Patents

Literature

58results about How to "Good economic and technical benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological slope protection structure of road cutting side slope and construction method

InactiveCN106703054AImprove survival rateGood economic and technical benefitsGeneral water supply conservationWatering devicesNutrientIrrigation

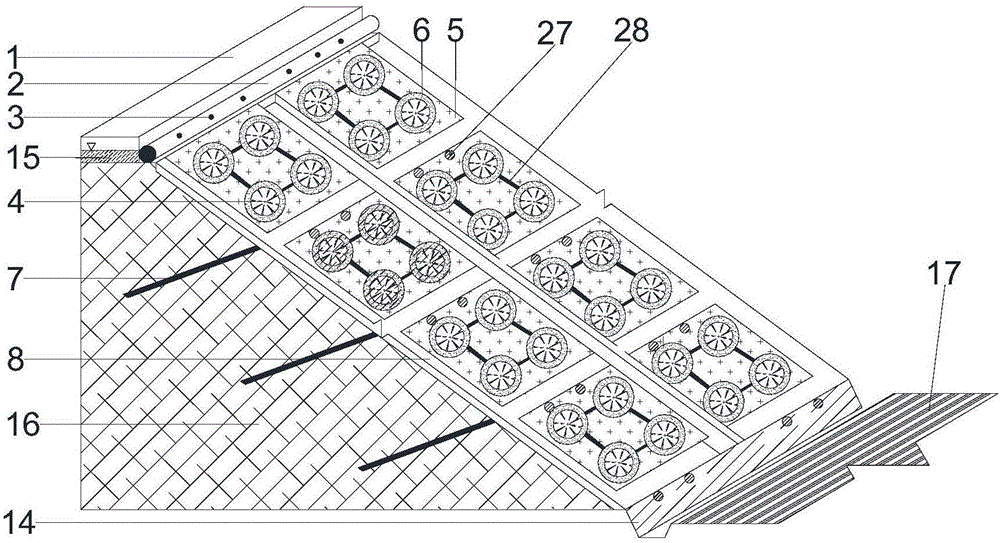

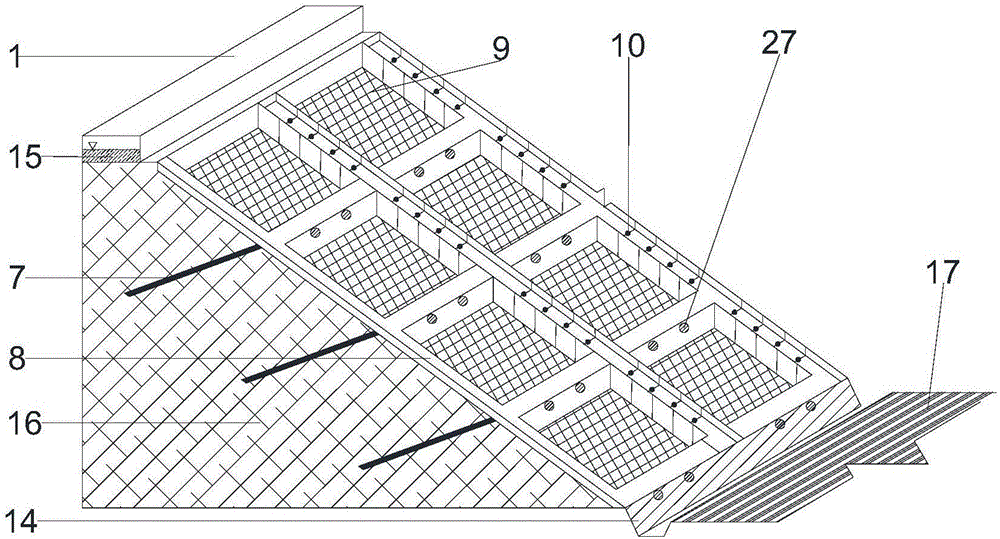

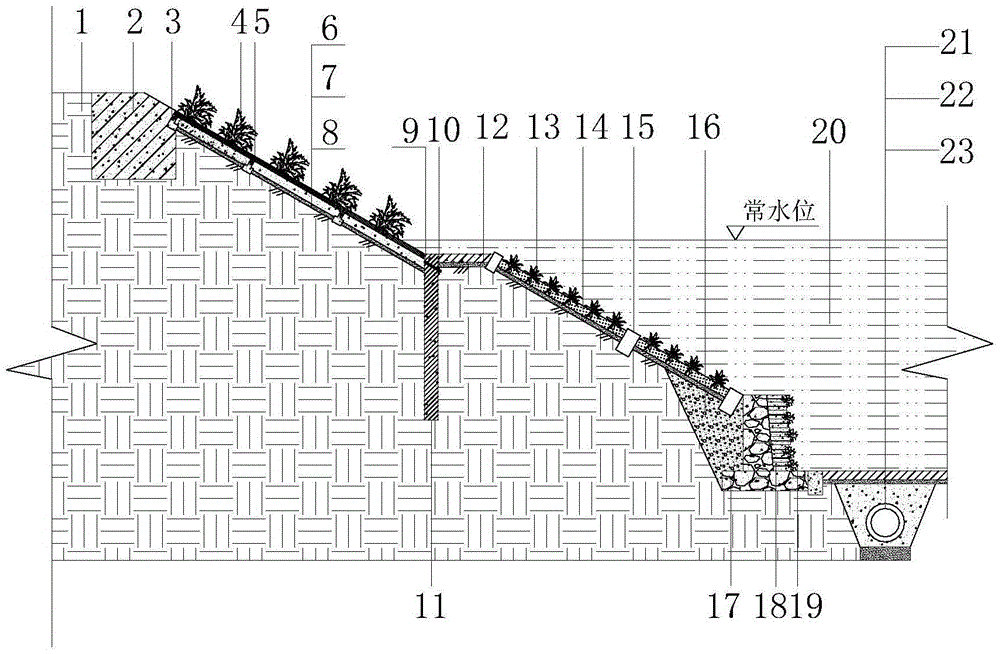

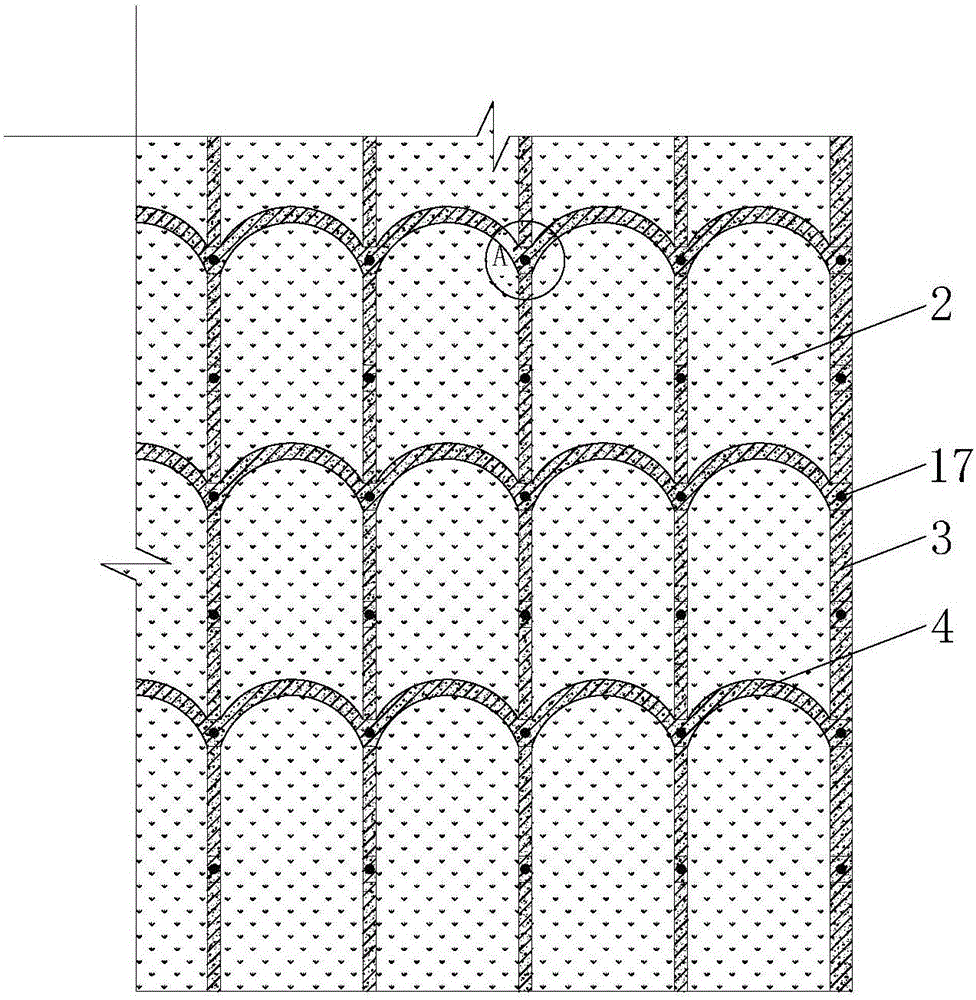

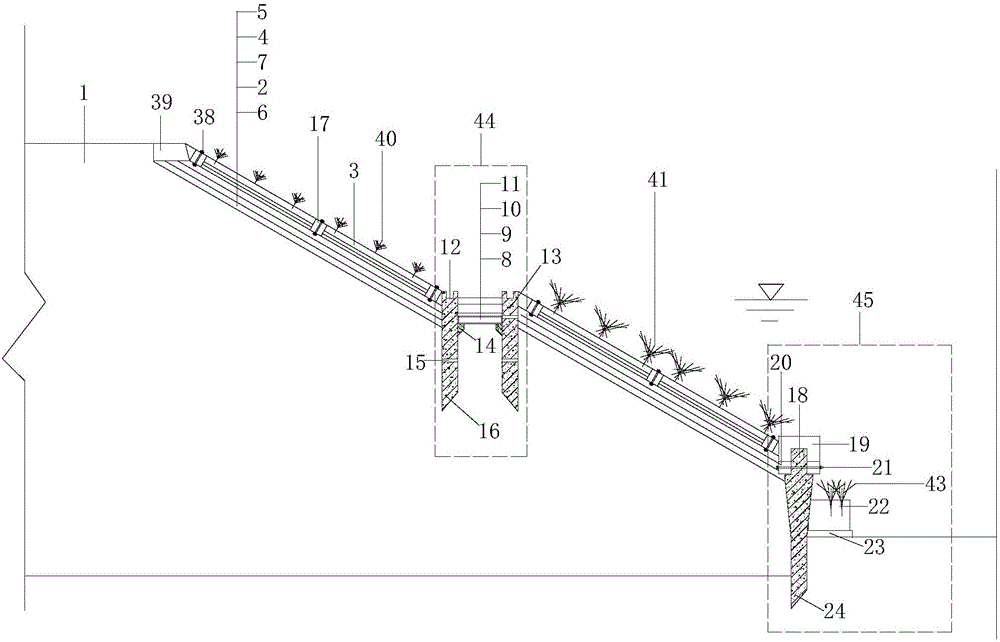

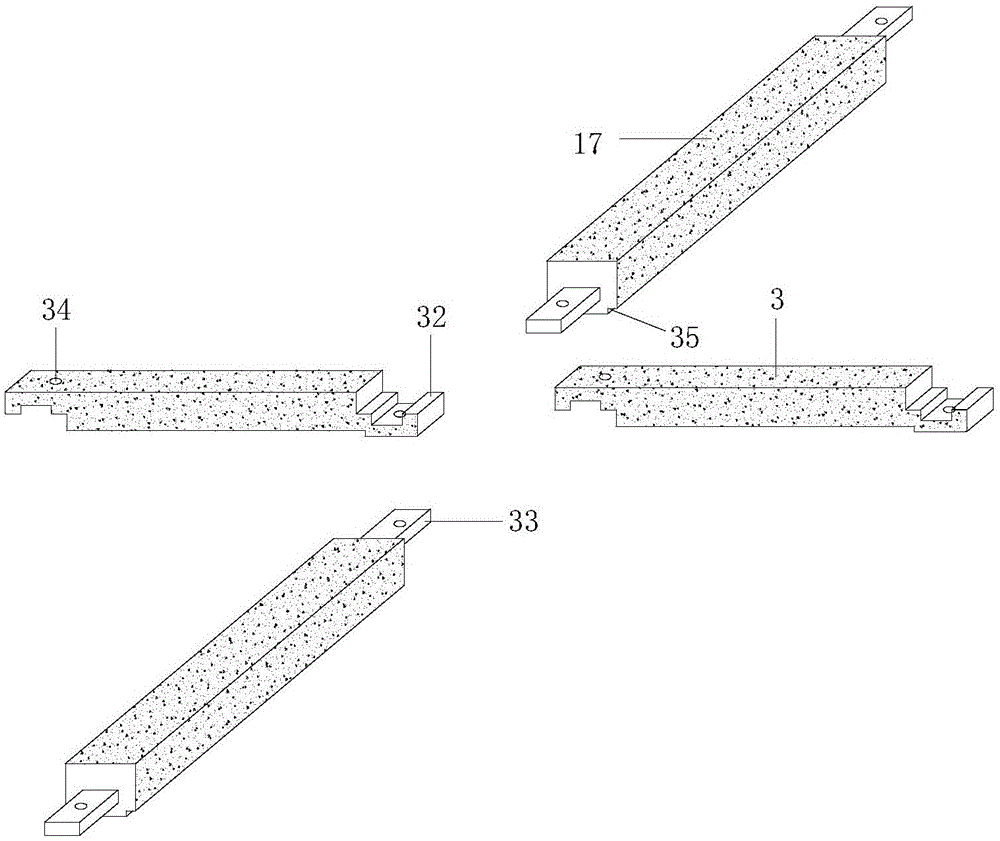

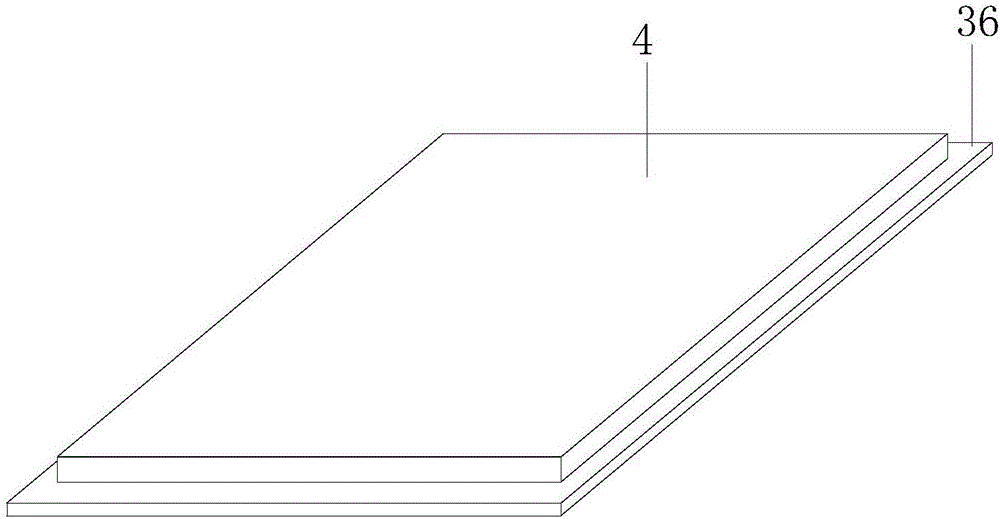

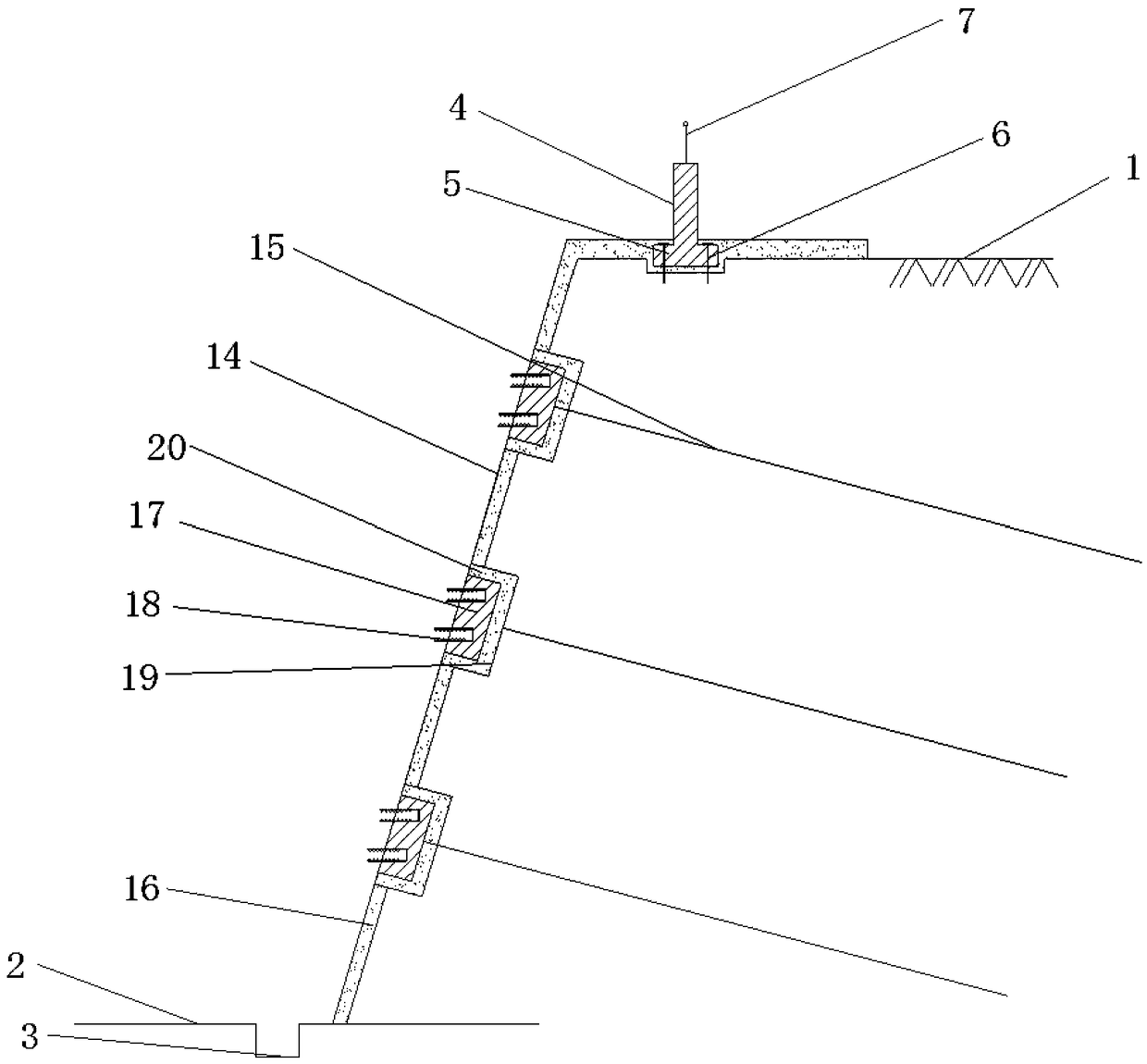

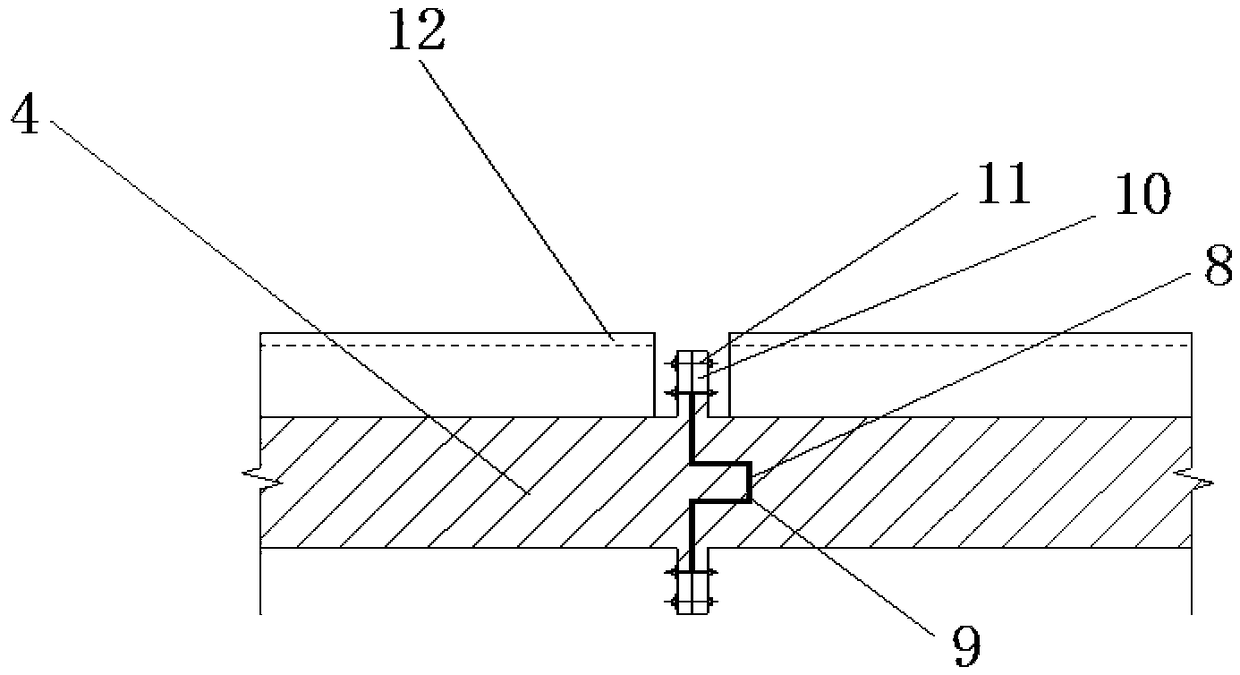

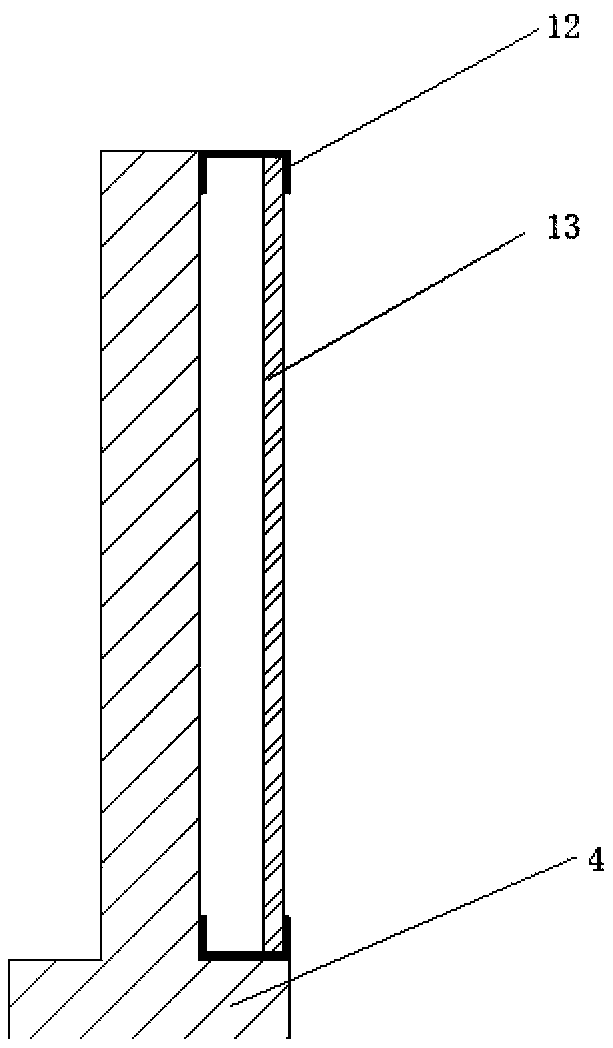

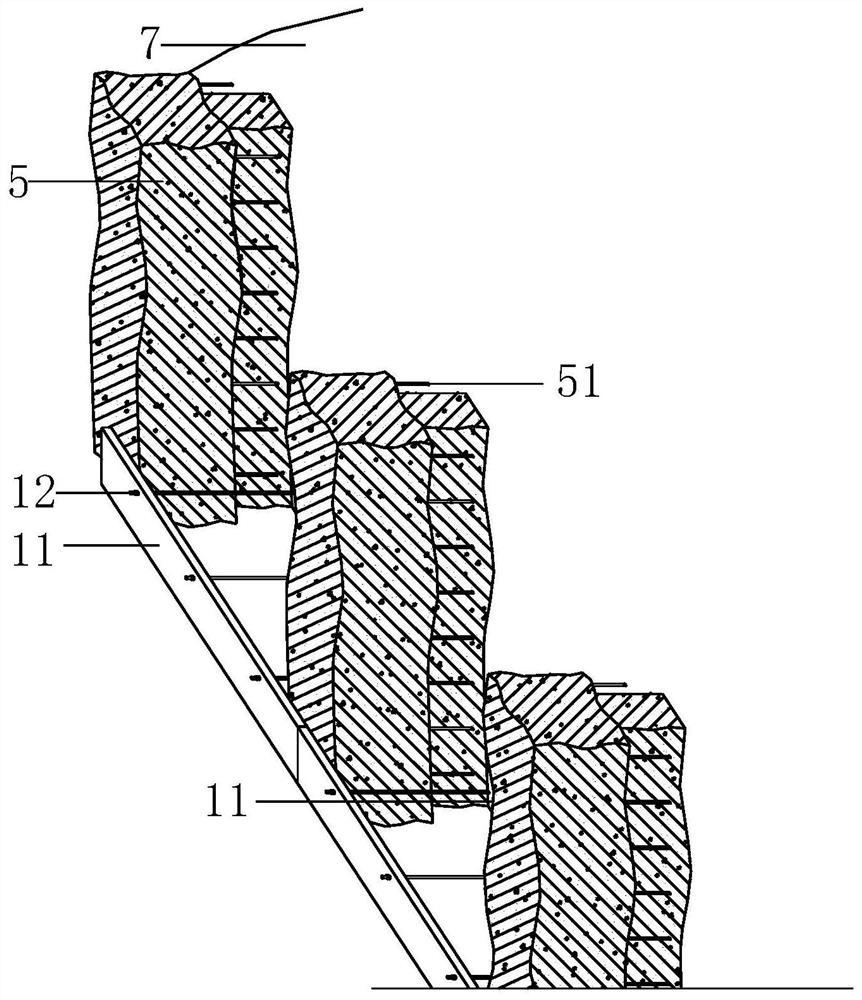

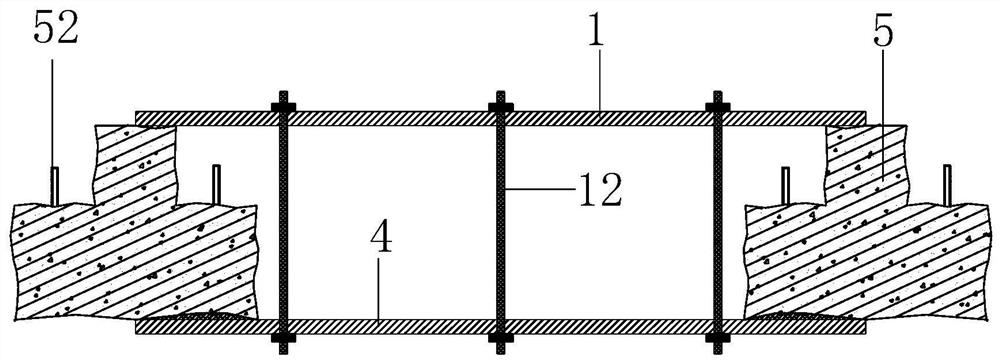

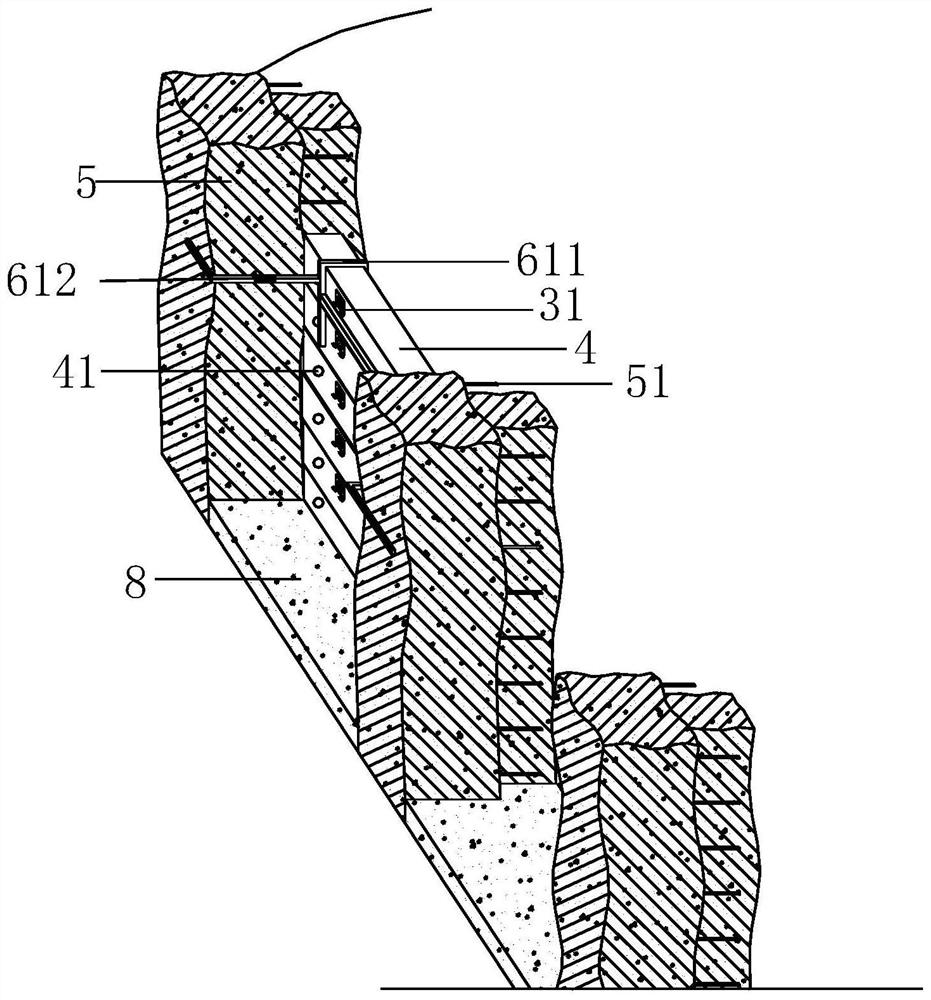

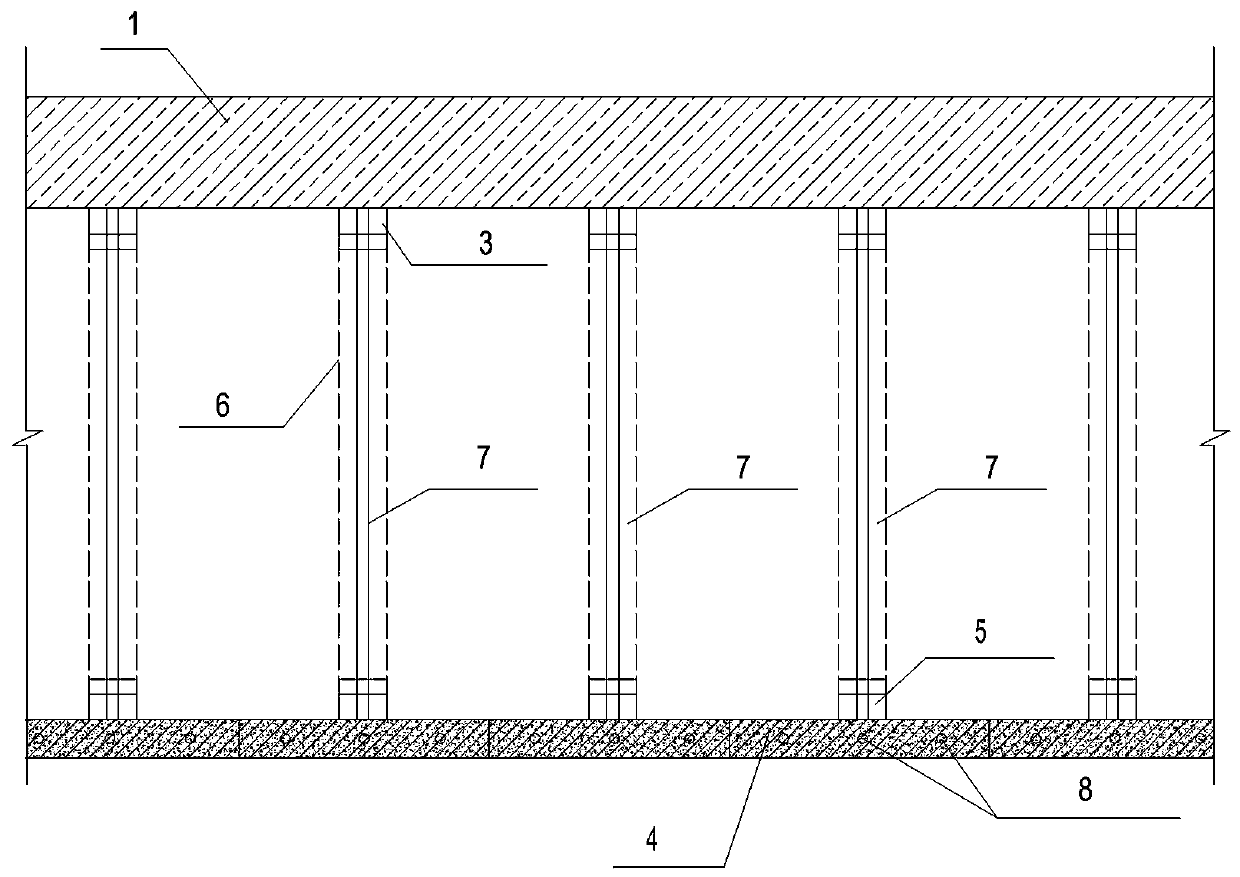

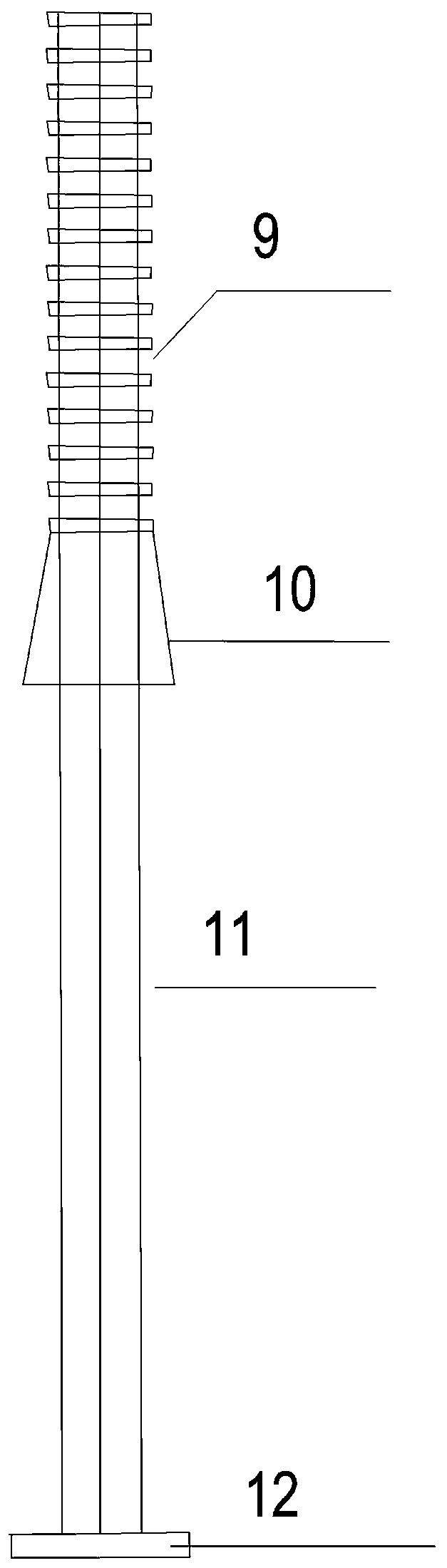

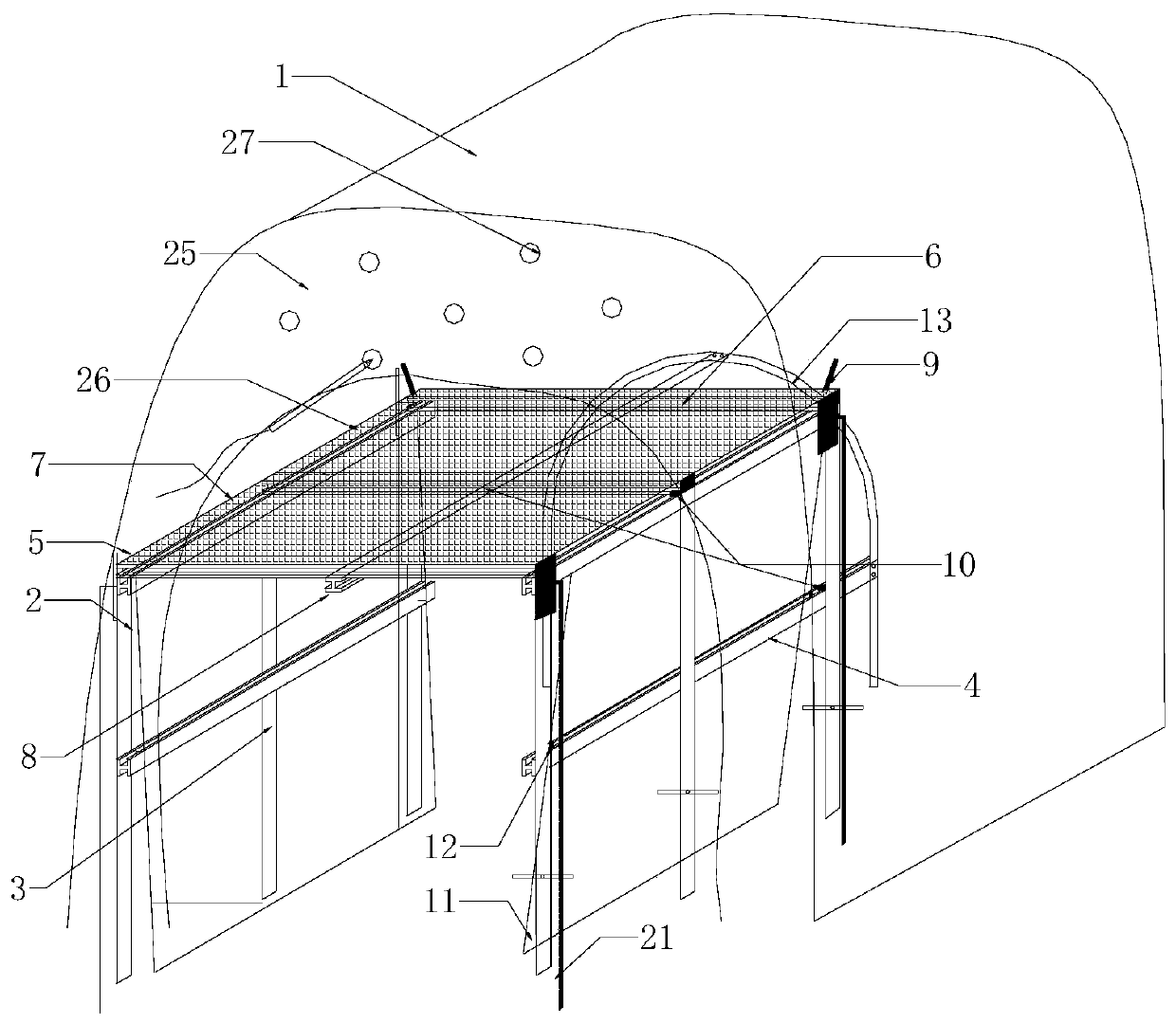

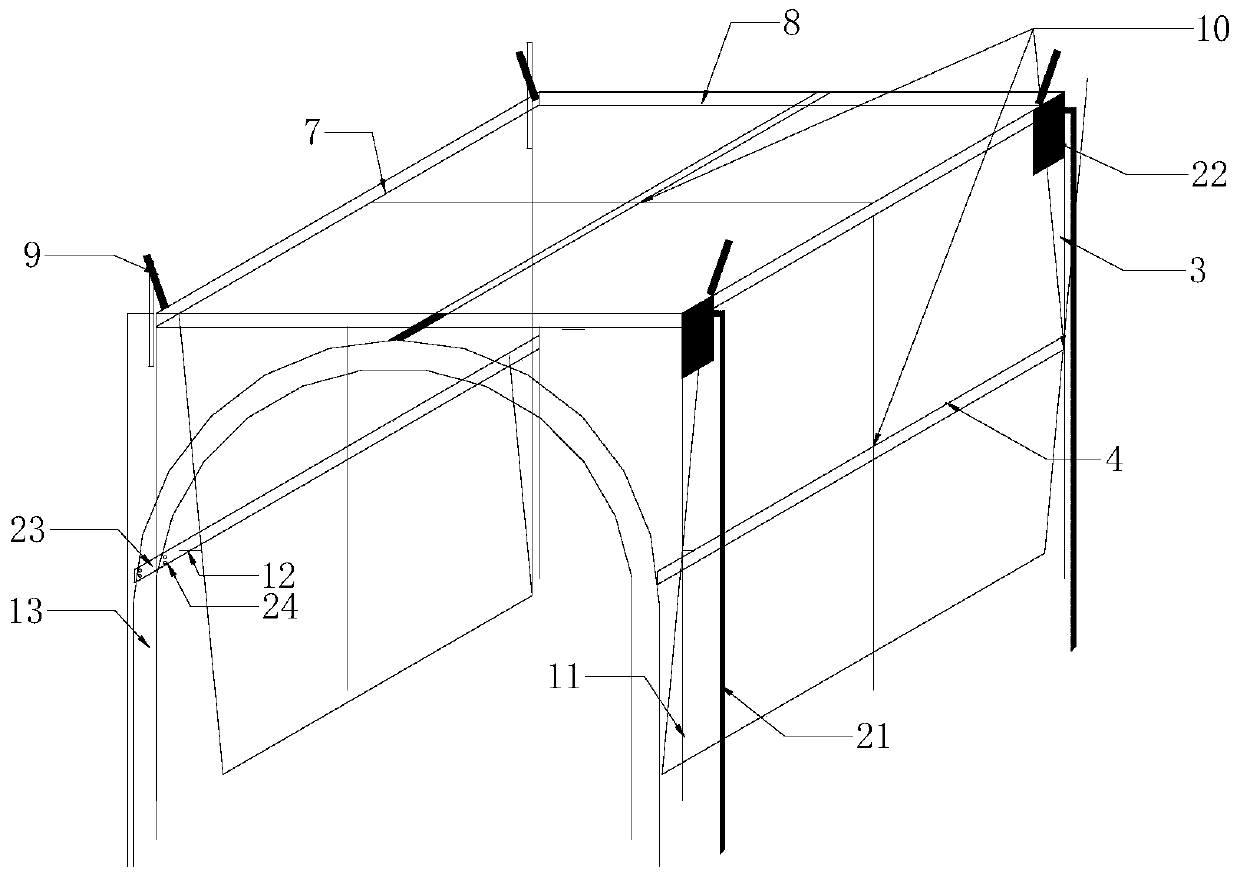

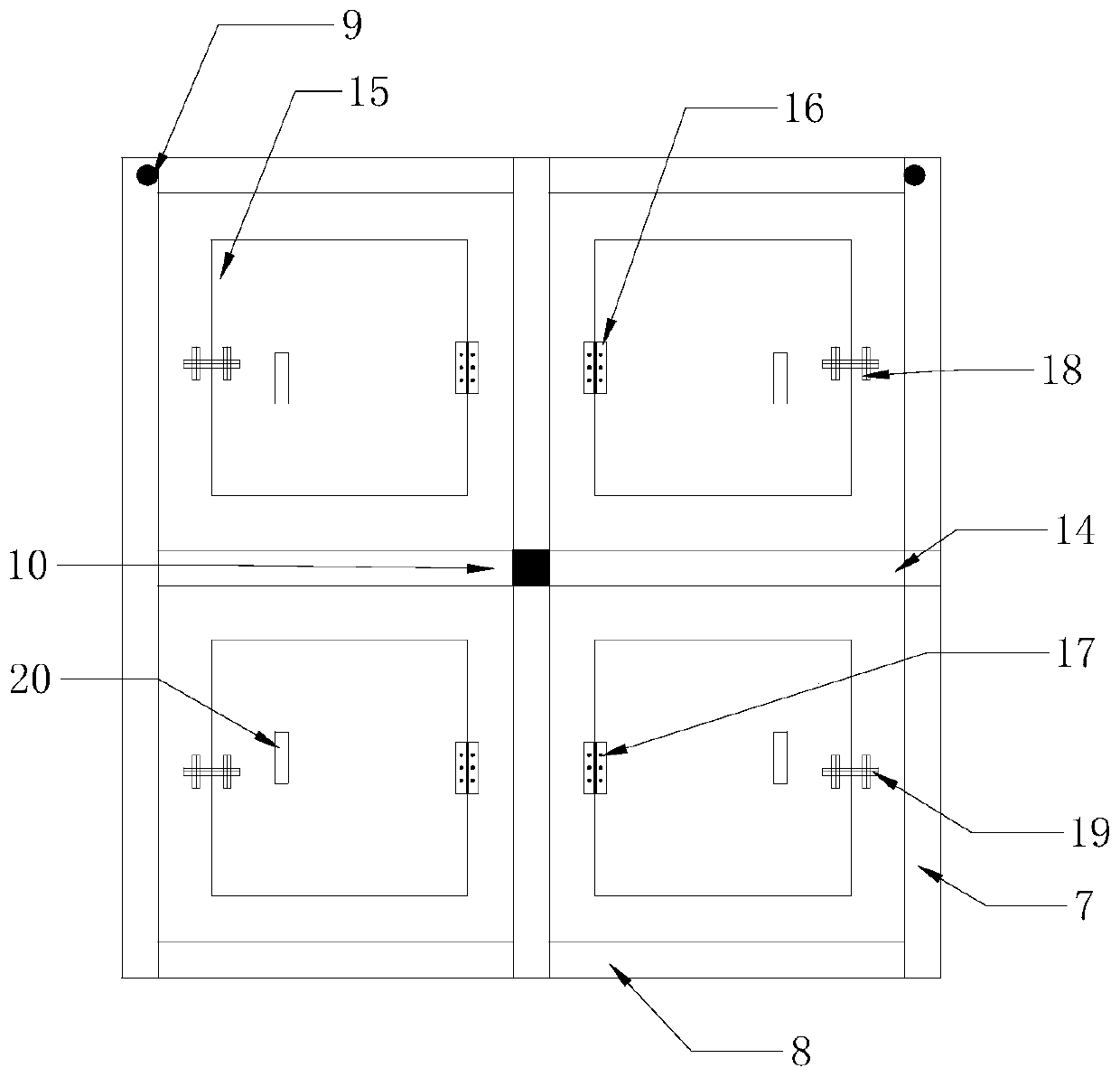

The invention discloses an ecological slope protection structure of a road cutting side slope. The ecological slope protection structure of the road cutting side slope comprises a side slope body, a framework beam fixed to the side slope body, seedling growing modules and an irrigation system; the framework beam comprises a plurality of cross beams and longitudinal beams which are staggered and fixed transversely and longitudinally; a plurality of planting cells provided with base material modules are defined by the cross beams and the longitudinal beams which are staggered transversely and longitudinally; each base material module comprises a planting pit excavated in the position of the corresponding planting cell, a protecting net covering the planting pit and fixed to the framework beam, and a nutrient medium arranged in the