Patents

Literature

32results about How to "Reduce the number of supports" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

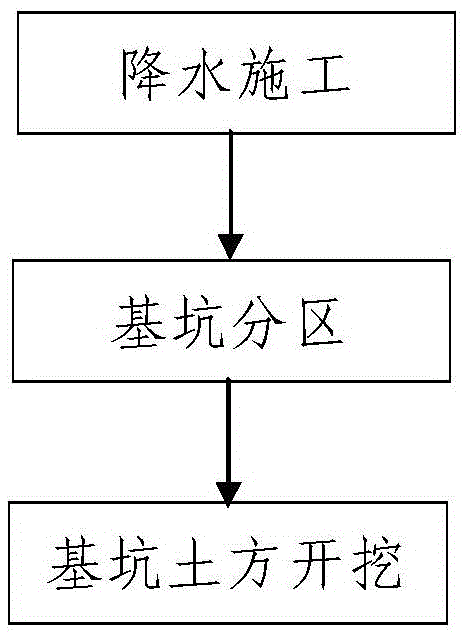

Subway station deep foundation pit excavation construction method

ActiveCN104612162AThe method steps are simpleReasonable designExcavationsReinforced concreteSubway station

The invention discloses a subway station deep foundation pit excavation construction method, wherein the upper portion of an excavated foundation pit is a sandy gravel stratum, and the lower portion of the excavated foundation pit is a mud rock stratum. The method includes the steps of 1, precipitation construction, wherein precipitation construction is conducted on the sandy gravel stratum through a precipitation well and 2, foundation pit excavation, wherein the foundation pit excavation includes the following steps of foundation pit partition and foundation pit earthwork excavation; the excavated foundation pit is divided into a plurality of small foundation pit bodies to conduct excavation respectively; the small foundation pits comprise first foundation pit bodies and second foundation pit bodies; excavation is conducted on the divided small foundation pit bodies; an open-cut method is adopted for the first foundation pit bodies and the second foundation pit bodies; the first foundation pit bodies are supported by fender posts, reinforced concrete supports and steel pipe inner supports; the second foundation pit bodies are supported by the fender posts, pre-stressed anchor cables and the steel pipe inner supports. The subway station deep foundation pit excavation construction method is simple in step, reasonable in design, convenient to construct, faster in construction process, good in construction effect and capable of easily conveniently and fast to finish deep foundation pit excavation construction process, and the influences on the surrounding environment by the excavation construction process are smaller.

