Construction method of water collection and drainage system

A construction method and drainage system technology, which is applied to waterway systems, sewer systems, drainage structures, etc., can solve the problems of lack of resource turnover, cracking and damage of drainage ditches and wells, and large maintenance costs, etc., and achieve simple, fast and economical construction Material, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

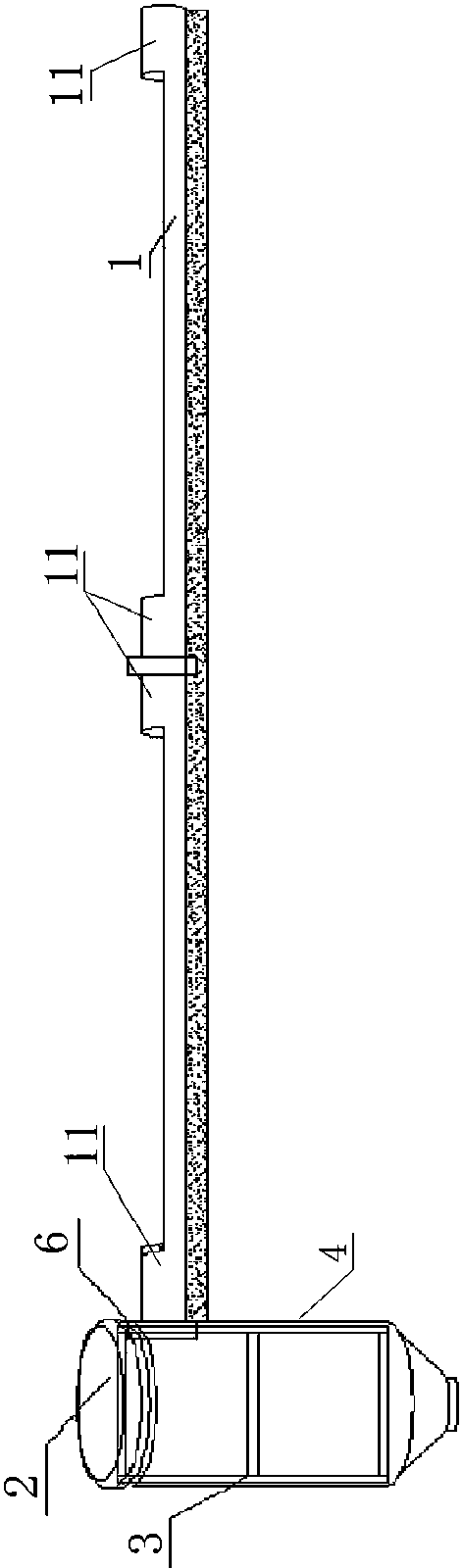

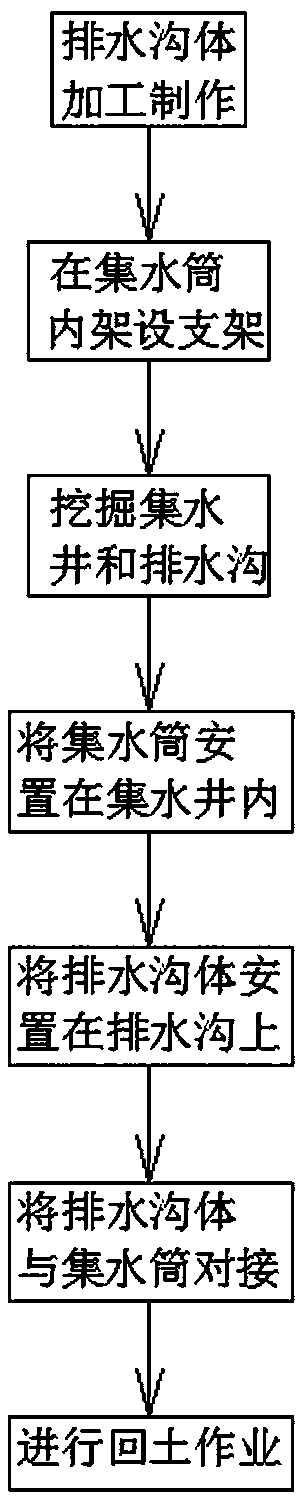

[0035] see Figure 1 to Figure 3 , a construction method of a drainage system, comprising the following steps:

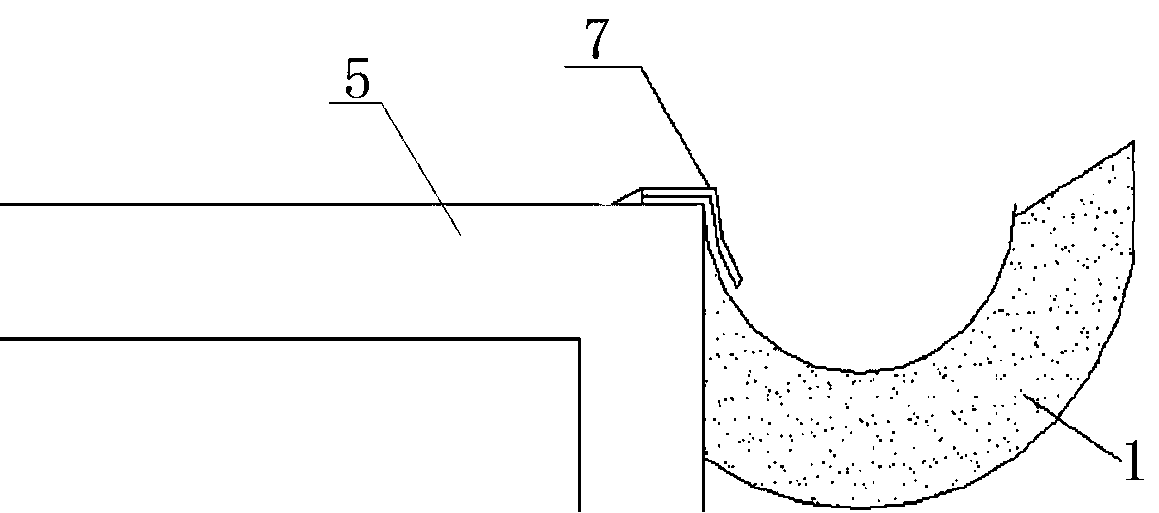

[0036] Step 1, the drainage ditch body 1 is processed and manufactured, and part of the pipe wall of the PVC pipe is cut off, so that the shape of the two ends 11 of the PVC pipe is complete, and the remaining part forms an open groove;

[0037] Step 2, erecting the bracket 3 in a water collecting bucket 4;

[0038] Step 3, excavate water collection wells and drainage ditches;

[0039] Step 4, placing the water collecting bucket 4 in the water collecting well;

[0040] Step 5. Place the drain body 1 on the drain. If the length of the drain body 1 is not enough, use a joint to connect the PVC pipe to extend;

[0041] Step 6. Connect the drainage ditch body 1 with the water collection bucket 4, so that the drainage ditch body 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com