planting pit; a plurality of seedling growing modules are arranged in each base material module; each seedling growing module comprises a nursery stock and a planting pot in which the nursery stock is planted; and each planting pot comprises nutrient soil filled in the planting pot, a degradable base and a degradable pot body fixed to the base. Construction is convenient, the nursery stocks are irrigated fully with natural rainfall, the nursery stocks are firstly cultivated and then are transplanted in a container seedling growing manner, it is guaranteed that the nursery stocks have a good survival rate, good economic and technological benefits are achieved, and it can be guaranteed that the greening project is effective for a long time.

Owner:HANGZHOU JIANGRUN TECH LIMITED

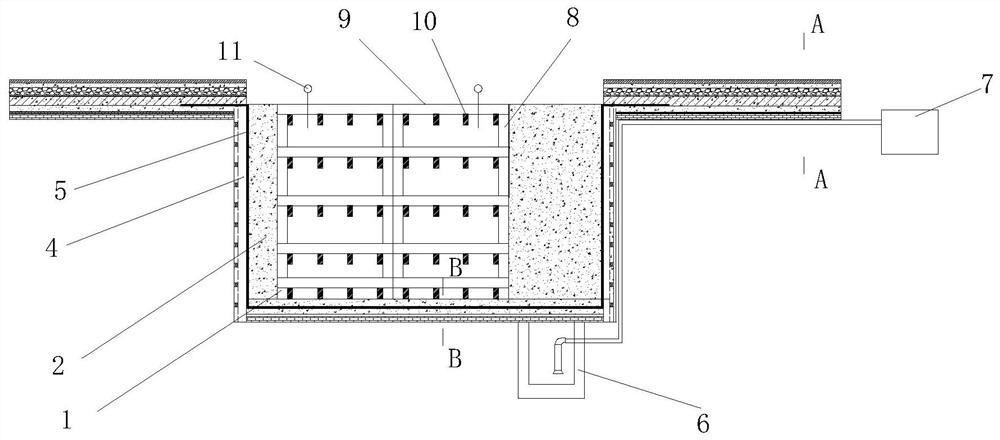

Construction method of cast-in-situ planting type ecological concrete slope protection

ActiveCN105544460AMeet stability and securityAchieve harmonyCoastlines protectionEngineeringRetaining wall

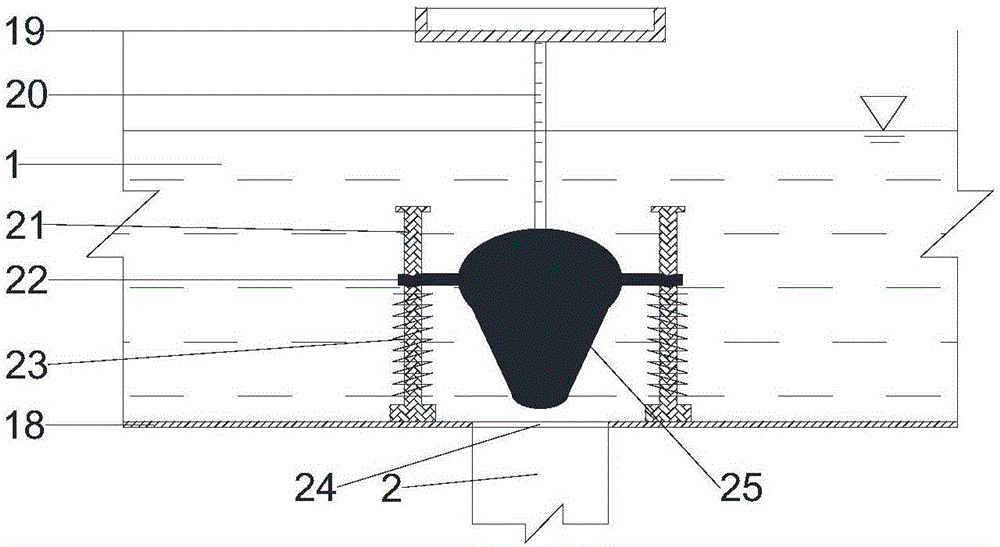

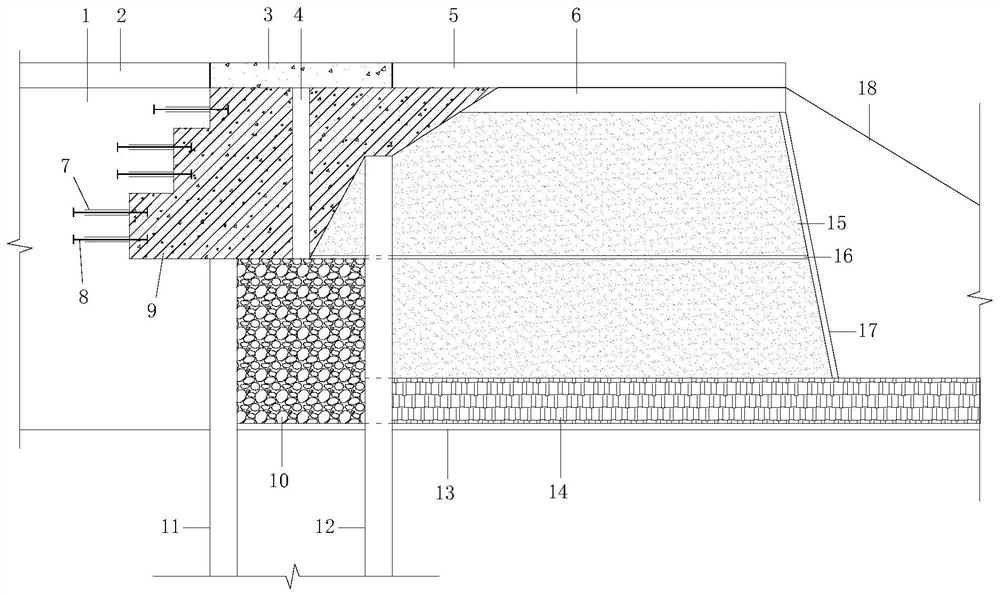

The invention relates to a construction method of a cast-in-situ planting type ecological concrete slope protection, which mainly comprises the steps of construction preparation, cast-in-situ construction of a concrete bottom protection, construction of a rubble concrete retaining wall, cast-in-situ construction of a grid, mounting of an erosion-resistant biological blanket, construction of a waterborne platform, construction of a permeable concrete slope protection wall, assembling of frame beams, pouring of planting concrete into the frame beams, mounting of coiled planting material and pouring of a concrete top protection. According to the invention, a slope protection structure is constructed quickly, and the surface of the slope protection is completely ecological from top to bottom.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