Owner:中铁二十局集团第三工程有限公司

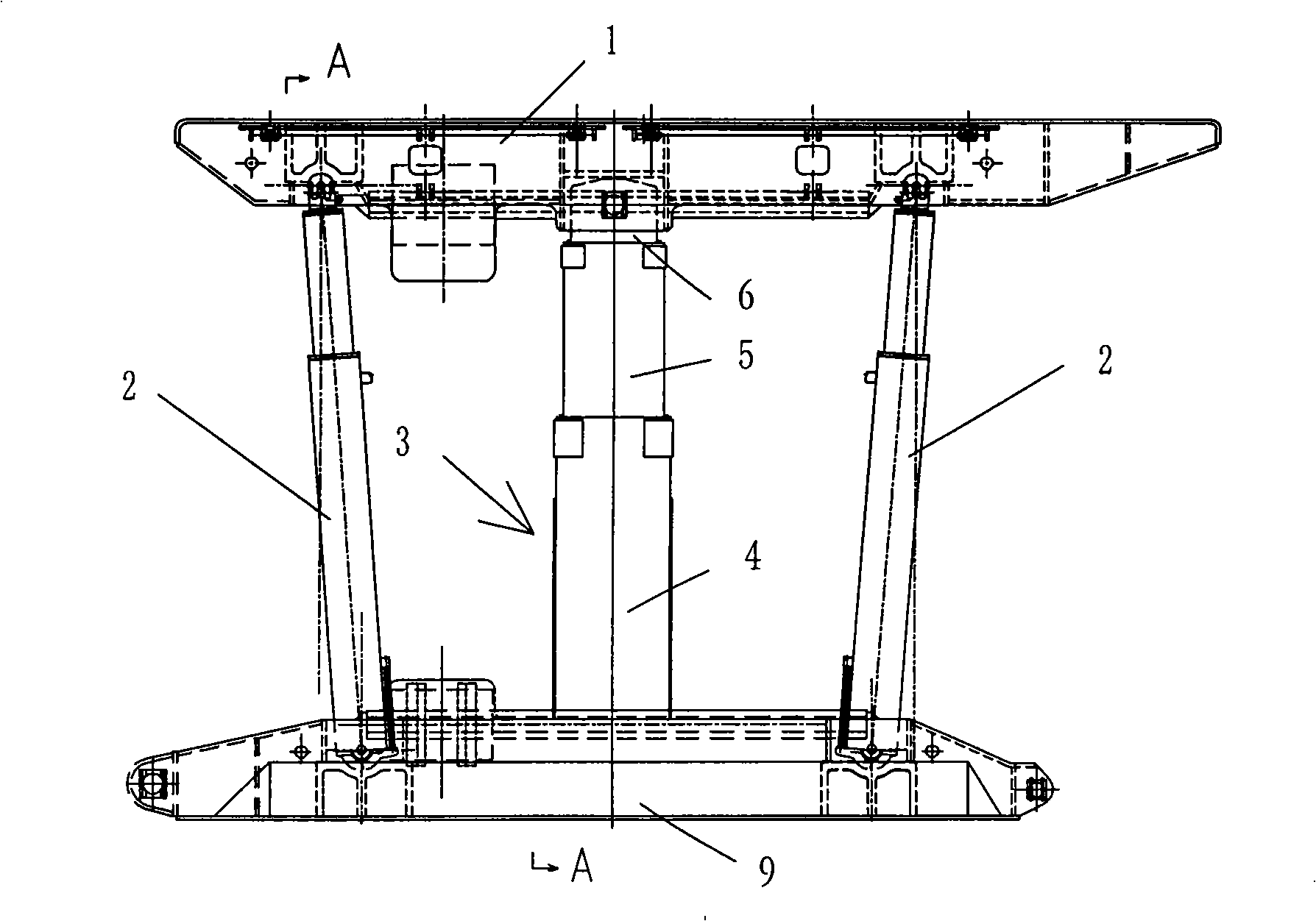

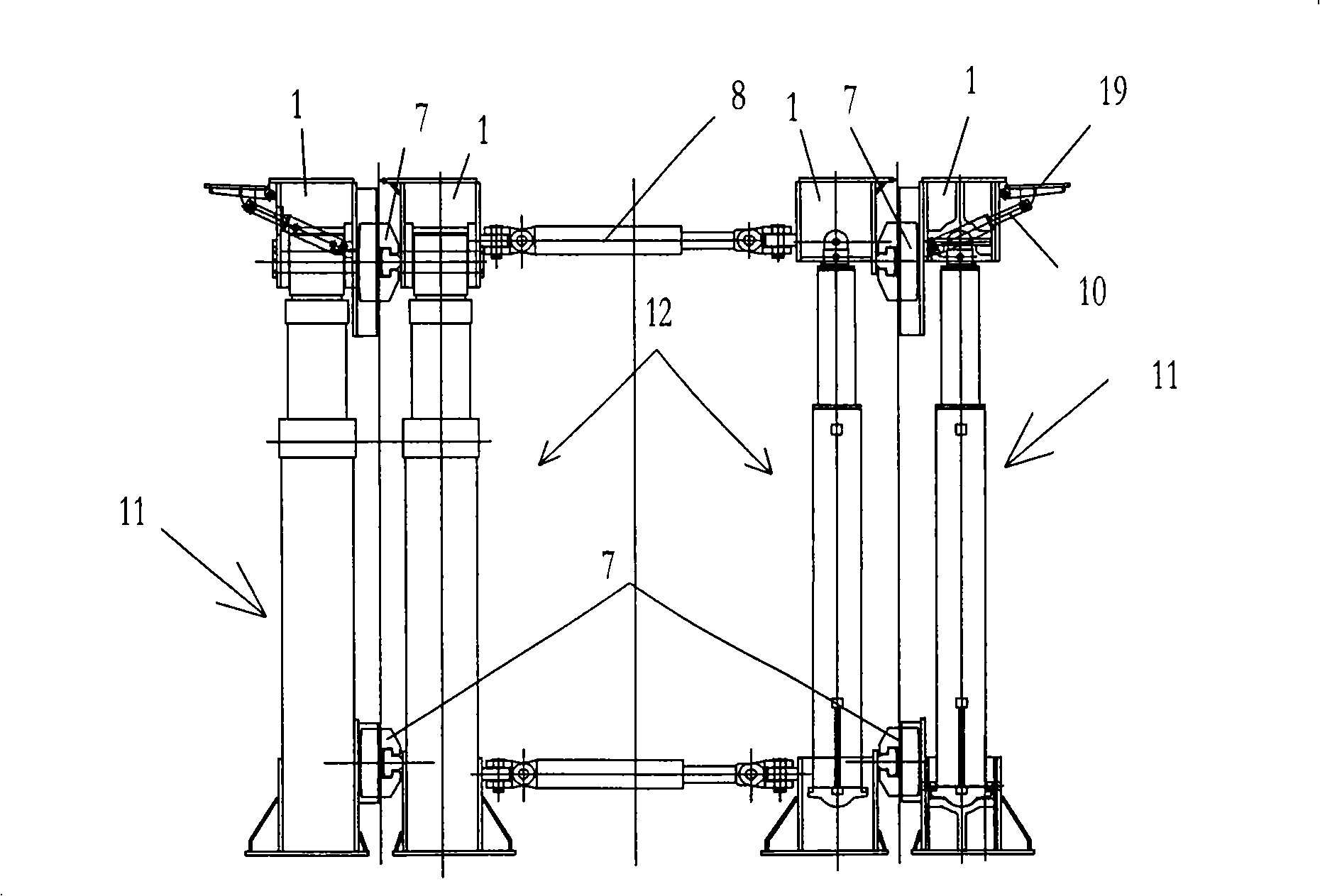

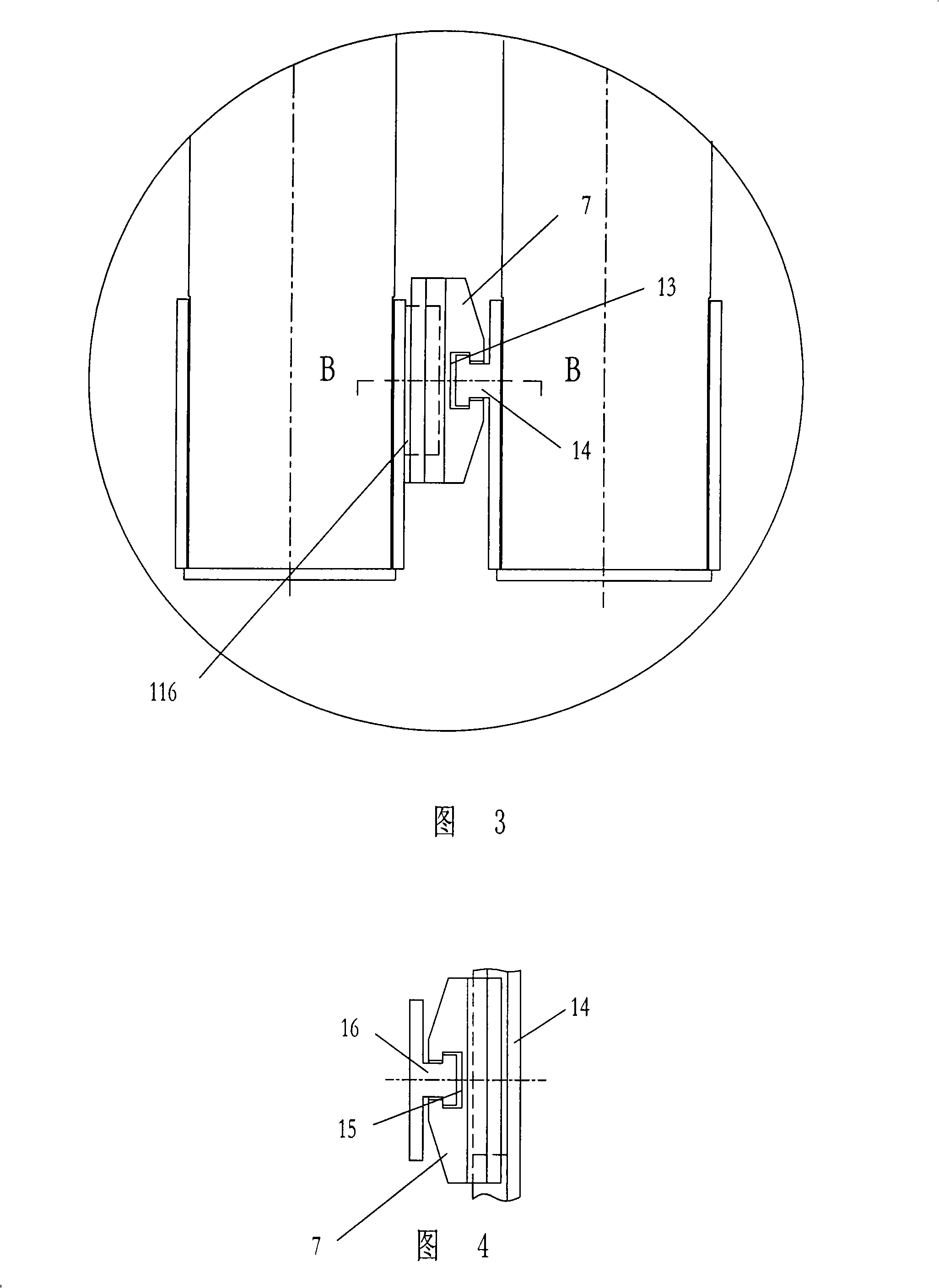

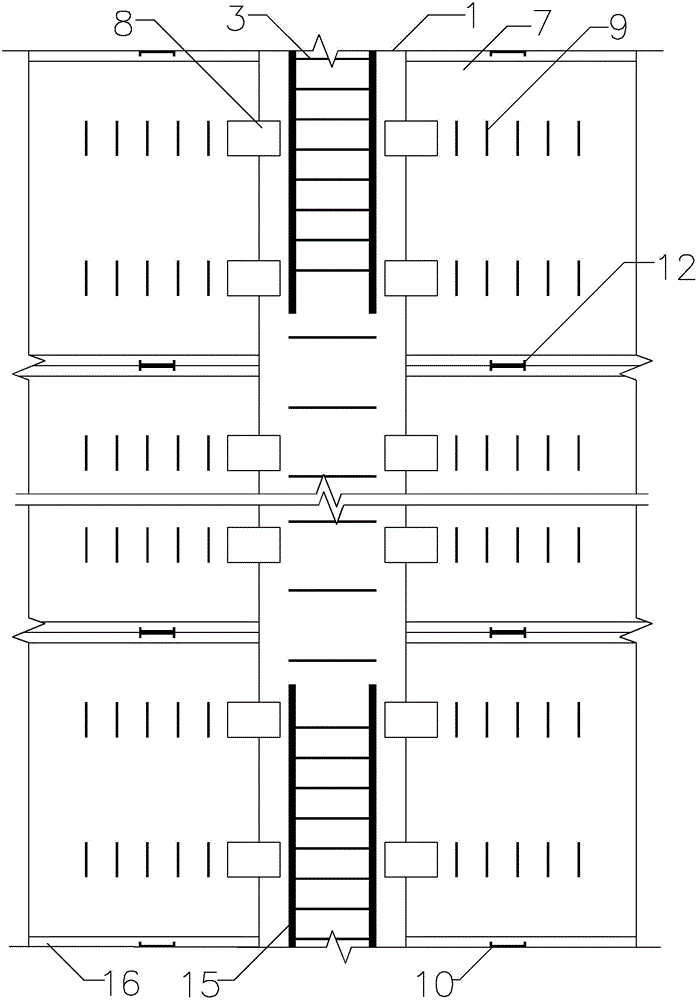

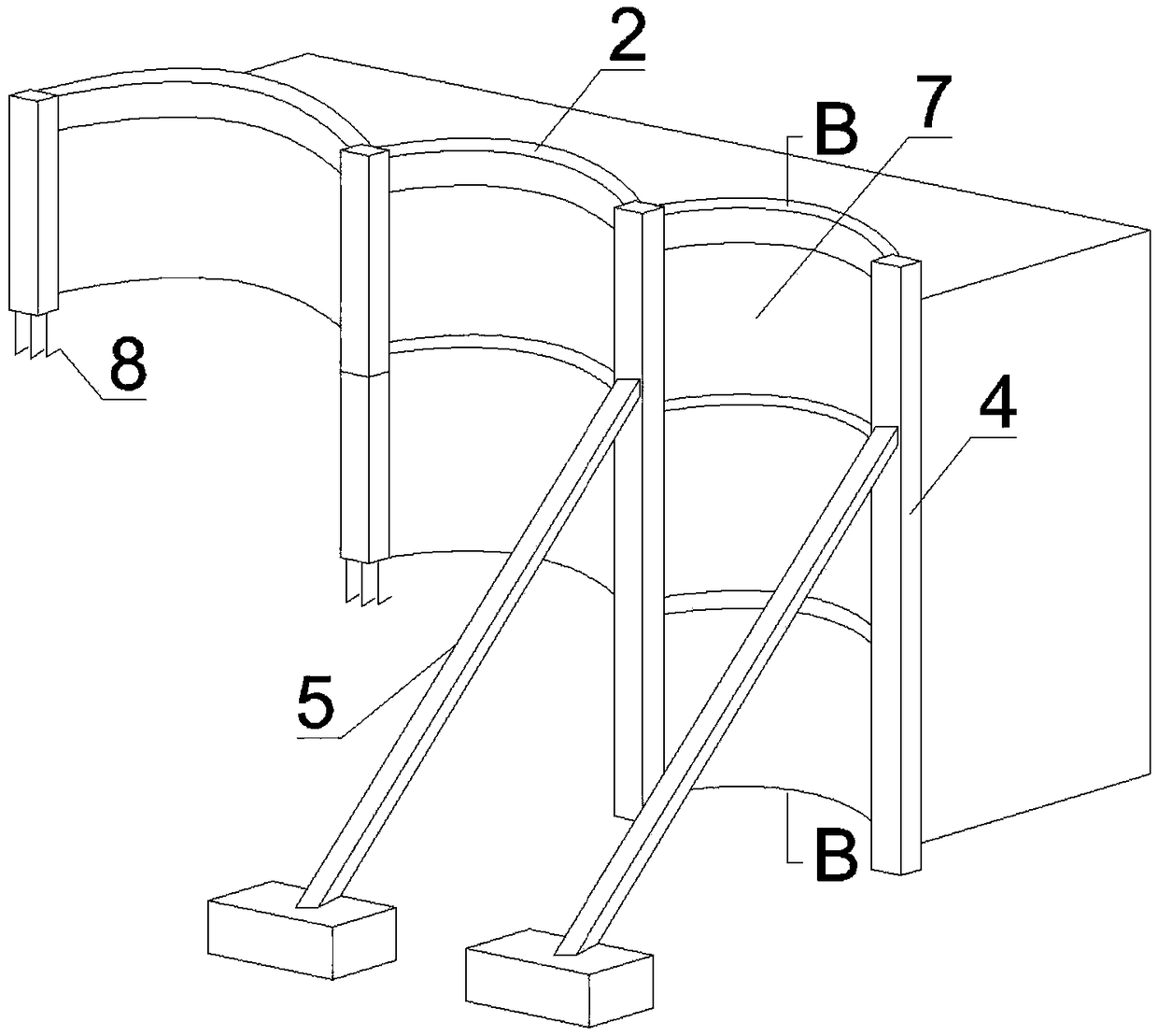

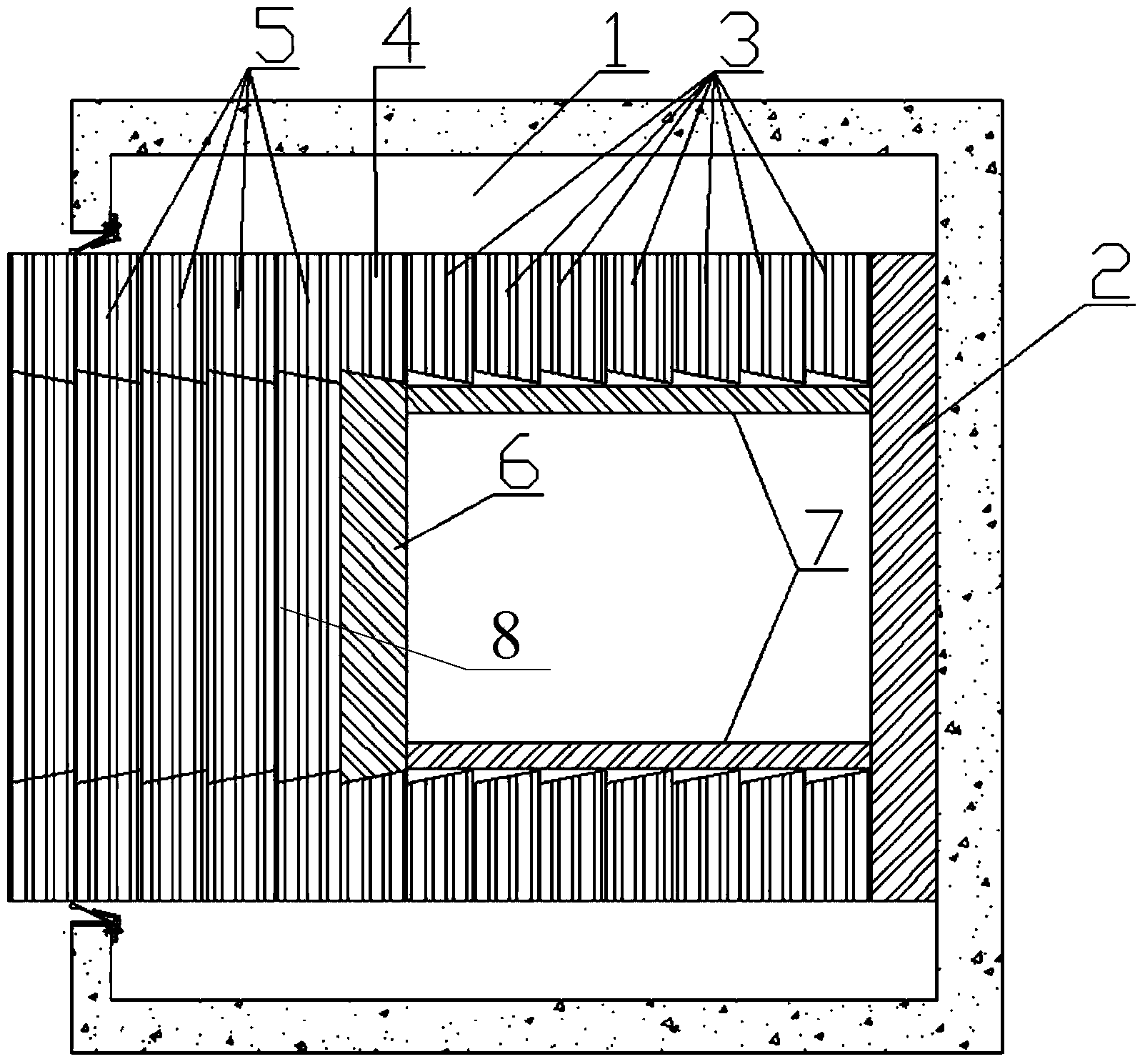

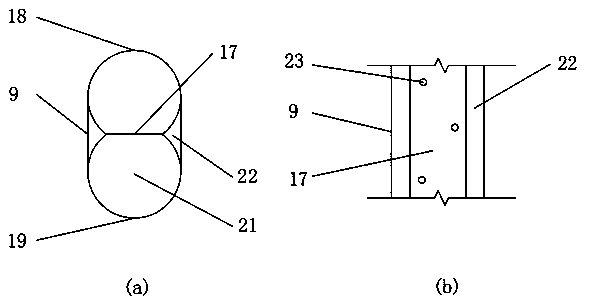

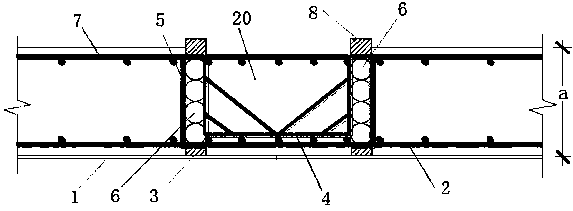

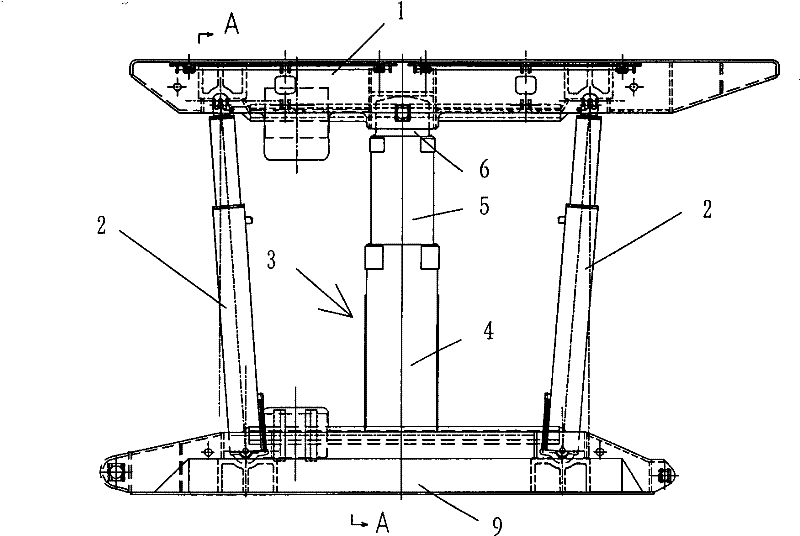

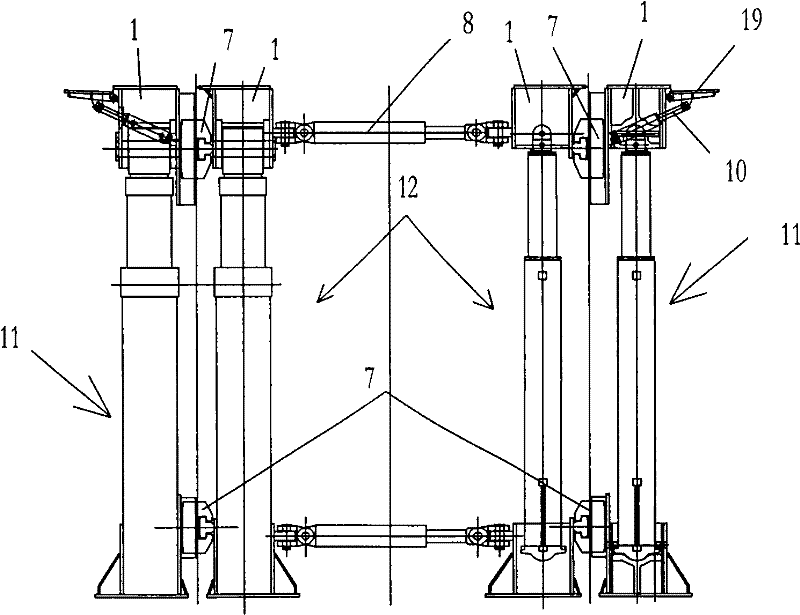

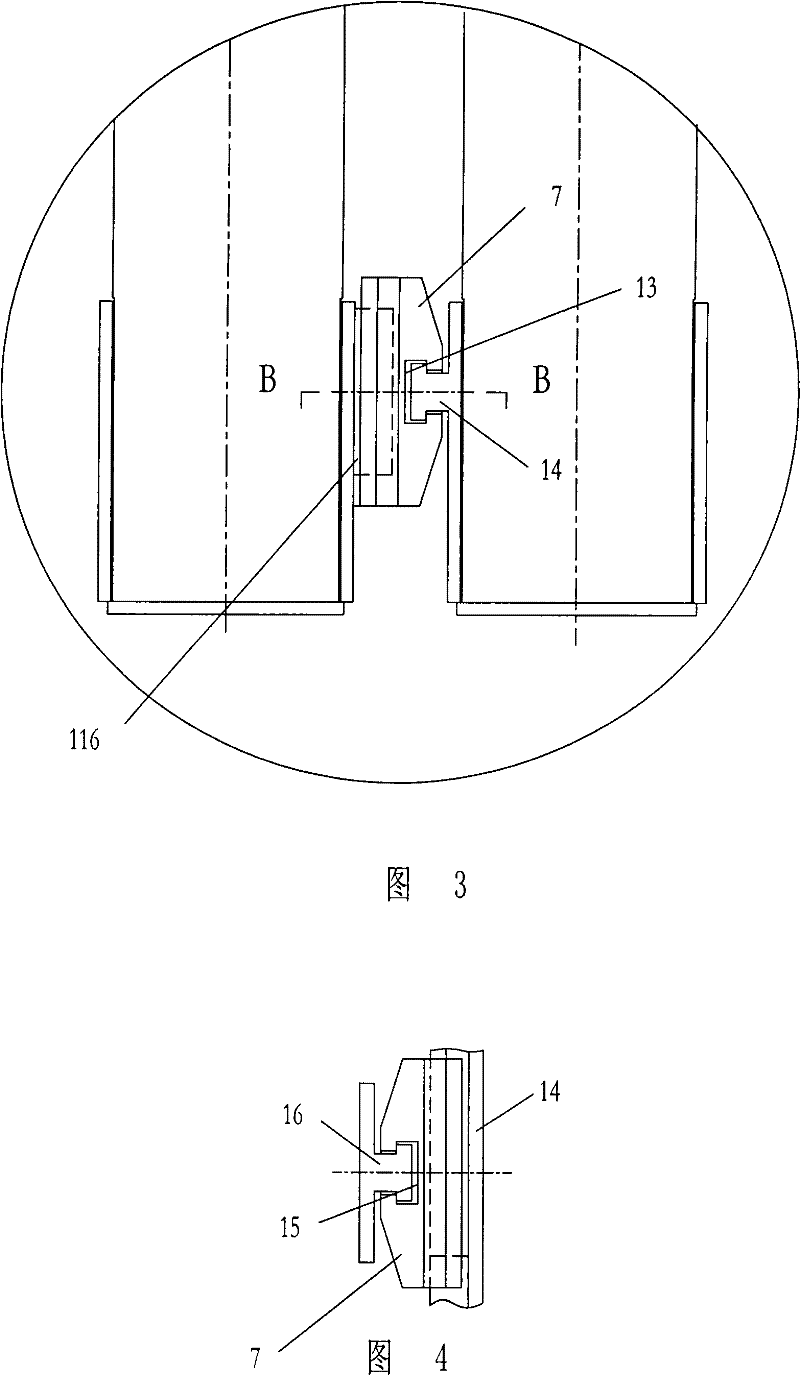

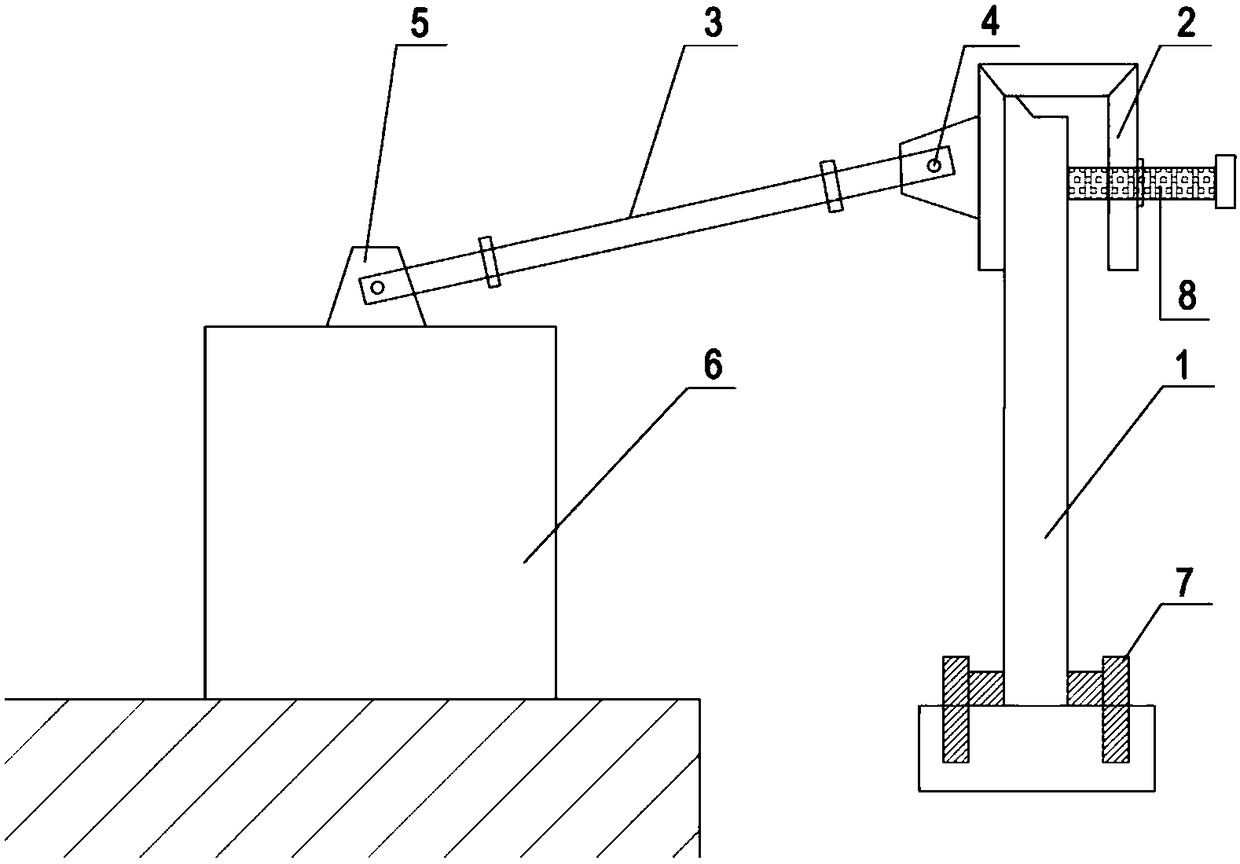

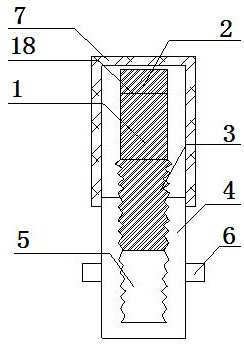

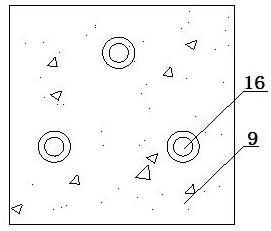

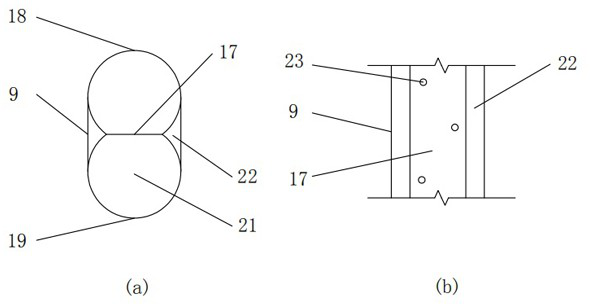

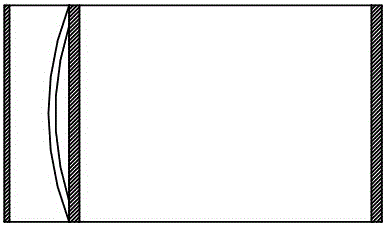

Combined guided slipping type forepoling hydraulic support

ActiveCN101338684AReduce the number of supportsNot easy to fallMine roof supportsHeadframeEngineering

The present invention provides a combined guide slippage type forepoling hydraulic bracket which comprises an internal support unit and an external support unit (12 and 11) which are symmetrical to each other at left and right. Each support unit comprises a top beam (1), a pedestal, a guide stabilizing mechanism and a hydraulic support component upright post. An upright post is articulated between the top beam and the pedestal. A telescopic link type guide stabilizing mechanism is arranged at the middle parts of the top beam and the pedestal. The outer side of the internal support unit is provided with the external support unit. Connecting slide rods (7) are respectively connected between the top beams and the pedestal beams at the same side of the adjacent internal and external support units. An inter-frame jack (8) is articulated between the top beam and the pedestal of the symmetrical internal support unit to form a section of bracket. The bracket forms an independent motor unit. The hydraulic bracket consists of a plurality of independent motor units. An advancing jack (17) is connected between the pedestals (9) of the independent motor units. The front end of the pedestal (9) of a section of bracket at the front end of the hydraulic bracket is connected with a head frame pulling and moving mechanism. The hydraulic bracket can effectively support a big section laneway and realizes the forepoling and the forepoling automatization of the big section laneway.

