Large-pipe-diameter Ni-V rotary target material containing microelements and preparation method of large-pipe-diameter Ni-V rotary target material

A technology with trace elements and large tube diameter, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as cracking of nickel-vanadium tubes, improve utilization rate, and improve grain boundary binding force , The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

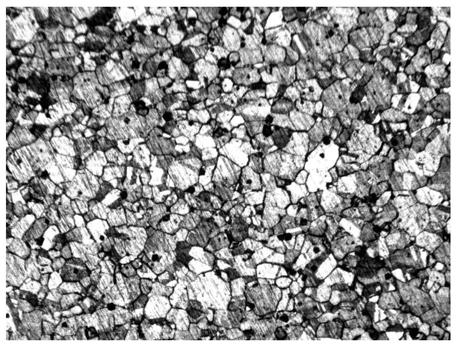

Image

Examples

Embodiment 1

[0050] In this embodiment, the components and contents of the large-diameter Ni-V rotating target containing trace elements are, by mass percentage, respectively: C 0.02%, B 0.03%, Ti 0.005%, Mg 0.01%, V 6% and The balance is Ni and unavoidable impurities.

[0051] The preparation method of the large-diameter Ni-V rotating target comprises the following steps:

[0052] (1) Vacuum smelting: prepare raw materials graphite, boron particles, metal titanium, metal magnesium, metal vanadium, electrolytic nickel, wherein the purity of the raw materials is 99.9% of graphite, 99.9% of boron particles, 99.9% of metal titanium, 99.9% of Metal magnesium, 99.9% metal vanadium, 99.96% electrolytic nickel;

[0053] Clean the surface oil and oxides of electrolytic nickel and metal vanadium, dry and weigh them, then bake the electrolytic nickel at 600°C and keep it warm for 6 hours; Graphite is put into a vacuum melting crucible, electrified and smelted, the smelting temperature is 1500°C, a...

Embodiment 2

[0065] The components and contents of the large-diameter Ni-V rotating target in this embodiment are, by mass percentage, respectively: C0.03%, B 0.01%, Ti 0.003%, Mg 0.03%, V 7%, and the balance Ni and unavoidable impurities.

[0066] The preparation method of the large-diameter Ni-V rotating target in this example is basically the same as that in Example 1, except that:

[0067] In step (1), the electrolytic nickel is baked at 580°C and kept warm for 5 hours; the melting temperature is 1450°C, the melting time is 70 minutes, and the refining time is 10 minutes:

[0068] In step (3), the ingot is heated to 1090° C., and after 20 minutes of heat preservation, forging is carried out. The starting forging temperature is 1090° C., and the final forging temperature is 1000° C.; the deformation of pier thickness is 55%, and the deformation of post-drawing is 55%;

[0069] In step (4), the central through hole with a diameter of 20 mm is machined, and a tapered hole with a 30° tap...

Embodiment 3

[0075] The components and contents of the large-diameter Ni-V rotating target in this embodiment are, by mass percentage, respectively: C 0.05%, B 0.08%, Ti 0.001%, Mg 0.05%, V 8% and the balance Ni and unavoidable impurities.

[0076] The preparation method of the large-diameter Ni-V rotating target in this example is basically the same as that in Example 1, except that:

[0077] In step (1), the electrolytic nickel is baked at 610°C for 8 hours; the melting temperature is 1400°C, the melting time is 90 minutes, and the refining time is 20 minutes:

[0078] In step (3), the ingot is heated to 1110°C, and after holding the heat for 40 minutes, it is forged. The starting forging temperature is 1110°C, and the final forging temperature is 990°C; the deformation of the pier thickness is 65%;

[0079] In step (4), machining a diameter is a central through hole of 30mm, and machining a tapered hole into a 40° taper at one end thereof;

[0080] In step (5), the induction heating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com