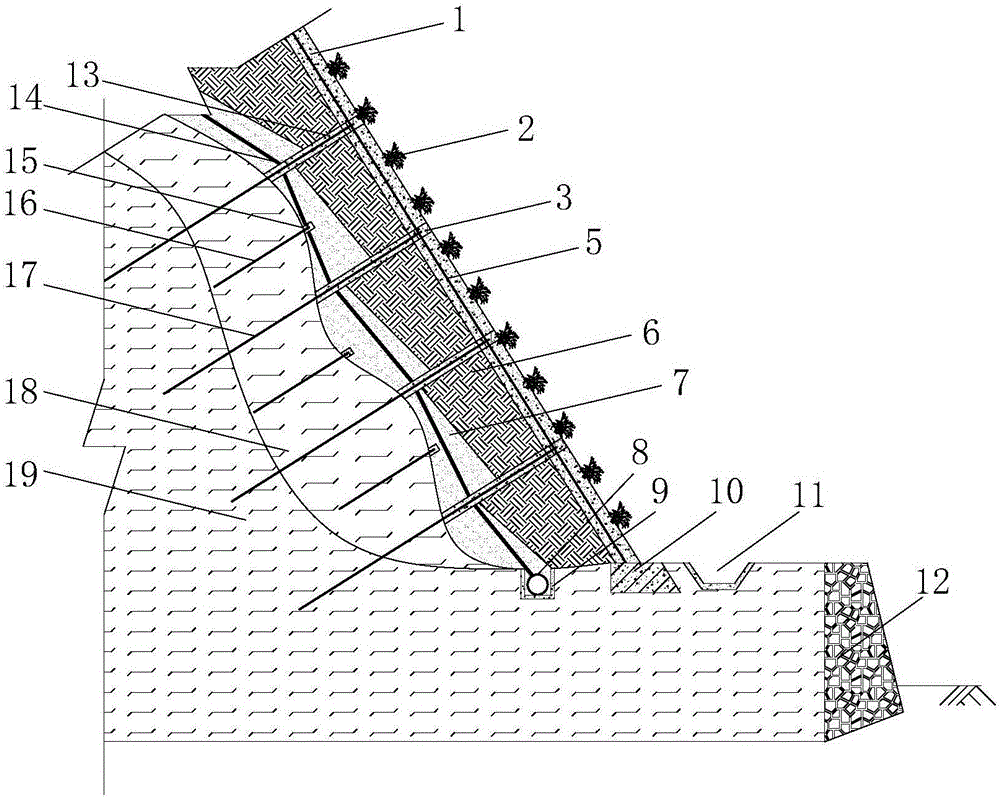

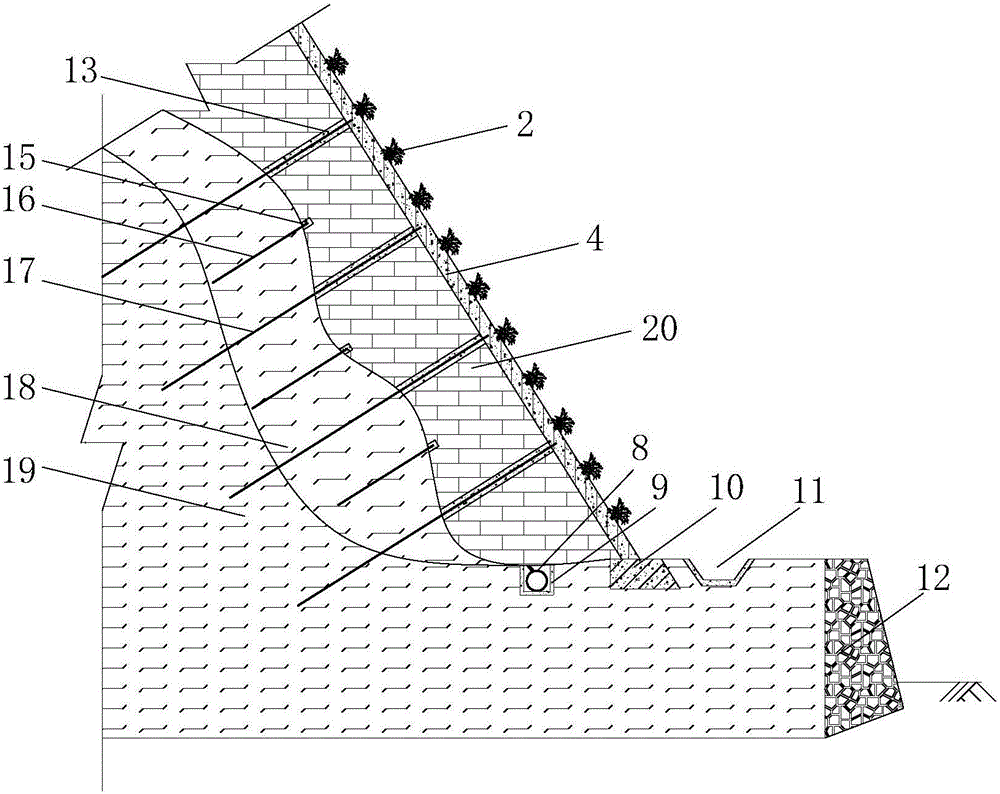

Environmental-friendly grass concrete highway slope protection structure and construction method thereof

ActiveCN106013191AImprove stabilityGood economic and technical benefitsExcavationsBulkheads/pilesSoil nailingDitch

The invention relates to an environmental-friendly grass concrete highway slope protection structure which mainly comprises grass concrete, prefabricated framed girders, anchor rods, soil nails, a mortar flag stone wall, a hillslope drainage system and a gravity retaining wall. The soil nails are arranged in an unstable rock mass of an original highway slope. Concrete piers are arranged at anchor heads. The mortar flag stone wall is additionally arranged on an original hillslope. The interior of the mortar flag stone wall is sequentially filled with a gravel bed, a clay bed and the grass concrete from bottom to top. The prefabricated framed girders are mounted at the top of the mortar flag stone wall. The anchor rods are arranged at the intersections of the prefabricated framed girders. Concrete inclusions are arranged at the peripheries of the anchor rods. The hillslope drainage system is arranged in the gravel bed. A drainage channel is arranged at a slope bottom. The gravity retaining wall is arranged on the outer side of a highway subgrade side ditch at a slope foot. The environmental-friendly grass concrete highway slope protection structure is high in integrality and stability, and combines safety embankment with environment protection really, and the traffic environment is effectively improved. The invention further provides a construction method of the environmental-friendly grass concrete highway slope protection structure.

Owner:ANHUI ROAD & BRIDGE GRP

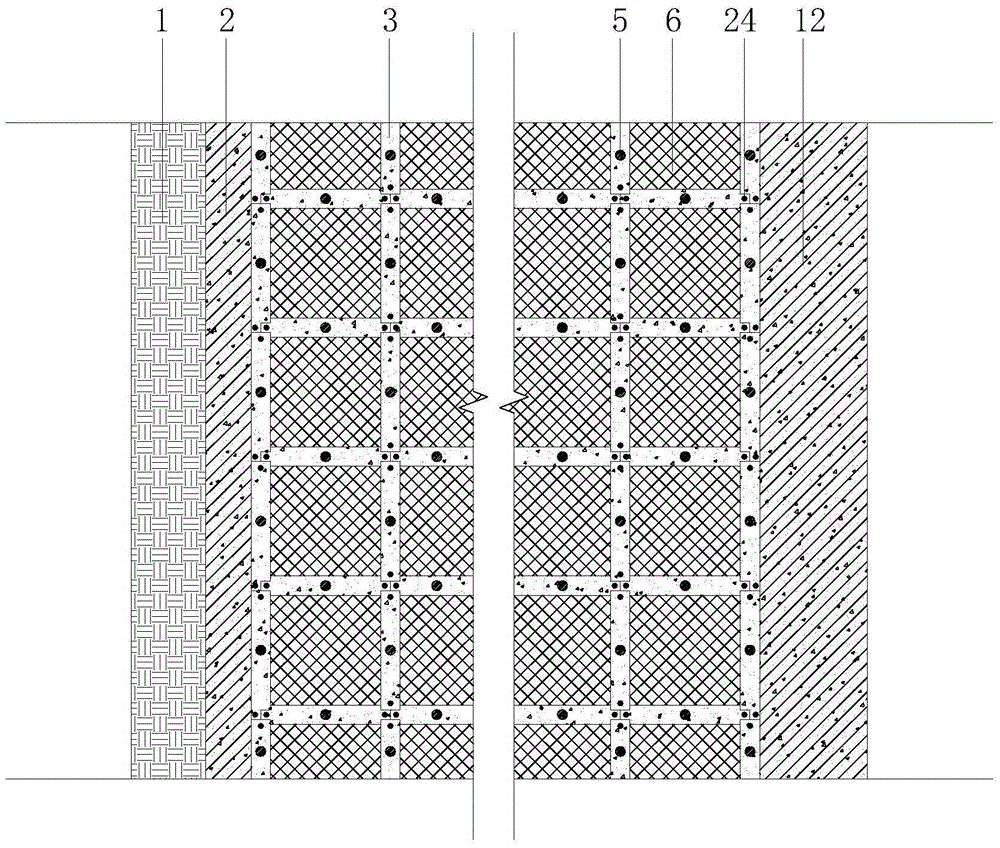

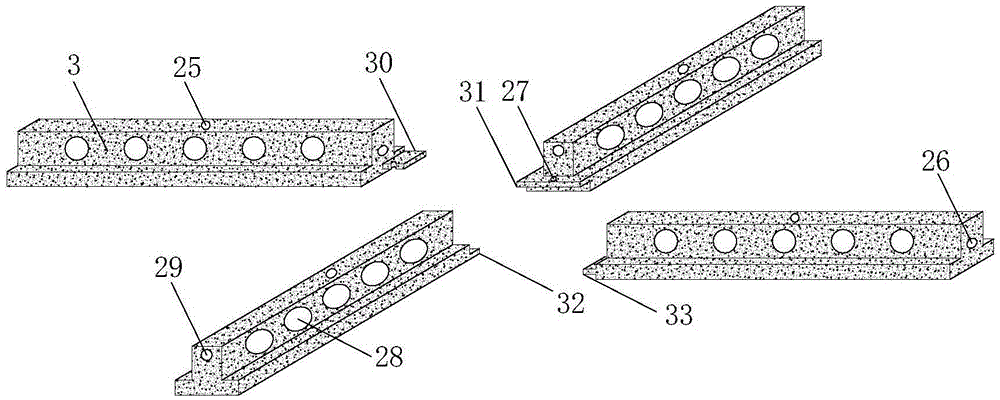

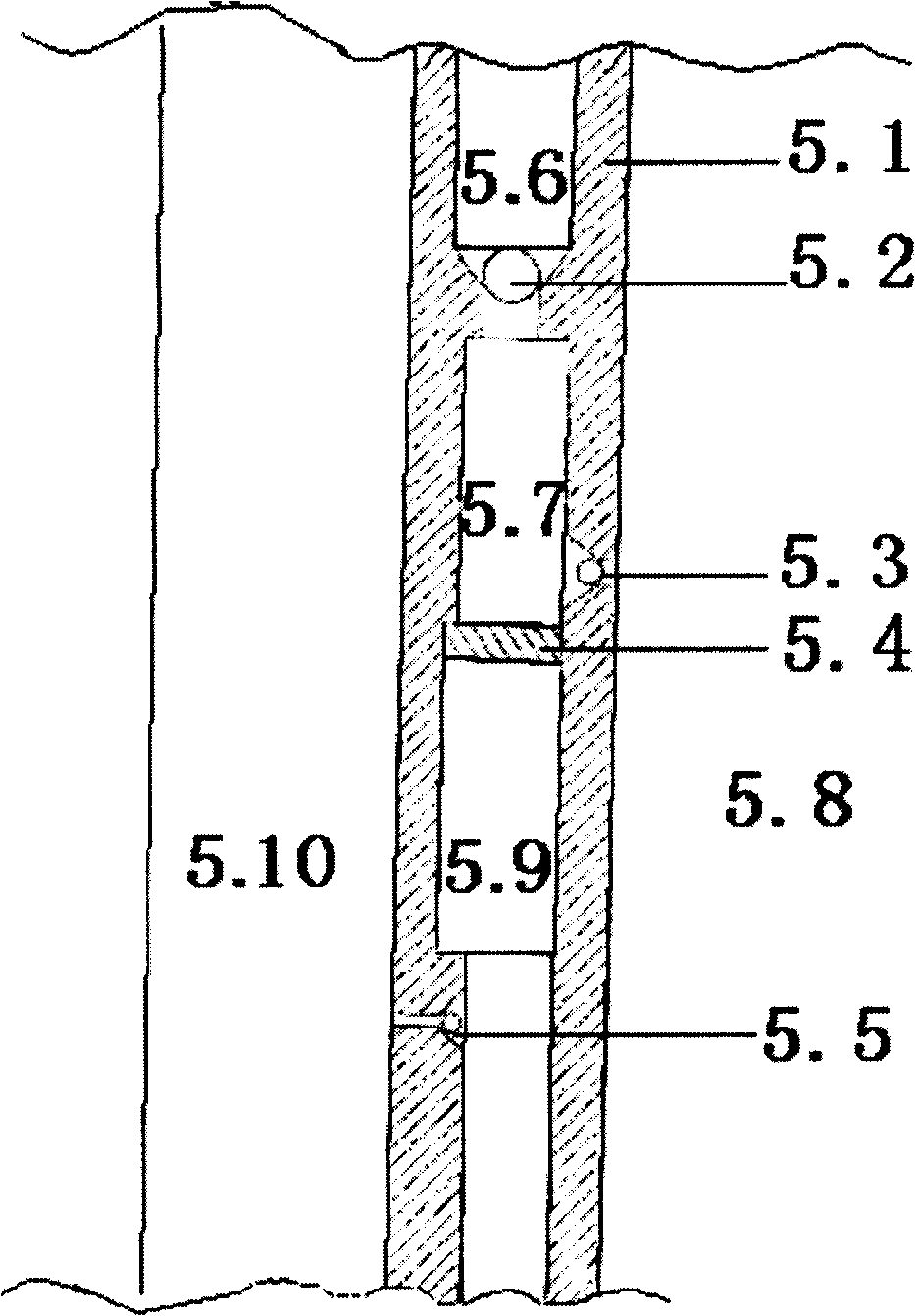

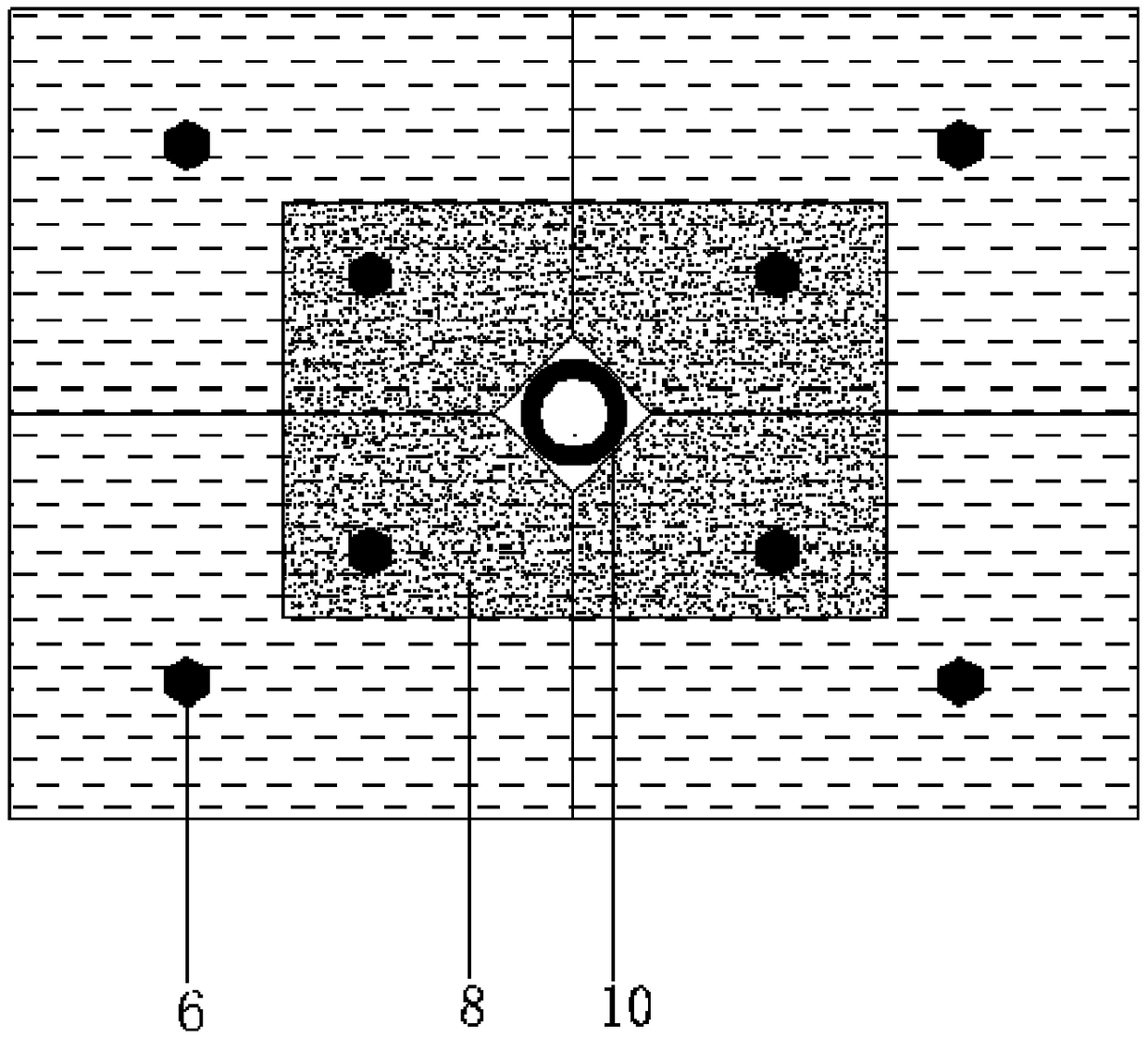

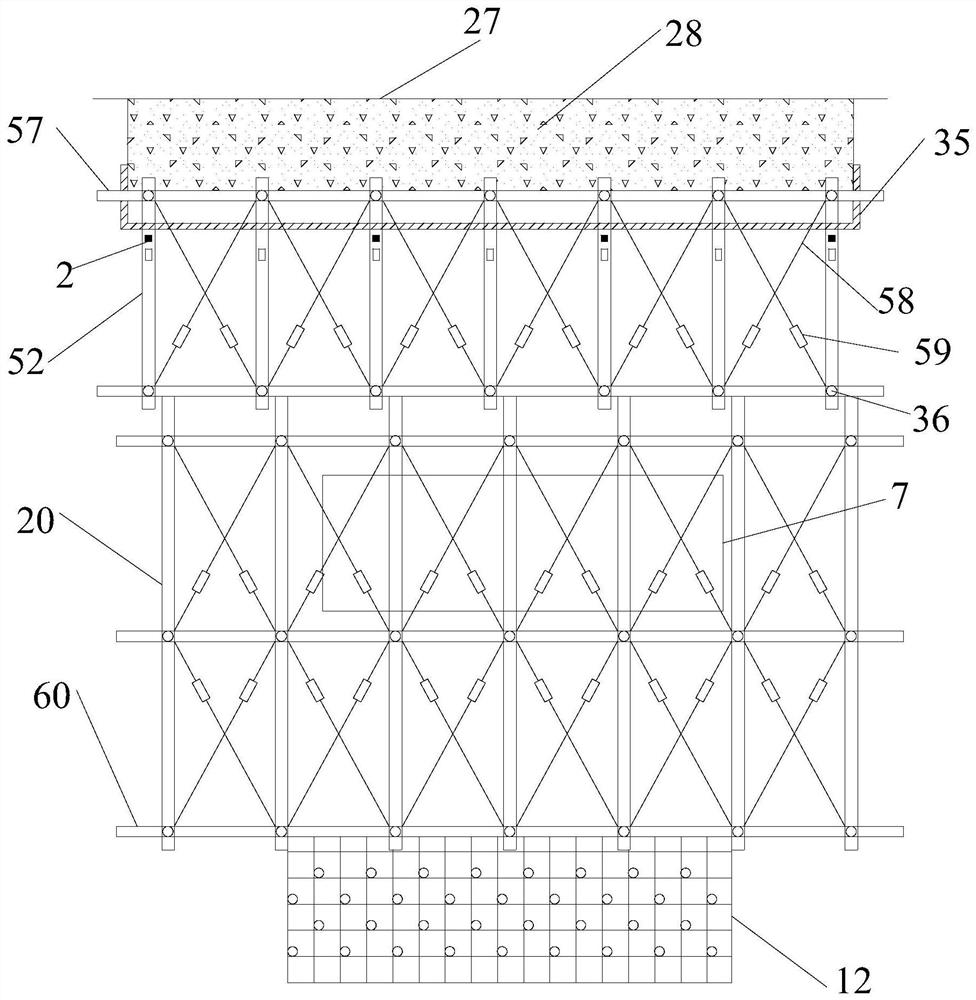

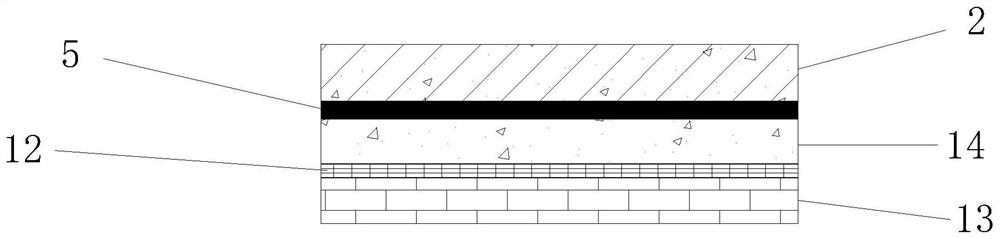

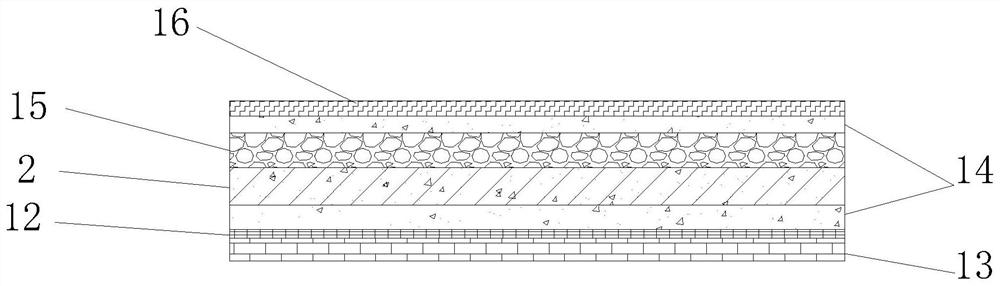

Ecological type slope protection structure and construction method

ActiveCN106759104AFast constructionGood economic and technical benefitsCoastlines protectionEngineeringPervious concrete

The invention relates to an ecological type slope protection structure and a construction method. The ecological type slope protection structure mainly comprises a prefabricated assembled type frame lattice beam, a vegetative coiled material, a vegetative concrete slab, a water-permeable ribbed plate pile wall, a water-permeable concrete guard wall and a ecological type hydrophilic platform, wherein the vegetative concrete slab and the vegetative coiled material are sequentially arranged in a space enclosed by a slope surface longitudinal beam and a slope surface transverse beam from bottom up; the ecological type hydrophilic platform is arranged in the middle of a side slope; and the water-permeable ribbed plate pile wall is arranged at the bottom of the side slope. The ecological type slope protection structure, disclosed by the invention, is high in construction speed, and the slope protection surface is fully ecological from top to bottom. The invention further provides the construction method of the ecological type slope protection structure.