Owner:TIANDI SCI & TECH CO LTD

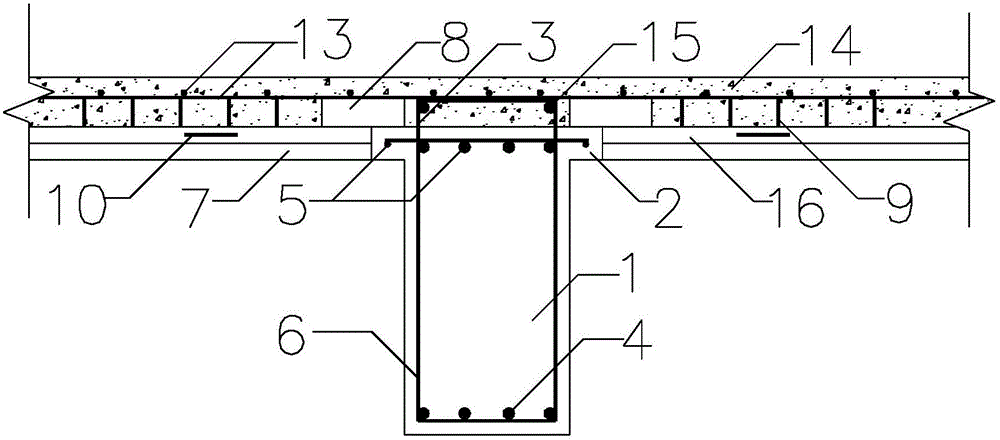

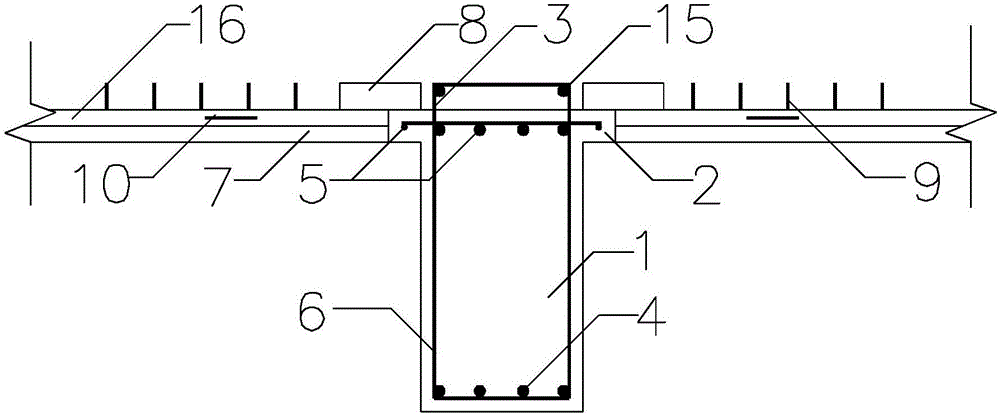

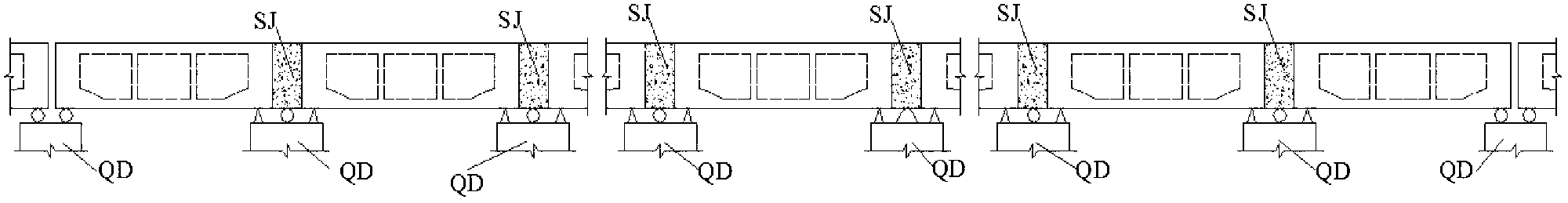

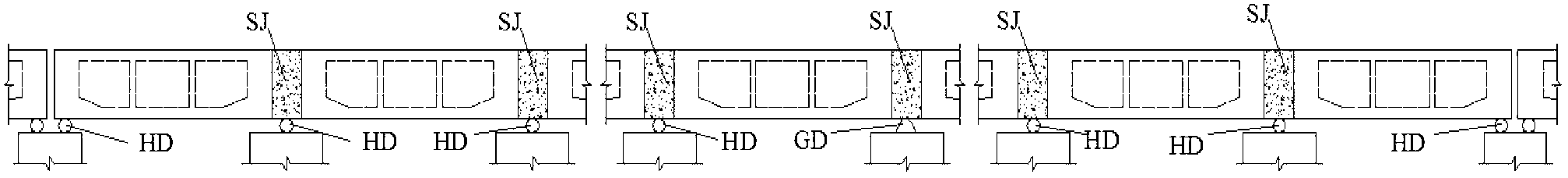

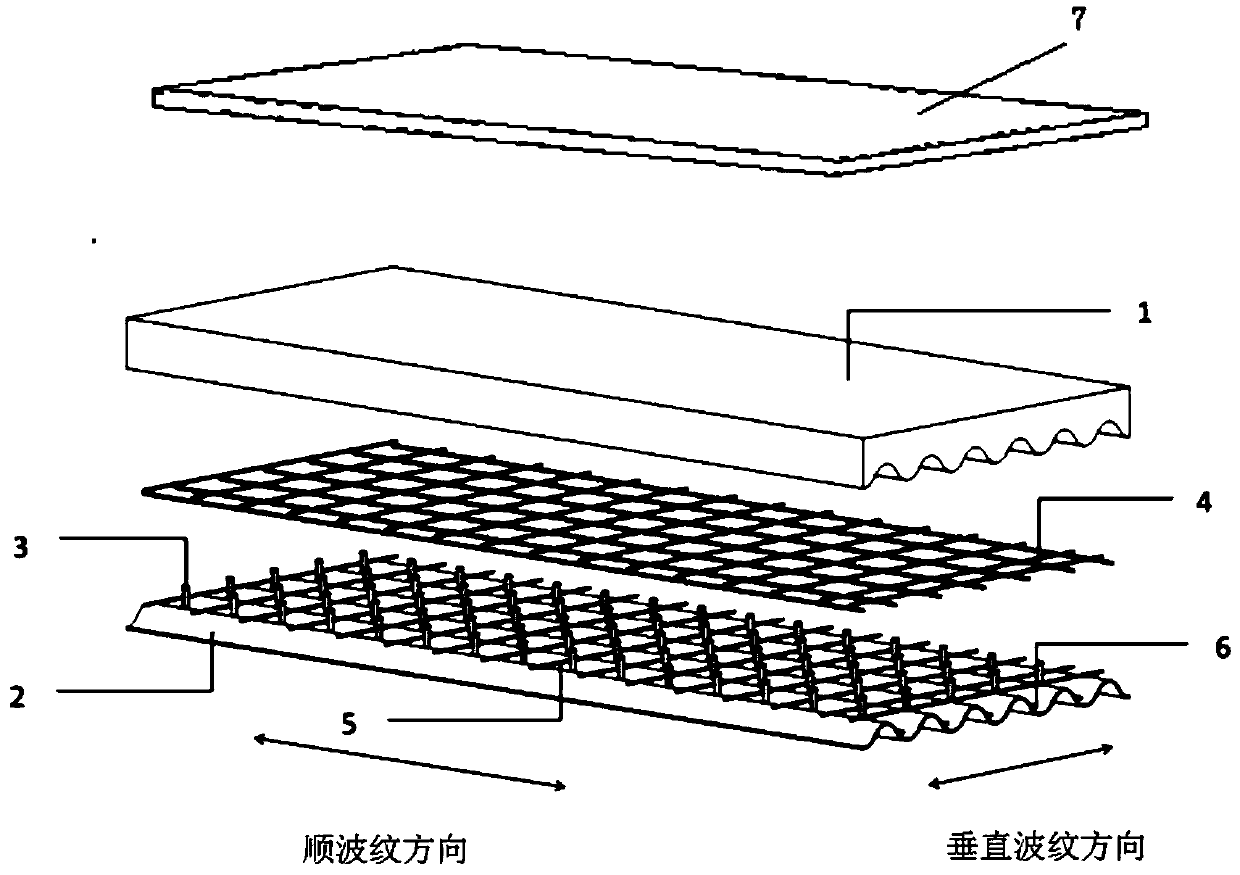

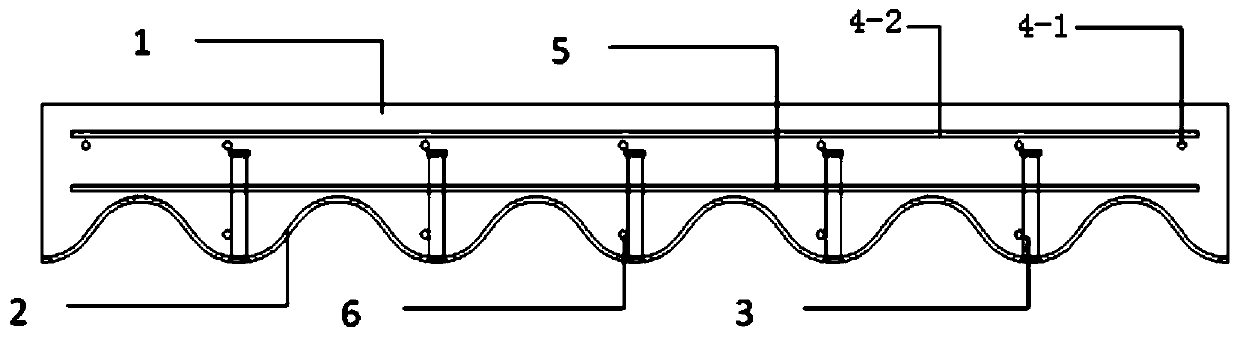

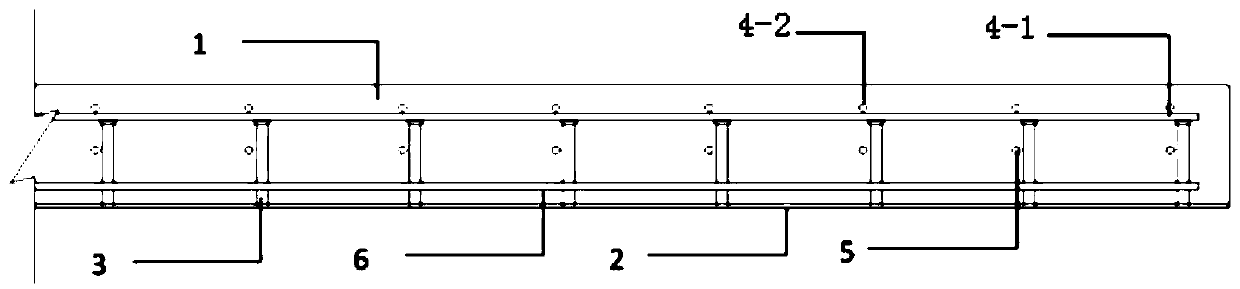

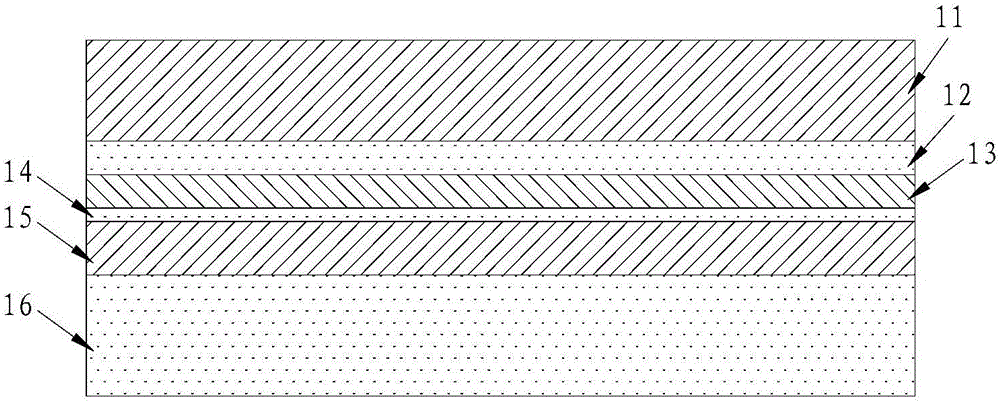

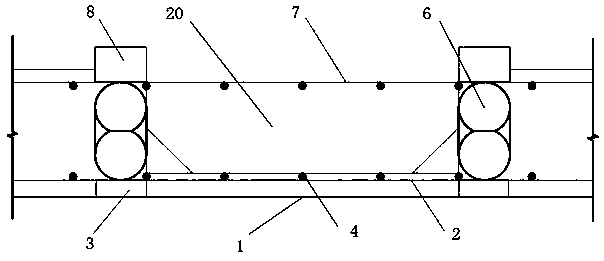

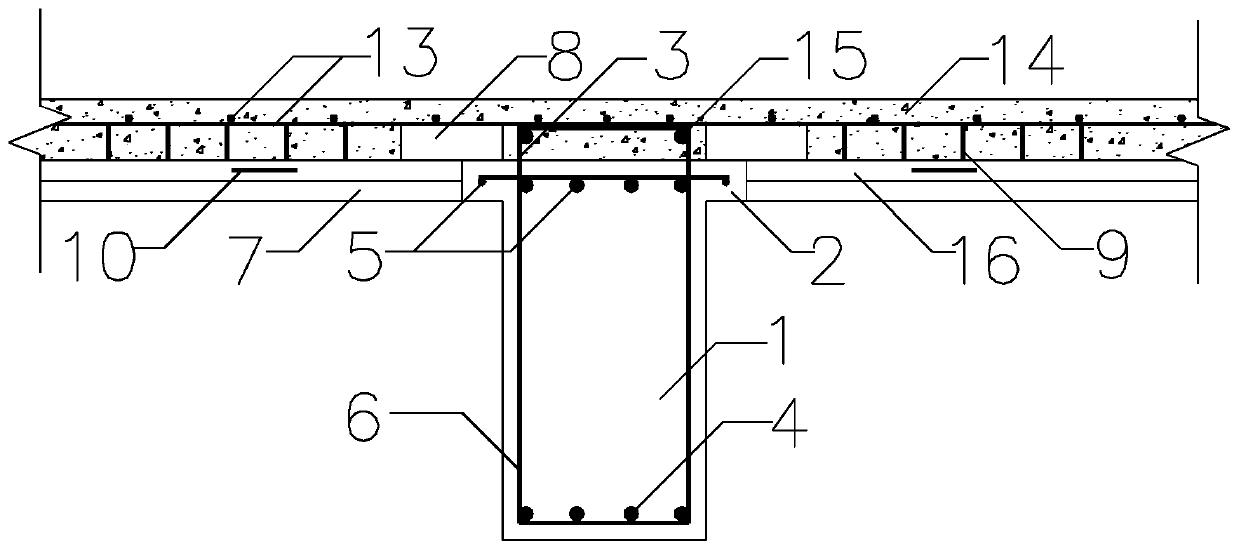

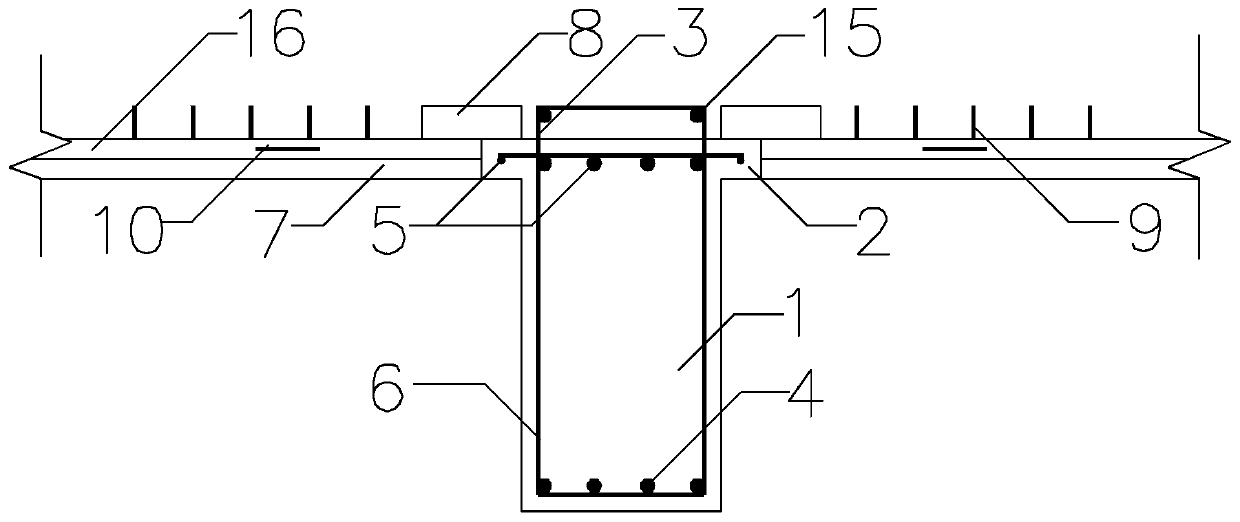

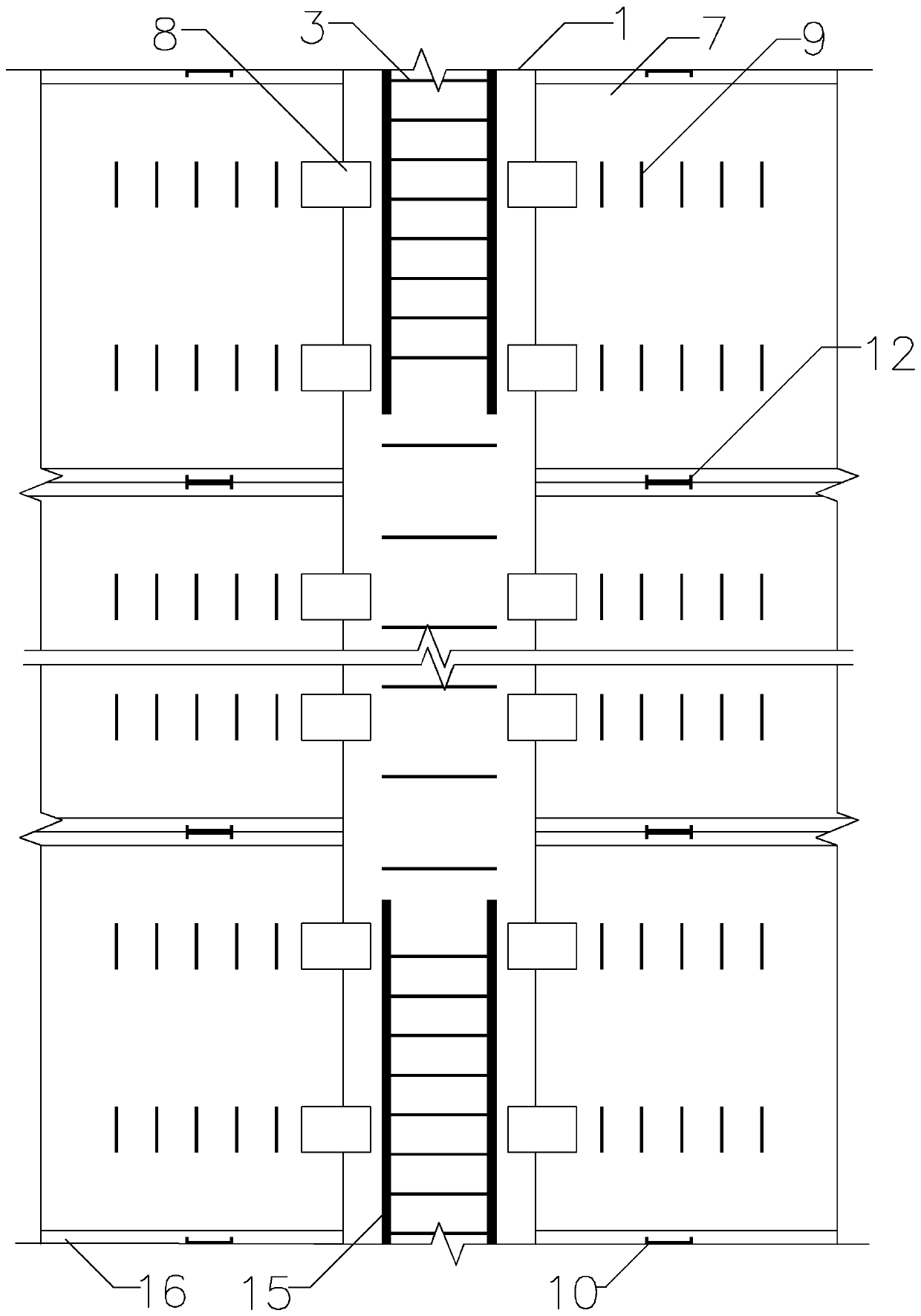

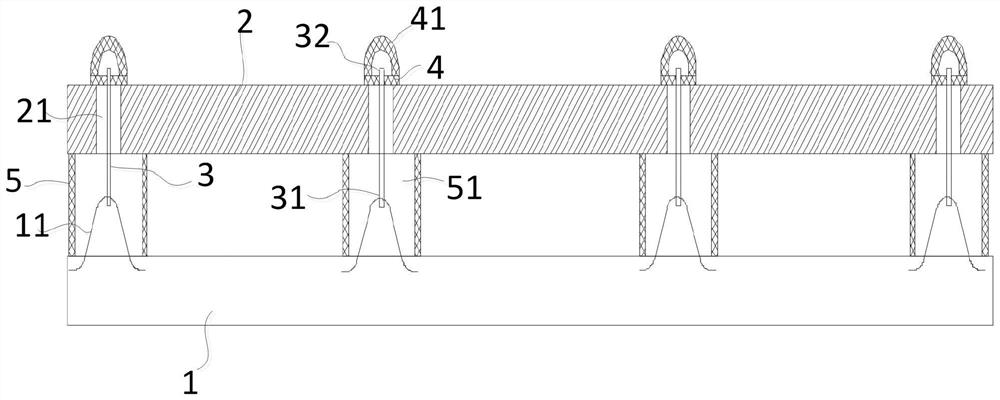

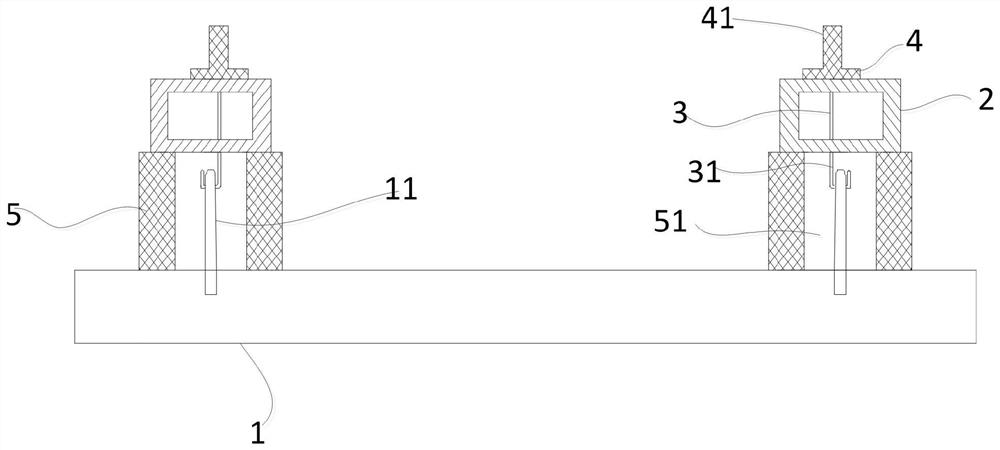

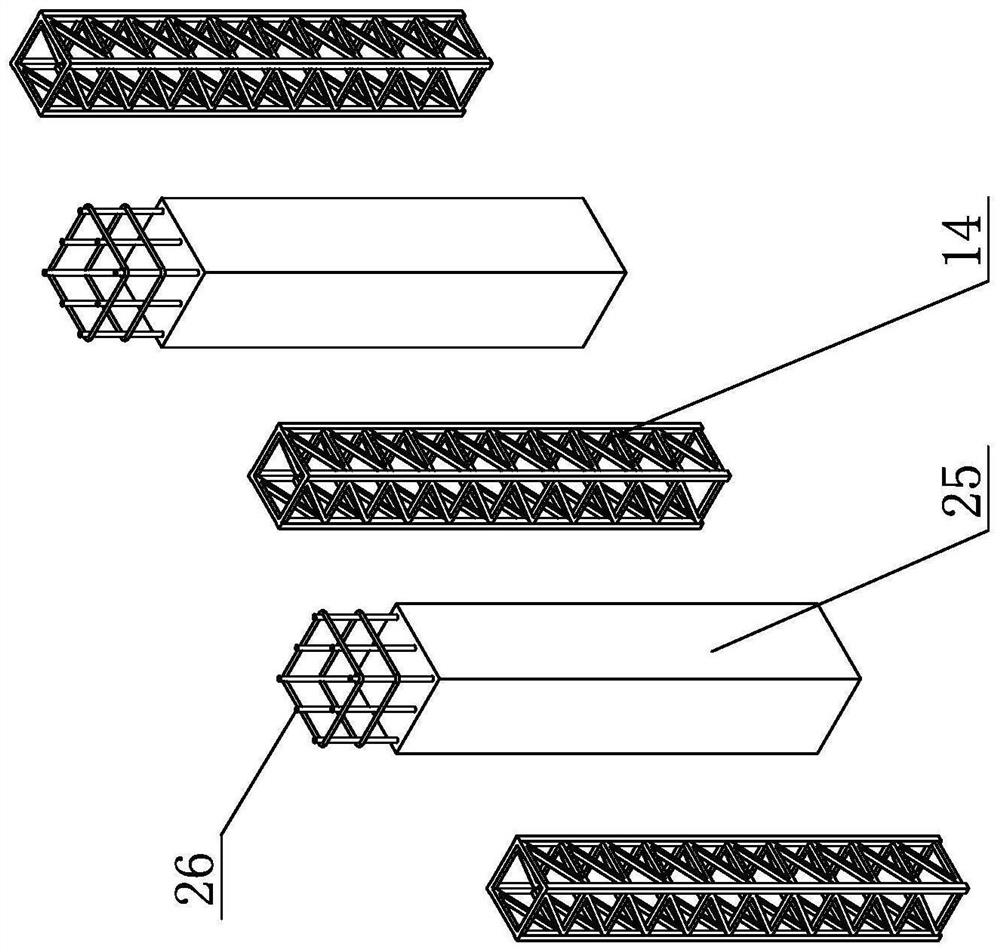

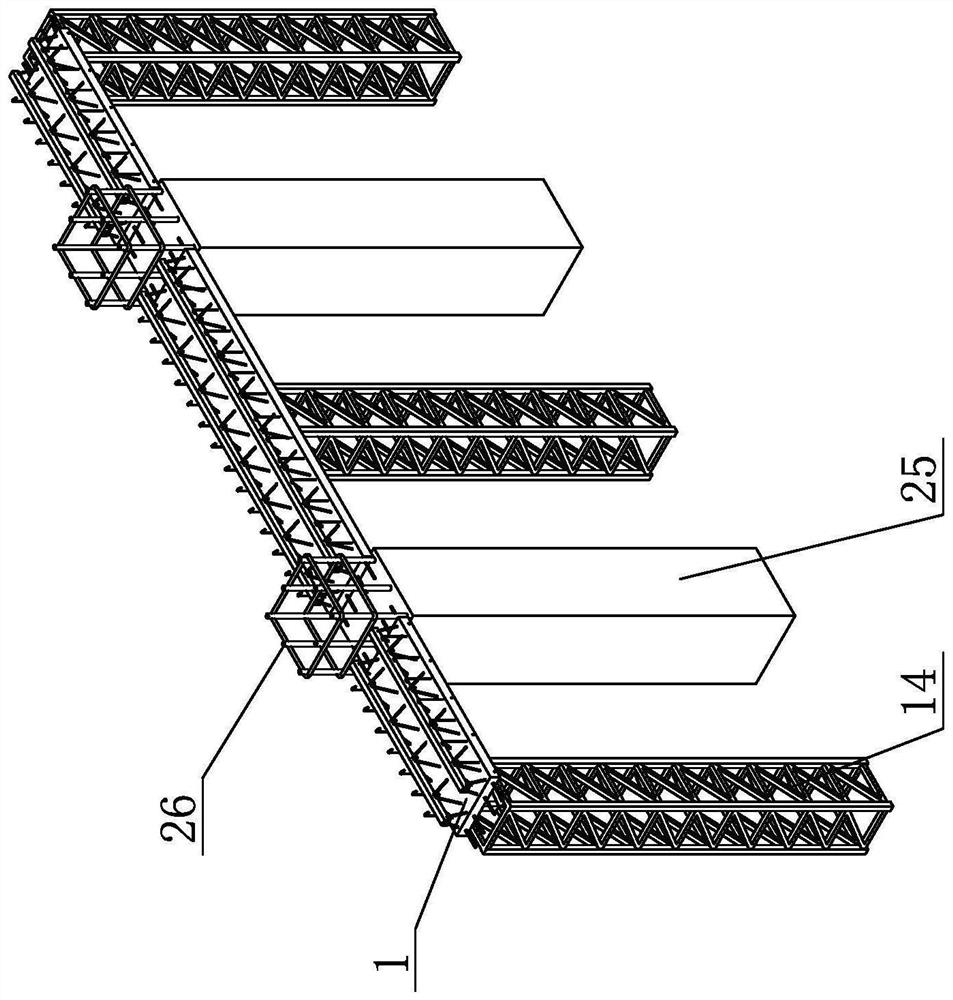

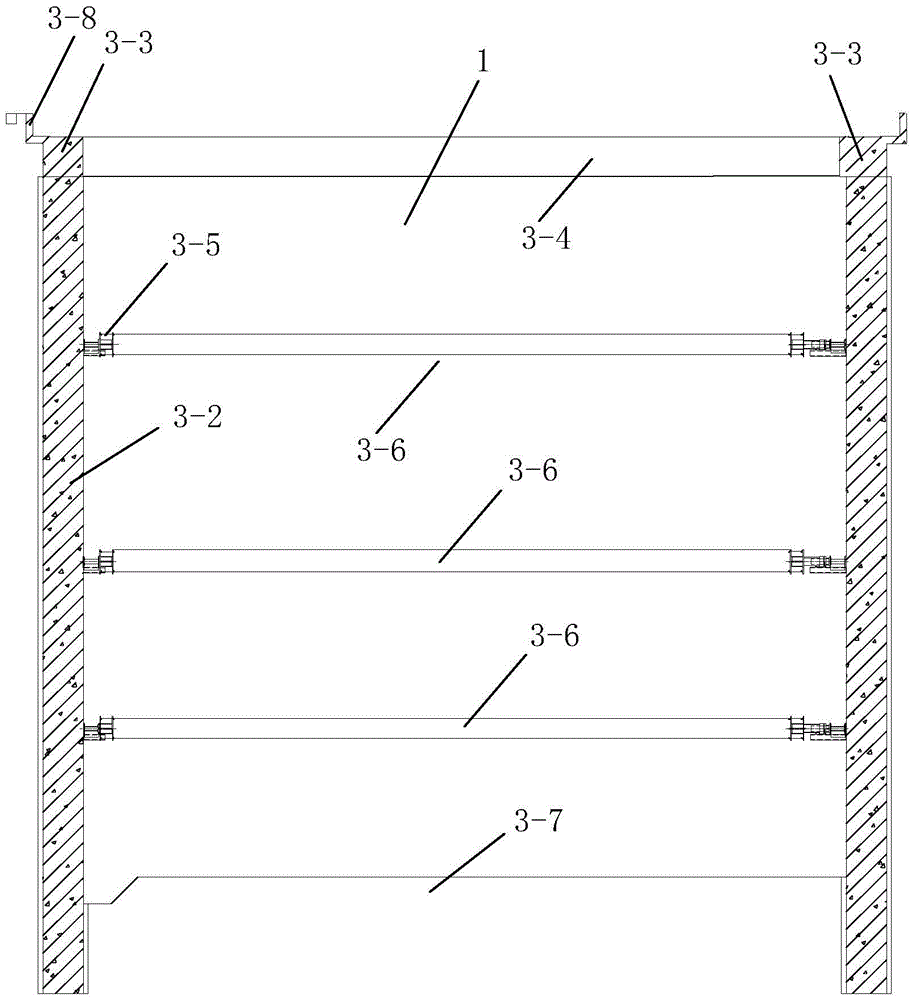

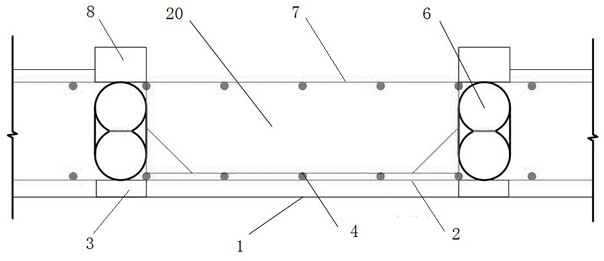

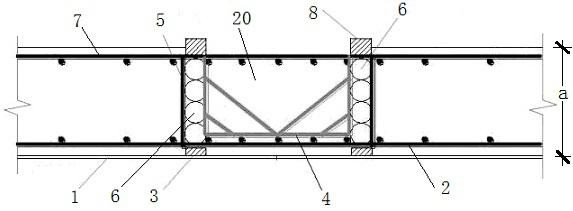

Assembled reinforced concrete beam-slab structural system with cast-in-situ layer in building structure

