Foundation pit supporting system based on splayed I-shaped steel and construction method thereof

A technology for foundation pit support and I-beam, which is applied in infrastructure engineering, excavation, construction, etc., can solve problems such as long demolition time, hidden safety hazards, and small construction work space, achieving significant economic and technical benefits and increasing support spacing. The effect of large and mature construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with specific embodiments.

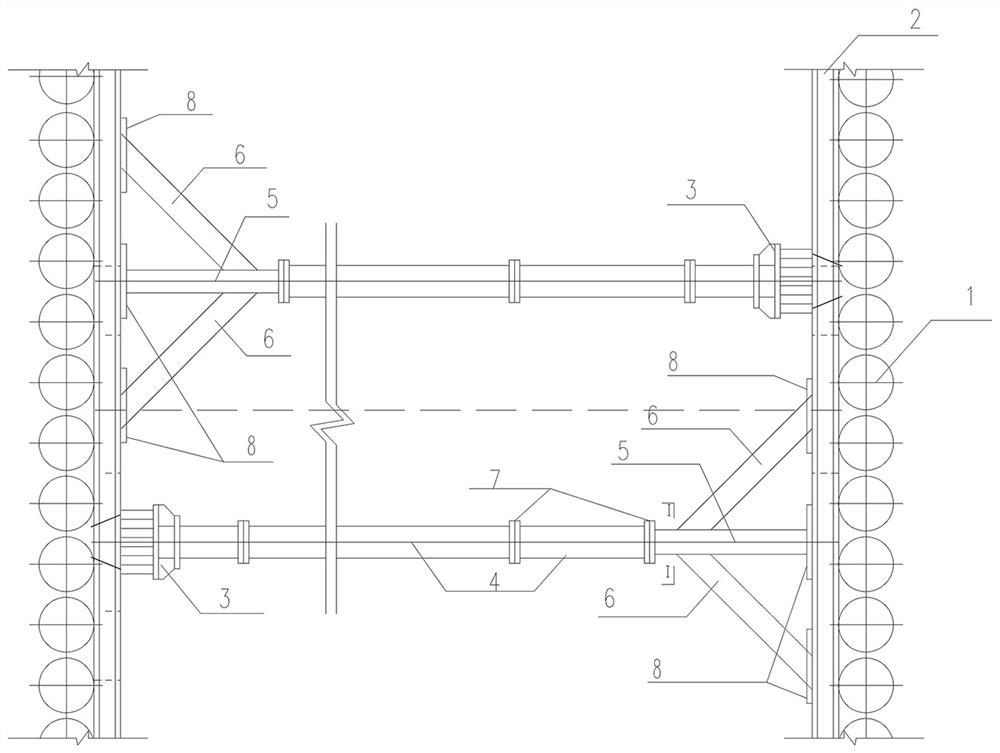

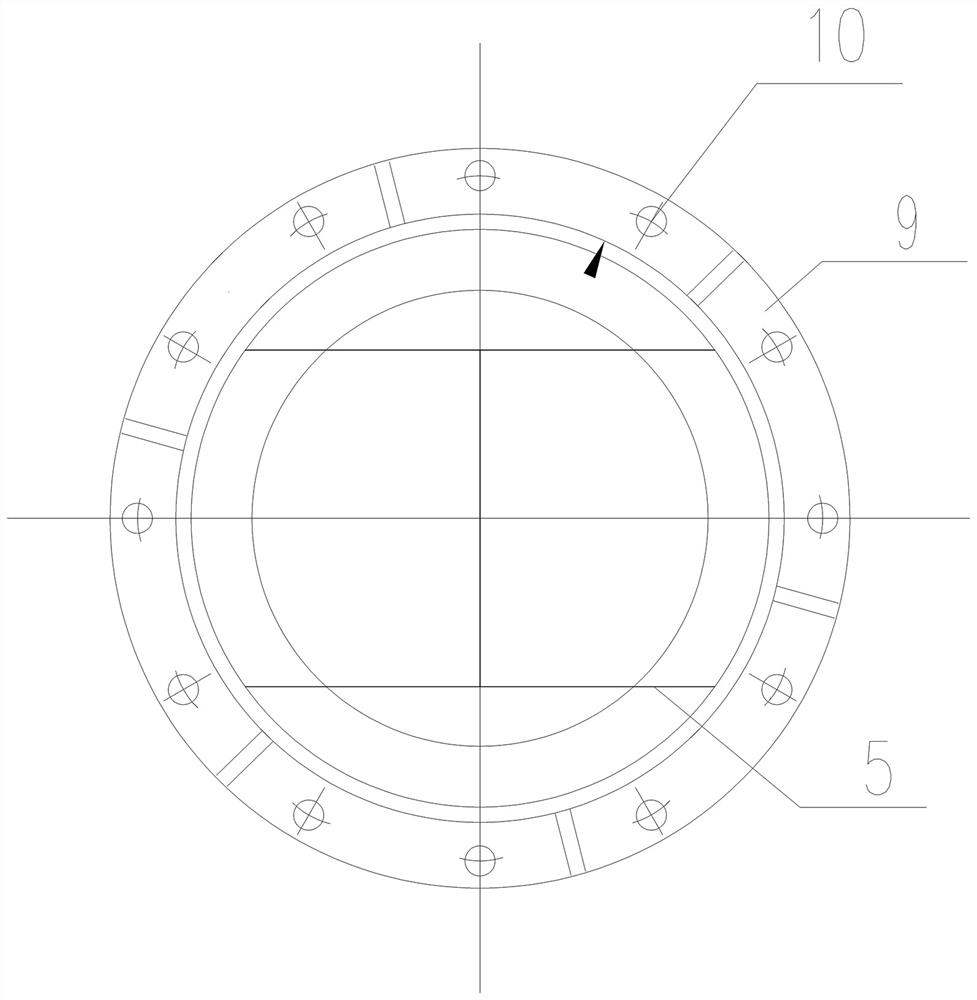

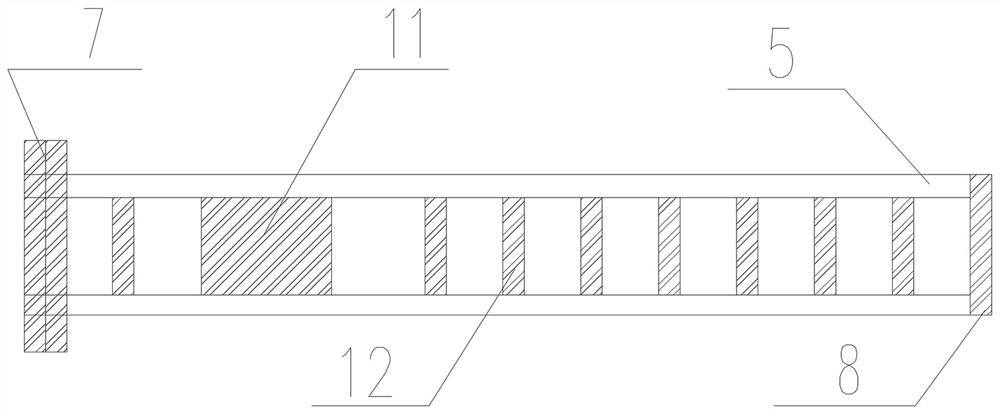

[0044] The present invention relates to a foundation pit support system based on octatimer-based steel, including the horizontal support within the foundation pit, and the support of the foundation pit includes eight-character working text steel support and steel pipe support 4 segments; eight words Type structure steel support includes a diagonal support 6 that is symmetrically arranged on both sides of the support 5 and the support 5; one end of the oblique support 6 is fixed to the surface of the base pit, and the other end is fixed to the side surface of the support 5; support 5 One end is fixed to the sacral 2 or crown beam in the foundation pit, and the other end is mechanically connected to the steel pipe 4; the other end of the steel pipe 4 is fixed to the sacral pit 2 or the crown beam.

[0045] Both the counter 5 and the opposing support 6 are allocated steel, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com