Owner:ZHEJIANG UNIV CITY COLLEGE

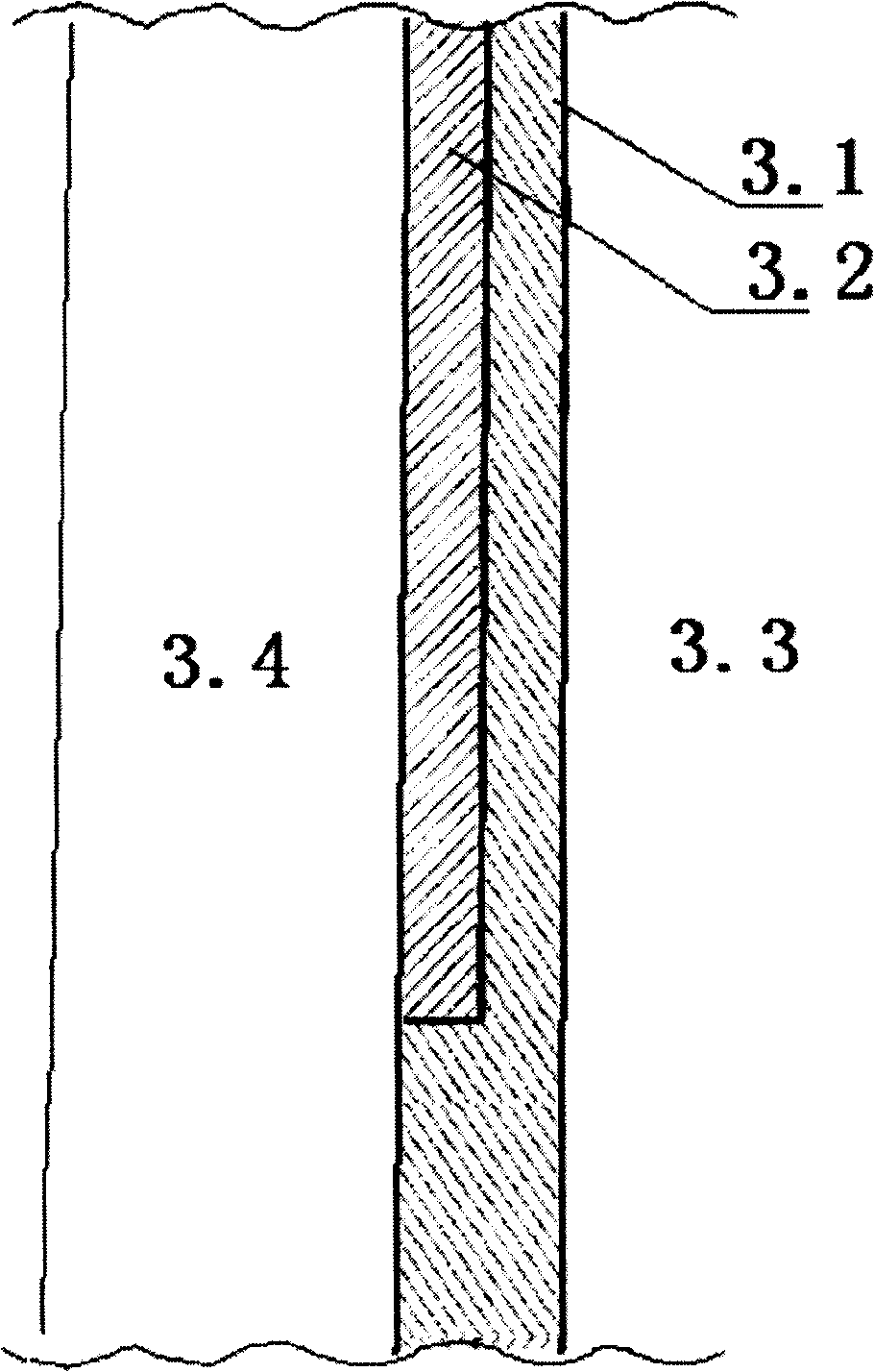

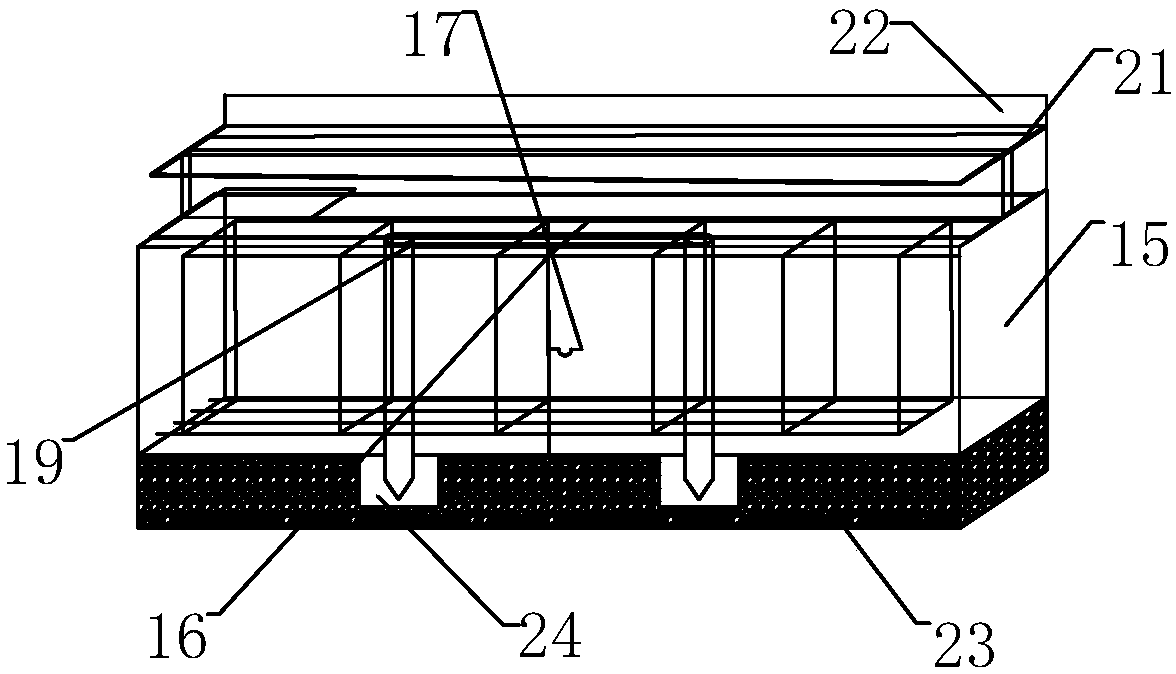

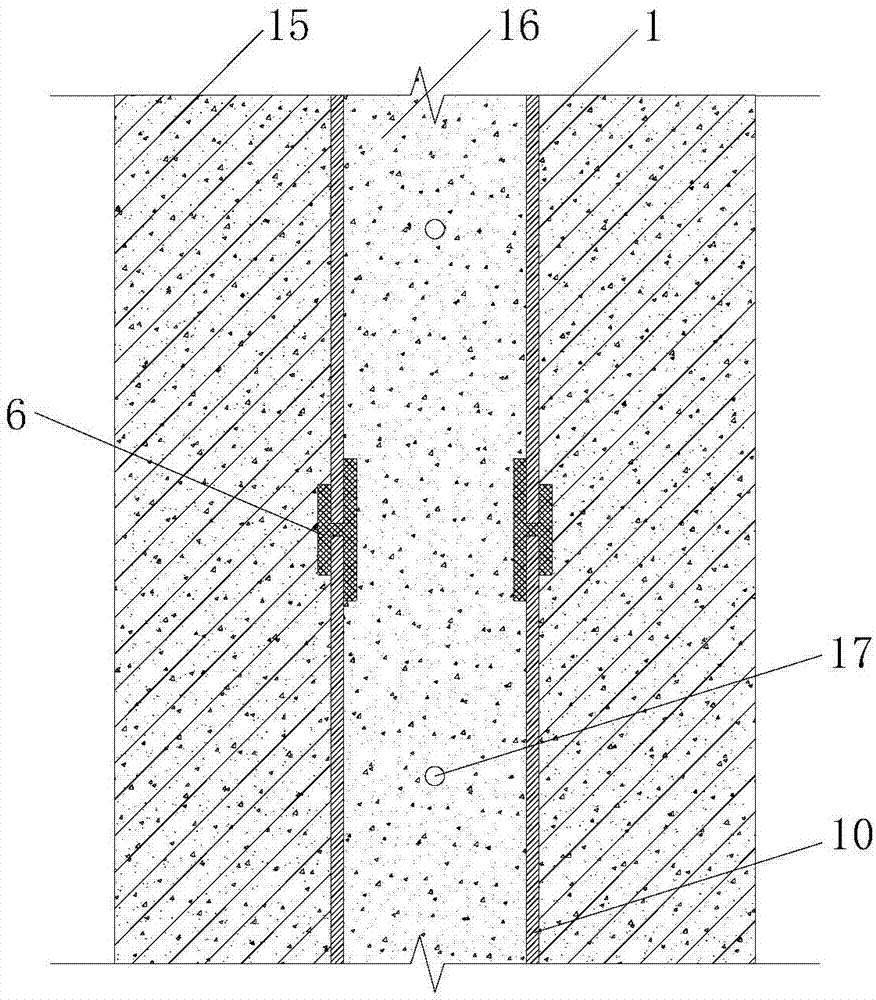

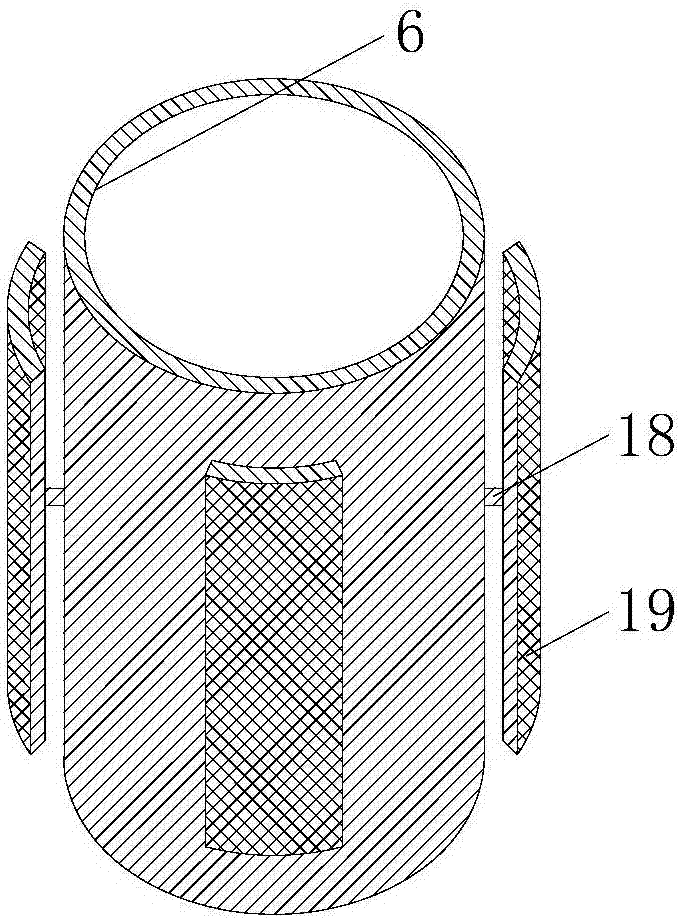

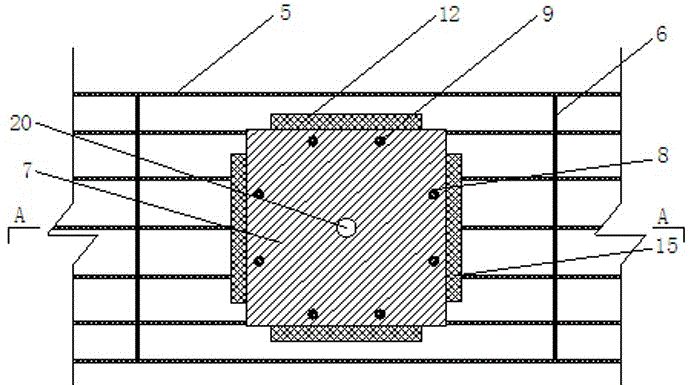

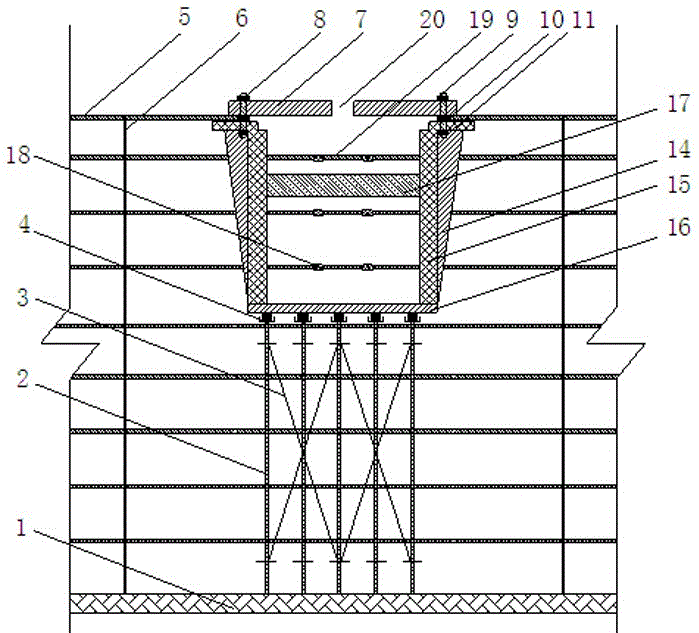

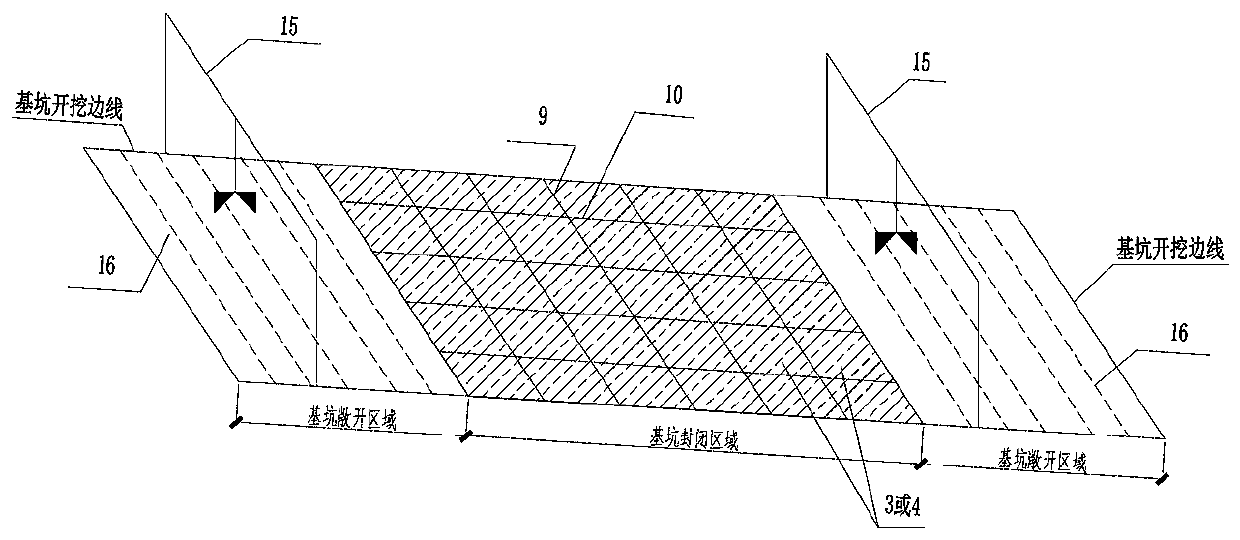

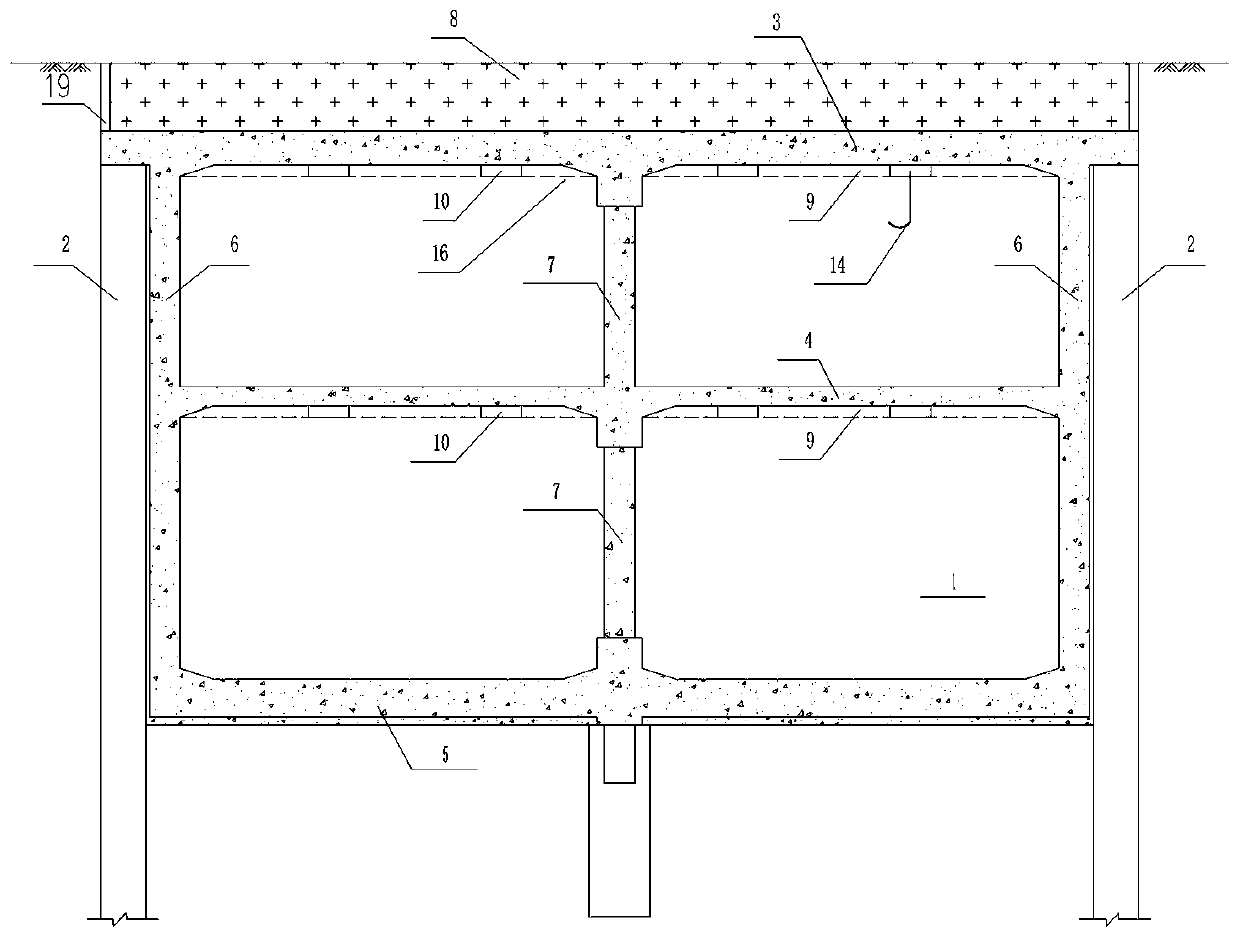

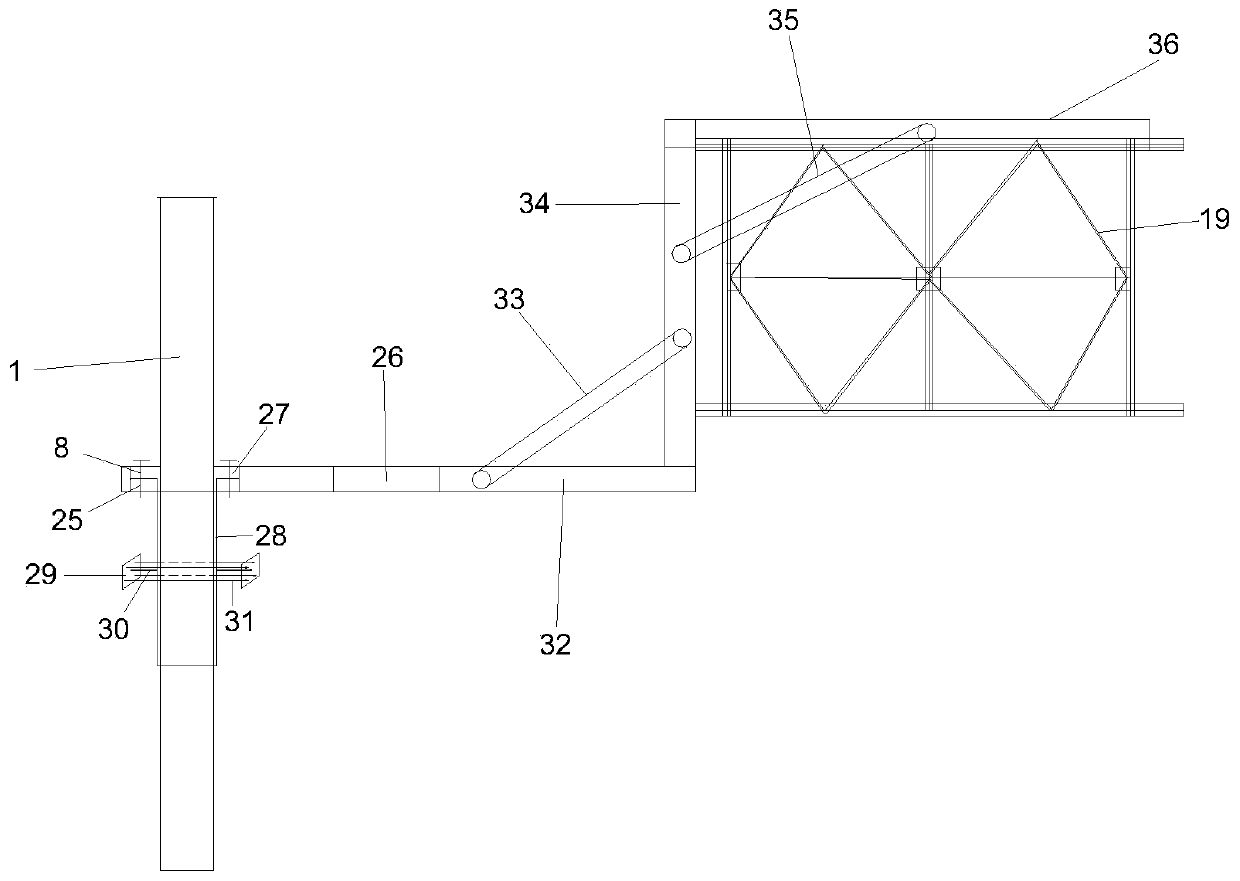

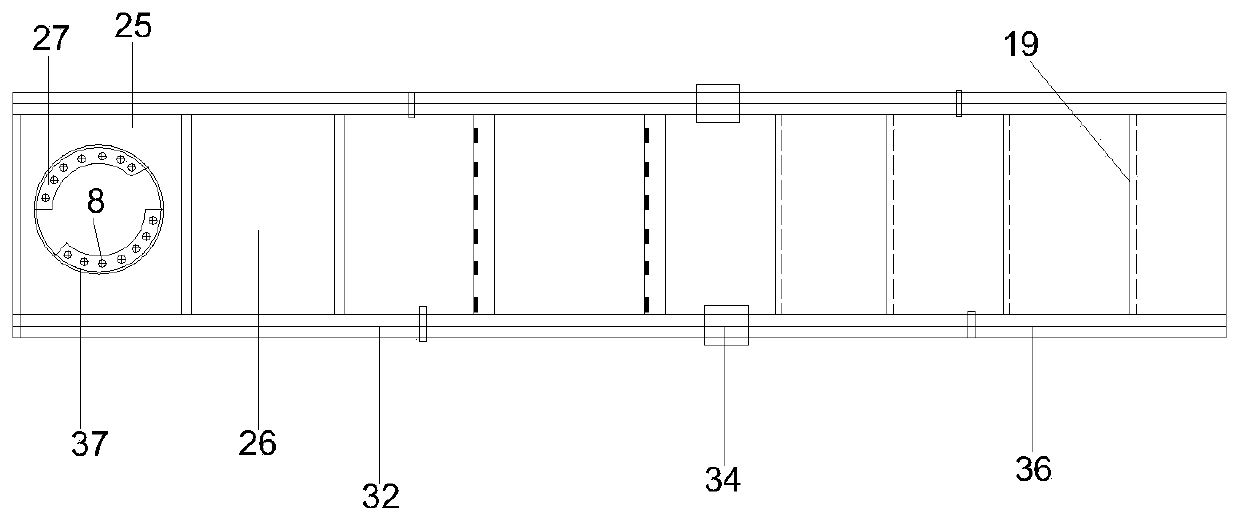

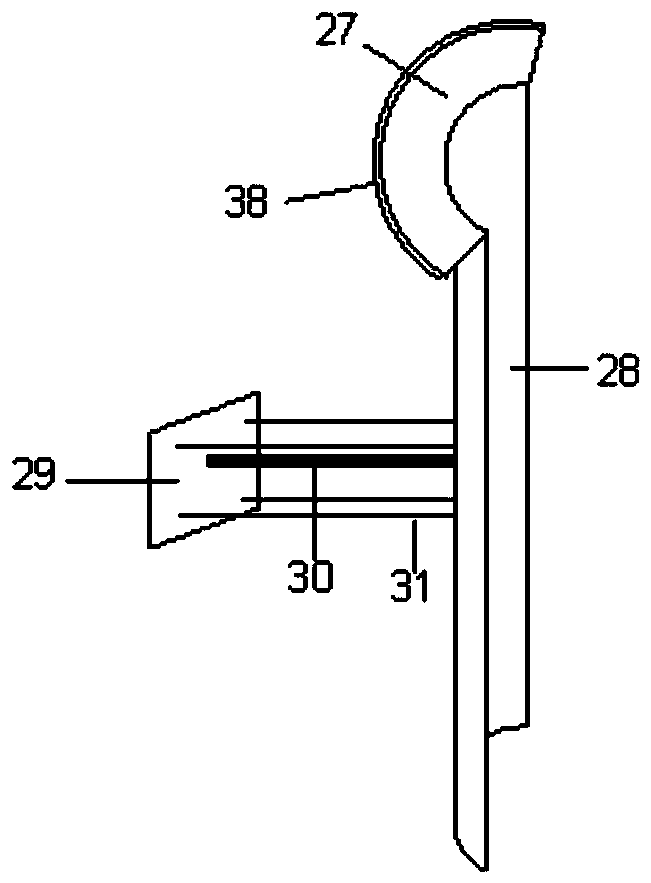

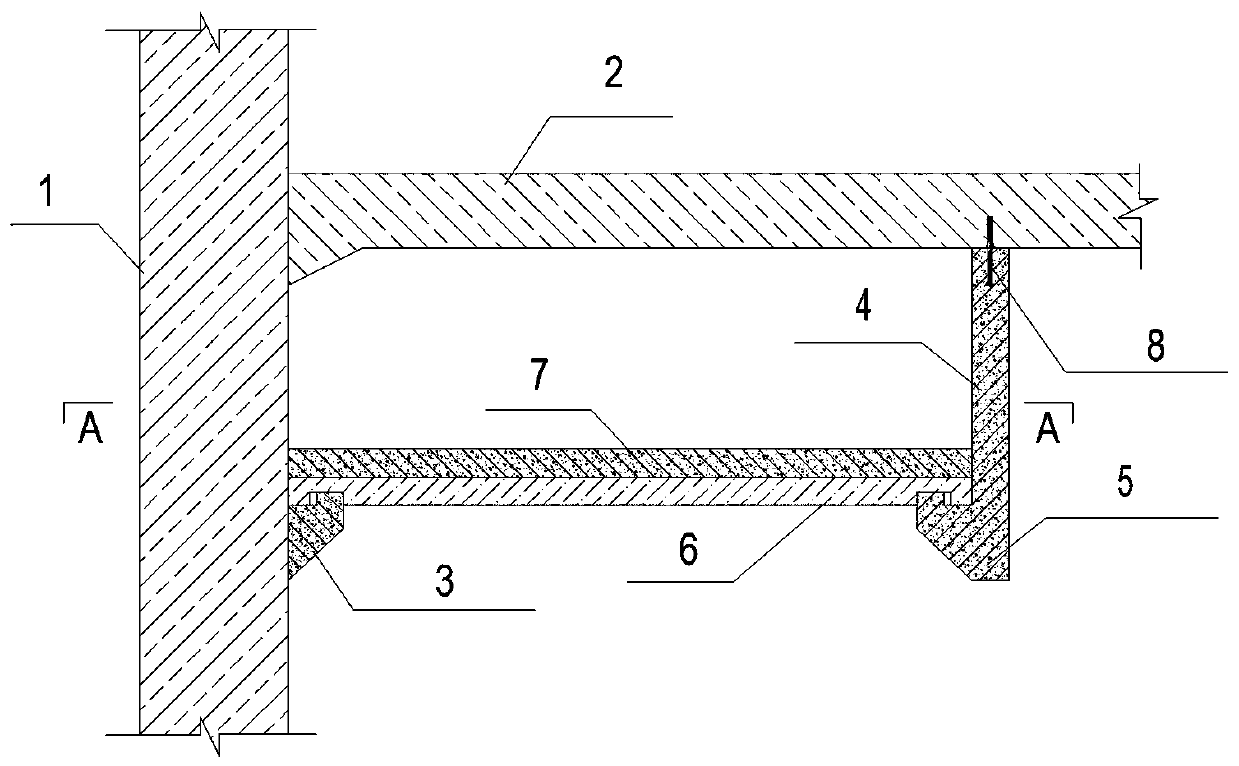

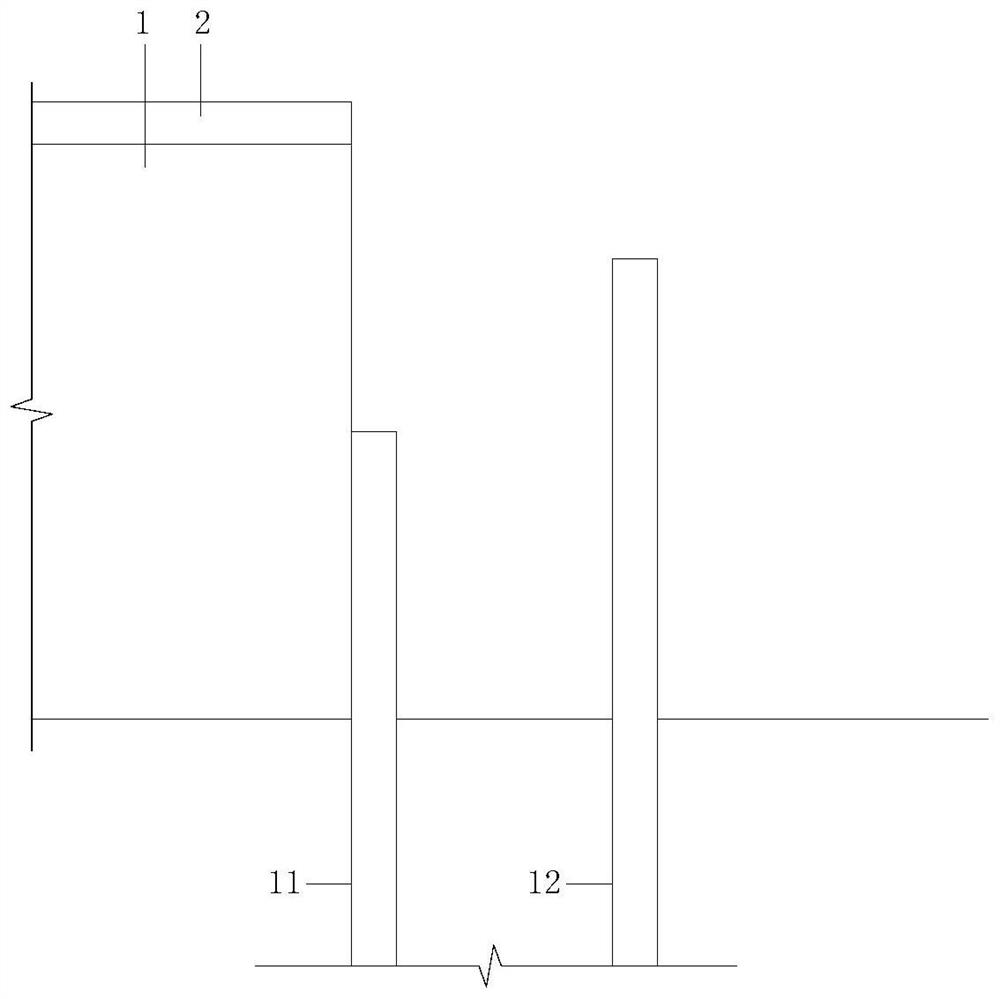

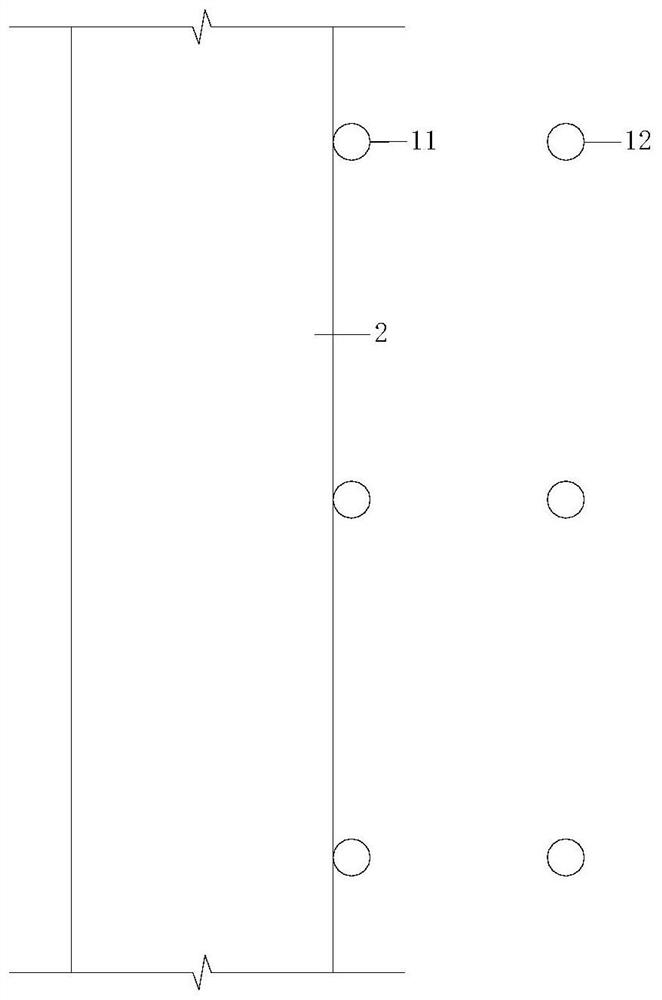

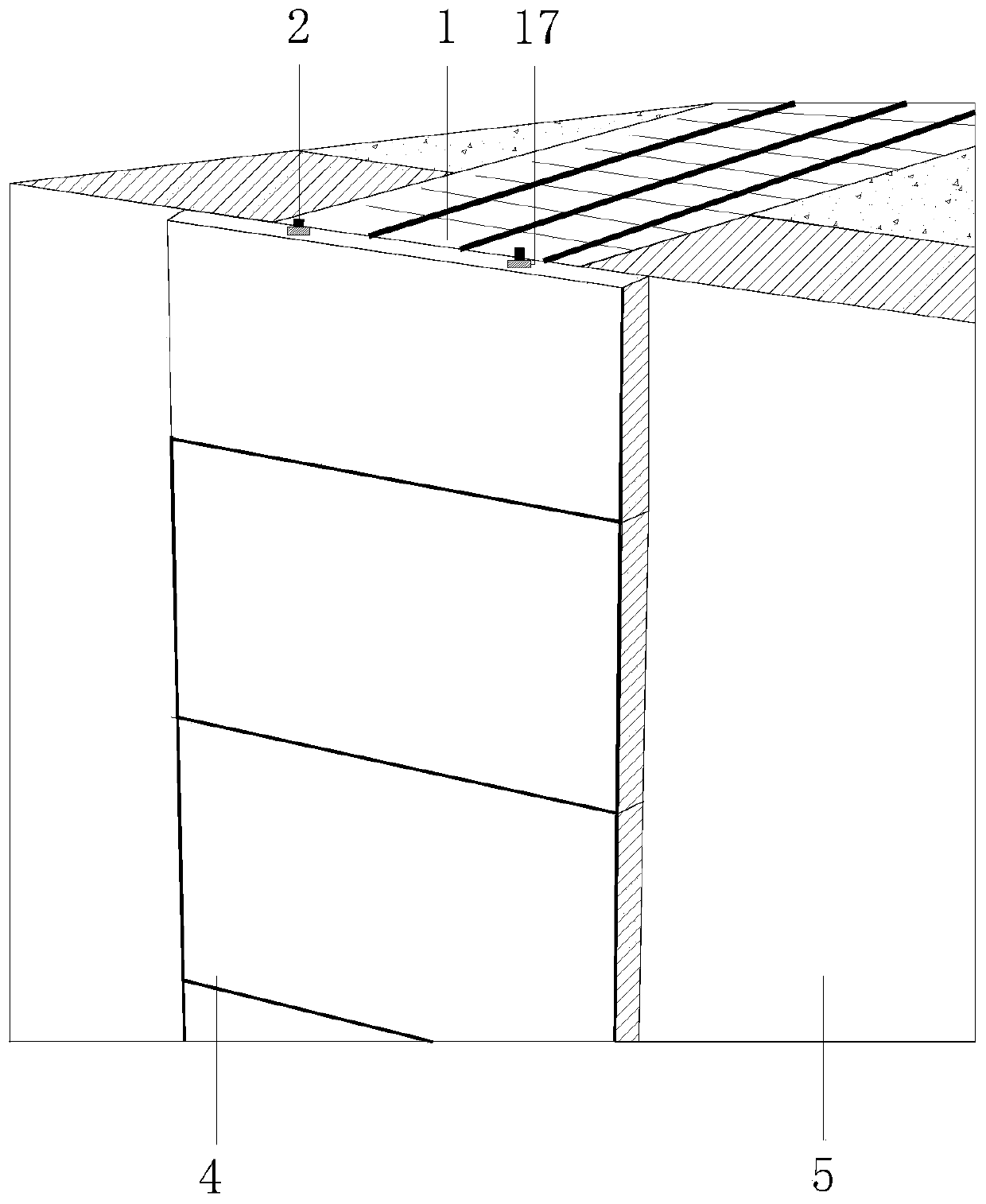

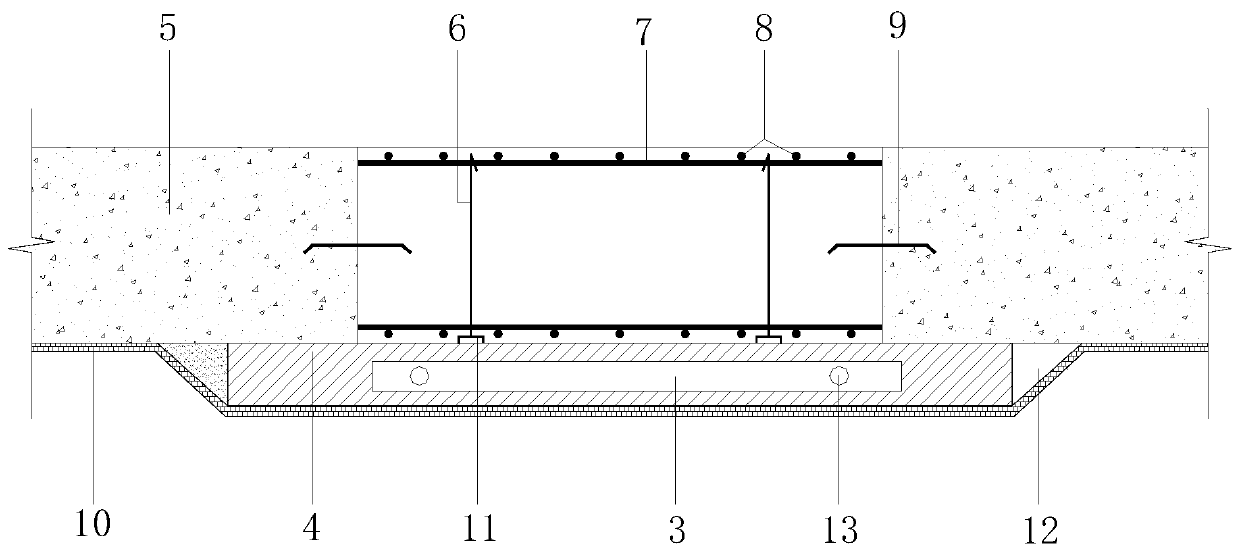

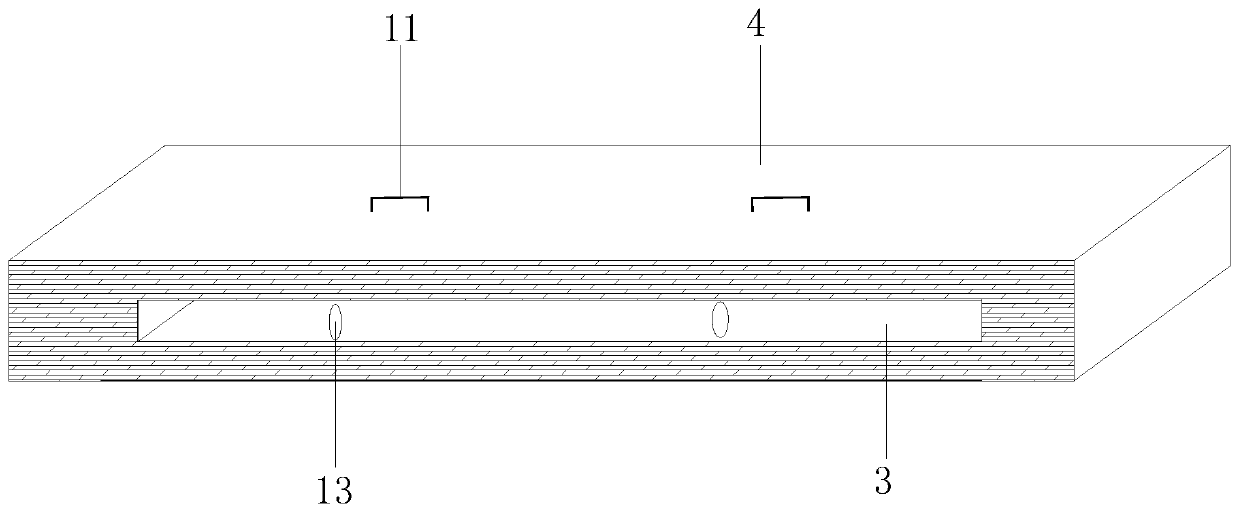

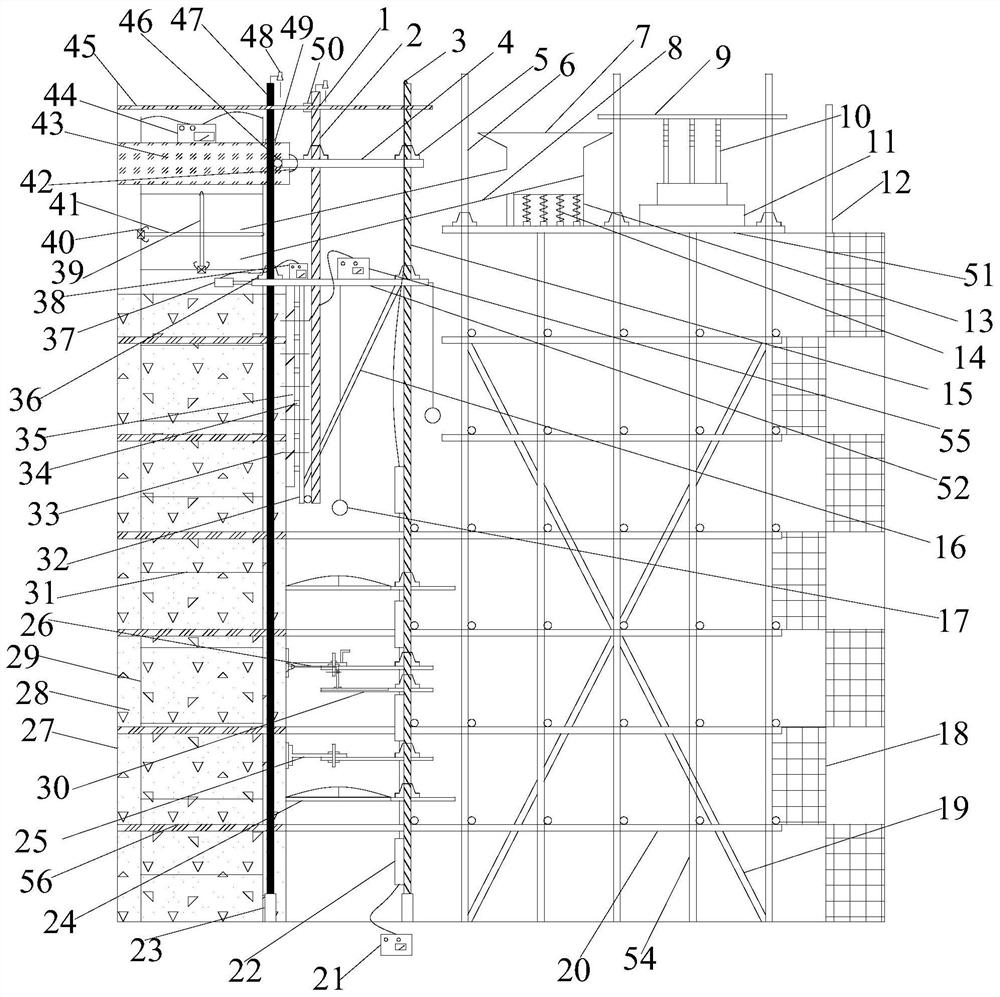

Cast-in-situ comprehensive pipe gallery and construction method

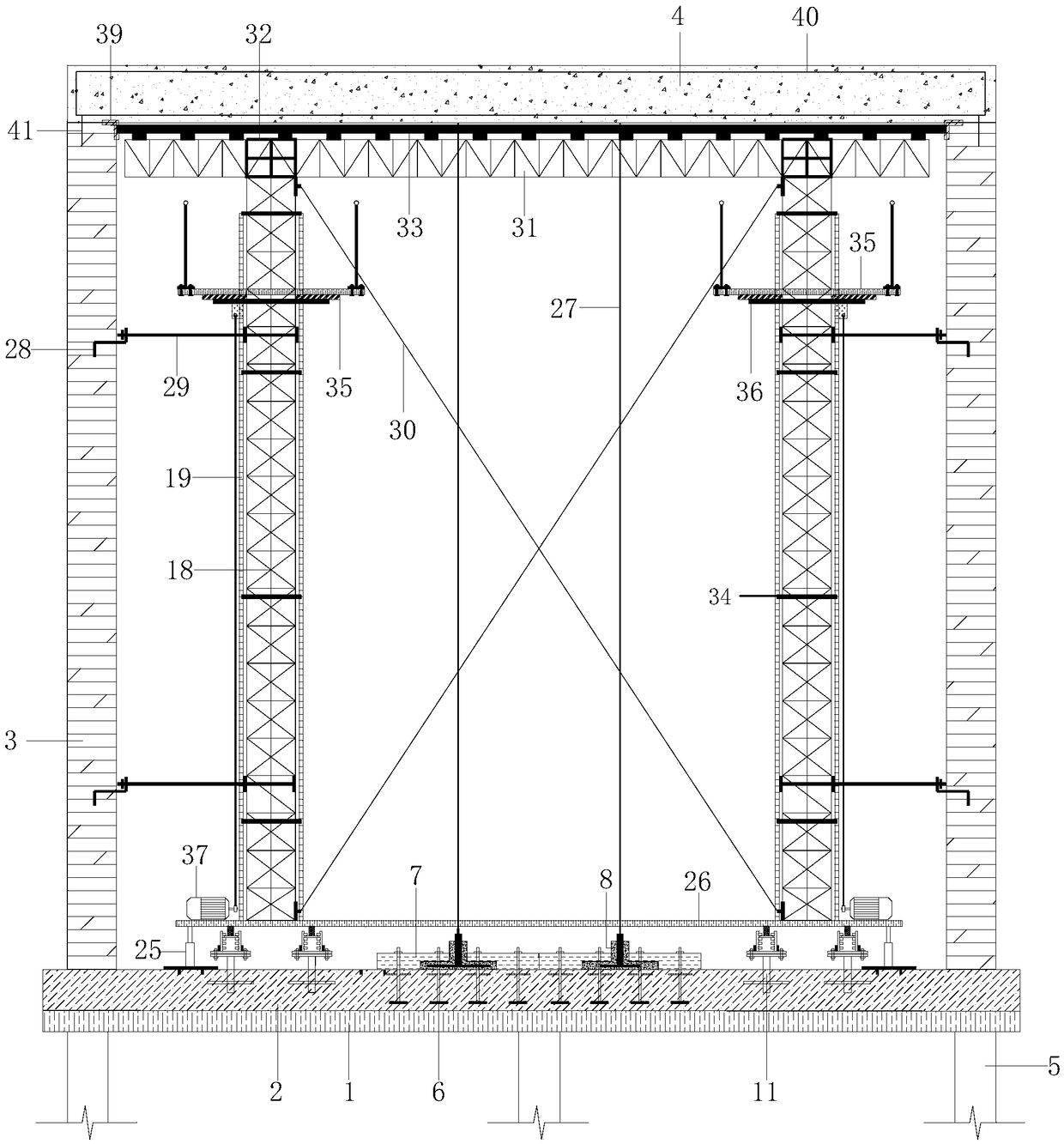

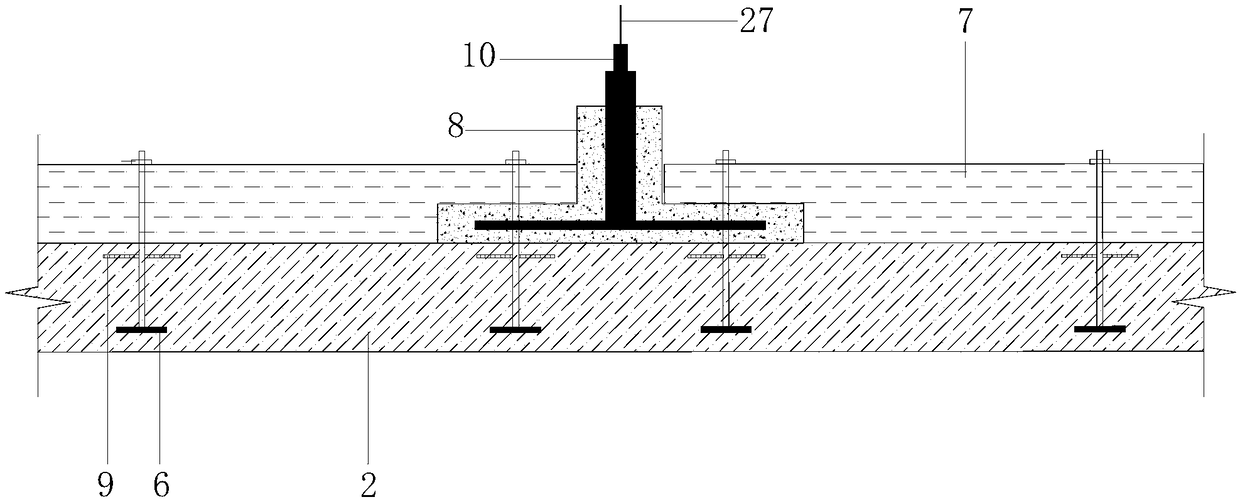

InactiveCN109339101AEasy to replaceEasy constructionArtificial islandsSewerage structuresGround currentSteel frame

The invention relates to a cast-in-situ comprehensive pipe gallery and a construction method. The cast-in-situ comprehensive pipe gallery comprises a base slot excavation bottom elevation located at the bottom of a foundation trench and an original ground current elevation located at the top of the foundation trench. A cast-in-situ comprehensive pipe gallery formwork system and cast-in-situ comprehensive pipe gallery foundation trench supporting systems located on the two sides of the cast-in-situ comprehensive pipe gallery formwork system are arranged on the base slot excavation bottom elevation. Each cast-in-situ comprehensive pipe gallery foundation trench supporting system comprises an excavation slope, wherein a plurality of foundation trench supporting devices are formed on the excavation slope at equal intervals. A prefabricated drainage ditch which can be used repeatedly is formed in the base slot excavation bottom elevation and is located between the excavation slope and cast-in-situ comprehensive pipe gallery formwork system. According to the cast-in-situ comprehensive pipe gallery and the construction method, a prefabricated