ActiveCN106065663AReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteEngineering

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

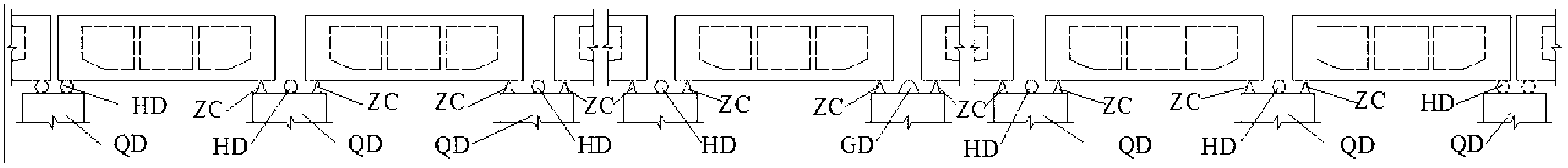

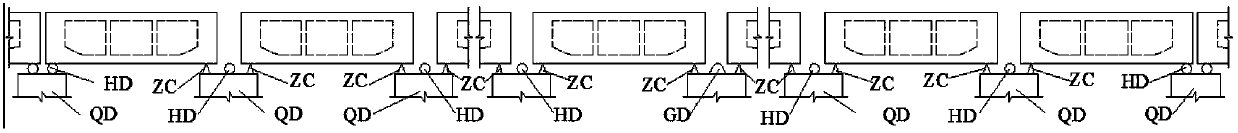

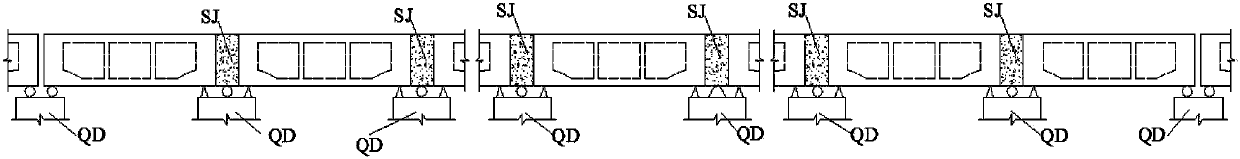

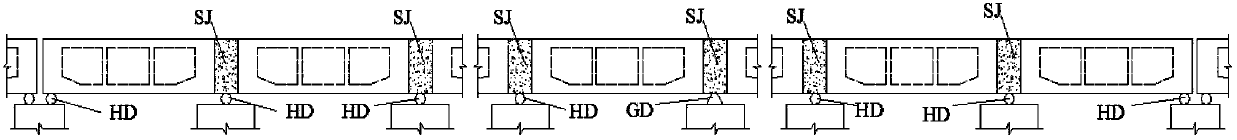

Realization method of seamless rail for straddle-type monorail transportation

ActiveCN102704355AImprove riding performanceReduce the number of supportsRailway tracksBridge structural detailsContinuous beamEngineering

The invention discloses a realization method of a seamless rail for straddle-type monorail transportation, relates to a rail beam in a straddle-type monorail transportation system and aims at enhancing the smoothness of the rail, reducing the number of straddle-type rail beam telescopic seams and support seats, reducing the abrasion on rubber tires and the engineering manufacture cost and prolonging the service life of vehicles. The seamless rail for the straddle-type monorail transportation is formed in a concatenated continuous beam bridge, concatenated continuous steel bridge or simple support beam bridge mode, or the seamless rail for the straddle-type monorail transportation is formed in a mode of mixing the three modes or any two modes. The continuous beam bridge or the continuous steel bridge is formed by connecting factory prefabricated concrete rail beams onto bridge pier cover beam top surfaces through wet joints by a method of converting simply-supported beams into continuous beams, simply-supported beam bridges are also prefabricated in factories, the adjacent continuous beam bridges, continuous steel bridges and simply-supported beam bridges adopt seamless telescopic seams, seam connecting plates or plate type rubber telescopic seams for connection, and the seamless effect of the straddle-type monorail transportation is realized.

Owner:BEIJING JIAOTONG UNIV

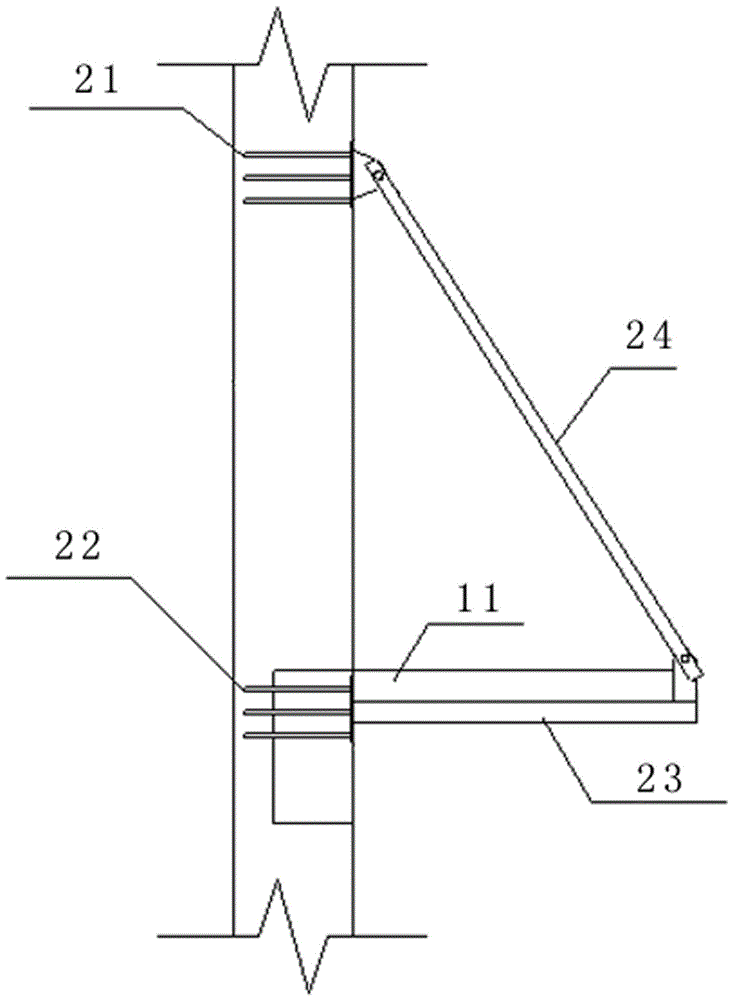

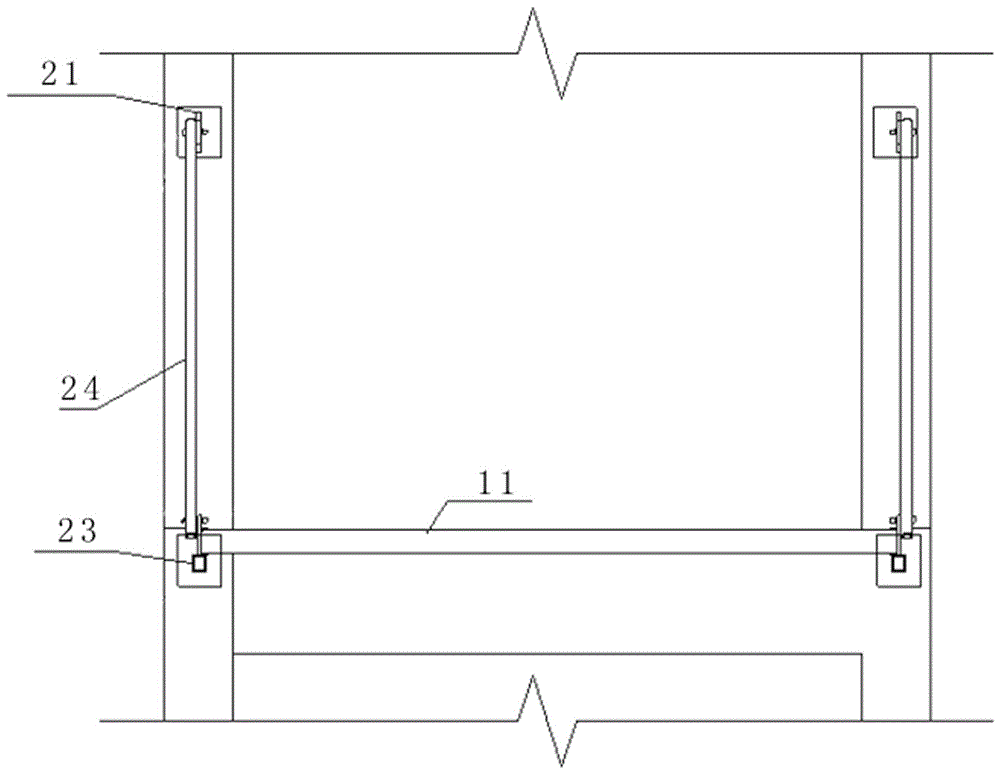

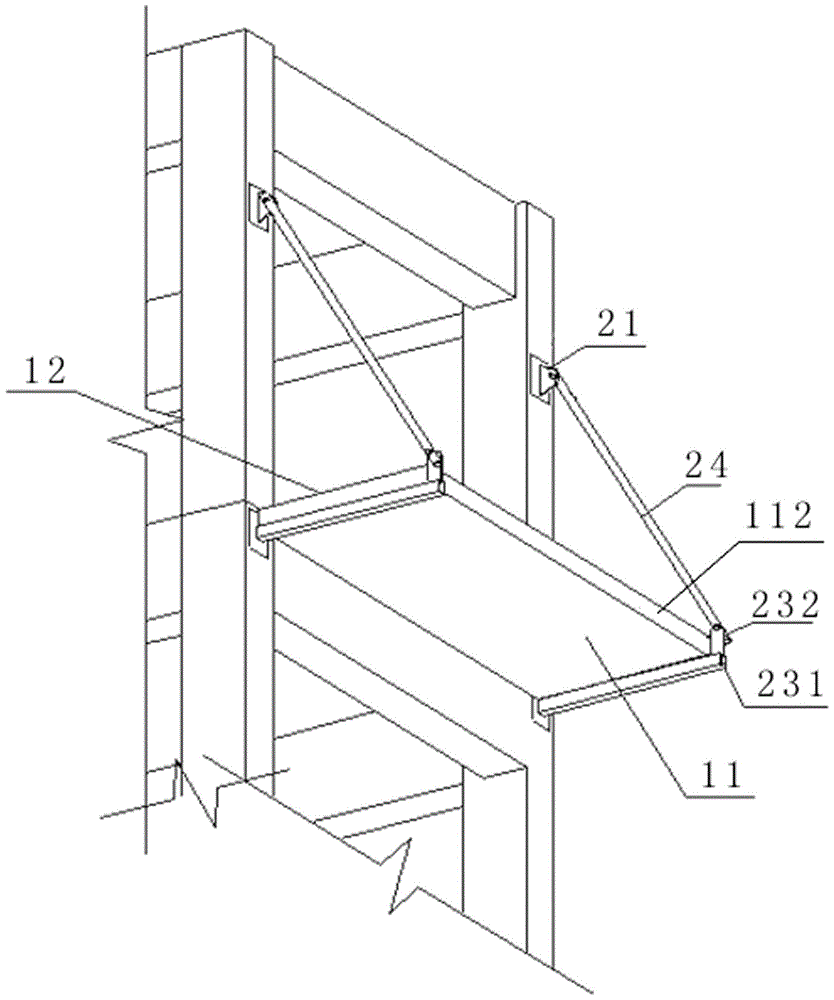

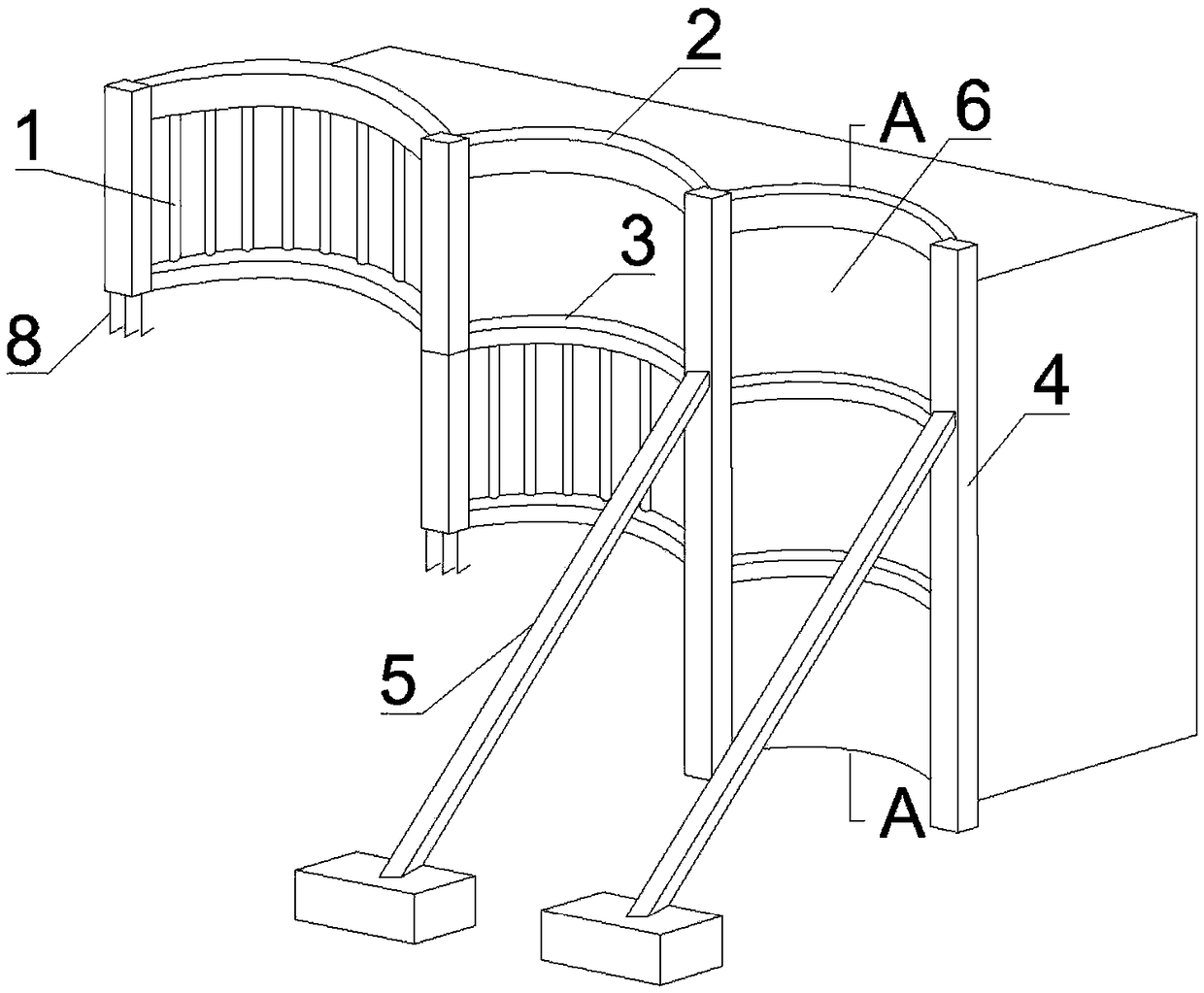

Assembly type prefabricated truss balcony and installation method therefor

InactiveCN105756186AQuick connect installationQuick installationBalconiesPulp and paper industryBuilding construction

The invention discloses an assembly type prefabricated truss balcony and an installation method therefor. The assembly type prefabricated truss balcony comprises a balcony slab, two first embedded parts, two second embedded parts, two first connecting pieces and two second connecting pieces, wherein the balcony slab is fixedly mounted between the two first connecting pieces; one end of any first embedded part and one end of any second embedded part are both embedded in a main body structure; and one end of the corresponding first connecting piece is fixedly connected with the second embedded part, and the other end of the corresponding first connecting piece is fixedly connected with the first embedded part through the corresponding second connecting piece. The prefabricated truss balcony disclosed by the invention is convenient and quick to mount; no form erecting and concrete pouring are required on site; the number of temporary supports is greatly reduced; and the purpose of improving the installation efficiency and construction quality is achieved.

Owner:SICHUAN PROVINCIAL ARCHITECTURAL DESIGN & RES INST

Horizontal-type supporting method for foundation pit of arch shell

The invention discloses a horizontal-type supporting method for a foundation pit of an arch shell and relates to the field of foundation pit supporting. The method comprises the steps that a continuous wall column pile with an orthographic projection curve is constructed at the top of the side wall of the foundation pit, the curve is composed of arcs of multiple circle centers at the same side, and the adjacent ends of every two adjacent arcs are connected; after a corresponding pile top beam is constructed at the top of the wall column pile, multiple digging layers are dug, a corresponding arch rack beam or a corresponding protection panel is constructed on each digging layer, integral buttresses are constructed at the two corresponding ends of each arc, the two adjacent ends of every twoarcs share one integral buttress, a supporting assembly corresponding to each integral buttress is constructed again and effectively supported, and an advanced vertical anchor pipe and an advanced horizontal anchor pipe are constructed on each digging layer. According to the horizontal-type supporting method, the defects of dense supporting of a traditional row pile wall are overcome, the span among the supporting assemblies is increased, and the digging difficulty is lowered.

Owner:ANHUI URBAN CONSTR DESIGN & RES INST

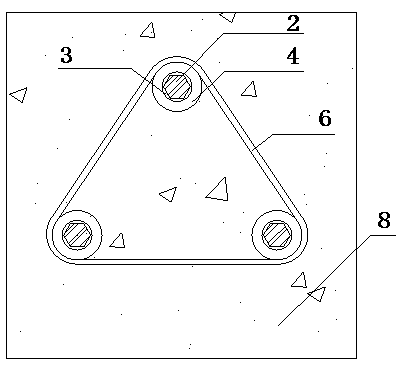

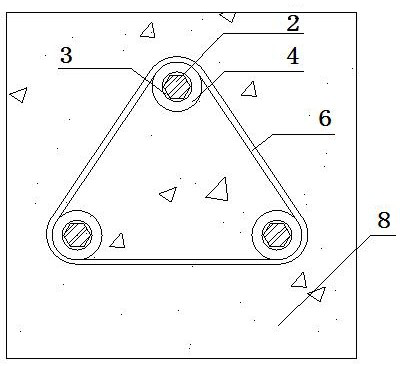

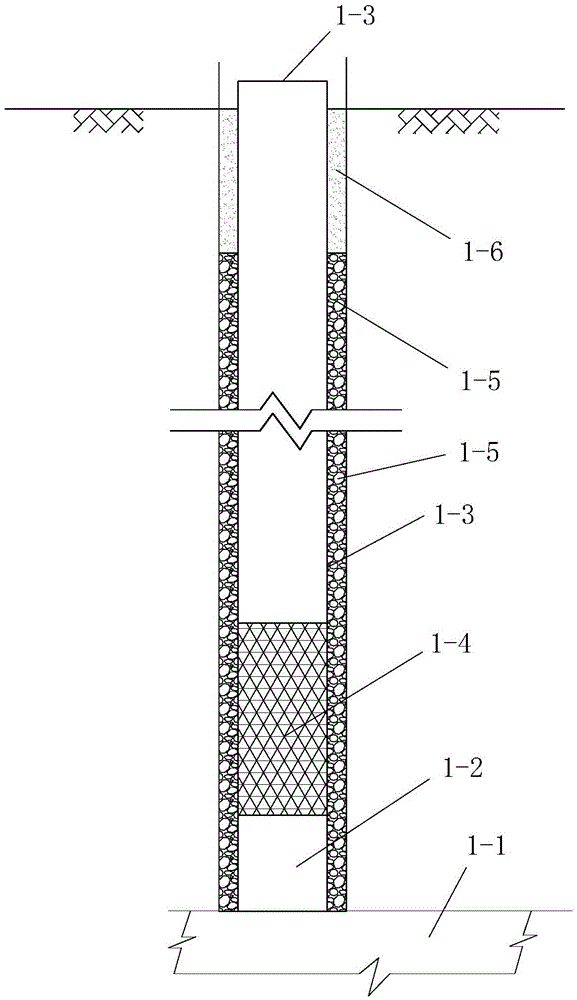

Hoisting elevation and verticality adjusting device for prefabricated concrete structural column and construction method thereof

ActiveCN109518980AGuaranteed widthEliminate construction safety hazardsBuilding material handlingStructural engineering

The invention relates to the technical field of assembly of prefabricated concrete structures, in particular to a hoisting elevation and verticality adjusting device for a prefabricated concrete structural column and a construction method thereof. The hoisting elevation and verticality adjusting device comprises a horizontal positioning iron ring used for being connected with a beam longitudinal bar of a joint core area cast-in-place part of a prefabricated concrete structure, the positioning iron ring is triangular or quadrangular, the ends of all inner corners of the positioning iron ring are provided with adjusting sets respectively, and embedded parts for abutting against the upper ends of the adjusting sets are correspondingly embedded in column heads located at the lower end of a prefabricated upper column. The device is compact in structure and facilitates the adjustment of the hoisting elevation and verticality of the prefabricated concrete structure, and the construction method is simple and convenient.

