A construction method for supporting with prestressed steel sheet pile supporting structure

A technology of support structure and construction method, which is applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problems of cumbersome support procedures, poor stability, inconvenient operation, etc., achieve large lateral rigidity, strong bending resistance, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

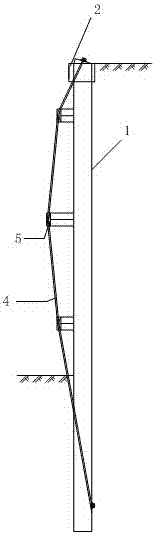

[0054] Determine the length of support pile 1, the number of steel supports 3, the length of steel supports 3 and the adjacent steel supports on each prestressed support unit according to the geological data of the foundation pit to be excavated, the depth of excavation and the surrounding environmental conditions The distance between the seat 3 is to anchor one end of the prestressed tendon 4 to the lower part of the support pile 1, and the other end of the prestressed tendon passes through the limit devices 5 on all steel supports 3 in turn to prefabricate the prestressed support unit.

[0055] Such as figure 1 As shown, the length of the support pile 1 is 15m, the excavation depth of the foundation pit is 10m, two steel sheet piles are connected between adjacent support units, and the entire support structure forms a cofferdam. Each support pile 1 is provided with three steel supports 3, the maximum distance between adjacent steel supports 3 on each support pile 1 is 3m, th...

Embodiment 2

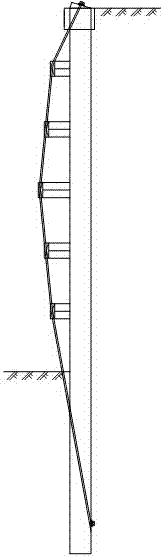

[0057] Such as Figure 4 As shown, the length of the support pile 1 is 18m, the excavation depth of the foundation pit is 12m, a steel sheet pile is connected between adjacent support units, and the entire support structure forms a cofferdam. Each support pile 1 is provided with five steel supports 3, the maximum distance between adjacent steel supports 3 on each support pile 1 is 3m, the minimum value is 1m, and the longest steel support 3 has a length of 0.7m, each prestressed support unit is provided with four prestressed prestressed tendons 4, the nominal diameter of each prestressed prestressed tendons 4 is 15.2mm, and the supporting pile 1 is 6m deep below the bottom of the pit.

Embodiment 3

[0059] Such as Figure 5 As shown, the length of the support pile 1 is 30m, the excavation depth of the foundation pit is 15m, a steel sheet pile is connected between adjacent support units, and the entire support structure forms a cofferdam. Each support pile 1 is provided with seven steel supports 3, the maximum distance between adjacent steel supports 3 on each support pile 1 is 3m, the minimum value is 1m, and the longest steel support 3 has a length of 0.9m, five prestressed tendons 4 are arranged on each prestressed support unit, the nominal diameter of each prestressed prestressed tendon 4 is 15.2mm, and the support pile 1 is 15m deep below the bottom of the pit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com