retention wall assembled by grooves and tongues is arranged on the top surface of the foundation trench, a channel steel frame is arranged on the outer side of the retention wall, and a propaganda board can be placed in the channel steel frame; and through the structure, the propaganda board can be replaced conveniently, and construction is simple and rapid.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Thin interlayer steam injection thermal production well mixing-proof well completion process

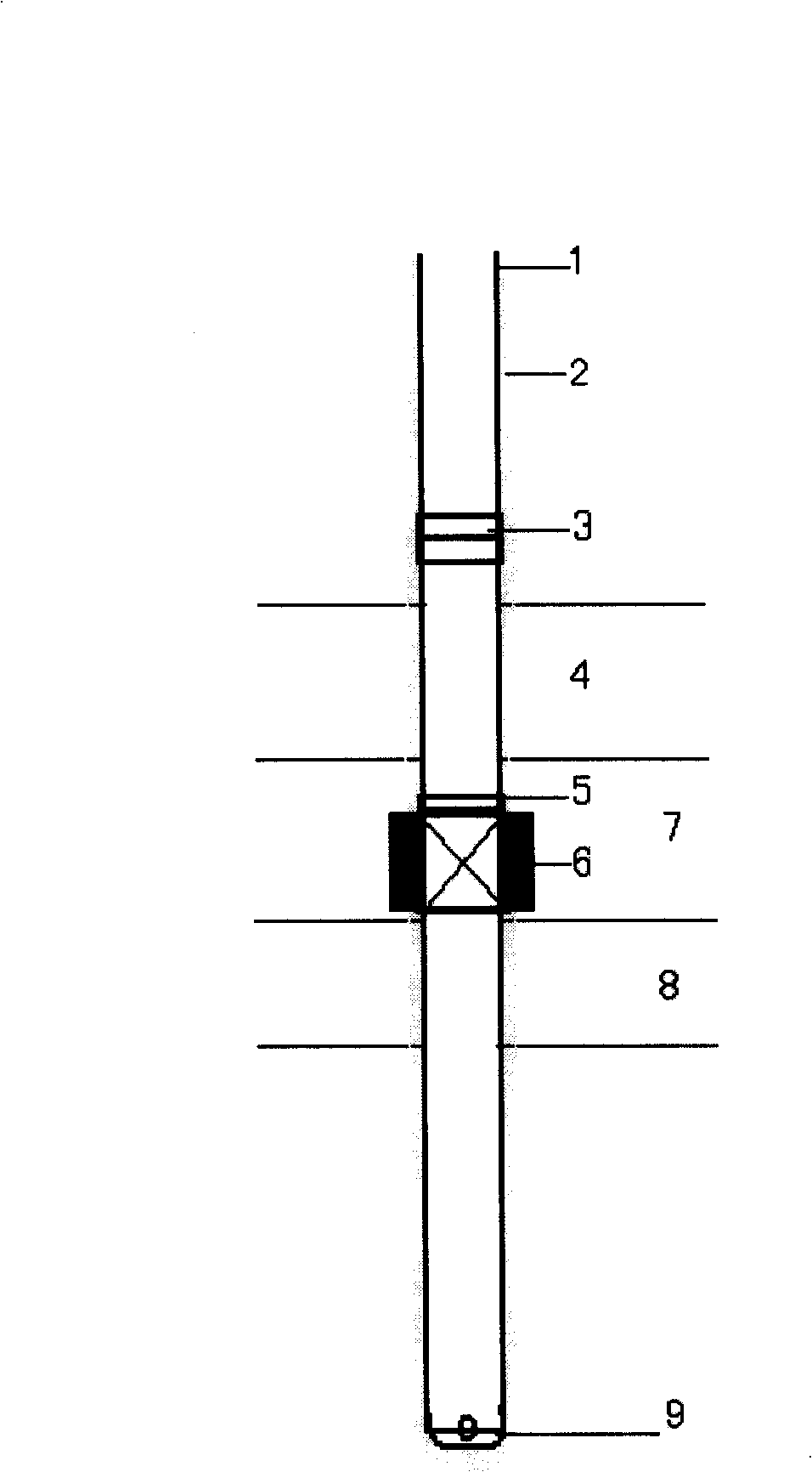

InactiveCN101307679ASimple cementingCementing safetyFluid removalSealing/packingWell cementingCement paste

The invention relates to a method for completing a thin interlayer steam-injection thermal-recovery well in petroleum engineering. The invention adopts the technical proposal that the method comprises the steps as follows: 1) a particular valve hoop is assembled with an external casing packer, and lengths and positions of tools arranged on a well completion string according to the oil well geologic condition after the drilling is completed; 2) a cementing truck is connected with a cementing head for cementing; 3) a bumping rubber plug is displaced to the position of a cementing shoe for bumping; 4) an inner cavity of a casing is decompressed, so that cement paste in a borehole can enter a cavity body through a one-way valve to drive a piston to compress a piston cylinder; pressure of the inner cavity of the casing is boosted for a certain period to drive the piston to compress the cavity body, so that the cement paste in the cavity body enters a flow passage of the cavity body leading to the external casing packer through the one-way valve, thereby expanding and sealing the external casing packer; 5) the external casing packer is completely expanded and sealed to complete the construction through repeating the step 4. The method has the advantages that: the method realizes that the external casing packer is expanded and sealed by the cement paste in the borehole without changing the cementing process, increasing construction risk or increasing the construction period, and has prominent economic and technological benefits.