Owner:FUJIAN UNIV OF TECH

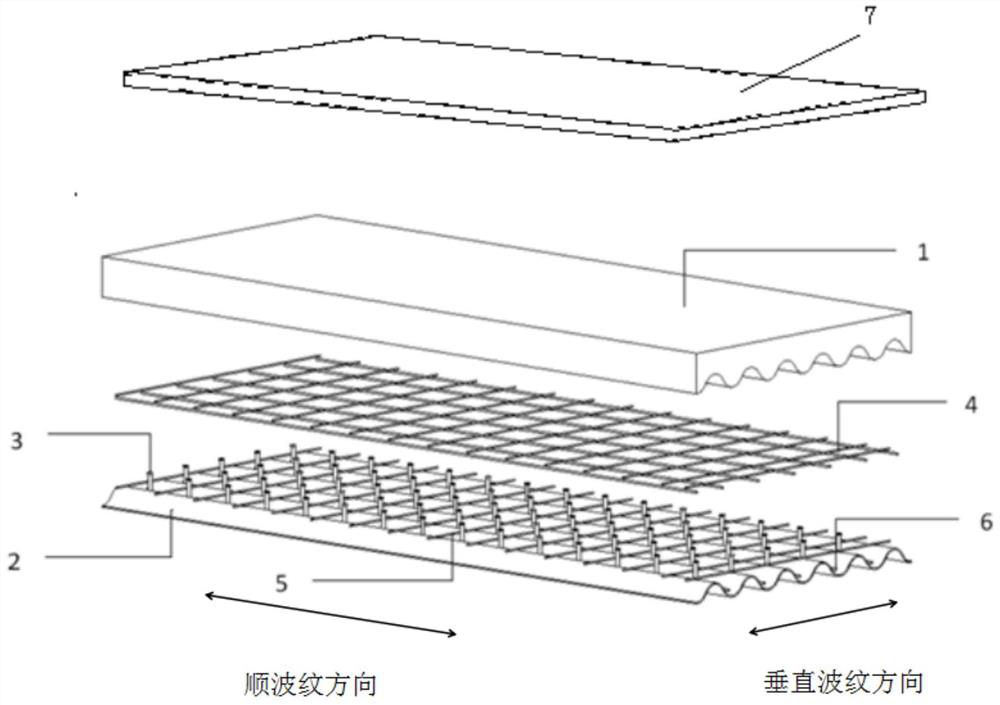

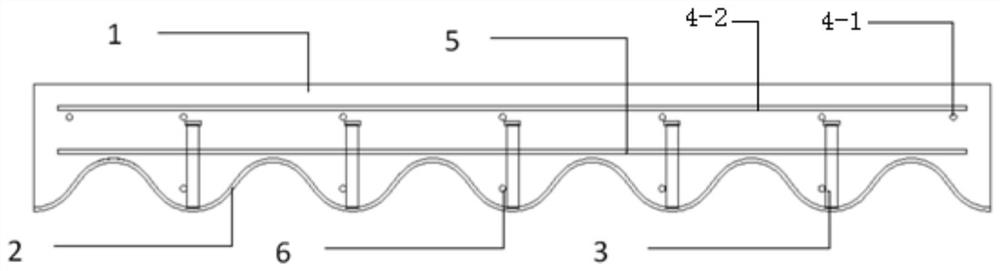

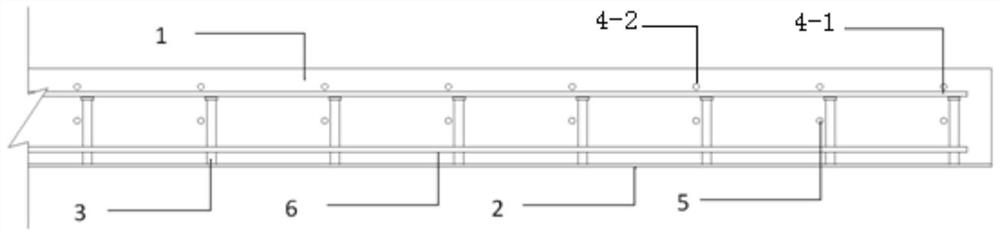

Corrugated steel-rubber concrete combination bridge deck slab

ActiveCN110055893AImprove bearing capacityIncrease stiffnessBridge structural detailsBridge materialsBridge deckRebar

The invention relates to a corrugated steel-rubber concrete combination bridge deck slab. The corrugated steel-rubber concrete combination bridge deck slab comprises a top plate and a bottom plate with the section being in a corrugated shape, a concrete structure is arranged between the top plate and the bottom plate, the concrete structure is internally provided with a plurality of shear parts fixedly connected with the bottom plate, the shear parts are fixed to the wave trough positions of the bottom plate, the concrete structure is internally provided with first longitudinal reinforcing steel bars and first transverse reinforcing steel bars, the first longitudinal reinforcing steel bars and the first transverse reinforcing steel bars are perpendicular to each other, the first longitudinal reinforcing steel bars are located on the wave trough positions and fixedly connected with the shear parts, and the first transverse reinforcing steel bars are located on the wave peak positions. According to the corrugated steel-rubber concrete combination bridge deck slab, construction is convenient, the structure intensity is high, and driving comfortableness is high

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST +1

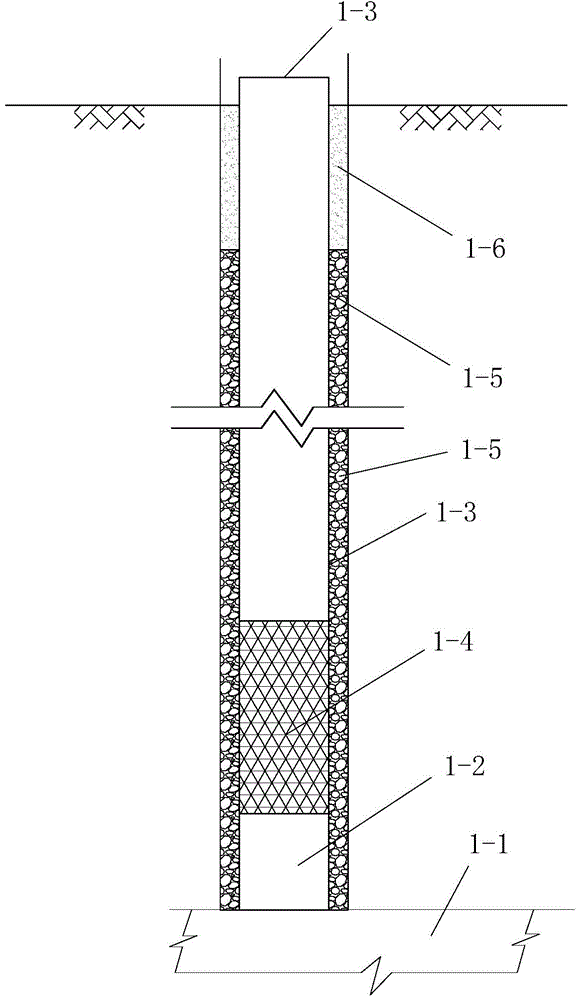

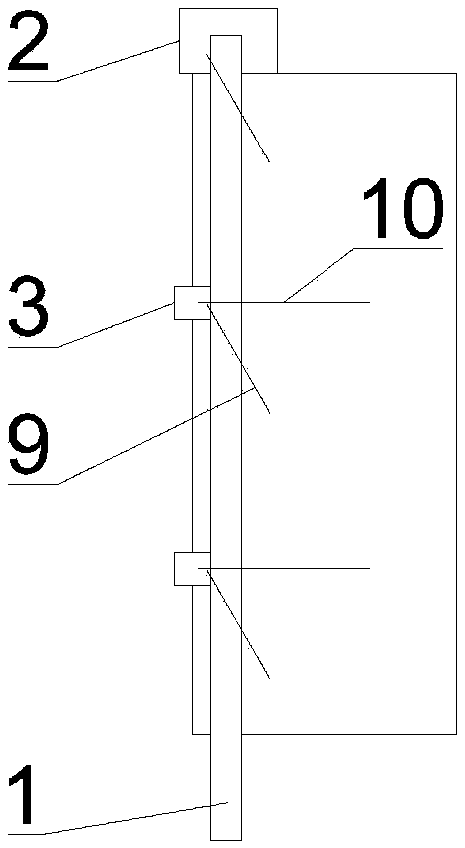

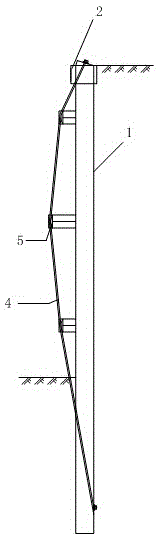

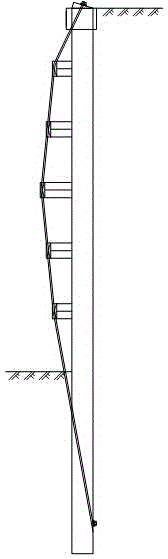

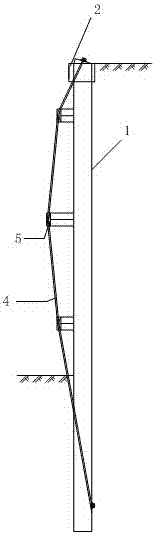

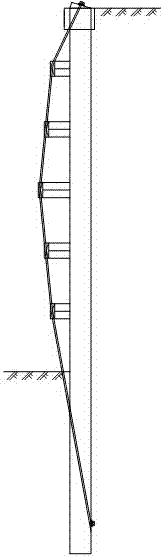

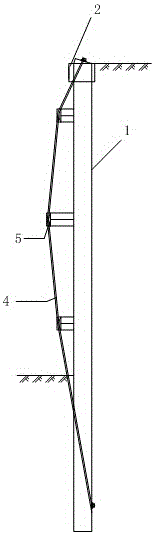

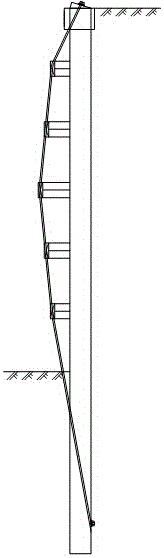

Prestressed steel sheet pile supporting structure and construction method thereof

The invention discloses a prestressed steel sheet pile supporting structure and a construction method thereof. The prestressed steel sheet pile supporting structure comprises a plurality of prestressed supporting units, wherein each prestressed supporting unit comprises a supporting pile, a plurality of steel supports and a prestressed tendon; each supporting pile is vertically arranged on one side of a to-be-excavated foundation pit; a plurality of the steel supports are arranged on the corresponding supporting pile from top to bottom; one end of each prestressed tendon is anchored at the lower part of the corresponding supporting pile. According to the construction method, a plurality of the prestressed supporting units are sequentially driven into soil around the to-be-excavated foundation pit, a plurality of the steel supports all face the to-be-excavated foundation pit, and a top beam is arranged at the top ends of the prestressed supporting units, so that the prestressed supporting units and the top beam form an integral body; tensile force is applied through the prestressed tendons, and the upper ends of the prestressed tendons are anchored on the top beam. According to the prestressed steel sheet pile supporting structure and the construction method thereof, the horizontal component of tensile force borne by the prestressed tendons is transmitted to the supporting structure, partial earth pressure of soil is counteracted, the supporting intensity is improved, and deformation of the supporting piles is reduced; besides, the supporting structure can be recycled, so that the cost is reduced.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

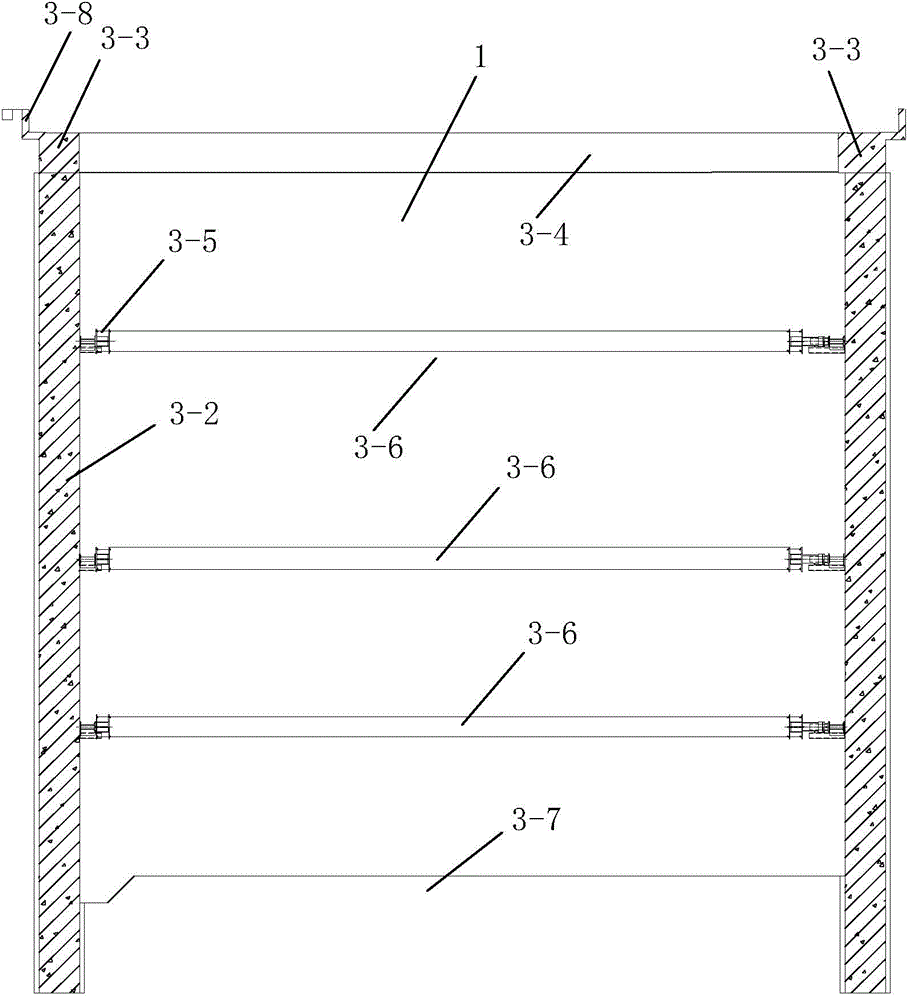

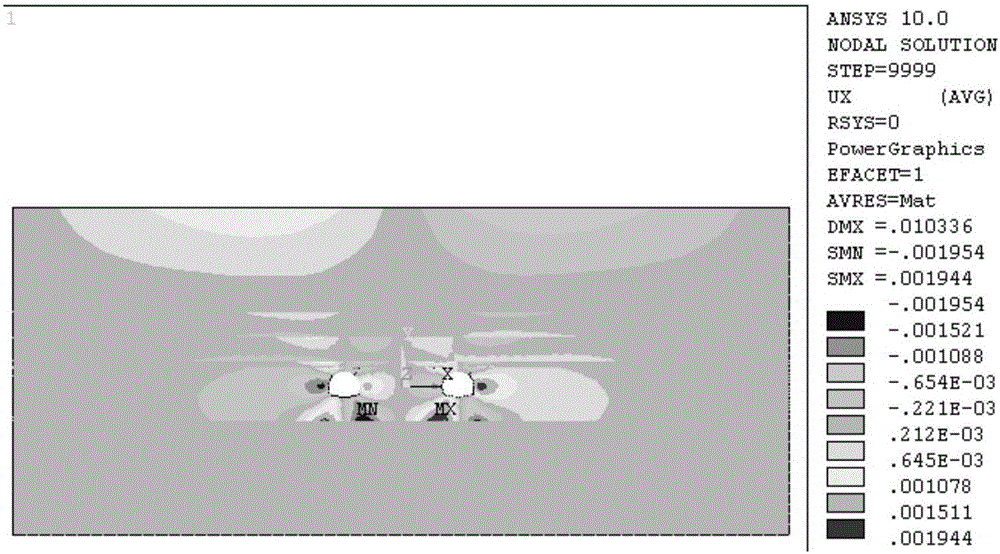

Counter-force system for rectangular shield tunneling

InactiveCN103711496AReduce the number of supportsIncrease the dispatch spaceTunnelsEngineeringShield tunneling

The invention provides a counter-force system for rectangular shield tunneling. The counter-force system is arranged inside an original well and comprises a counter-force frame, an opened negative ring, a closed negative ring system and a steel beam, wherein the counter-force frame, the opened negative ring and the closed negative ring system are connected in sequence in the direction of shield tunneling, the counter-force frame is fixedly arranged on the side wall of the original well, opposite to the opening of the original well, the closed negative ring system penetrates through the opening of the original well, the steel beam is located on the inner side of the opened negative ring, and the two ends of the steel beam are connected with the closed negative ring system and the counter-force frame respectively. Due to the introduction of the unique closed negative ring system and steel beam, the whole system is clearly stressed, the structure is more stable, and the steel beam does not need to be machined every time to meet the length demand; meanwhile, due to the fact that the number of counter-force steel supports is reduced, the allocation and transportation space of construction materials is increased. The counter-force system suitable for the rectangular shield tunneling is provided.

Owner:SHANGHAI MECHANIZED CONSTR GRP

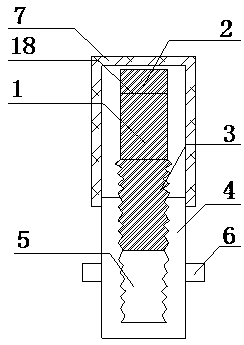

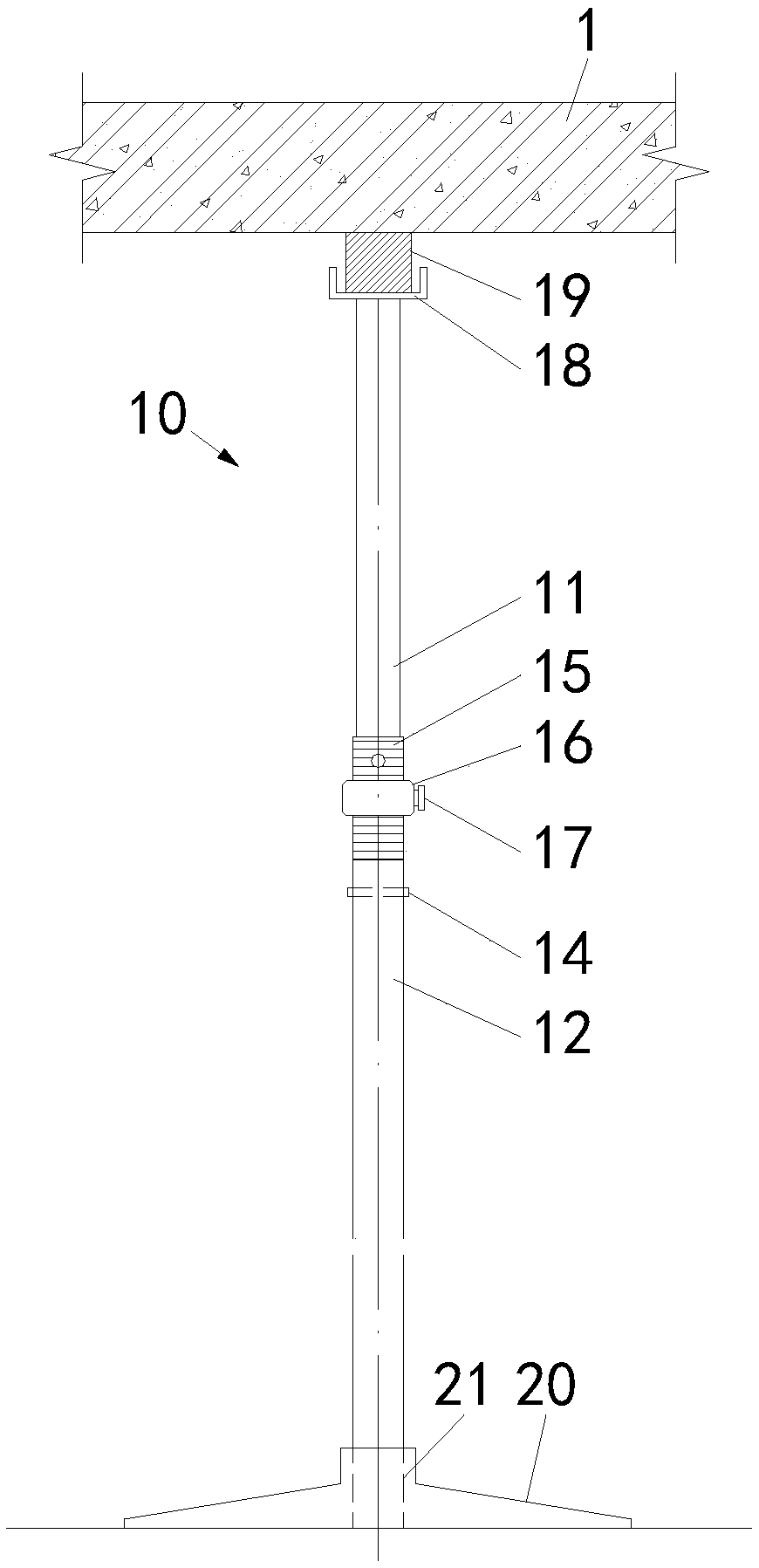

Adjustable supporting device and using method thereof

PendingCN109098437AImprove bearing capacitySimple structureForms/shuttering/falseworksShoresWork periodArchitectural engineering

The invention relates to an adjustable supporting device and a using method thereof, and relates to the technical field of assembly type building supporting. The invention aims to solve the problems that a working period is long during assembling and disassembling of an existing fastener type steel tube support, and the construction efficiency is low. The adjustable supporting device is verticallyarranged on the bottom of an assembly type prefabricated component, and comprises a steel stand column and a base connected to the bottom of the steel stand column; the steel stand column comprises an inner tube and an outer tube which are arranged in the up-down direction and are arranged in a sleeving manner; a plurality of corresponding positioning pin holes are formed in the side walls of theinner tube and the outer tube in the length directions of the inner tube and the outer tube; the inner tube and the outer tube are fixed and are coarsely adjusted through positioning latches which penetrate through the positioning pin holes; the base is provided with a rectangular or circular cross section; a through hole is formed in the center of the base; and the bottom of the steel stand column perpendicularly penetrates through the through hole and is fastened.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

