Construction method of self-supporting single-side formwork system for super high exterior wall of basement

A construction method and one-side formwork support technology, applied in the direction of formwork/formwork/work frame, joints of formwork/formwork/work frame, artificial island, etc., can solve the problem of base plate damage, large space occupation, and time-consuming Many problems, to achieve the effect of ensuring stability, increasing anchoring force, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, the pile foundation and support and protection pile reinforcement binding and forming, cushion layer and bottom plate reinforcement binding and pouring process, waterproofing work and other construction technologies will not be repeated in this embodiment, and the structural implementation of the formwork system of the present invention will be focused on The way, and with the accompanying drawings, the detailed description is as follows:

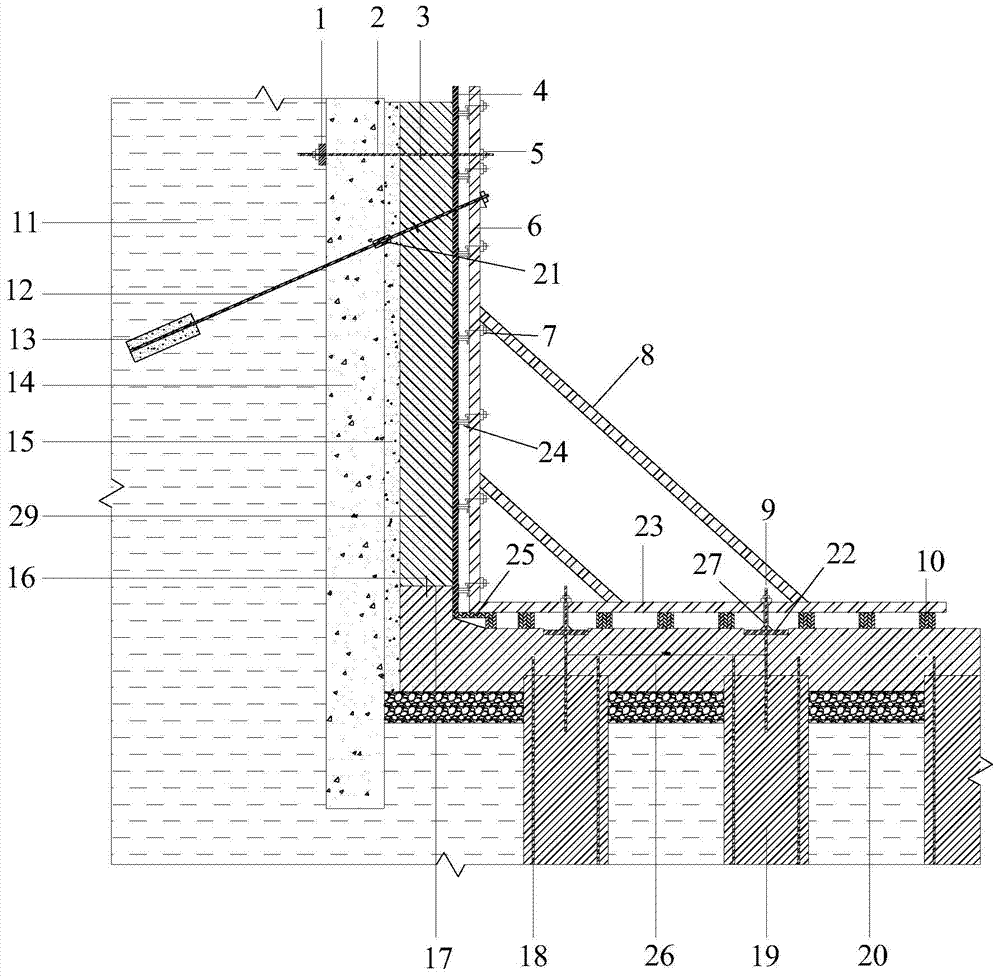

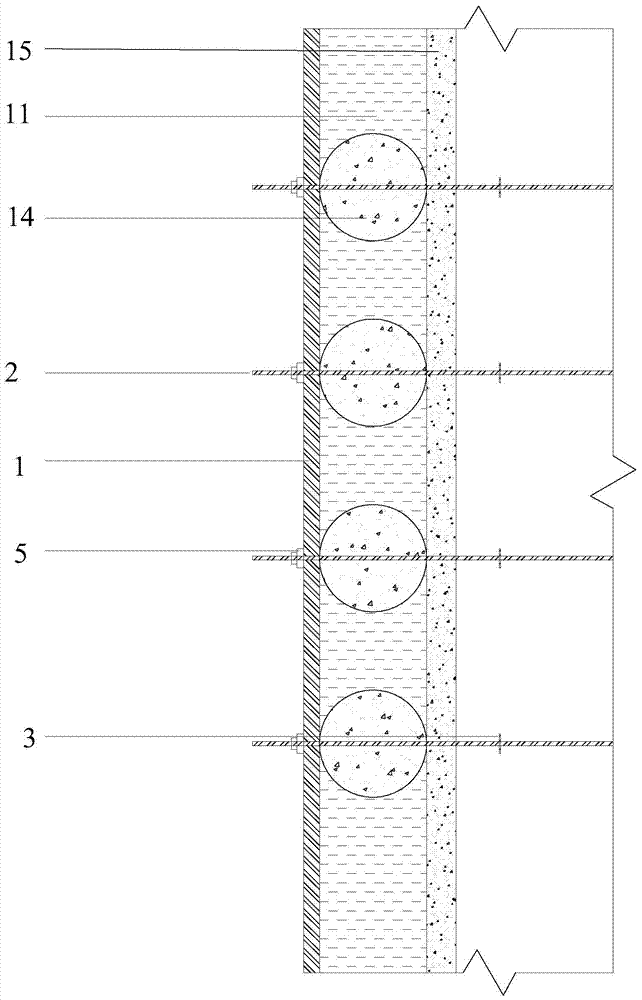

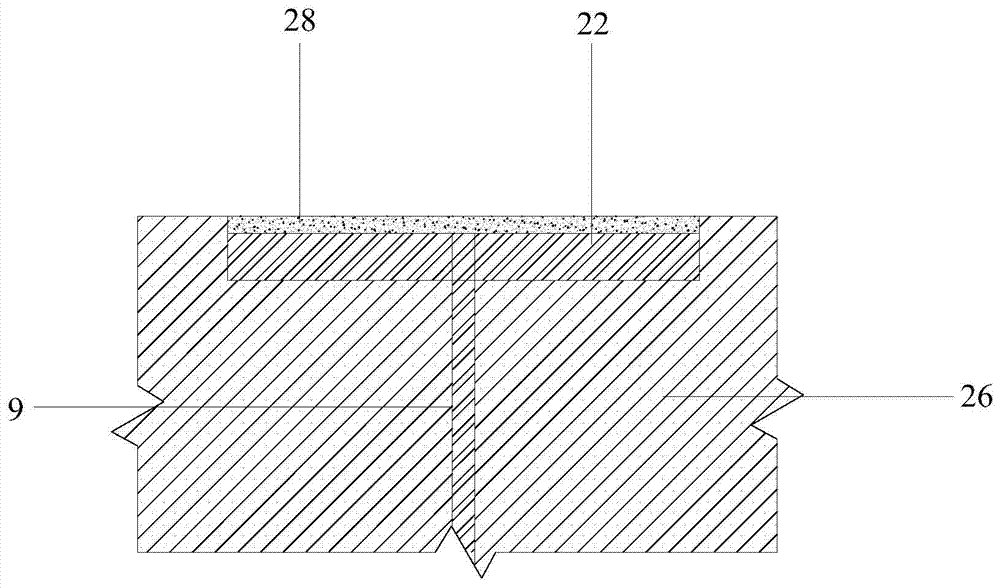

[0037] figure 1 is a side view of the formwork system of the present invention, figure 2 It is a plan view of the pre-embedded tie bars of the formwork system of the present invention, image 3 It is a sectional view of the pre-embedded steel plate of the formwork system of the present invention.

[0038] refer to figure 1 , figure 2 , image 3 A self-supporting single-side formwork system for a super-high exterior wall of a basement is shown. Before the construction of the exterior wall formwork, anchor ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com