Owner:SHENGLI OILFIELD PETROLEUM DEV CENT

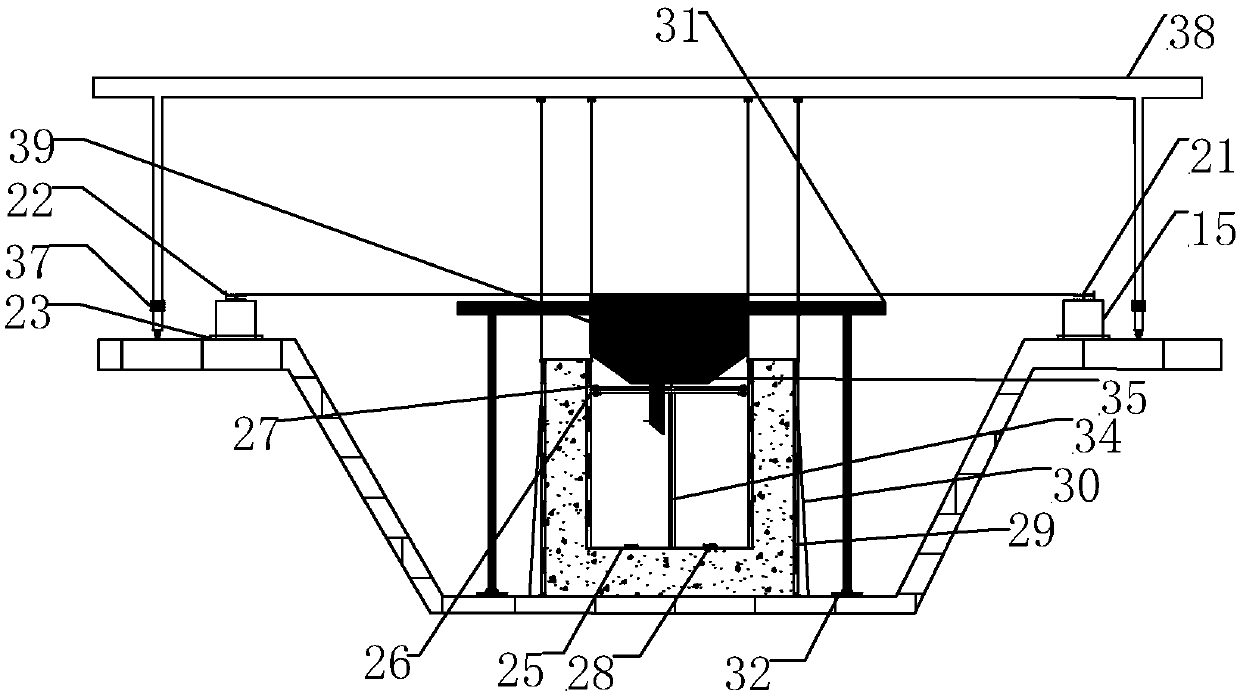

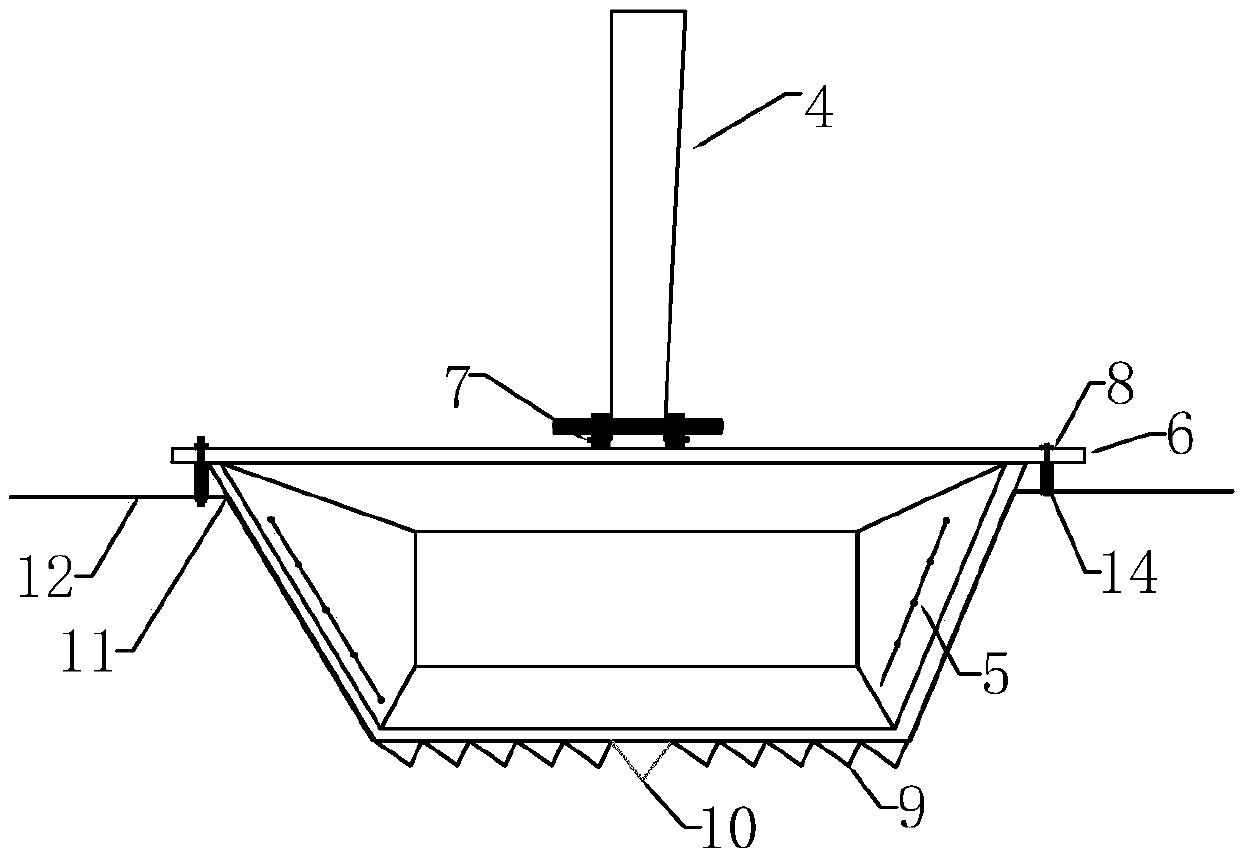

Integrally-formed drainage ditch and construction method thereof

The invention discloses an integrally-formed drainage ditch, which comprises a drainage ditch body, a shaped digging bucket, a shaped slope scraper, sliding mold rails, a shaped side mold and a bottomscraping cross beam frame, wherein the sliding mold rails are assembled on two sides of the drainage ditch body; the shaped side mold is arranged in the drainage ditch body; the bottom scraping crossbeam frame is arranged at the bottom of the drainage ditch body; the shaped side mold can be fixedly arranged on the bottom scraping cross beam frame; the bottom scraping cross beam frame is connected with a sliding cross beam gantry and is dragged and slid by the sliding cross beam gantry; and the shaped side mold is connected with a side mold gantry and is dragged and slid by the side mold gantry. The drainage ditch simplifies the construction steps, saves the construction time, reduces the construction cost, is easy to excavate and form, has low operation difficulty, so that the safety inthe construction process can be effectively ensured; and the drainage ditch has beautiful appearance and good quality. The second object of the invention is the construction method of the integrally-formed drainage ditch, the method is applied to the integrally-formed drainage ditch, and further has the advantages of high safety, high convenience and the like.

Owner:HANGZHOU JIANGRUN TECH LIMITED

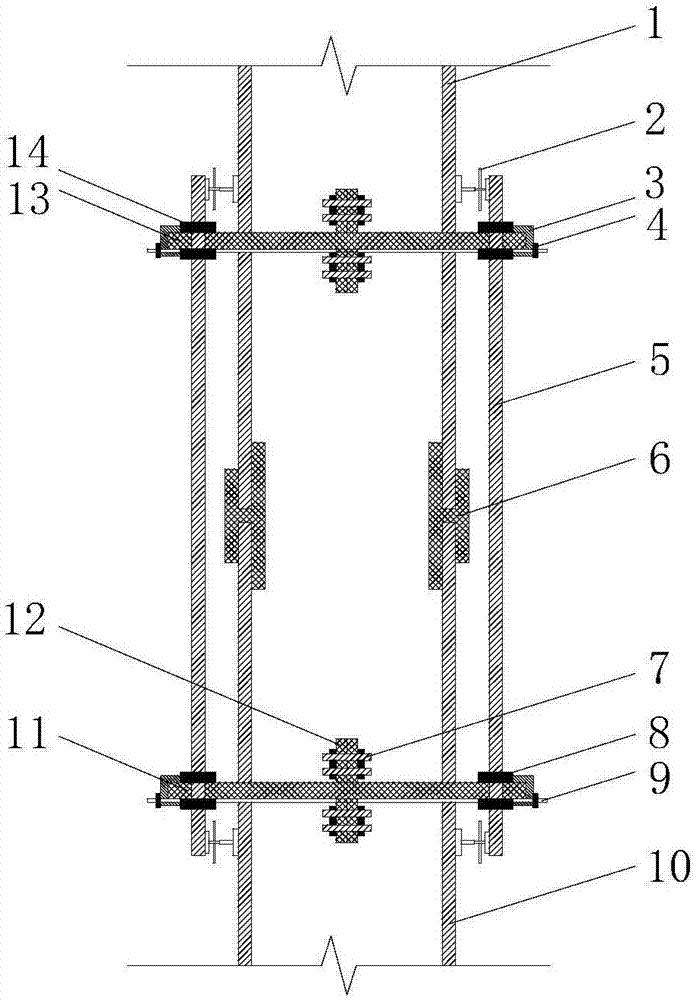

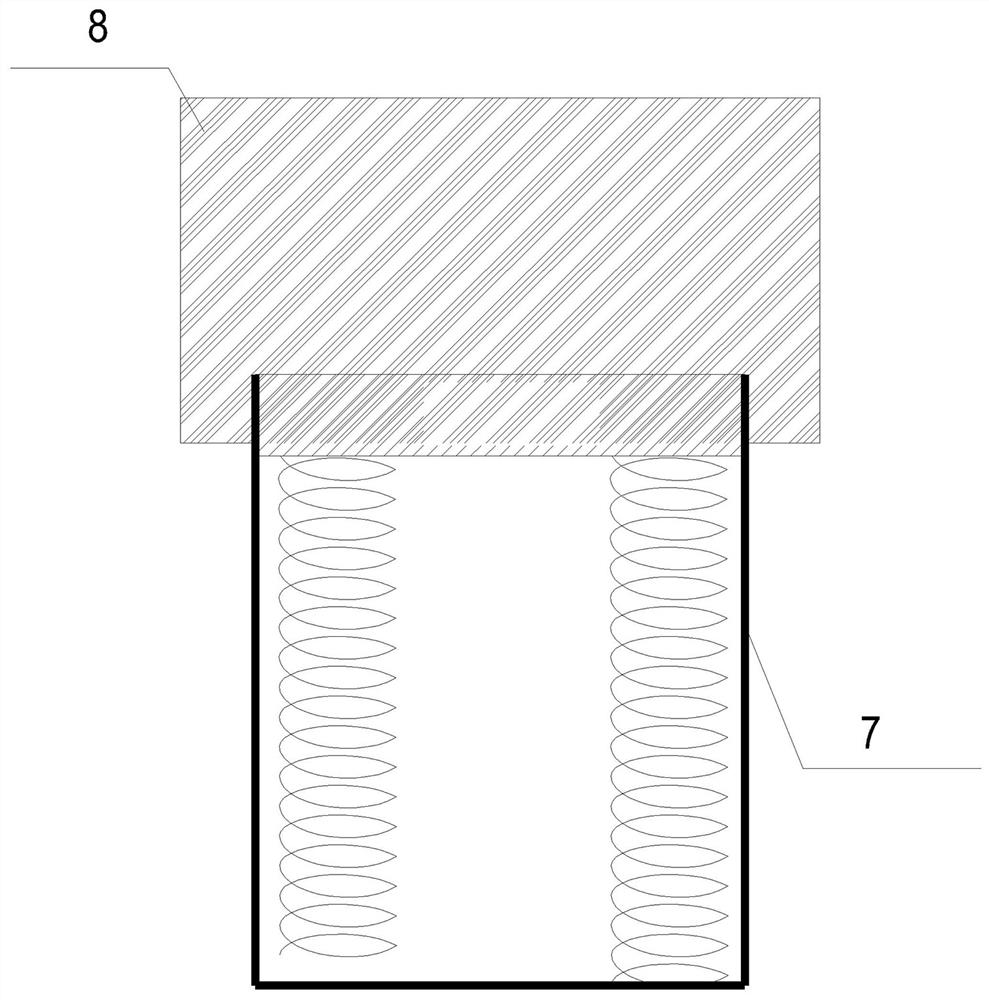

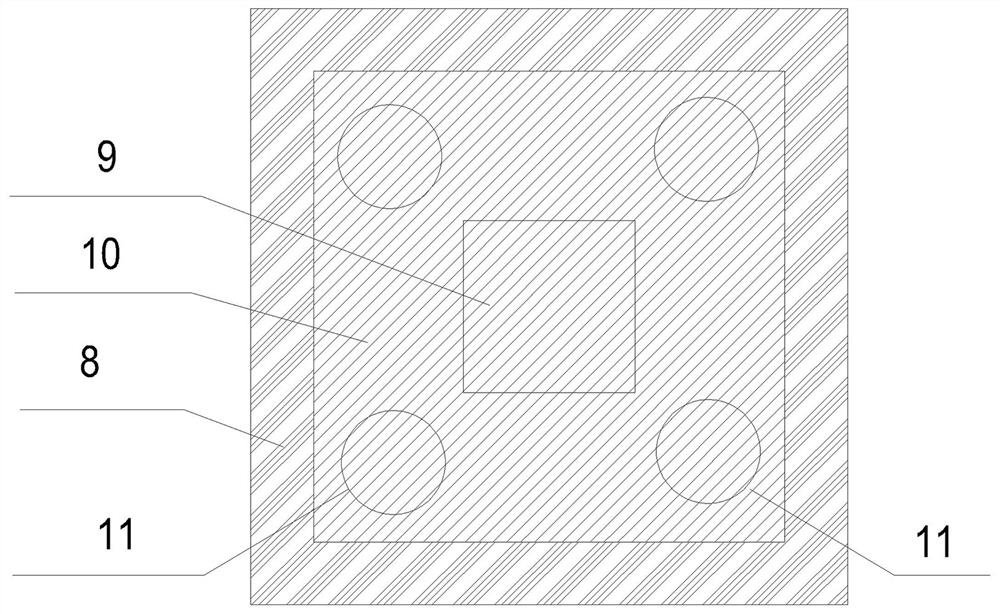

Reinforced concrete combination column structure and simultaneous pouring construction method

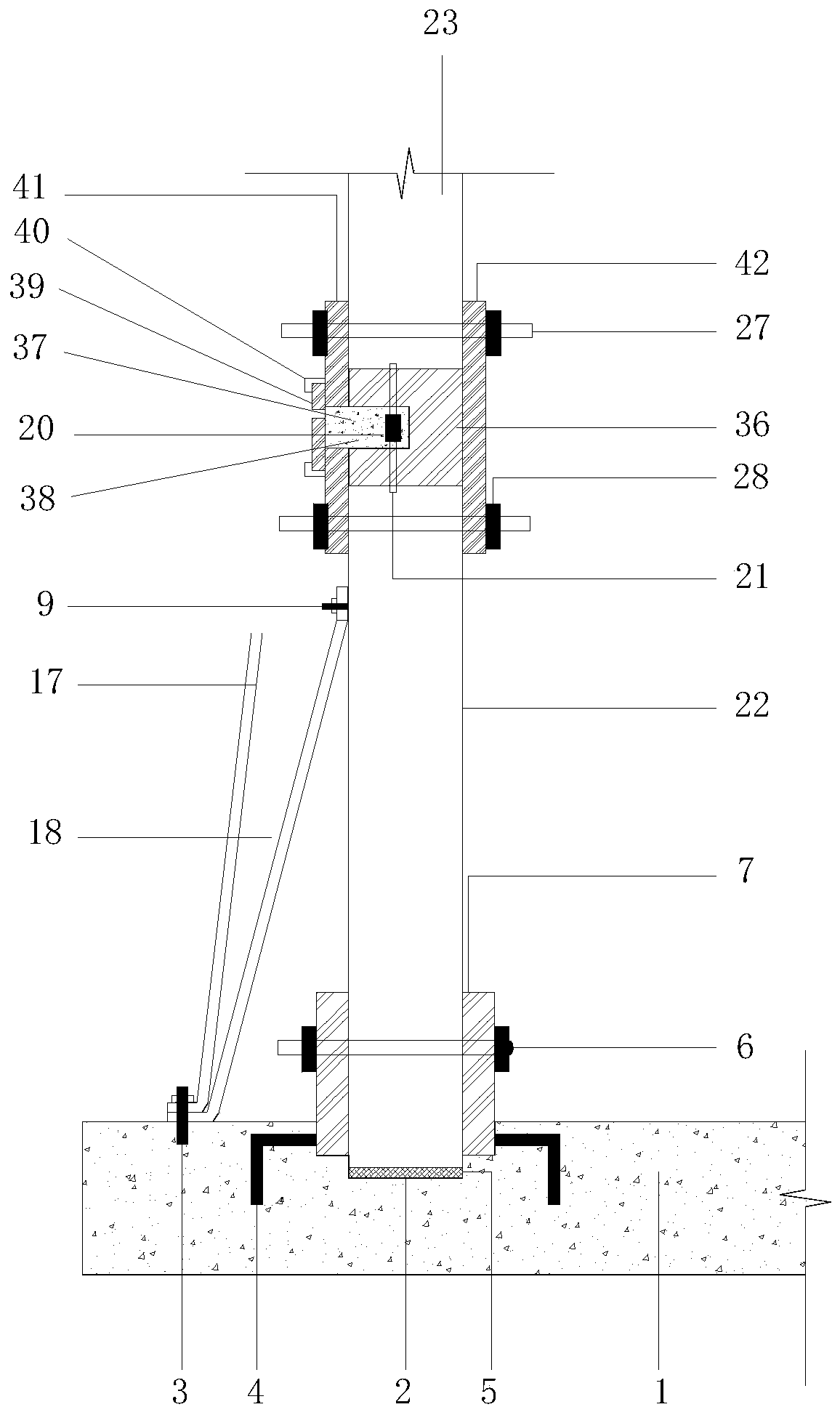

PendingCN106884502AIncreased shear strengthHigh structural construction efficiencyStrutsPillarsReinforced concreteArchitectural engineering

The invention relates to a reinforced concrete combination column structure which mainly comprises an upper steel tube column, a lower steel tube column, a lining tube, connecting ring plates and a vertical connecting screw; the upper steel tube column and the lower steel tube column are connected through the lining tube, concrete air vents and concrete pouring holes are formed in the surface of the steel tube columns, the connecting ring plates are arranged on the upper steel tube column and the lower steel tube column, the connecting ring plates are put on a cross-shaped rod and are anchored through horizontal screws on ring plate connecting end plates, and are horizontally clamped through U-shaped fastening brackets connected in series on the cross-shaped rod; the upper connecting ring plate and the lower connecting ring plate are connected through the vertical connecting screw, the vertical connecting screw and the upper connecting ring plate and the lower connecting ring plate are anchored by adopting screw caps, and a regulating and positioning top support is arranged on the end of the vertical connecting screw; and beam-column reinforcements are bound at the outer peripheries of the steel tube columns and templates are erected at the outer peripheries of the steel tube columns. According to the reinforced concrete combination column structure, the connecting node of the upper steel tube column and the lower steel tube column has strong anti-shearing performance, all members are simply and conveniently assembled, and the technical and economic benefits are prominent.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

Method for separating and extracting fine particle Ta-Nb concentrate

The invention provides a method for separating and extracting fine particle Ta-Nb concentrate. Ta-Nb slurry is used as a raw material. The method comprises the steps of (1) pretreatment; (2) dispersion flocculation; (3) centrifugal grading selection; the pretreatment (1) comprises the steps of treating the Ta-Nb slurry till that the mass percentage is not lower than 20% as selection ore pulp 1; the dispersion flocculation (2) comprises the steps of adding a dispersant hexametaphosphate into the selection ore pulp 1, stirring for plural minutes, then adding a flocculant and stirring for plural minutes to obtain selection ore pulp 2; the centrifugal grading (3) comprises the steps of placing the selection ore pulp into a centrifugal separator for centrifugal grading so as to obtain the fine particle Ta-Nb concentrate. According to the method, the grade of the recycled fine particle Ta-Nb concrete is high, the recycle rate of the Ta-Nb concrete is high, the economic technical benefits are obvious, the treatment to three wastes is small, and the influence on the environment is small.

Owner:YICHUN TANTALUM & NIOBIUM MINE

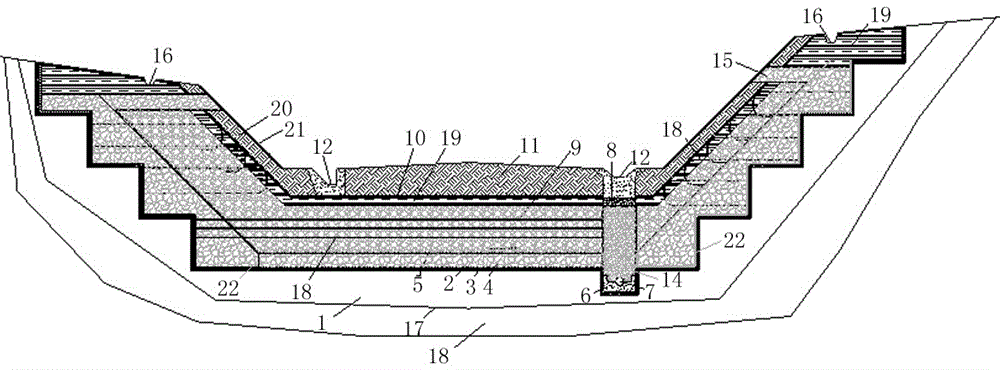

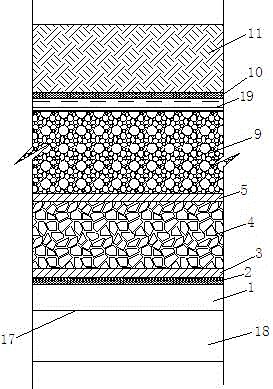

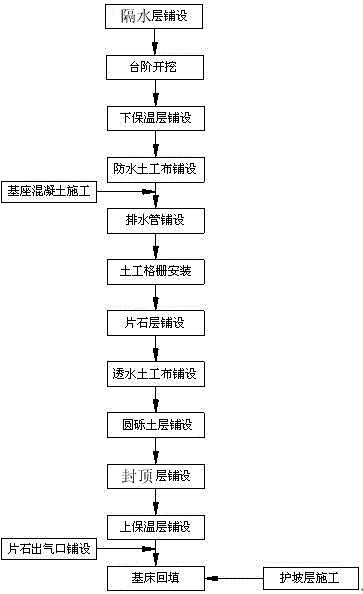

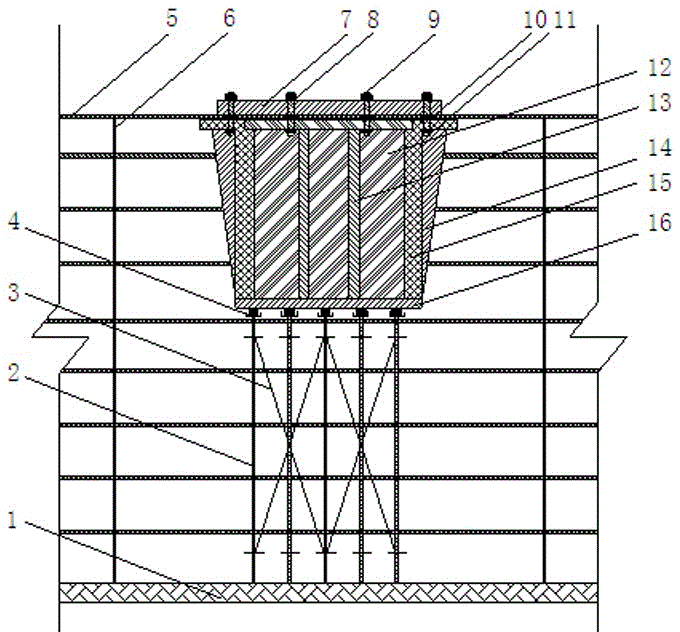

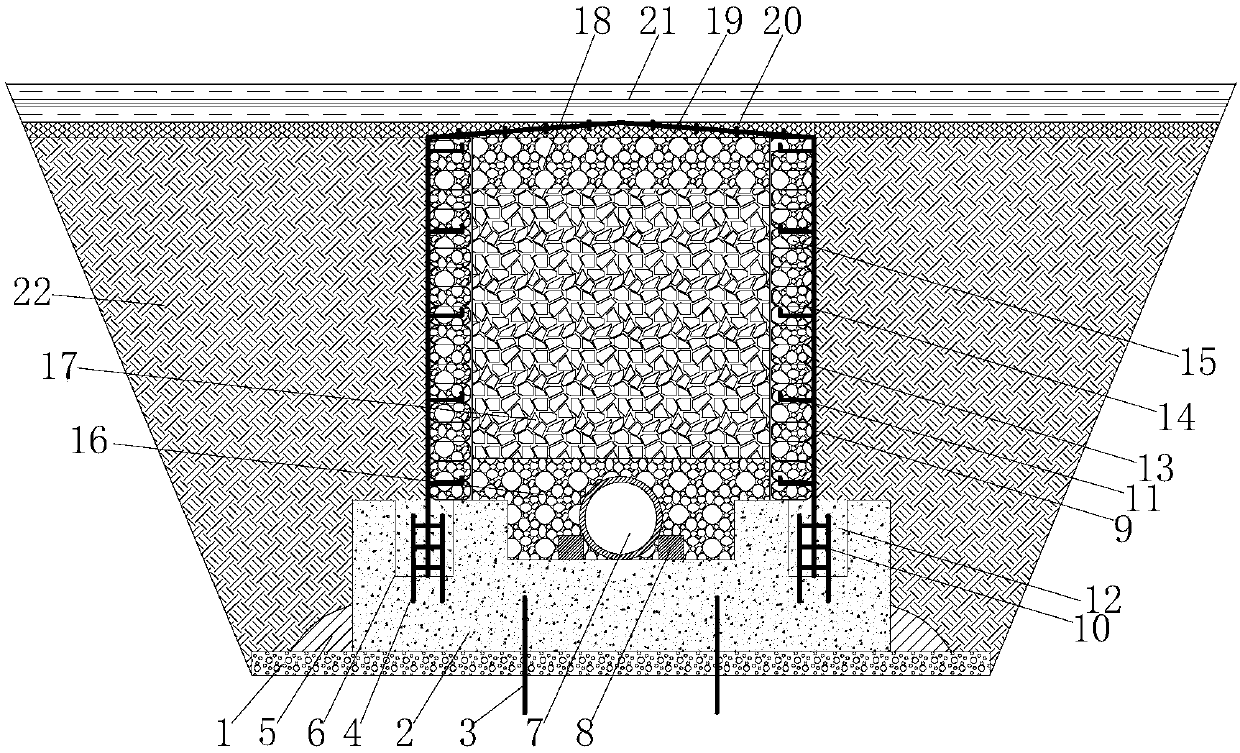

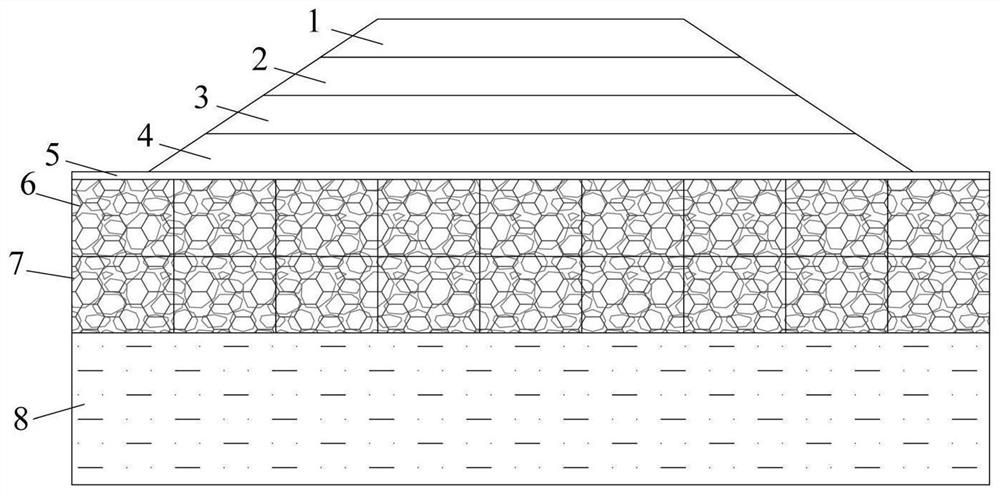

Heat-preservation and water-seepage compound type blind ditch of deep trench of severely cold and frozen earth area and construction method of heat-preservation and water-seepage compound type blind ditch

The invention relates to a heat-preservation and water-seepage compound type blind ditch of a deep trench of a severely cold and frozen earth area and a construction method of the heat-preservation and water-seepage compound type blind ditch. The structure mainly comprises a water separation layer, a lower heat-preservation layer, a waterproof geotextile, a flag stone layer, a non-woven geotextile inverse filtering layer, a concrete base, a water drainage pipe, a medium-coarse sand cushion layer, a round gravel soil layer, an upper heat-preservation layer, a foundation bed, a geogrid, a slope protection layer, a flag stone air outlet hole, a top sealing layer, an edge slope backfilling layer and a slope protection layer. The construction method mainly comprises the following construction steps: spreading the water separation layer, digging a step, spreading the lower heat-preservation layer, spreading the waterproof geotextile, mounting the water drainage pipe, mounting the geogrid, spreading the flag stone layer, spreading the non-woven geotextile inverse filtering layer, spreading the round gravel soil layer, spreading the top sealing layer, spreading the upper heat-preservation layer and backfilling the foundation bed. The construction method provided by the invention is simple and the construction efficiency is high; the obtained heat-preservation and water-seepage compound type blind ditch of the deep trench of the severely cold and frozen earth area has stable quality, has advantages of good heat-preservation effect, high water-seepage efficiency and the like, has relatively good economic and technical benefits and is worthy of being popularized and applied.