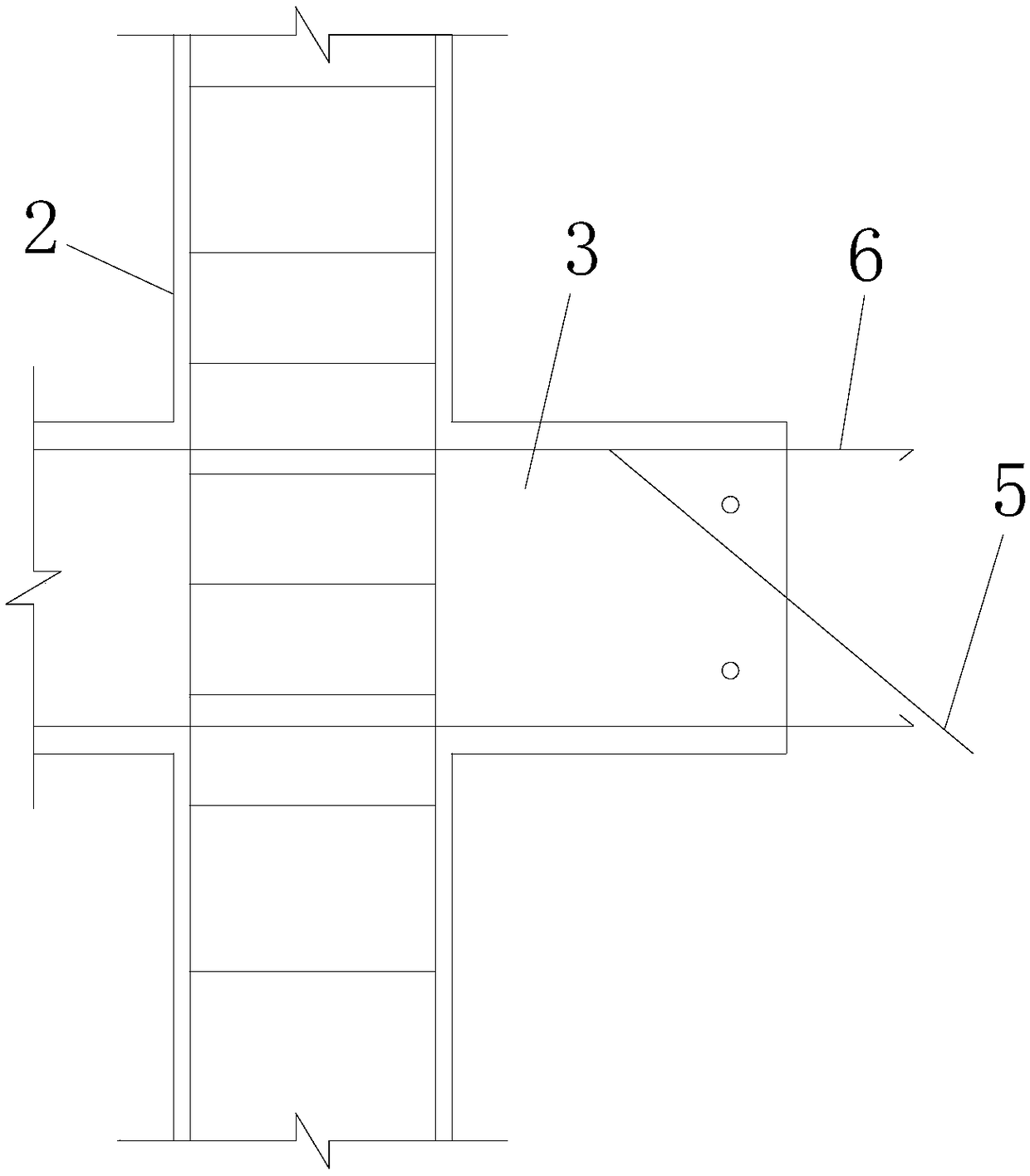

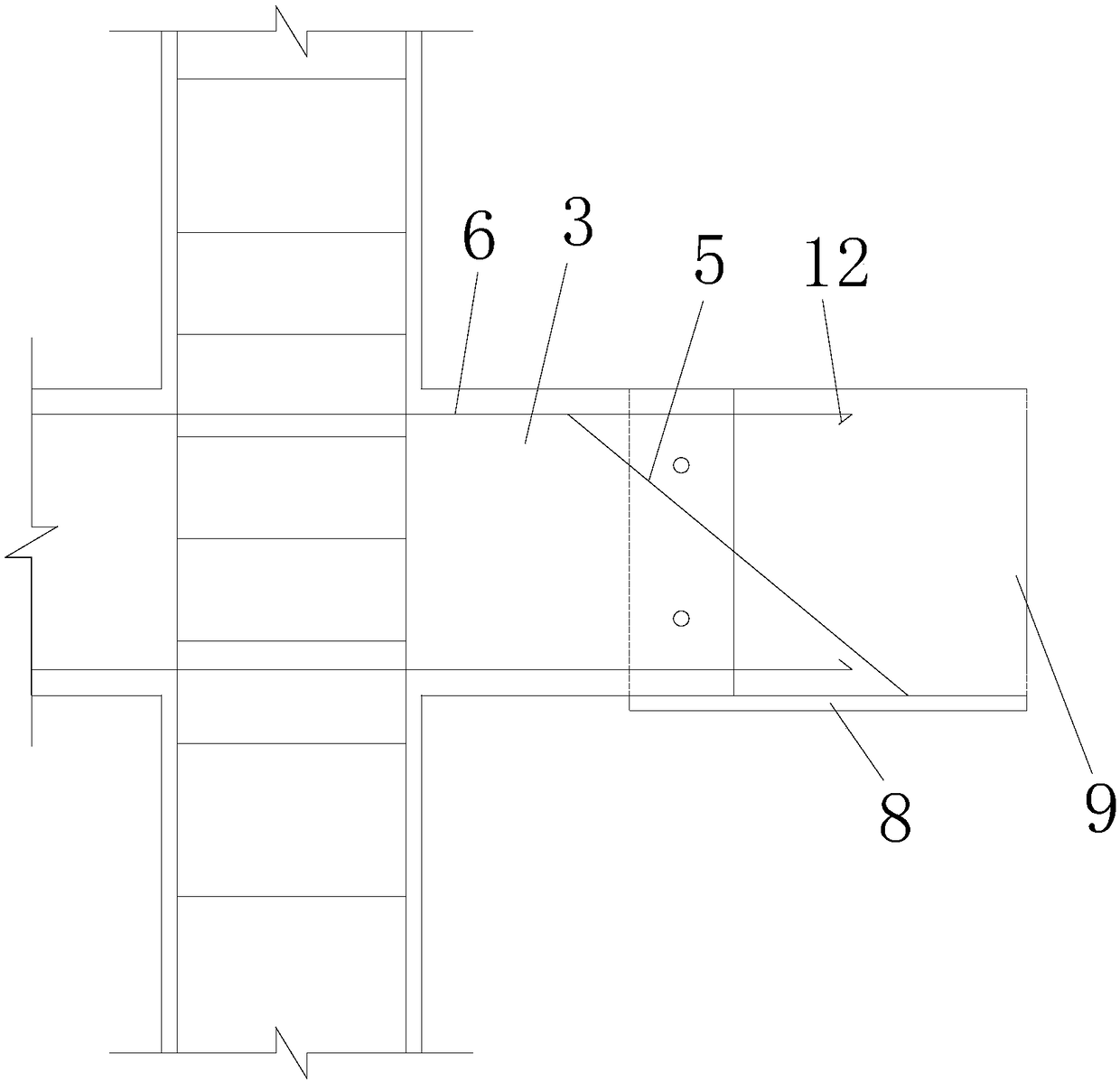

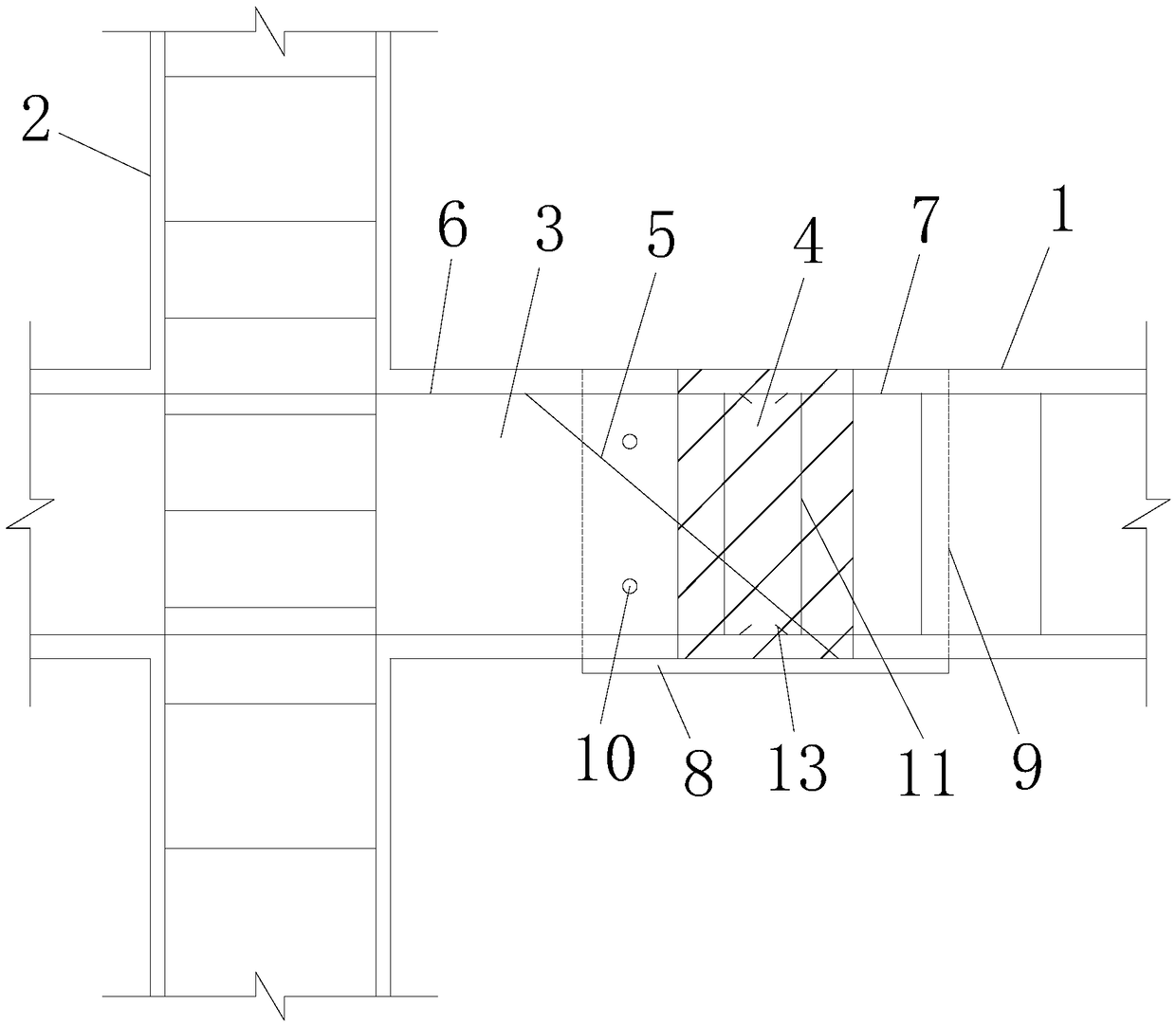

Beam column integral prefabricated joint with rigid template support at connecting position and construction method of beam column integral prefabricated joint

The invention discloses a beam column integral prefabricated joint with a rigid template support at a connecting position and a construction method of the beam column integral prefabricated joint. Thebeam column integral prefabricated joint with the rigid template support at the connecting position comprises a cross beam, a steel template and a prefabricated column with a prefabricated joint, theprefabricated joint extends to form a butt-joint segment in butt joint with the cross beam, the steel template is fixedly connected with the butt-joint segment, the cross beam is connected to the steel template, the steel template, the butt-joint segment and the cross beam are fixedly connected through a casting connecting segment, the butt-joint segment extends to form an inclined connection steel bar and column connection steel bars, the inclined connection steel bar and the column connection steel bars extend into the casting connecting segment, the extending-out end of the inclined connection steel bar is fixedly connected with the steel template, the cross beam extends toward the casting connection segment to form beam connecting steel bars, and the beam connecting steel bars in thecasting connection segment are in overlap joint with the beam connection steel bars. The stress of the casting connection segment is smaller than that of a casting segment of a traditional beam columnjoint.

Owner:SOUTH CHINA UNIV OF TECH

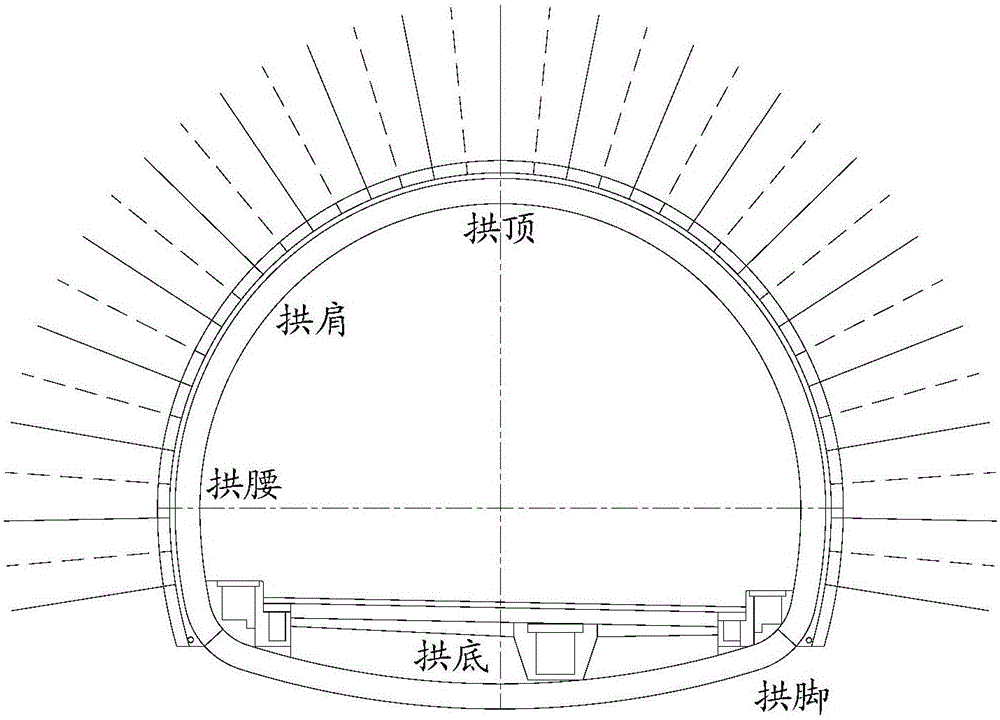

Horizontal soft and hard interbeded layer surrounding rock tunnel anchor rod support structure and method

InactiveCN106121693AReduce the number of supportsSavings in the number of supportsAnchoring boltsLeft halfStructure of the Earth

The invention provides a bolt support structure for a horizontal soft-hard interbedded surrounding rock tunnel, which includes a bolt supporting the surrounding rock. The surrounding rock divides the excavation surface into a left half section and a right half according to the center line of the tunnel excavation section. The cross-section, the left half-section and the right half-section are equipped with bolts for supporting the horizontal soft-hard interbedded surrounding rock, and the bolts are arranged perpendicular to the tunnel excavation contour line, and the angle between the horizontal rock formation and the horizontal rock formation is less than 35° There are no bolts arranged on the tunnel excavation outline. The invention also provides a bolt support method for horizontal soft and hard interbedded surrounding rock tunnels. In the bolt support structure and method provided by the present invention, the bolts arranged on the tunnel excavation contour line with an included angle of less than 35° with the horizontal rock formation are canceled, that is, when the tunnel excavation with an included angle with the horizontal rock formation is less than 35° No bolts are arranged on the excavation contour, thus reducing the number of bolts supported in the tunnel construction, not only can obtain a good reinforcement effect, but also save the number of bolts supported, thereby reducing the consumption of supporting materials and supporting costs .

Owner:中电建路桥集团有限公司

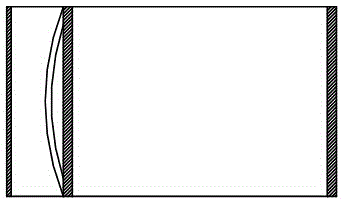

Post-cast strip inflatable arc angle rectangular flexible pipe side mold support construction method

ActiveCN109025294AReduce the number of supportsReduce the number of units usedBuilding material handlingBuilding insulationsEngineeringRebar

The invention relates to a post-cast strip side mold support construction method; an inflatable arc angle rectangular flexible pipe is arranged in a gap between an upper layer steel bar and a lower layer steel bar in the post-cast strip position; in inflation, the arc angle rectangular flexible pipe is extruded by the upper and lower layer steel bars so as to fill the gap caused by the steel bars;the soft pipe is inflated to form an air column so as to space the concrete; the cross section outer contour of the arc angle rectangular flexible pipe is an arc-shaped rectangular shape; the arc angle rectangular is a rectangular with four arc-shaped corners, and is an axially symmetrical and centrosymmetric geometric figure; the arc angle rectangular flexible pipe comprises a soft pipe outer wall and a soft pipe inner wall; the soft pipe outer wall cross section is the cross section contour of the arc angle rectangular flexible pipe, i.e., an arc angle rectangular; the soft pipe inner wallcomprises an upper pipe inner wall, a lower pipe inner wall and a common inner wall; the area enclosed by the upper pipe inner wall and the lower pipe inner wall is an air pump pressurization area; anarea enclosed by the soft pipe outer wall, the lower portion of the upper pipe inner wall and the upper portion of the lower pipe inner wall is an air connection area; the common inner wall has a constant pressure hole. The method employs the inflatable arc angle rectangular flexible pipe support, is good in moulding effect, high in construction quality, and high in efficiency.

