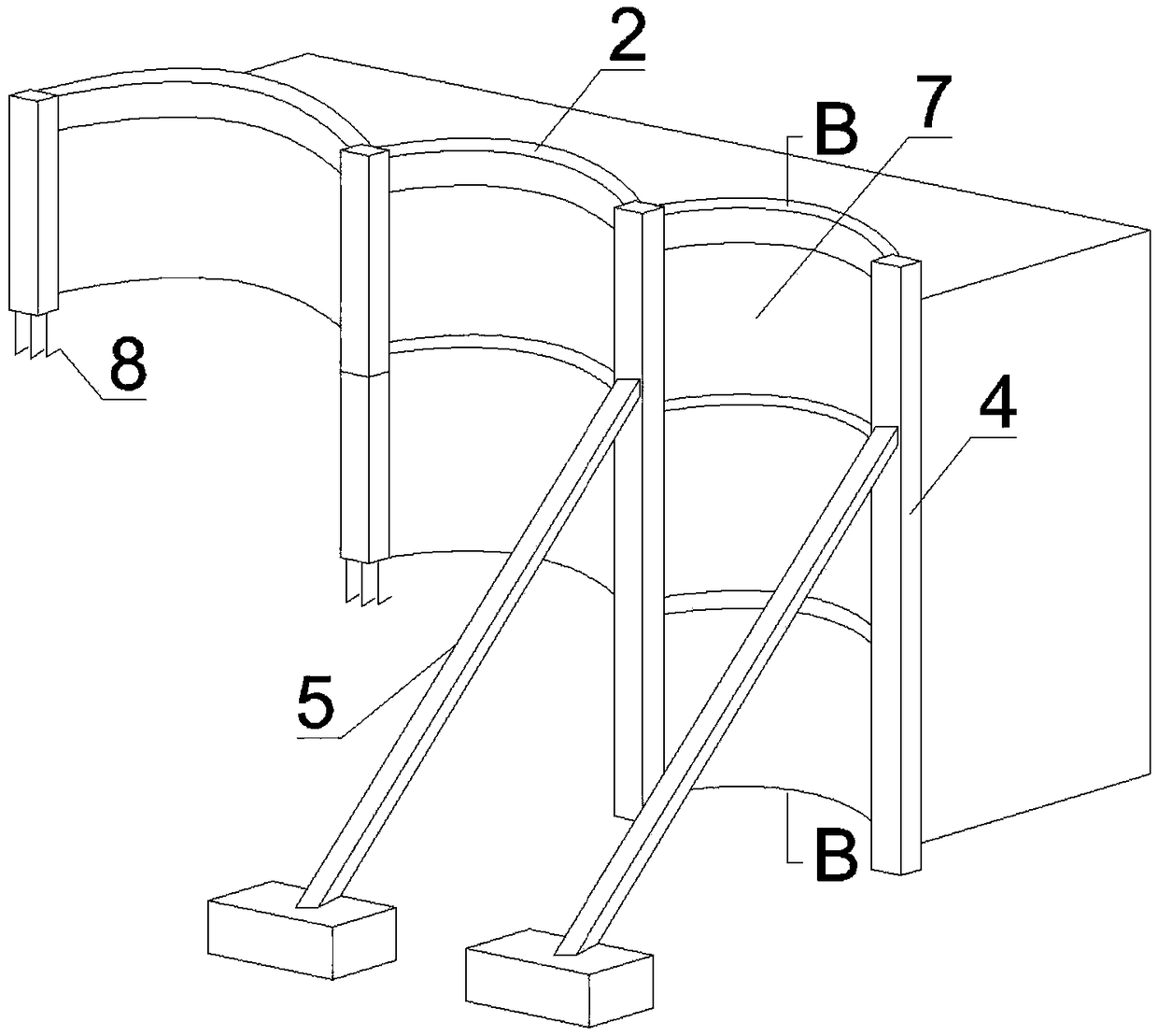

[0077] refer to image 3 and Figure 4 , the support method in this embodiment is similar to that in the first embodiment, the main difference is that the arch beam 3 in the first embodiment is replaced by a reinforced concrete upside-down arch slab 7 poured in layers from top to bottom. The head of the vertical anchor pipe 9 and the head of the horizontal anchor pipe 10 are all anchored in the corresponding upside-down arch 7 .

[0078] That is, the arch beam 3 constructed on each floor is replaced with an upside-down arch slab 7, so that the protective panel 6 can no longer be constructed. The thickness of the 7 floors of the upside-down arch slabs is greater than that of the upside-down arch slab 7 on the upper floor, which constitutes a downwardly extending ladder shape, which is helpful for construction. At the same time, it is equivalent to providing a gravity wall, which can effectively improve the foundation For the strength of the pit support, after the two ends of ...

Embodiment 3

[0081] In this embodiment, the construction steps are similar to Embodiment 1, the main difference is that the support assembly 5 has the original diagonal bracing replaced with a symmetrical During construction, it is only necessary to mirror the same support structure on both sides of the foundation pit with respect to the center of the foundation pit, and the whole pier 4 on both sides shares the same support assembly 5, so that the support structure can be greatly reduced. cost, and the support frame can be constructed synchronously after the construction pier of each excavation layer is completed. Reduce support costs.

[0082] It can be seen from the above examples that the horizontal arch shell foundation pit support method provided by the present invention has changed the disadvantages of using dense support in the traditional pile wall support, effectively improved the support span, and the arch shell type support The support structure can greatly improve the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com