Owner:ANHUI ROAD & BRIDGE GRP

Construction method for large steel structural embedded part in dense reinforcement distribution region

ActiveCN105649213AShorten post-work timeImprove construction efficiencyWelding/cutting media/materialsBuilding material handlingEngineeringRebar

The invention relates to a construction method for a large steel structural embedded part in a dense reinforcement distribution region. The method comprises the steps of mounting a bottom die and binding girder stirrups; binding a longitudinal main reinforcement; mounting transverse lacing wires and split bolts; mounting a bottom supporting frame; lifting a bottom plate of the embedded part; mounting a main side plate of the embedded part; mounting connecting reinforcements; lifting an auxiliary side plate of the embedded part; lifting an internal stiffened steel plate of the embedded part; mounting a connecting cover plate; mounting and reinforcing a template; performing concrete pouring; performing concrete curing; re-checking the position of the embedded part; and the like. With the adoption of the technology, firstly the steel reinforcements are bound with a post method, previously the main reinforcement is disconnected in the position of the embedded part, and the embedded part is lifted and assembled after the steel reinforcements are bound, so that the construction difficulties in subsequent steel reinforcement binding, stirrup mounting, prestress anchor cable positioning and reinforcement, and the like in a large steel structural embedded part project are effectively overcome; and therefore, the method has the advantages of capability of greatly shortening the later operation time, high construction efficiency and the like.

Owner:JINAN CHANGXING CONSTR GRP

Production of multi-layer metal bush tile spreading materials

A technology for preparing the developed material of multi-layer metallic bush includes such steps as providing a developed steel plate of semi-circular bush, welding a copper layer to its one surface, spreading a layer of Cu-alloy powder, putting it along with its mould in a sinter furnace containing protecting atmosphere, sintering, cooling to 500-800 deg.C, putting it on an axial swinging-rolling machine, thermally swinging rolling on the sintered layer for compacting it, and heat treating.

Owner:胡长安

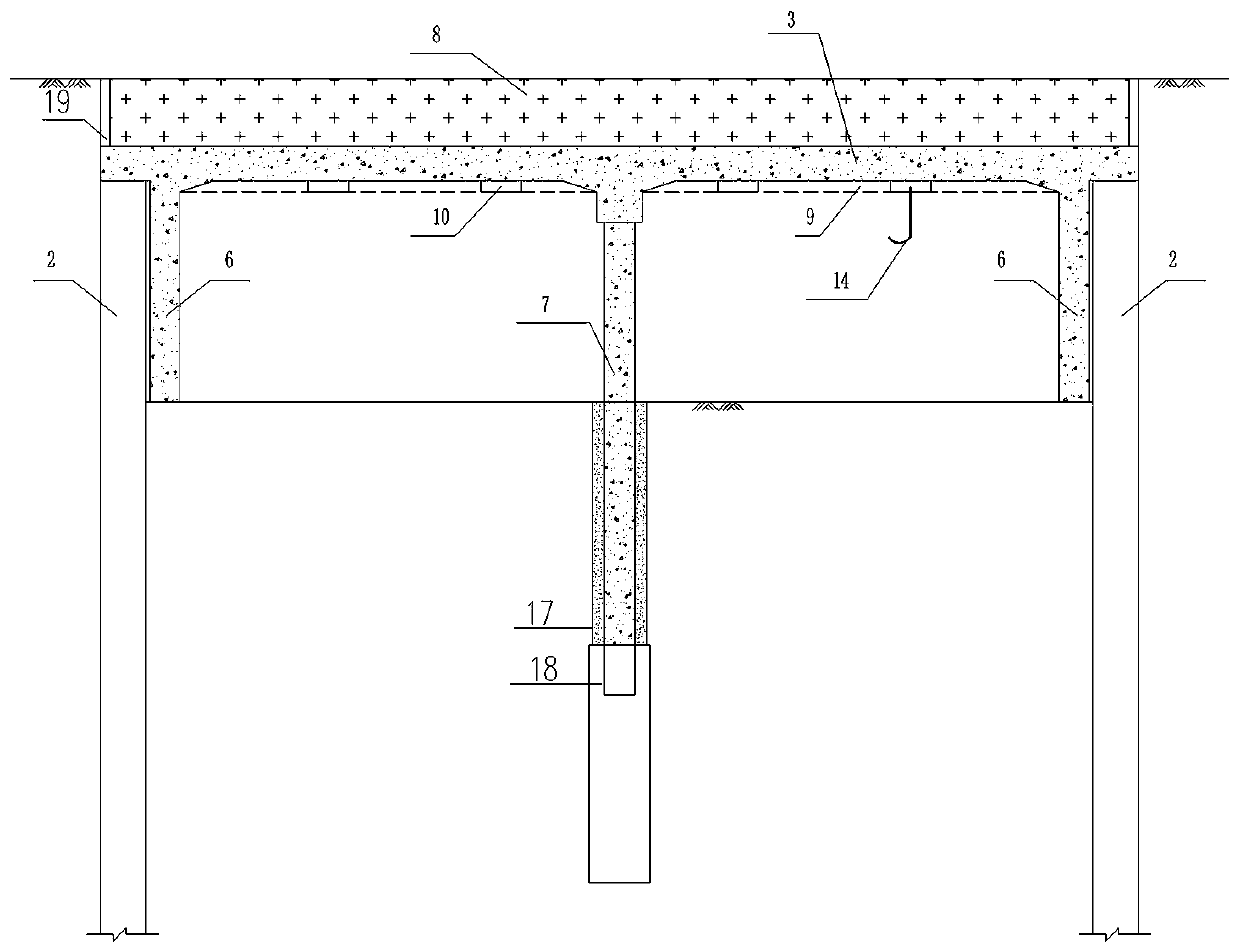

Underground structure internal transportation system based on under-plate sliding groovesand construction method of underground structure internal transportation system

PendingCN110439000AImprove transportation efficiencyMature construction technologyArtificial islandsBase supporting structuresPre embeddingGantry crane

The invention relates to an underground structure internal transportation system based on under-plate sliding grooves and a construction method of the underground structure internal transportation system. Criss-crossed downward overturning beams are arranged at the bottoms of a structural top plate and a structural middle plate, pre-embedded sliding grooves are formed in the beam bottoms of the downward overturning beams, T-shaped anchor bolts can be conveniently fixed into the sliding grooves, friction-free sliding between the T-shaped anchor bolts and the sliding grooves is realized by usingballs, and the T-shaped anchor bolts provide anchorage points required by material transportation in a station. According to the underground structure internal transportation system and the construction method, the pre-embedded sliding grooves in the downward overturning beams of an under-plate structure and the T-shaped anchor bolts form a stress system, the requirements of material transportation in a foundation pit cover-excavation area are met, efficient transportation of various materials in the period of foundation pit excavation and main structure pouring is realized based on a foundation pitopen excavation part gantry crane and a cover-excavation part structure under-plate transportation system, the conflict between a material transportation path in the station and the supportingspace in a foundation pit in the period of regular foundation pit excavation and main structure pouring is effectively avoided, the construction efficiency of underground engineering can be significantly improved, the time limit and project investment are saved, and reference can be provided for underground structure construction.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Construction method of steel trestle with steel pipe piles

ActiveCN110847169AImprove insertion accuracyFirmly connectedBridge applicationsBulkheads/pilesArchitectural engineeringWater flow

The invention discloses a construction method of a steel trestle with steel pipe piles, and relates to the technical field of trestle construction. The construction method comprises the following steps of 1, manufacturing the steel pipe piles; 2, installing an assembled cantilever guide frame positioning device; 3, installing the steel pipe piles in place; 4, performing pile vibrosinking; 5, performing flat connector installation between the piles; 6, constructing sleeper beams; 7, constructing annular lug plates; 8, constructing Bailey main beams; 9, constructing I-shaped steel load distribution beams and a deck; and 10, performing prepressing construction on an upper part system. The construction method has the advantages that the insertion and driving precision of the steel pipe piles is high; temporary fixing measures are not needed; the connection between the sleeper beams and the steel pipe piles is firm; the performance for resisting transverse impact force of vehicles is high;the influence caused by water flow is small; the bearing capacity is great; the construction quality is improved; and good economical and technical benefits are realized. The assembled cantilever guide frame using the design is formed by processing section steel and is hung on the single group of Bailey main beams, so that the operation is convenient and flexible, and the speed is high.

Owner:湖北省路桥集团有限公司

Landslide zone pile plate type comprehensive protection construction system and method

PendingCN112376589AReduce the safety risk of protective constructionGuaranteed installation accuracyArtificial islandsExcavationsArchitectural engineeringRock bolt

The invention provides a landslide zone pile plate type comprehensive protection construction system and a construction method. A foundation shaping formwork, a slideway type leveling repair mold anda plate surface green plant hanging groove device are arranged; a foundation shaping formwork is erected between every two adjacent anti-slide piles, concrete is poured into the space defined by the foundation shaping formwork and the anti-slide piles to form a breast board foundation, breast boards are hoisted on the breast board foundation layer by layer, and the breast boards are connected withreserved anchor rods of the anti-slide piles in an anchored mode; and after the breast boards are hoisted, the slideway type leveling repair mold is installed through a drain hole reserved in the breast board, the outer vertical face of the anti-slide pile is leveled through the slideway type leveling repair mold, and a board green plant hanging groove is installed through a hook arranged on theouter vertical face of the breast board. According to the landslide zone pile plate type comprehensive protection construction system, the construction mode that the anti-slide piles are poured firstly and then excavation and restoration are conducted is adopted, the safety risk of landslide zone protection construction is effectively reduced, the technical benefits are remarkable, the safety is high, the ecological effect is good, and meanwhile the economic and technical benefits are outstanding.

Owner:ANHUI ROAD & BRIDGE GRP

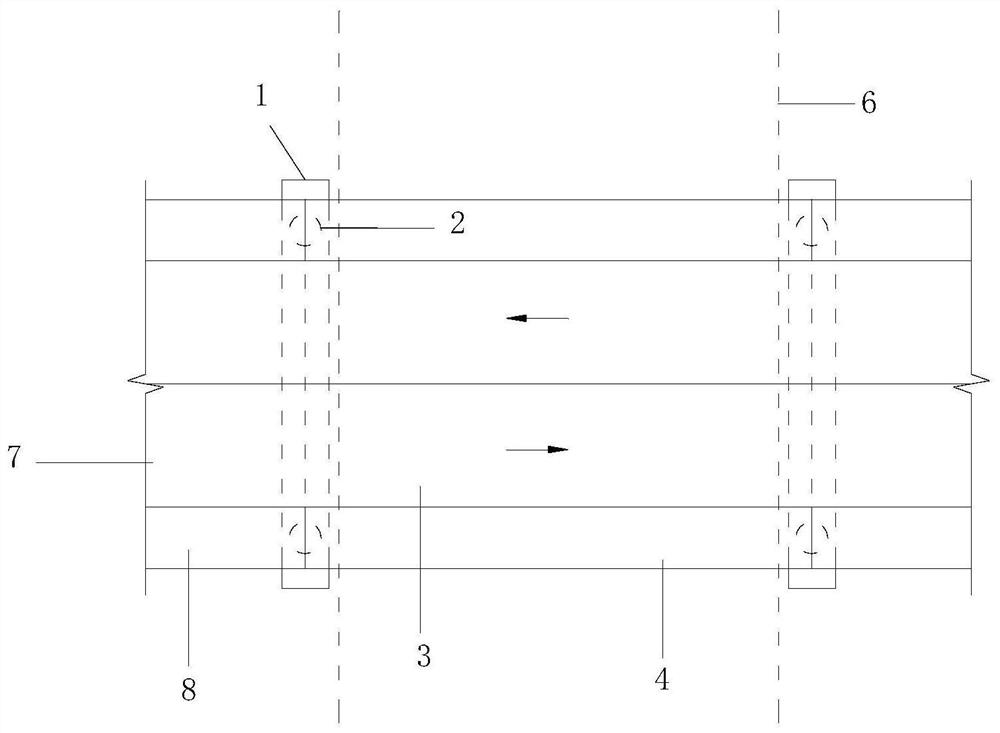

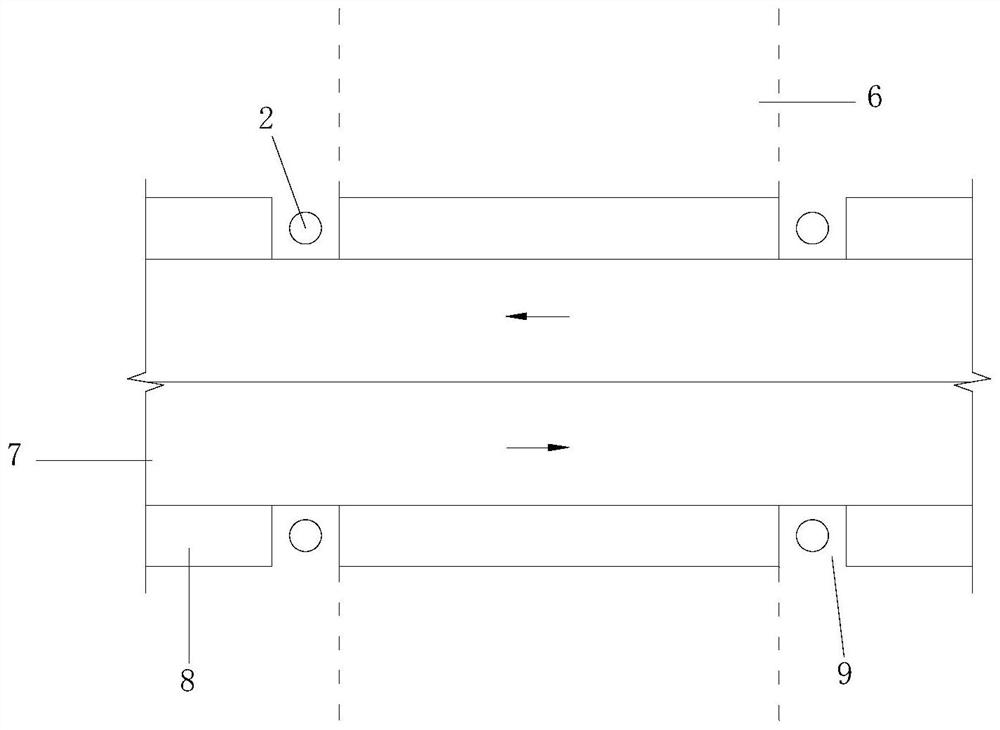

Underground station fabricated rail top air duct structure and construction method thereof

PendingCN111535361ARich construction methodsMature construction technologyArtificial islandsUnderwater structuresArchitectural engineeringStructural engineering

The invention relates to an underground station fabricated rail top air duct structure and a construction method thereof. The construction method comprises the steps that a horizontal beam and a vertical air duct web are arranged on the inner side of a structural side wall and a structural middle plate; the inner side of the beam is connected to the structural side wall through a bracket, the outer side of the beam is connected to the bottom of the air duct web through winged feet, and the top of the air duct web is connected to the structural middle plate through pre-embedded bolts; and an air duct plate is arranged above the beam, and the structural side wall, the structural middle plate, the air duct plate and the air duct web form the air duct structure. According to the underground station fabricated rail top air duct structure and the construction method thereof, plug type bolts and the bracket are used for effectively fixing the beam and the air duct plate, a connection mode ofa cast-in-place air duct structure and a main structure generally based on planted bars is transformed into a fabricated member of plug-in type bolt mechanical occlusion and bracket clamping and fixing, and the novel fabricated rail top air duct with field rapid installation and reliable connection is realized; and the stress characteristic between novel and old structures is improved, the multiple problems of form erecting and concrete pumping related in air duct structure site concrete pouring are solved, and the construction benefits are improved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

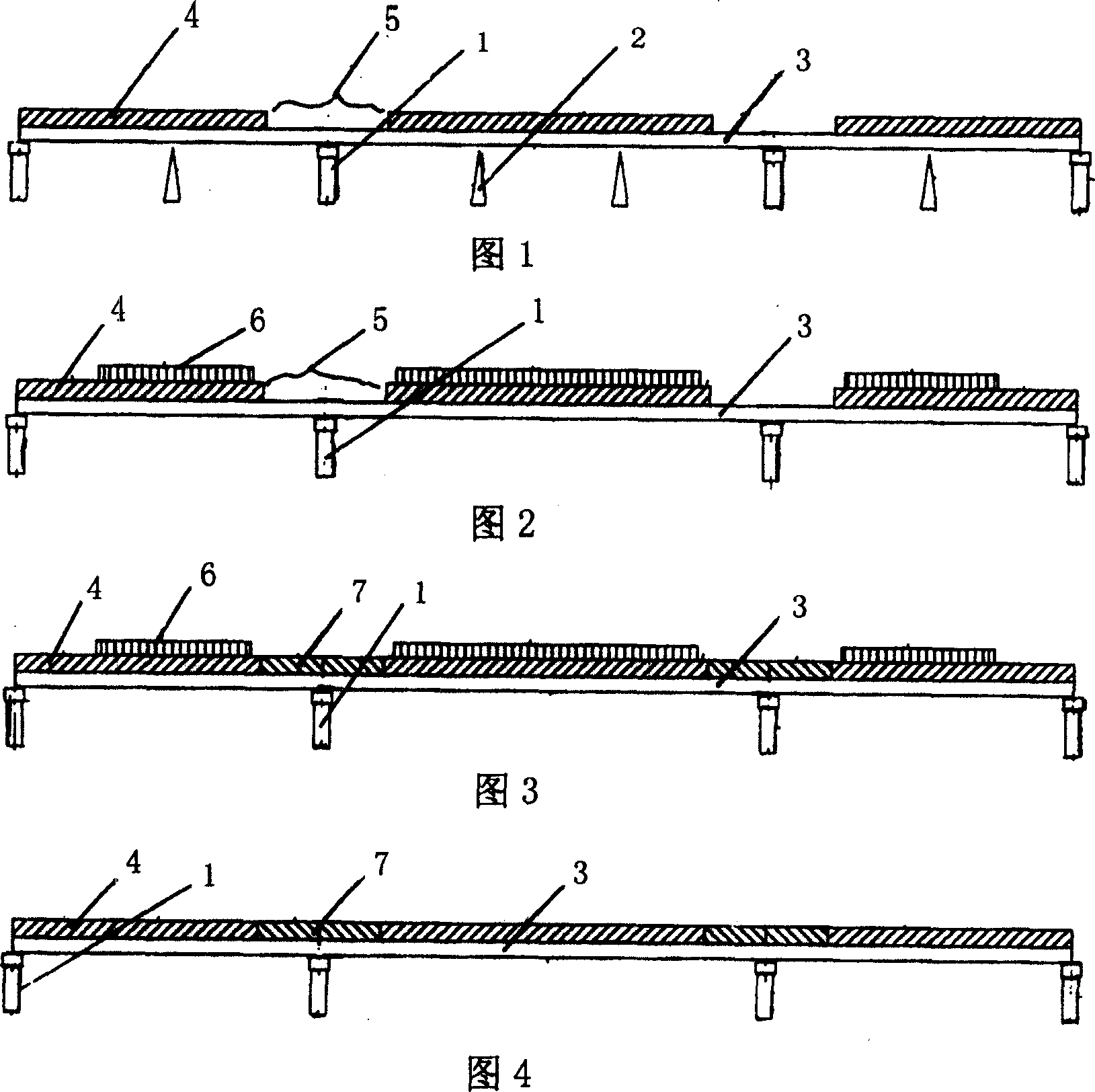

Slab culvert cast-in-situ roof truss type slip form system and construction method

The invention relates to a slab culvert cast-in-situ roof truss type slip form system. The slab culvert cast-in-situ roof truss type slip form system comprises a cushion course, a culvert bottom plate, culvert side plates, a culvert top plate, foundation treatment piles, truss uprights, a sliding adhesion vertical rail, an integral counter-force prepressing frame, an integral jacking cross beam and a top plate bottom die; the cushion course and the culvert bottom plate are arranged on the foundation treatment piles; a counter-force prepressing embedded piece and a bottom plate track embedded piece are embedded in the culvert bottom plate; a frame format type counter-force plate and an expanded counter-force disc are connected with the counter-force prepressing embedded piece; a channel steel ear plate is arranged at the upper part of the bottom plate track embedded piece; the upper part of the channel steel ear plate is connected with a pulley; an integral jacking cross beam is arranged at the upper part of the pulley; truss uprights are arranged at the upper part of the integral jacking cross beam; and the sliding adhesion vertical rails are arranged on the truss uprights. The slab culvert cast-in-situ roof truss type slip form system has the beneficial effects that the slab culvert top plate adopts a truss type slip form system, a unit truss is assembled outside, a top reinforcement cage is integrally molded and hoisted on site, and a sliding type operation platform is placed on the truss uprights and is combined and fixed by using overhanging channel steels and rotary supporting steel plates, and therefore, the construction speed can be increased.

Owner:德达交通建设发展集团有限公司

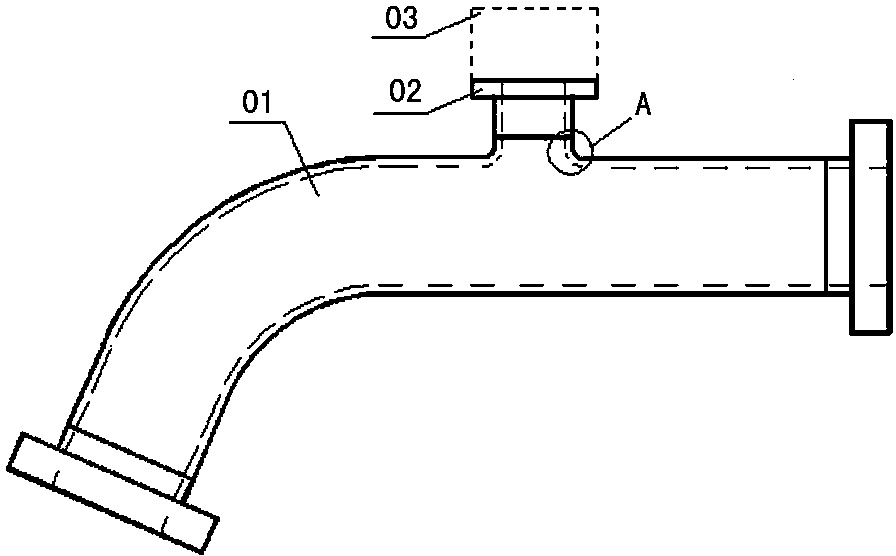

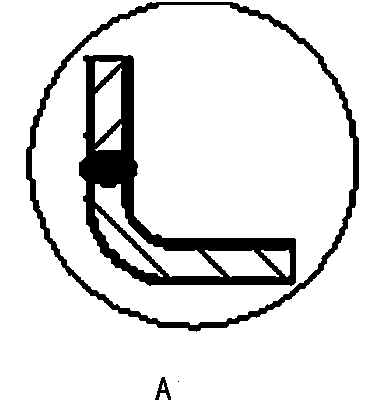

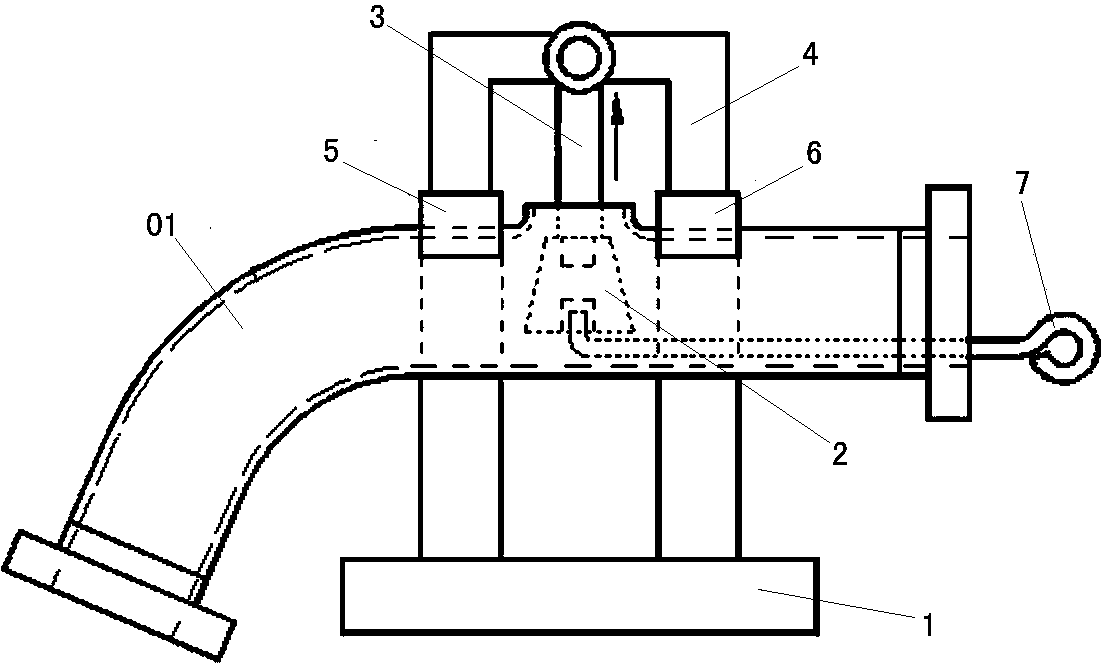

Large-diameter high-temperature-resistant aluminum alloy pipe flanging method and large-diameter high-temperature-resistant aluminum alloy pipe flanging device

In order to solve the problems of great work load, quality ensuring difficulty and the like of the large-diameter high-temperature-resistant aluminum alloy pipe flanging method in the prior art, the invention provides a large-diameter high-temperature-resistant aluminum alloy pipe flanging method and a large-diameter high-temperature-resistant aluminum alloy pipe flanging device. The large-diameter high-temperature-resistant aluminum alloy pipe flanging device comprises a support frame, a flanging cone, a pull rod, a cantilever, a left pipe blocking device, a right pipe blocking device and a cone moving rod. According to the method provided by the invention, an oval hole is formed in the radial direction of an aluminum alloy pipe through calculation, then, the large-diameter high-temperature-resistant aluminum alloy pipe flanging device is adopted for flanging and deforming the oval hole formed in the aluminum alloy pipe into a cylindrical pipe opening, and the size and the shape meet the design requirements. The large-diameter high-temperature-resistant aluminum alloy pipe flanging method and the large-diameter high-temperature-resistant aluminum alloy pipe flanging device have the beneficial technical effects that the cylindrical pipe opening formed by the flanging can be enabled to meet the design requirements, and in addition, the manufacturing process is simple and reliable. The flanging device has the advantages that the structure is simple, the manufacturing cost is low, and good economic technical benefits are realized.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Complex terrain steep rock mass top-down tunnel portal tunnel entrance and construction method

ActiveCN111577294AEnsure construction safetyGuaranteed stabilityUnderground chambersTunnel liningArchitectural engineeringRockfall

The invention provides a complex terrain steep rock mass top-down tunnel portal tunnel entrance and a construction method. The complex terrain steep rock mass top-down tunnel portal tunnel entrance comprises a safety protection channel, a channel top falling stone prevention cleaning device, a temporary reinforcing device rapidly installed on the outer side of the protection channel, a lifting jacking rack inner supporting type steel arch correcting and auxiliary inverted arch suspended formwork system. The safety of constructors is effectively guaranteed in top-down construction, the construction difficulty is reduced in tunnel body construction, and the construction efficiency is improved. The invention further discloses a complex terrain steep rock mass top-down tunnel portal tunnel entrance construction method. The method which mainly comprises the steps of tunnel opening measurement, tunnel opening primary excavation, safety protection channel installation, tunnel top disposal, tunnel body excavation, steel arch frame erection, concrete spraying, inverted arch reinforcement cage binding, end formwork hoisting and inverted arch concrete construction. The construction efficiencyis high, manpower and working hours can be saved and good economic and technical benefits are achieved.