Owner:FUJIAN JIANGXIA UNIV

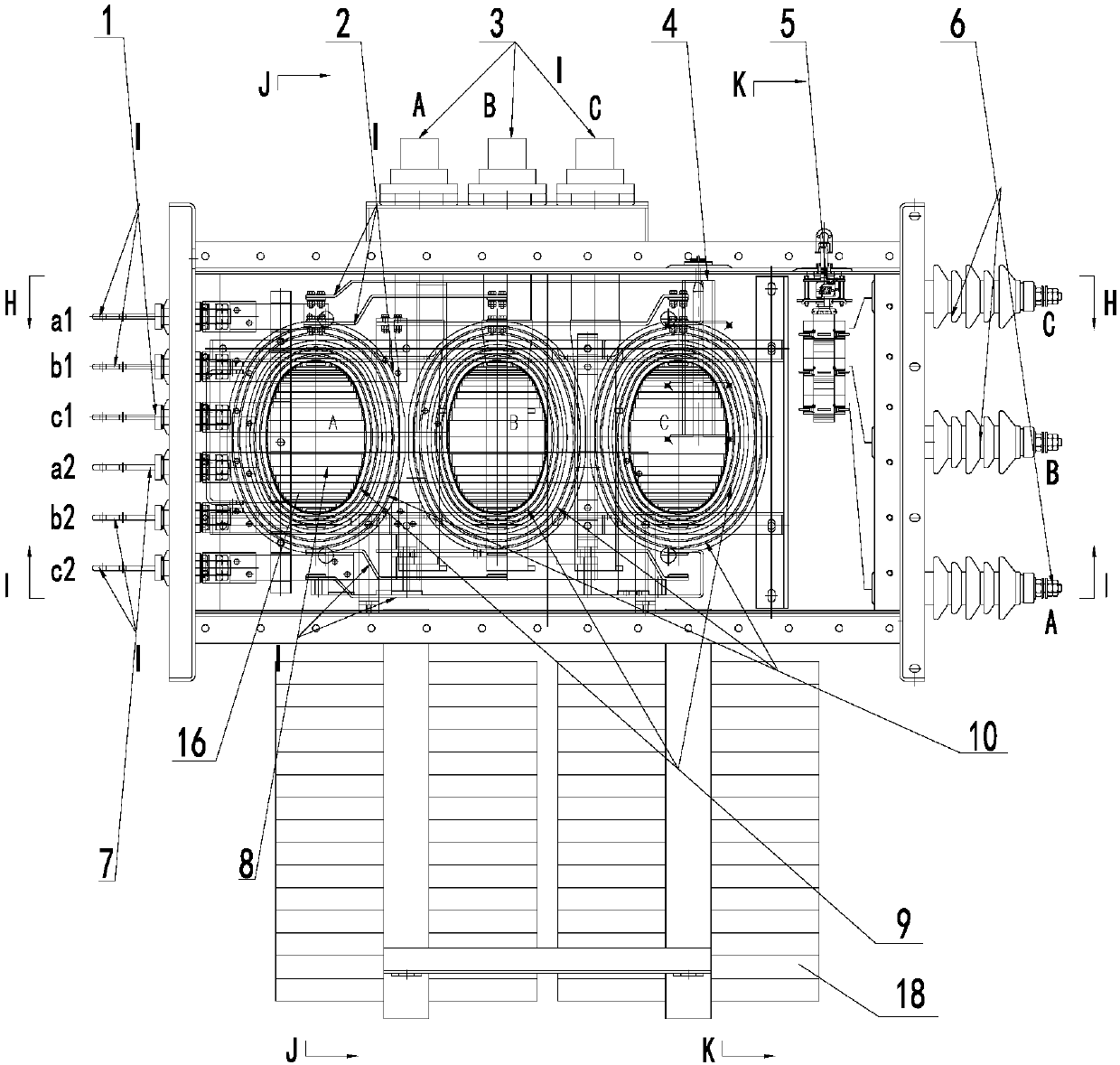

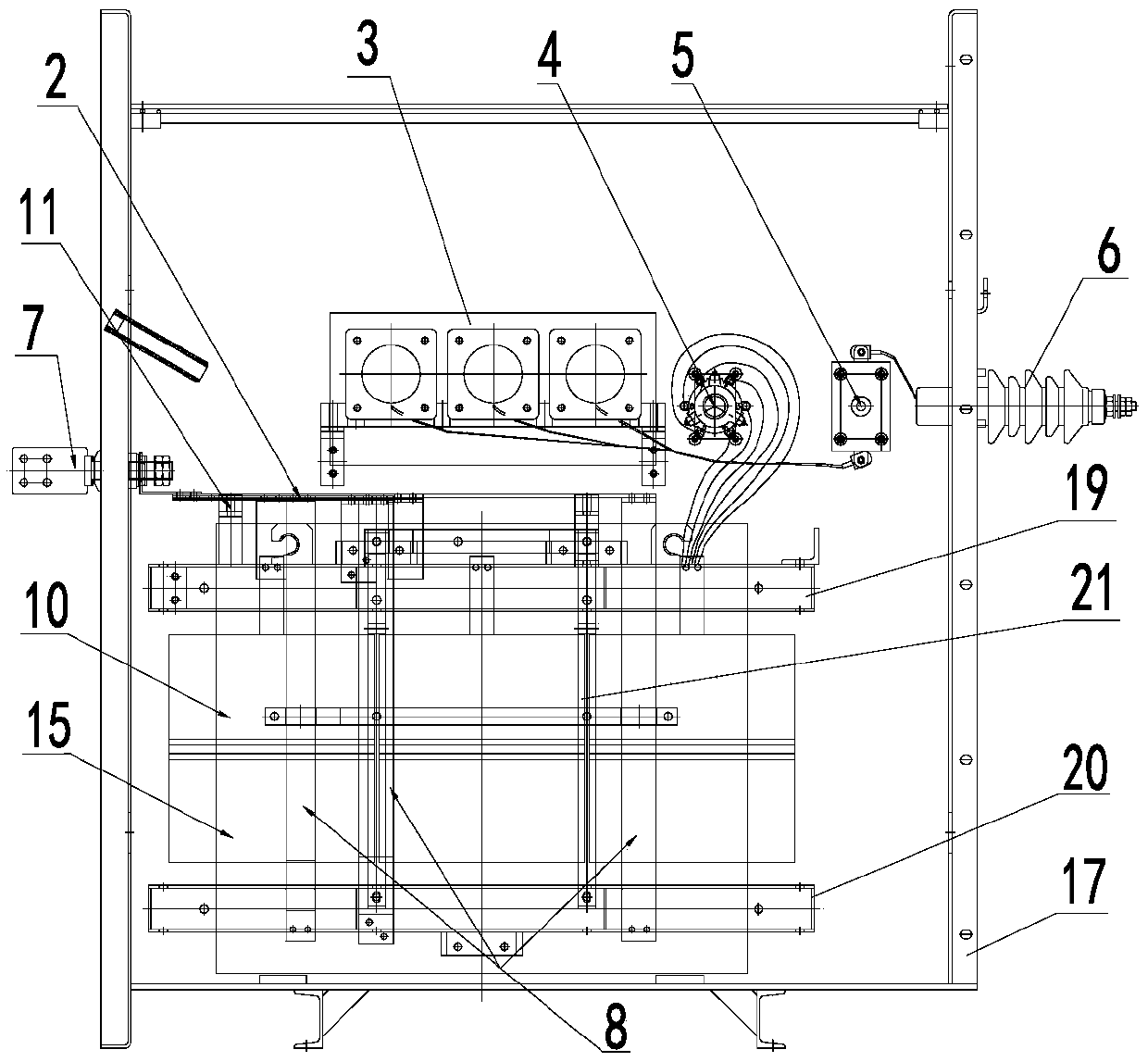

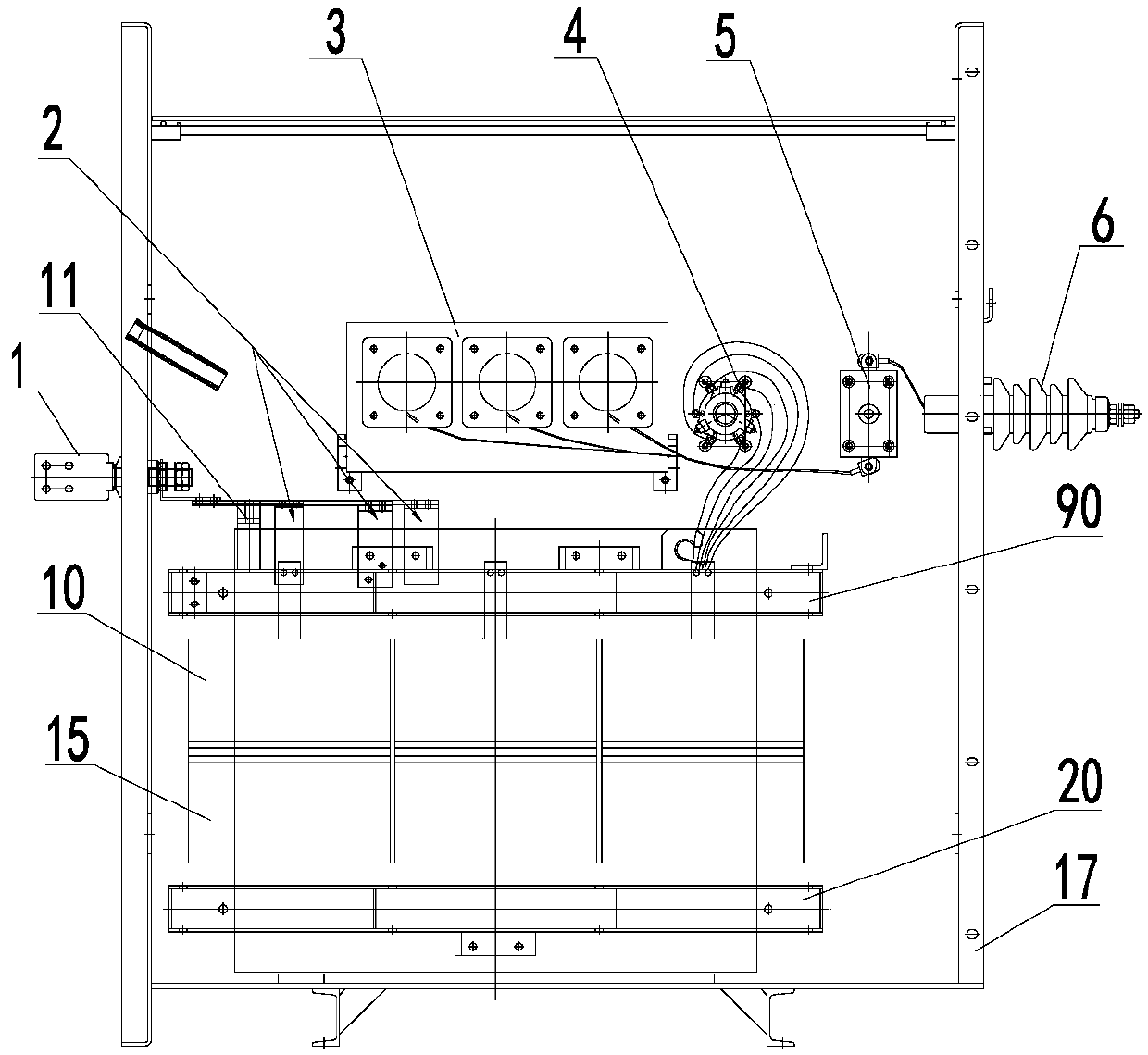

Double-split transformer wire outlet structure

InactiveCN109767899AReduce the number of supportsReduce dosageTransformers/inductances coolingTransformers/inductances coils/windings/connectionsLow voltageNew energy

The invention relates to the technical field of new energy power generation, in particular to a double-split transformer wire outlet structure. The double-split transformer wire outlet structure comprises three phases of three-column iron cores, and A, B and C three phases of coils which are wound around the three phases of three-column iron cores respectively; each phase of the coils comprises anupper part low-voltage coil, a lower part low-voltage coil, an upper part high-voltage coil and a lower part high-voltage coil; the upper part low-voltage coil and the upper part high-voltage coil are concentrically arranged on the upper half parts of the three phases of three-column iron cores, and the lower part low-voltage coil and the lower part high-voltage coil are concentrically arranged on the lower half parts of the three phases of three-column iron cores; the upper part low-voltage coil is connected with a first path of low-voltage sleeve through a first path of low-voltage outgoingline located on one side of the device body, and the lower part low-voltage coil is connected with a second path of low-voltage sleeve through a second path of low-voltage outgoing line located on the other side of the device body; the upper part high-voltage coil is connected with the lower part high-voltage coil in parallel, and a tapping lead is connected with a tapping switch. According to the double-split transformer wire outlet structure, the supporting number of low-pressure wood clamping pieces is reduced, the width of an oil tank is reduced, and the use amount of the transformer oilis reduced.

Owner:特变电工山东沈变电气设备有限公司

Combined guided slipping type forepoling hydraulic support

ActiveCN101338684BReduce the number of supportsNot easy to fallMine roof supportsHeadframeEngineering

The present invention provides a combined guide slippage type forepoling hydraulic bracket which comprises an internal support unit and an external support unit (12 and 11) which are symmetrical to each other at left and right. Each support unit comprises a top beam (1), a pedestal, a guide stabilizing mechanism and a hydraulic support component upright post. An upright post is articulated between the top beam and the pedestal. A telescopic link type guide stabilizing mechanism is arranged at the middle parts of the top beam and the pedestal. The outer side of the internal support unit is provided with the external support unit. Connecting slide rods (7) are respectively connected between the top beams and the pedestal beams at the same side of the adjacent internal and external support units. An inter-frame jack (8) is articulated between the top beam and the pedestal of the symmetrical internal support unit to form a section of bracket. The bracket forms an independent motor unit. The hydraulic bracket consists of a plurality of independent motor units. An advancing jack (17) is connected between the pedestals (9) of the independent motor units. The front end of the pedestal (9)of a section of bracket at the front end of the hydraulic bracket is connected with a head frame pulling and moving mechanism. The hydraulic bracket can effectively support a big section laneway and realizes the forepoling and the forepoling automatization of the big section laneway.

Owner:TIANDI SCI & TECH CO LTD

Prefabricated reinforced concrete beam-slab structure system with cast-in-place floors in building structures

ActiveCN106065663BReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteTongue and groove

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

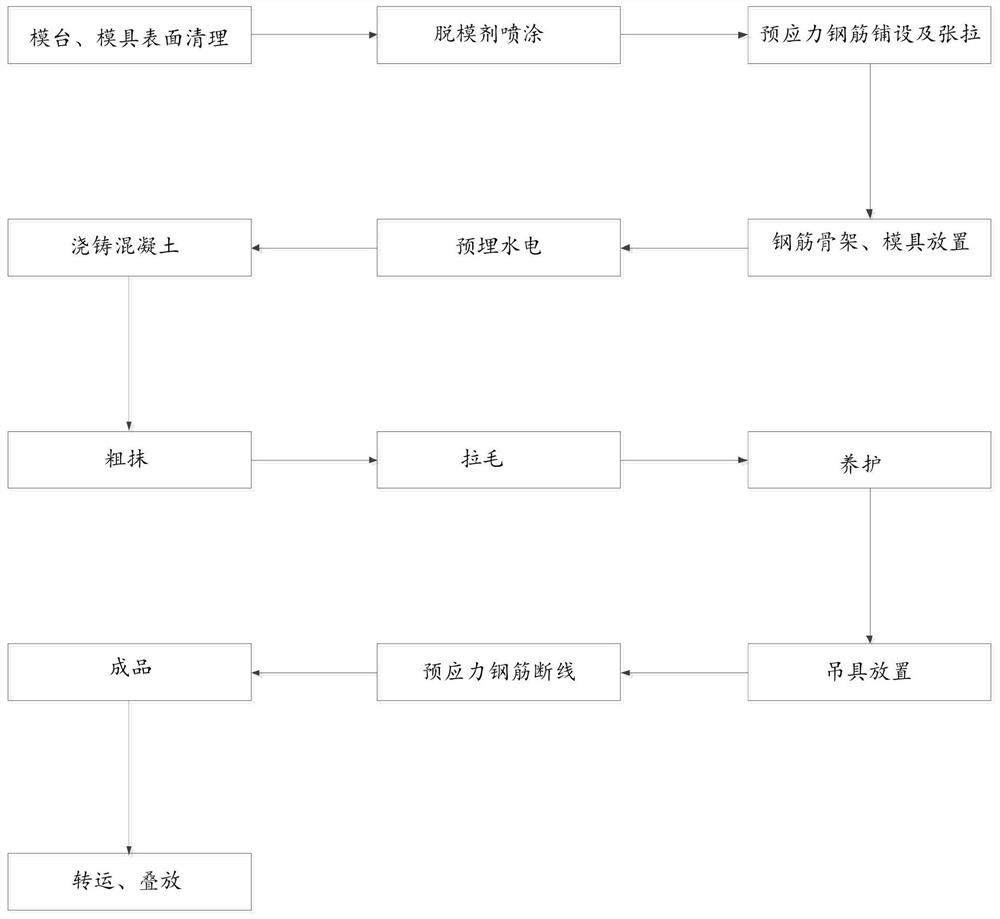

Production process of prestressed concrete laminated slab bottom plates

InactiveCN112976256AIncrease the number of stacked strataAvoid warpingFeeding arrangmentsAuxillary shaping apparatusPre stressArchitectural engineering

The invention belongs to the technical field of building material processing and application, and particularly relates to a production process of prestressed concrete laminated slab bottom plates. The production process comprises the following effective steps of cleaning the surfaces of a mold table and a mold; spraying a release agent; laying and tensioning prestressed steel bars, and placing a steel bar framework and the mold; pre-embedding water tubes and electric wire tubes; casting concrete; carrying out rough smearing; carrying out galling; carrying out maintenance and placing a lifting appliance; breaking the prestressed steel bars; removing the mold; and obtaining finished products, transferring and stacking the finished products, and the like. According to the production process, an existing production process is improved, the lifting appliance is additionally arranged before the prestressed steel bars are broken, multi-point supporting of a plate body is formed, and then the problems of plate surface warping and cracking of the laminated slab bottom plates due to the fact that the prestressed steel bars are broken are avoided; meanwhile, due to arrangement of the lifting appliance, the number of layers of the stacking places of the laminated slab bottom plates can be increased, limitation that only six layers of the prestressed laminated slab bottom plates can be stacked is broken through, the stacking places are saved, and the loading number in the transportation process is increased; and in addition, only two ends need to be supported in the stacking and using process of the laminated slabs.

Owner:王示

Realization method of seamless rail for straddle-type monorail transportation

ActiveCN102704355BImprove riding performanceReduce the number of supportsRailway tracksBridge structural detailsContinuous beamExpansion joint

The invention discloses a realization method of a seamless rail for straddle-type monorail transportation, relates to a rail beam in a straddle-type monorail transportation system and aims at enhancing the smoothness of the rail, reducing the number of straddle-type rail beam telescopic seams and support seats, reducing the abrasion on rubber tires and the engineering manufacture cost and prolonging the service life of vehicles. The seamless rail for the straddle-type monorail transportation is formed in a concatenated continuous beam bridge, concatenated continuous steel bridge or simple support beam bridge mode, or the seamless rail for the straddle-type monorail transportation is formed in a mode of mixing the three modes or any two modes. The continuous beam bridge or the continuous steel bridge is formed by connecting factory prefabricated concrete rail beams onto bridge pier cover beam top surfaces through wet joints by a method of converting simply-supported beams into continuous beams, simply-supported beam bridges are also prefabricated in factories, the adjacent continuous beam bridges, continuous steel bridges and simply-supported beam bridges adopt seamless telescopic seams, seam connecting plates or plate type rubber telescopic seams for connection, and the seamless effect of the straddle-type monorail transportation is realized.

Owner:BEIJING JIAOTONG UNIV

A Corrugated Steel-Rubber Concrete Composite Bridge Deck

ActiveCN110055893BImprove bearing capacityIncrease stiffnessBridge structural detailsBridge materialsArchitectural engineeringBridge deck

The invention relates to a corrugated steel-rubber concrete composite bridge deck, comprising a top plate and a bottom plate with a corrugated cross-section, a concrete structure is arranged between the top plate and the bottom plate, and a plurality of bridges fixedly connected with the bottom plate are arranged inside the concrete structure. A shear member, the shear member is fixed at the position of the trough of the bottom plate, a first longitudinal reinforcement and a first transverse reinforcement perpendicular to each other are arranged inside the concrete, and the first longitudinal reinforcement is located above the trough of the bottom plate and is connected to the The shear members are fixedly connected, and the first transverse steel bar is located above the wave crest of the bottom plate. The bridge deck of the present invention is convenient in construction, high in structural strength, and high in driving comfort.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST +1

A construction method for supporting with prestressed steel sheet pile supporting structure

ActiveCN105133623BResist lateral pressureImprove support strengthExcavationsPre stressUltimate tensile strength

The invention discloses a construction method for supporting with a prestressed steel sheet pile support structure. The prestressed steel sheet pile support structure includes a plurality of prestressed support units, and each prestressed support unit includes support piles, multiple Steel supports and prestressed tendons. The support pile is vertically arranged on one side of the foundation pit to be excavated, a plurality of steel supports are arranged on the support pile from top to bottom, and one end of the prestressed tendon is anchored to the lower part of the support pile. Drive multiple prestressed support units into the surroundings of the foundation pit to be excavated in sequence, with multiple steel supports facing the foundation pit to be excavated, and set a crown beam on the top of the prestressed support unit so that the prestressed support unit It is integrated with the crown beam; the tension is applied through the prestressed tendons, and the upper end of the prestressed prestressed tendons is anchored on the crown beam. The horizontal component of the tensile force on the prestressed tendons is transmitted to the support structure, which offsets part of the earth pressure of the soil, improves the support strength, and reduces the deformation of the support pile; in addition, the support structure can be recycled and reused, saving cost.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

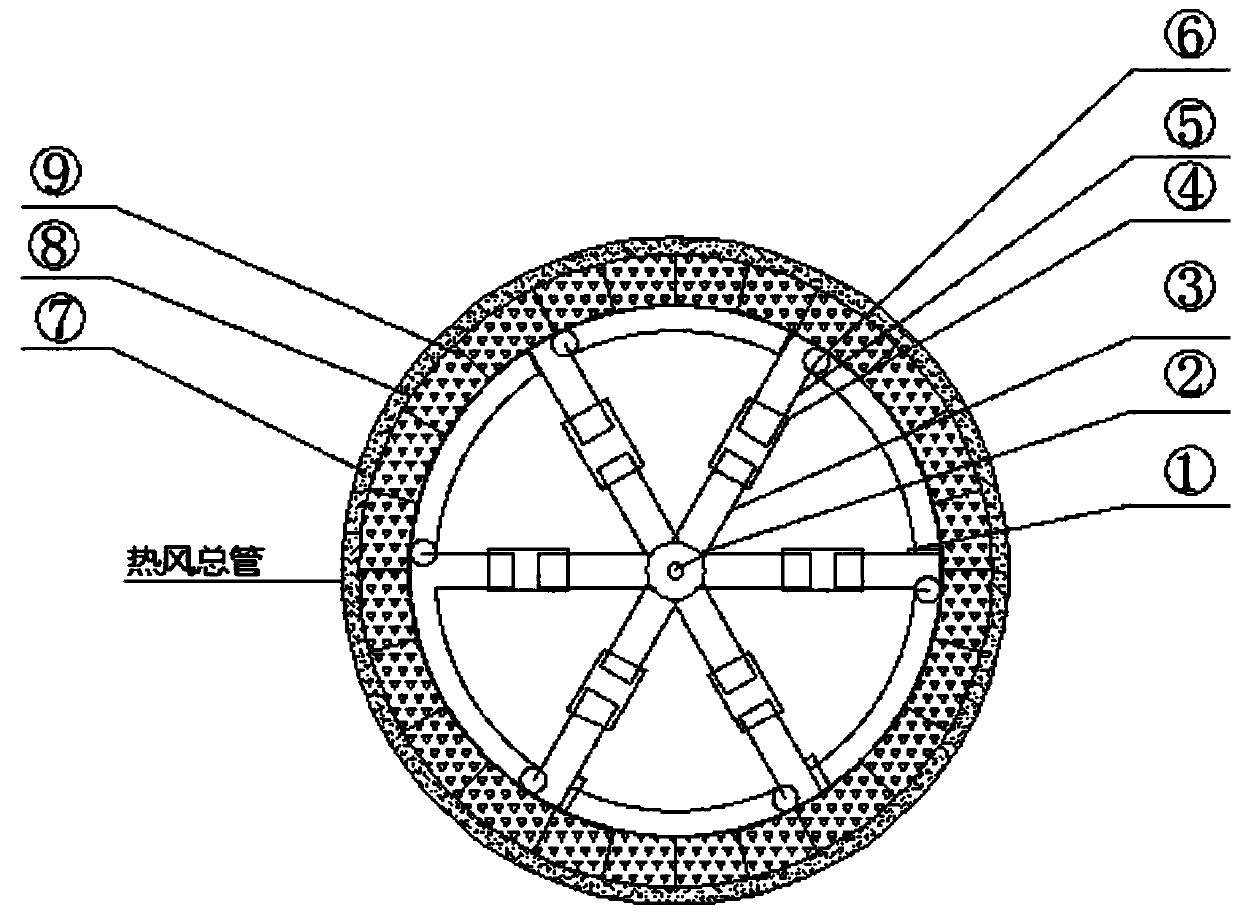

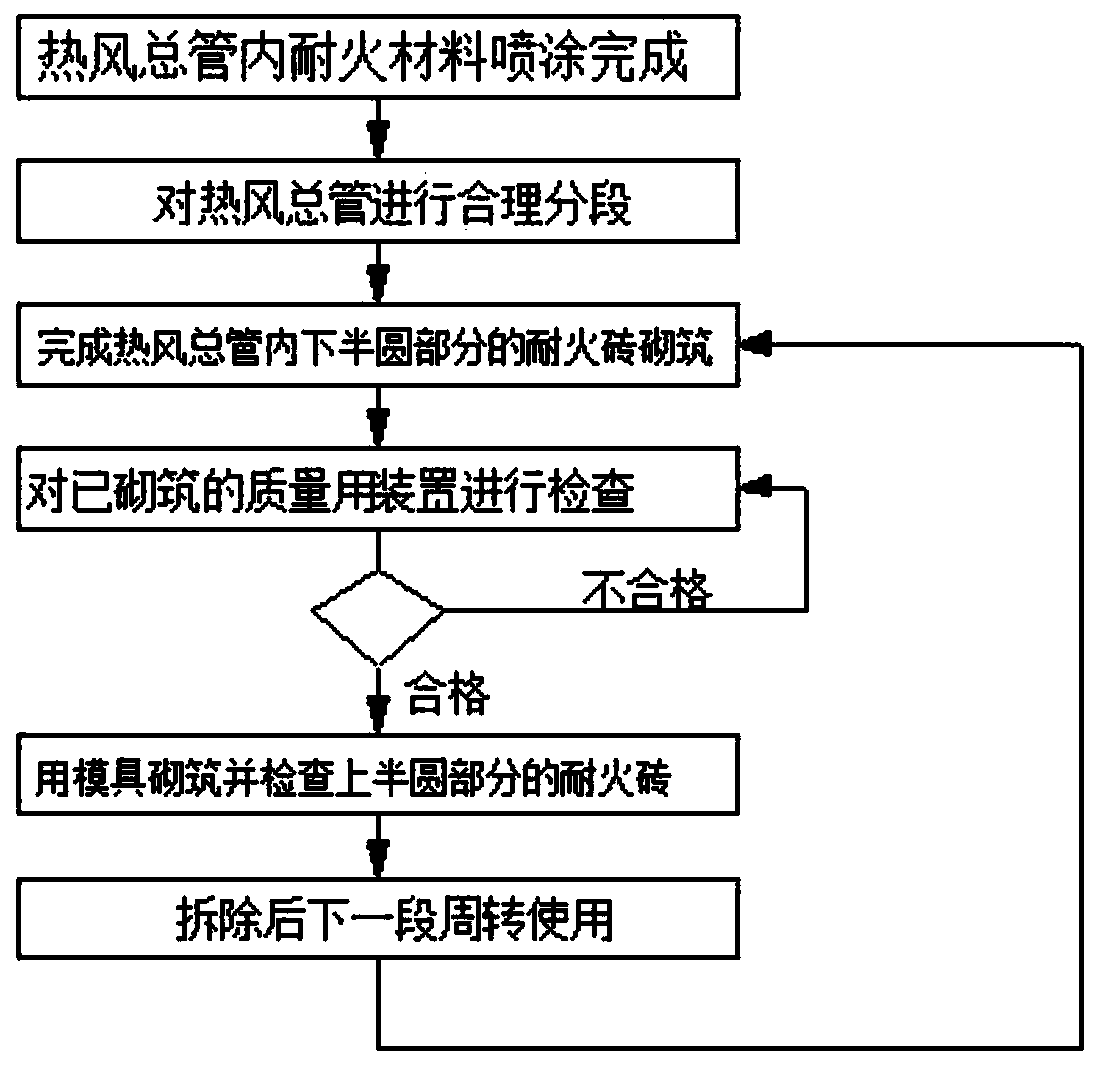

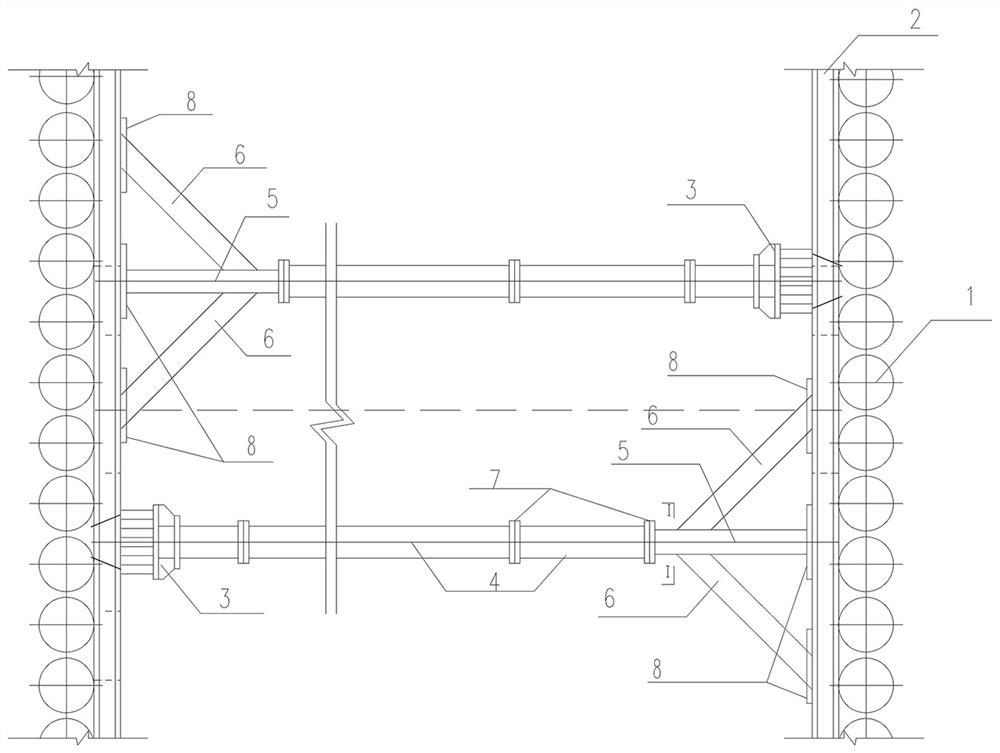

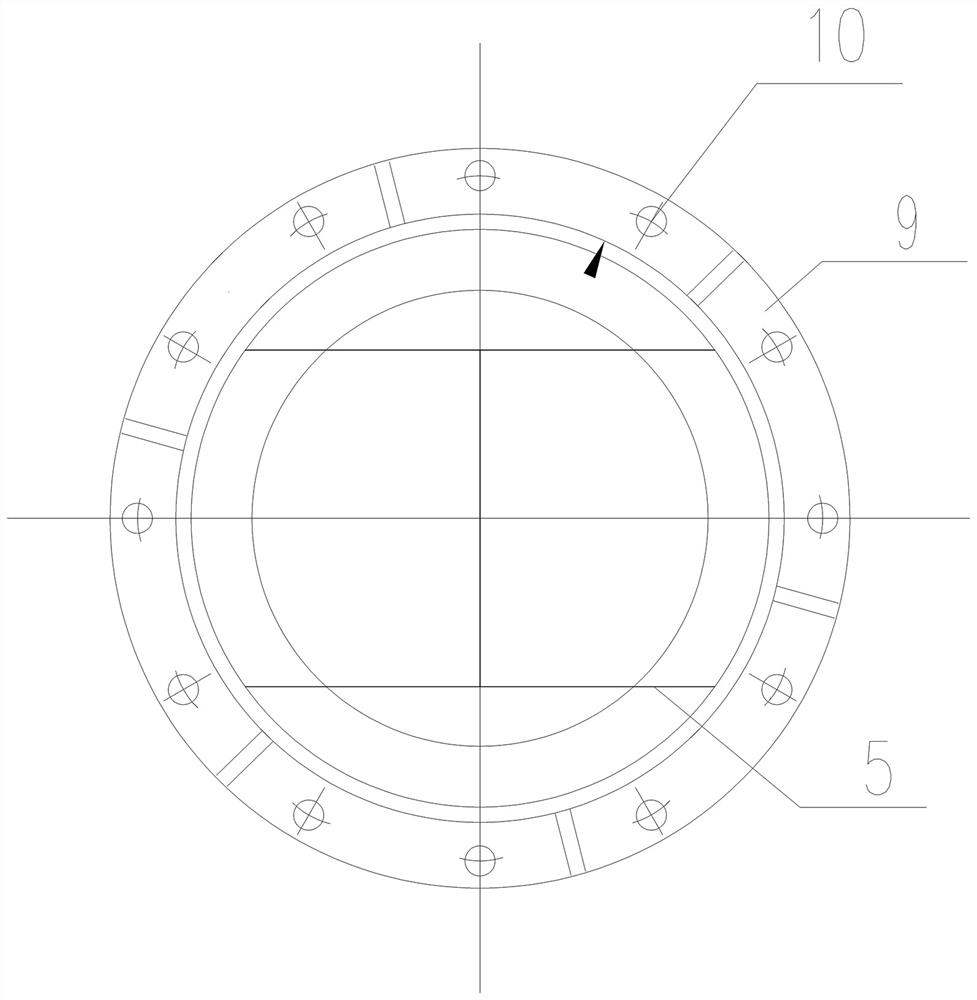

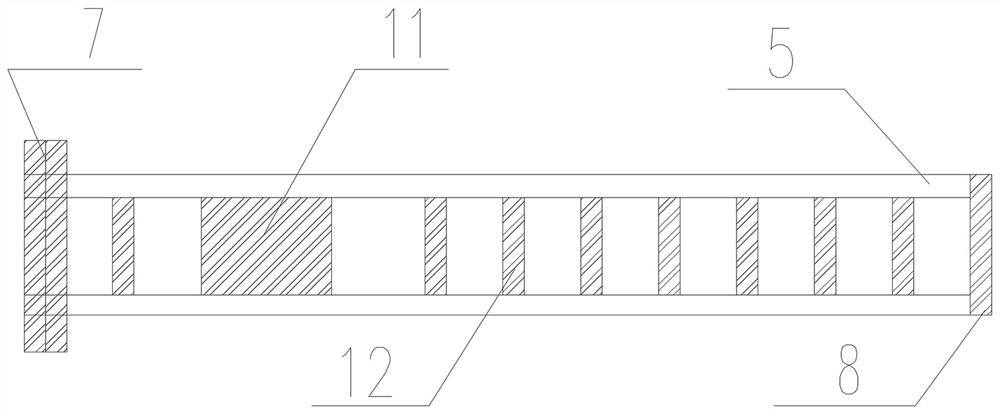

Hot air main pipe refractory masonry mold and its construction method

ActiveCN108396090BPrevent slidingImprove masonry qualityBlast furnace detailsHeating stovesBrickButt joint

The invention relates to a hot blast main refractory material building die and a construction method thereof. The die comprises a center shaft and three supporting rods with the middle portions rotationally arranged on the center shaft. The supporting rods can stretch and contract on the two sides of the center shaft. Arc arms are hinged to the two ends of each supporting rod, one ends are provided with butt-joint clamping grooves, the arc arms are distributed around the center shaft in the same direction and are equal in length, the other ends of the arc arms can be connected with the butt-joint clamping grooves in the next supporting rods in a matched manner, and the refractory brick inner circle meeting the design requirement can be defined after the arc arms and the butt-joint clampinggrooves are connected in a matched manner. According to the die, construction is conducted in a rotation pushing manner, the number of pipe interior supports is reduced on the premise that the quality testing and die dismounting time is saved, the quality is guaranteed on the premise that space is saved, the construction quality problem can be rapidly found, repeated usage can be achieved in thenarrow space of a hot blast main, and collisions are avoided.

Owner:CHINA FIRST METALLURGICAL GROUP

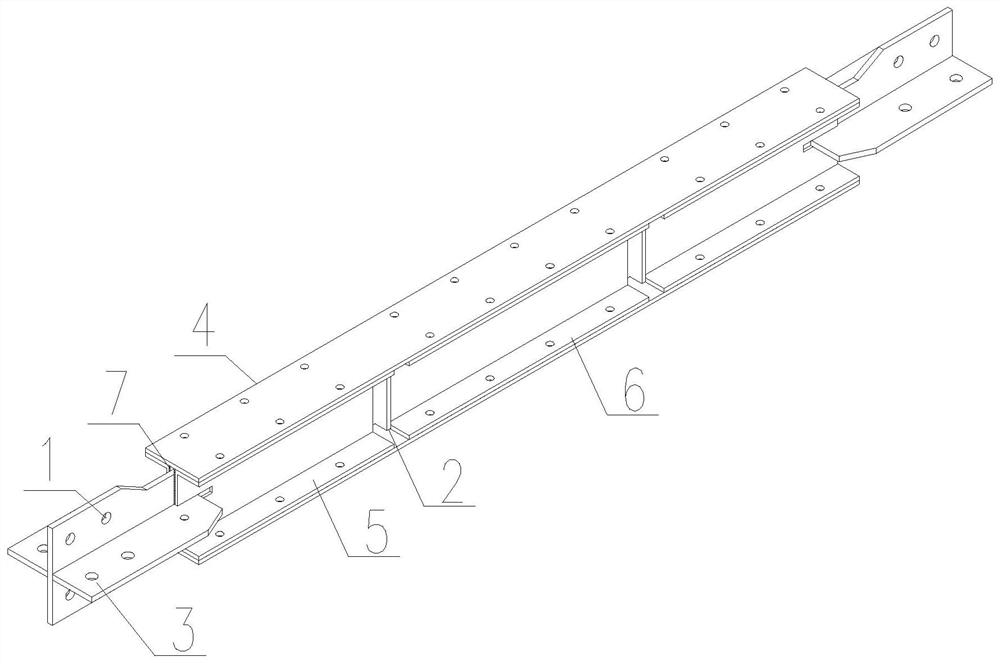

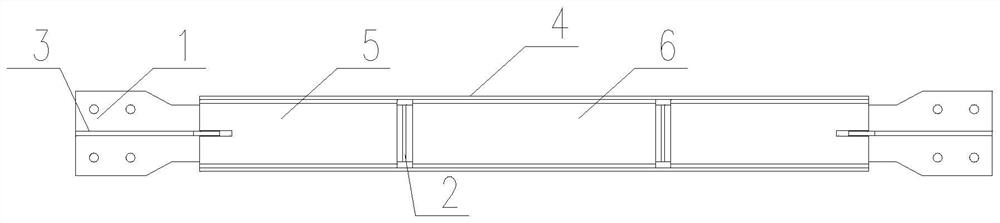

Foundation pit supporting system based on splayed I-shaped steel and construction method thereof

The invention relates to a foundation pit supporting system based on splayed I-shaped steel and a construction method thereof. The system comprises an inner support horizontally arranged in a foundation pit, wherein the inner support comprises two sections, namely a splayed I-shaped steel support and a steel pipe support; the splayed I-shaped steel support comprises a diagonal support and diagonal braces symmetrically arranged on two sides of the diagonal support; one end of each diagonal brace is fixed to a surrounding purlin or a crown beam in the foundation pit, and the other end of each diagonal brace is fixed to the side face of the diagonal support; one end of the diagonal support is fixed to the surrounding purlin or the crown beam in the foundation pit, and the other end of the diagonal support is connected with the steel pipe support; and the other end of the steel pipe support is fixed to the surrounding purlin or the crown beam in the foundation pit through a movable head. The novel inner support with one or two ends made of the splayed I-shaped steel is designed, so that the action range of each steel support is widened, the number of the inner supports is reduced, the cost is reduced, and the construction period is shortened; and meanwhile, the operation space in the foundation pit can be enlarged, more abundant operation conditions are reserved for large machinery, the earthwork outward transport and material feeding and discharging efficiency is improved, and a more efficient and economical foundation pit steel support system is realized.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

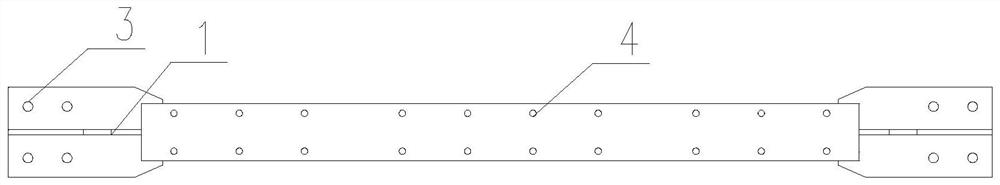

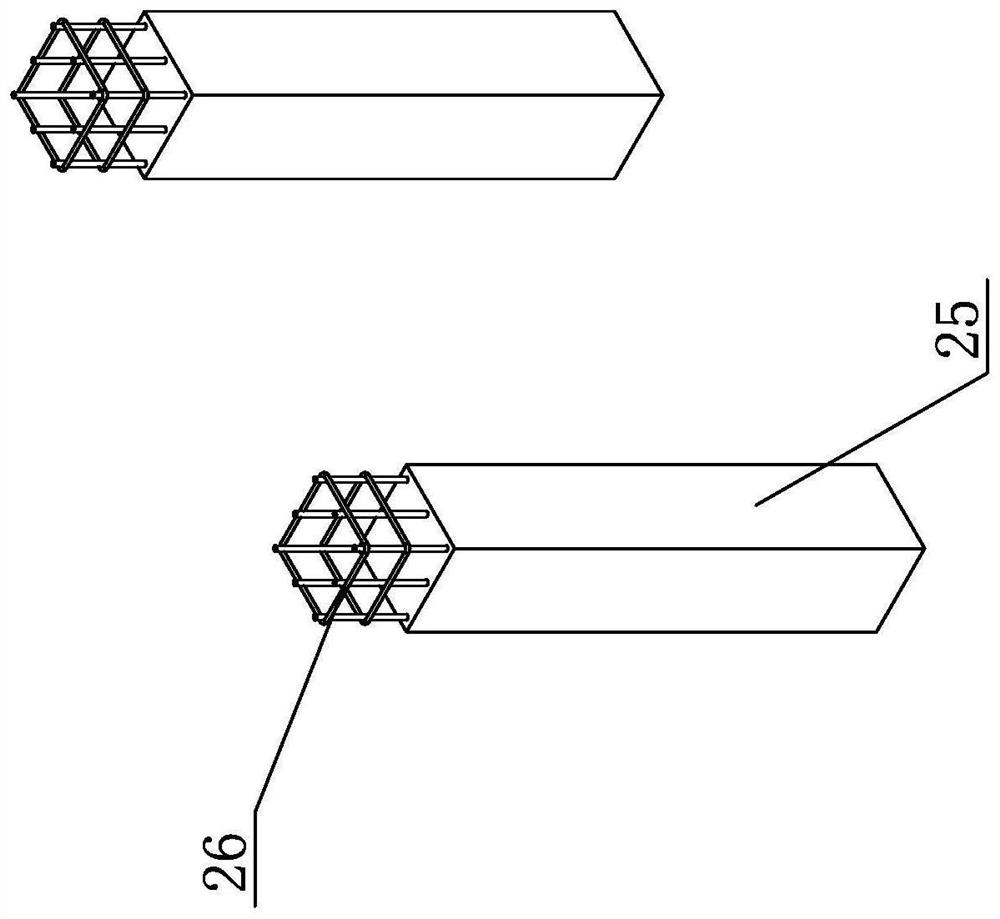

Full-bolt buckling-restrained brace and preparation method thereof

PendingCN113565228AReduce typesSimple designProtective buildings/sheltersShock proofingArchitectural engineeringStructural engineering

The invention discloses a full-bolt buckling-restrained brace and a preparation method thereof, and belongs to the technical field of building structure engineering. Two groups of end part stiffening ribs and at least two groups of limiting rib plates are arranged on a core plate, the two groups of end part stiffening ribs are arranged at the two ends of the core plate respectively, the limiting rib plates are arranged between the two groups of end part stiffening ribs in the axial direction of the core plate, an end part restraining unit is arranged between the end part stiffening ribs and the adjacent limiting rib plates, a middle restraining unit is arranged between every two adjacent limiting rib plates, the upper ends of the end part restraining units and the upper ends of the middle restraining units are connected with the corresponding restraining unit cover plates, and the lower ends of the end part restraining units and the lower ends of the middle restraining units are connected with the corresponding restraining unit cover plates. The full-bolt buckling-restrained brace is convenient to process and transport, and therefore the engineering quantity and resource consumption are reduced; the core plate enters plasticity after multi-section buckling, and the energy dissipation capacity of the core plate is fully exerted; the construction is simple and fast, and the safety of the structure is ensured while the working efficiency is improved; and the problem that a traditional concrete support needs regular maintenance is avoided, and green and energy-saving effects are achieved.

Owner:JILIN JIANZHU UNIVERSITY

Floor system construction method for fabricated building and fabricated plane floor system

ActiveCN114263303AImprove construction efficiencyAvoid unevennessFloorsBuilding material handlingFalseworkArchitectural engineering

The floor system construction method for the fabricated building and the fabricated plane floor system have the positive effects that according to the floor system construction method for the fabricated building and the fabricated plane floor system, the longitudinal beam truss plates and the transverse beam truss plates are laid in advance, then concrete pouring is conducted, and the situation that the bottom of the floor system is not flush is avoided. Wherein the beam truss plates and the laminated slabs form a whole, the upper and lower surfaces of the floor can be ensured to be flush with each other, the longitudinal beam truss plates can also be used as supporting plates of the beam truss plates and the laminated slabs in the construction process, the number of supports of scaffolds can be effectively reduced, labor is saved, and the upper and lower surfaces of the floor are flush with each other, so that later ceiling decoration can be saved; the overall construction efficiency of the floor system is improved, the building floor height is reduced, the beams and the plates are all plates, and manufacturing and construction are efficient.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

A new installation method of anchor block

ActiveCN106400673BImprove the efficiency of backfill constructionImprove securityBridge structural detailsBridge erection/assemblyEngineeringWrench

The invention provides a novel mounting method of an anchor pulling block. The novel mounting method comprises the following steps of: (1) placing a concrete square mound in a center direct-facing position of the anchor pulling block; (2) fixing a connecting iron part on the concrete square mound, and fixing all holes at the four corners of the connecting iron part with expansion bolts; (3) sleeving a reinforcing part, namely a steel cap, of the anchor pulling block in the middle position at the top of the anchor pulling block, and fastening bolts on the inner side to enable the steel cap to be tightly clung to the anchor pulling block; (4) connecting the steel cap and the concrete square mound with a lead screw, wherein the lead screw is connected with the connecting iron part and the steel cap through bolts, and the bolts need to be tightened with a wrench; and (5) tightening the bottom of the anchor pulling block and a prepared reinforcing steel bar by using a wood chip of 10cm long. According to the novel mounting method provided by the invention, only the outside of the anchor pulling block needs to be supported, so that supporting materials can be saved, and besides, the efficiency of backfill construction on the rear side of the anchor pulling block is improved.

Owner:CCCC FIRST HARBOR ENG +1

Assembled concrete structural column hoisting elevation and verticality adjustment device and its construction method

ActiveCN109518980BGuaranteed widthEliminate construction safety hazardsBuilding material handlingArchitectural engineeringStructural engineering

Owner:FUJIAN UNIV OF TECH

Construction method for deep foundation pit excavation of subway station

ActiveCN104612162BThe method steps are simpleReasonable designExcavationsReinforced concreteSubway station

The invention discloses a subway station deep foundation pit excavation construction method, wherein the upper portion of an excavated foundation pit is a sandy gravel stratum, and the lower portion of the excavated foundation pit is a mud rock stratum. The method includes the steps of 1, precipitation construction, wherein precipitation construction is conducted on the sandy gravel stratum through a precipitation well and 2, foundation pit excavation, wherein the foundation pit excavation includes the following steps of foundation pit partition and foundation pit earthwork excavation; the excavated foundation pit is divided into a plurality of small foundation pit bodies to conduct excavation respectively; the small foundation pits comprise first foundation pit bodies and second foundation pit bodies; excavation is conducted on the divided small foundation pit bodies; an open-cut method is adopted for the first foundation pit bodies and the second foundation pit bodies; the first foundation pit bodies are supported by fender posts, reinforced concrete supports and steel pipe inner supports; the second foundation pit bodies are supported by the fender posts, pre-stressed anchor cables and the steel pipe inner supports. The subway station deep foundation pit excavation construction method is simple in step, reasonable in design, convenient to construct, faster in construction process, good in construction effect and capable of easily conveniently and fast to finish deep foundation pit excavation construction process, and the influences on the surrounding environment by the excavation construction process are smaller.

Owner:中铁二十局集团第三工程有限公司

A post-casting tape inflatable arc angle rectangular hose side formwork support construction method

ActiveCN109025294BReduce the number of supportsReduce the number of units usedBuilding material handlingBuilding insulationsAir pumpEngineering

The invention relates to a post-cast strip side mold support construction method; an inflatable arc angle rectangular flexible pipe is arranged in a gap between an upper layer steel bar and a lower layer steel bar in the post-cast strip position; in inflation, the arc angle rectangular flexible pipe is extruded by the upper and lower layer steel bars so as to fill the gap caused by the steel bars;the soft pipe is inflated to form an air column so as to space the concrete; the cross section outer contour of the arc angle rectangular flexible pipe is an arc-shaped rectangular shape; the arc angle rectangular is a rectangular with four arc-shaped corners, and is an axially symmetrical and centrosymmetric geometric figure; the arc angle rectangular flexible pipe comprises a soft pipe outer wall and a soft pipe inner wall; the soft pipe outer wall cross section is the cross section contour of the arc angle rectangular flexible pipe, i.e., an arc angle rectangular; the soft pipe inner wallcomprises an upper pipe inner wall, a lower pipe inner wall and a common inner wall; the area enclosed by the upper pipe inner wall and the lower pipe inner wall is an air pump pressurization area; anarea enclosed by the soft pipe outer wall, the lower portion of the upper pipe inner wall and the upper portion of the lower pipe inner wall is an air connection area; the common inner wall has a constant pressure hole. The method employs the inflatable arc angle rectangular flexible pipe support, is good in moulding effect, high in construction quality, and high in efficiency.

Owner:FUJIAN JIANGXIA UNIV

A construction method for supporting with prestressed h-shaped steel support structure

The invention discloses a prestressed H-type steel supporting structure and a construction method thereof. The prestressed H-type steel supporting structure comprises a plurality of prestressed supporting units. Each prestressed supporting unit comprises a supporting pile, a plurality of steel supports and prestressed bars, wherein the supporting pile is vertically arranged on one side of a foundation pit to be excavated, the steel supports are arranged on the supporting pile from top to bottom, and one end of each prestressed bar is anchored to the lower portion of the supporting pile. The prestressed supporting units are sequentially driven into the periphery of the foundation pit to be excavated, the steel supports all face the foundation pit to be excavated, a top beam is arranged at the top end of each prestressed supporting unit, and each prestressed supporting unit and the corresponding top beam are integrated. Tensile force is applied to the prestressed bars, and the upper ends of the prestressed bars are anchored to the top beams. The horizontal component of the tensile force borne by the prestressed bars is transferred to the supporting structure, and therefore partial soil pressure of soil is counteracted, the supporting strength is improved, and deformation of the supporting piles is reduced. In addition, the supporting structure can be recycled, and therefore the cost is reduced.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com