Owner:四川路桥盛通建筑工程有限公司

Roadbed splicing broadening structure and construction method

ActiveCN112681043AAvoid enteringEasy dischargeGround-workPaving gutters/kerbsArchitectural engineeringStructural engineering

A related roadbed splicing broadening structure comprises a permeable pavement layer, a new and old roadbed transition section, a permeable grading layer and a permeable pavement layer, wherein the new and old roadbed transition section is arranged at a roadbed splicing position in a full-length mode, the new and old roadbed transition section is fixedly connected with an original roadbed through anchor bars arranged in guide holes, vertical water pipes are arranged in the new and old roadbed transition section at intervals, and inner side piles and outer side piles are arranged below the new and old roadbed transition section at intervals; the permeable grading layer is arranged below the vertical water pipe and between the inner side piles and the outer side piles in the longitudinal direction of the roadbed in a full-length mode, and the bottom of the side, close to the outer piles, of the permeable grading layer is connected with one end of transverse drainage blind ditches arranged at intervals. The invention has the advantages that the irregular new and old roadbed transition section is adopted, the dead weight and cost are effectively reduced, the anchor bars are tightly connected with the original roadbed, the pile foundations are arranged at the bottom, the structure is stable, sedimentation displacement is effectively prevented, the integrity is high, and economic and technical benefits are obvious.

Owner:湖北省路桥集团有限公司

Pre-closed super-front water-retaining post-cast strip for outer wall of basement and construction method

ActiveCN111074950AFast constructionImprove bearing capacityArtificial islandsProtective foundationPre stressArchitectural engineering

The invention provides a pre-closed super-front water-retaining post-cast strip for an outer wall of a basement and a construction method. The method comprises the main construction steps of (1) processing and mounting a rebar net rack; (2) mounting a slurry discharging component; (3) pouring concrete for the outer wall of the basement; (4) discharging slurry in a side die of the post-cast strip;(5) mounting an assembly-type pre-stress prefabricated slab; (6) performing grouting and stretch-drawing; (7) suspending construction racks and mounting columns; (8) constructing a waterproof coiled material; (9) constructing waterproof mortar; (10) suspending the construction racks and dismounting the columns; (11) constructing other post-cast strips. According to the construction method, the engineering cost can be effectively lowered, construction can be performed according to centralized prefabrication and site assembly methods, the construction speed is increased, and the method can achieve a good technical economic benefit when the post-cast strip is applied to actual engineering.

Owner:中峥建设集团有限公司

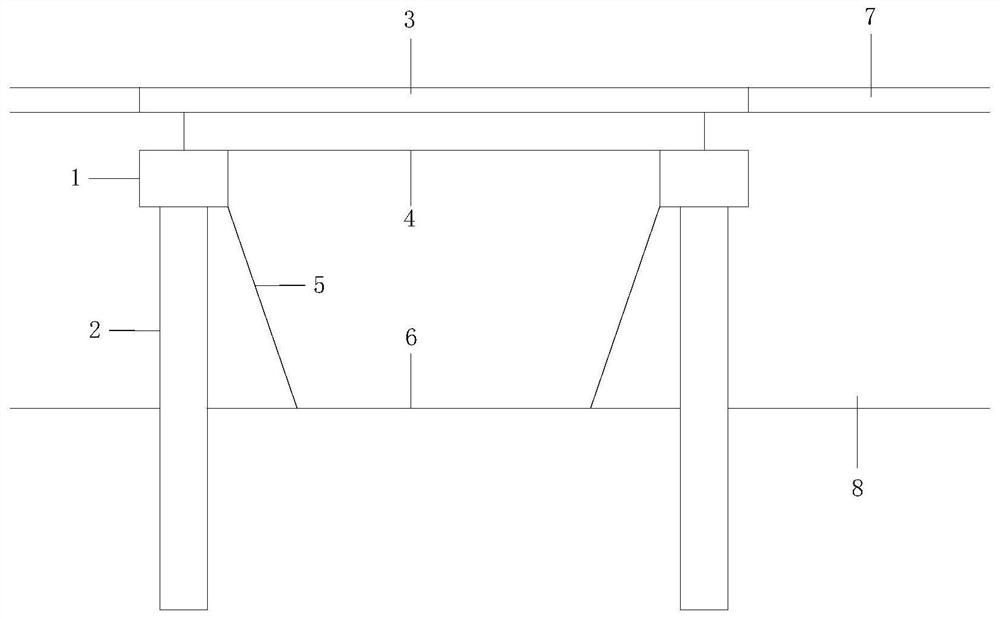

Existing roadbed-modified bridge at route intersection and construction method

ActiveCN112681140AAvoid secondary connectionsAvoid makingRoadwaysClimate change adaptationArchitectural engineeringBridge deck

The invention relates to an existing roadbed-modified bridge at a route intersection. The existing roadbed-modified bridge comprises a bent cap, pile foundations, a newly-built road surface system and a bridge deck slab. The pile foundations are arranged on slopes on the two sides of an existing roadbed at the route intersection, the bent cap is arranged at the tops of the pile foundations, and the pile foundations and the bent cap form a pile foundation bent cap structure. The bridge deck slab is arranged on the bent cap, the newly-built road surface system in lap joint with an existing road surface system is arranged on the bridge deck slab, a channel with an inclined protection slope is arranged below the bridge deck slab, and a newly-built route penetrates through the channel; and a bent cap groove is dug in a closed expressway, and a T-shaped gap bridge is arranged on the dug bent cap groove. The construction method has the beneficial effects that compared with the traditional technology, the existing roadbed is changed into the bridge at the route intersection, pile and column integrated pile foundation construction is conducted on local excavation of the roadbed slope, secondary connection between piles and manufacturing of pier column steel formworks are avoided, the construction period is shortened, normal traffic is not affected, and the technical advantages are obvious.

Owner:湖北省路桥集团有限公司

Method for anti-cracking in hogging moment area of steel-concrete combined beam

InactiveCN1322202CLow costEasy constructionLoad-supporting elementsBridge structural detailsConcrete beamsBending moment

Owner:TSINGHUA UNIV

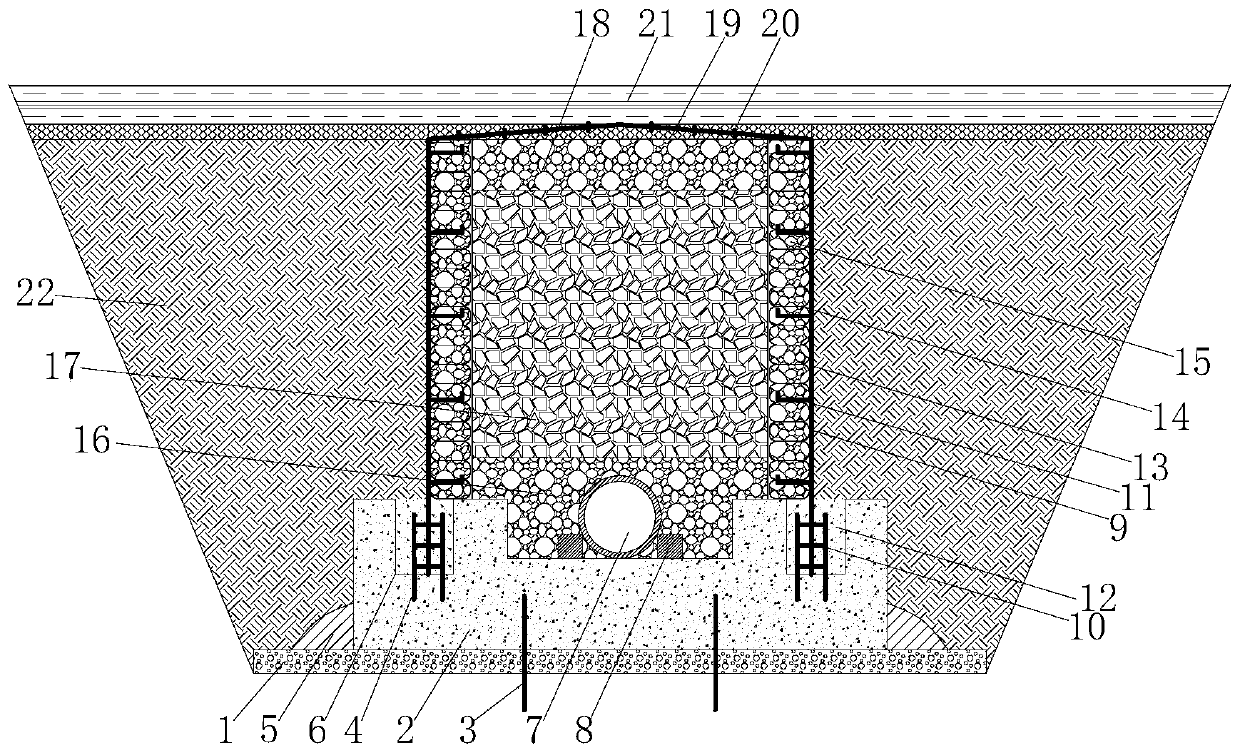

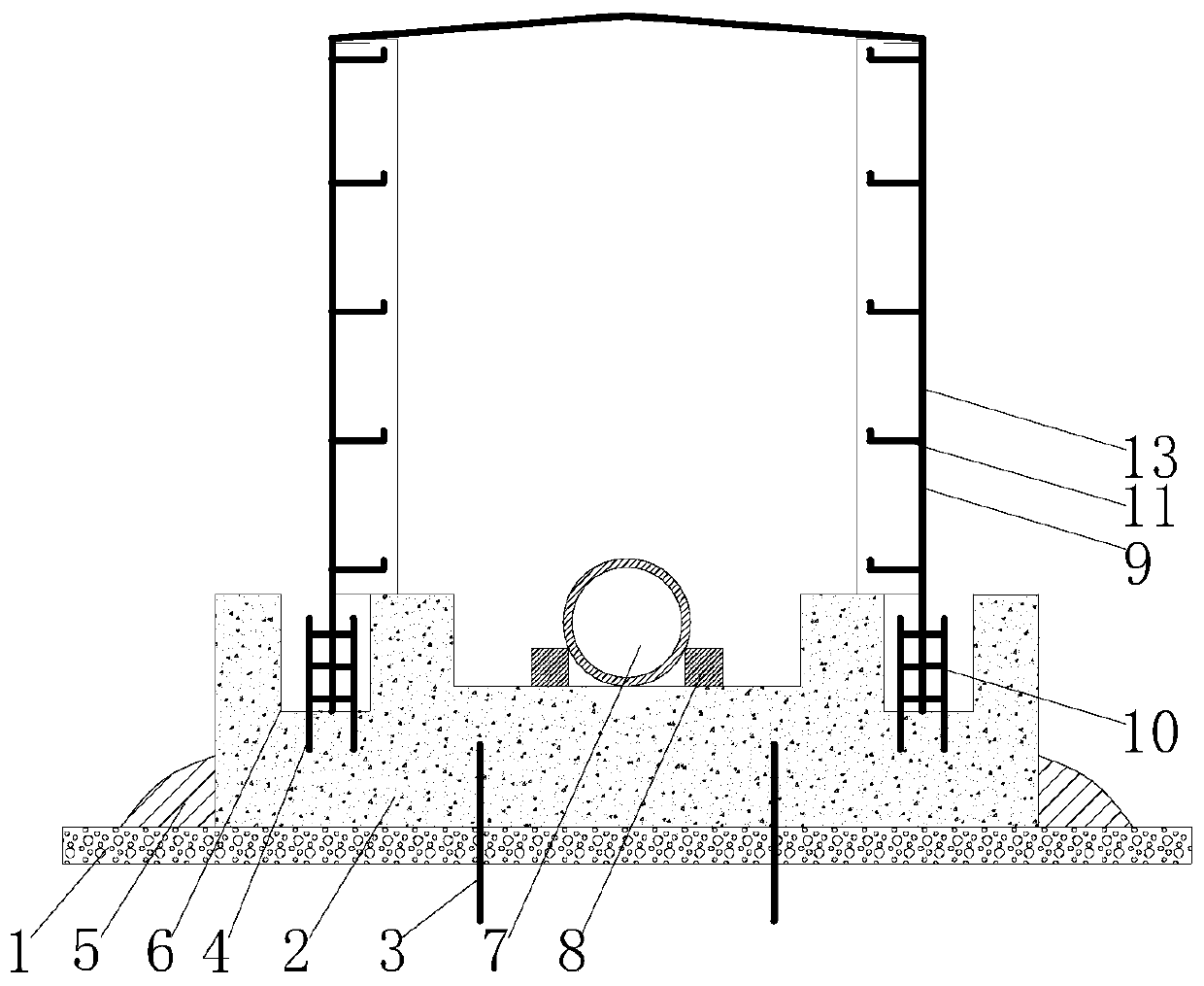

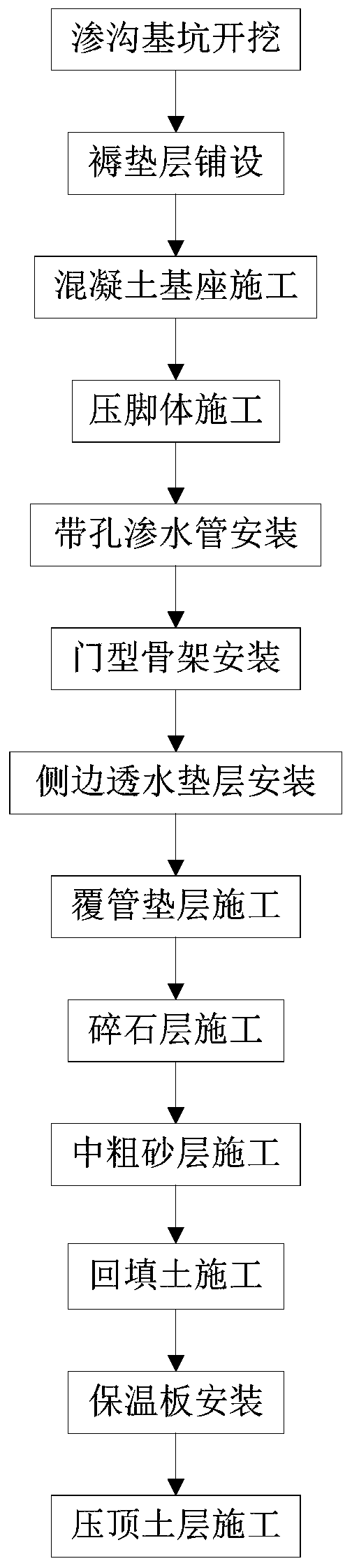

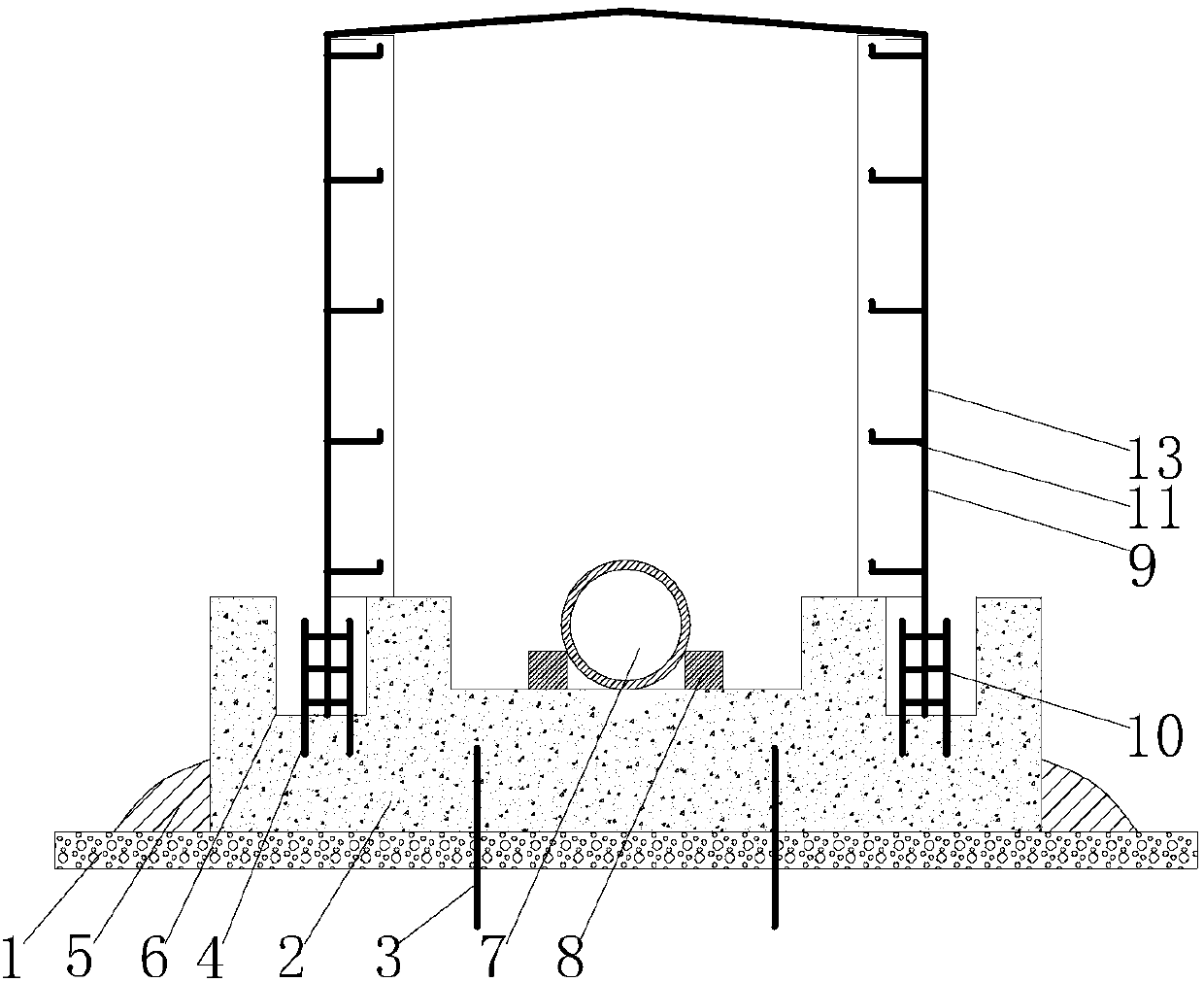

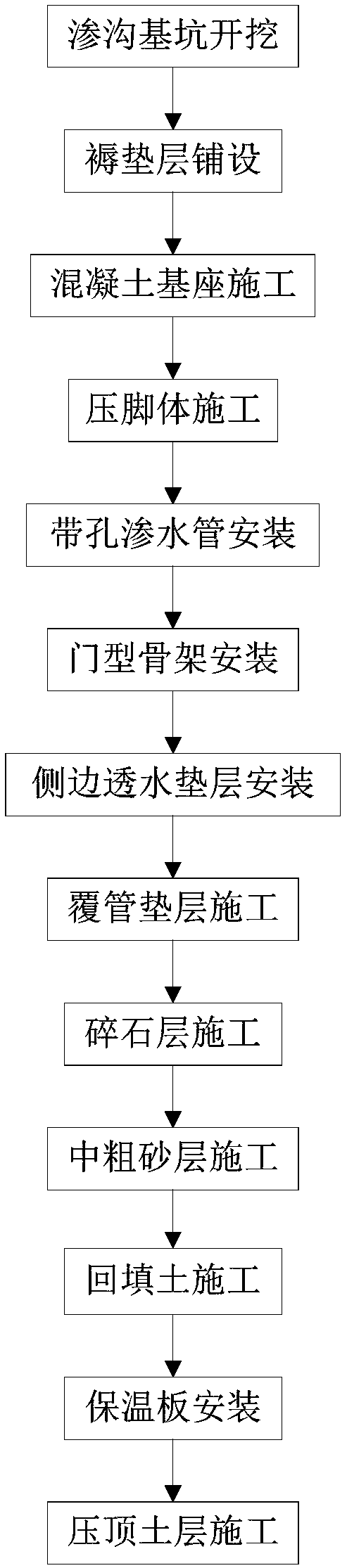

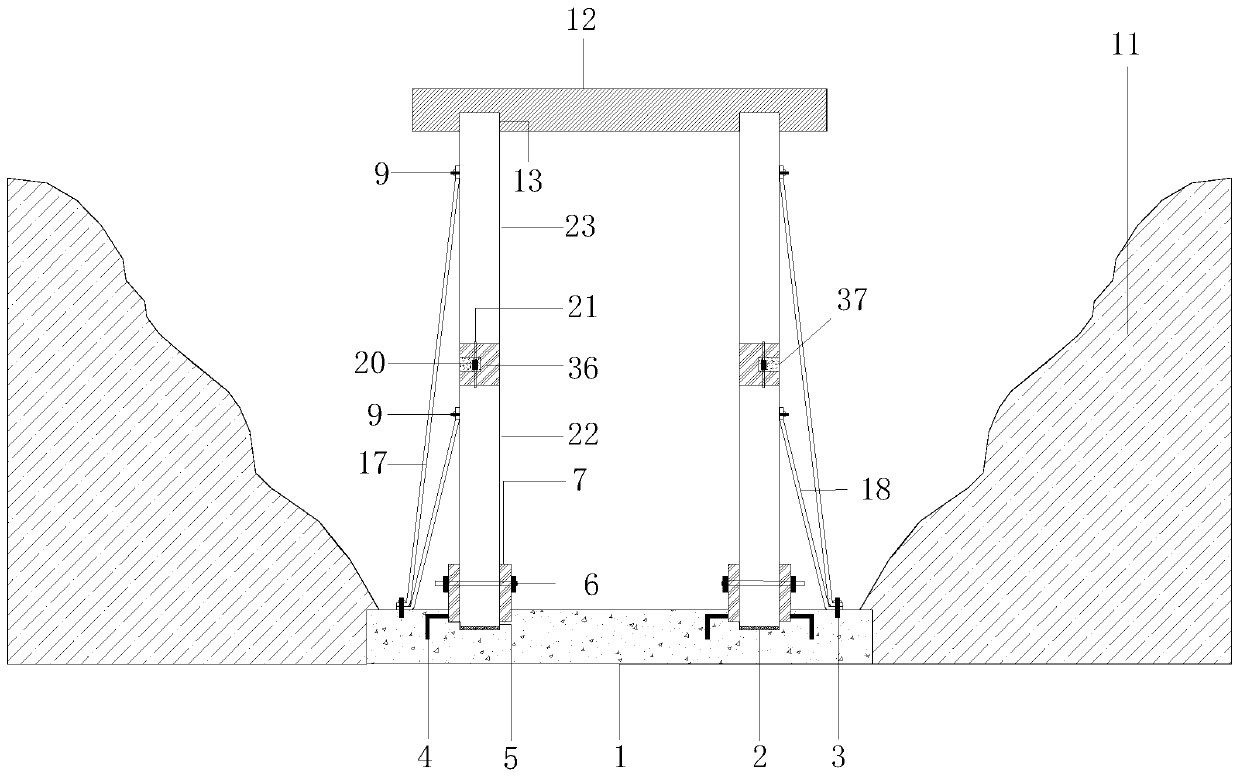

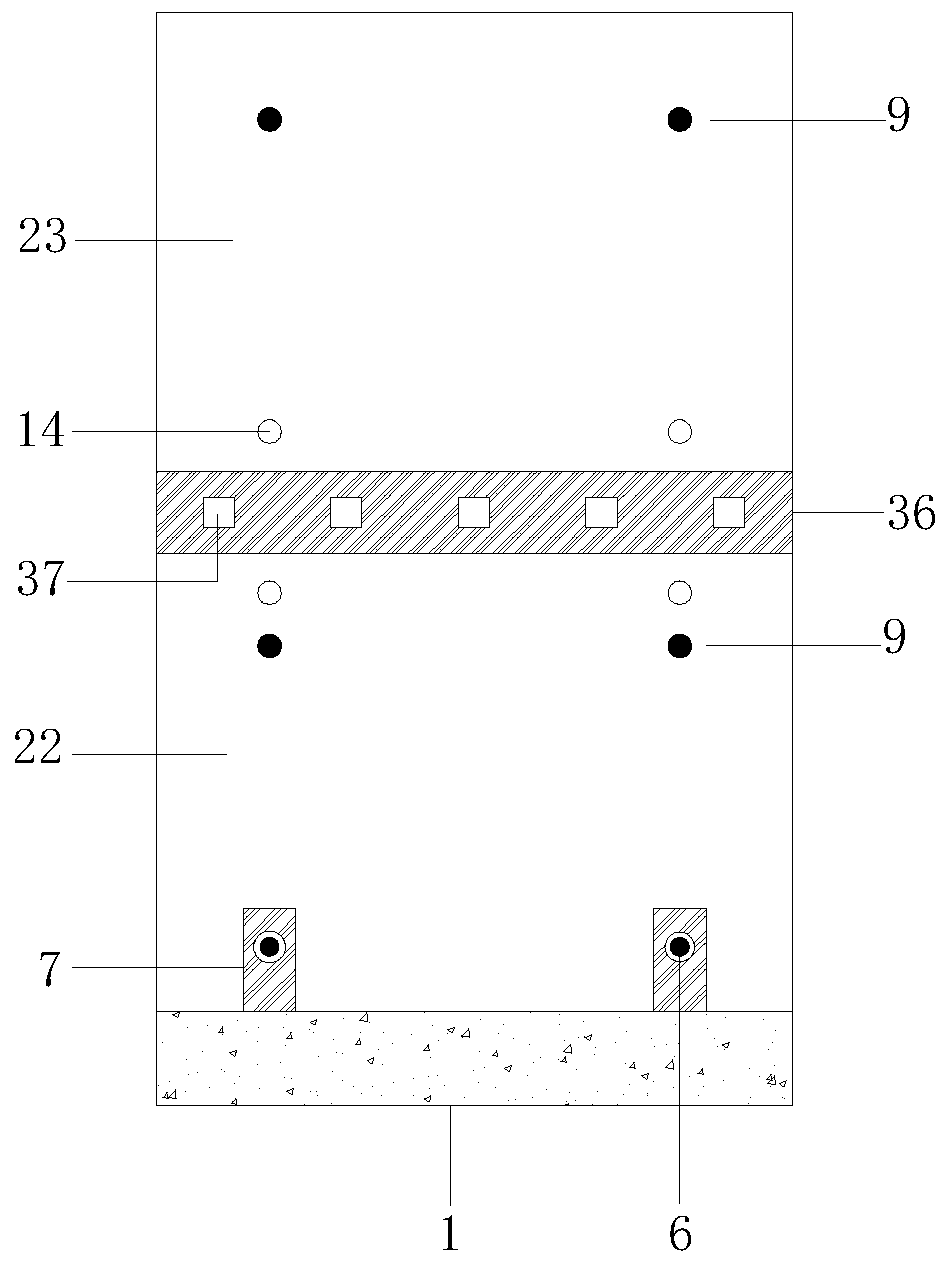

Construction method of thermal insulation and water seepage composite underground ditch

ActiveCN107700632BImprove integrityStand uprightRoadwaysSewerage structuresThermal insulationEngineering

The invention discloses a construction method of a heat preservation porous combined blind ditch. The construction method comprises the following steps of excavation of a seepage ditch foundation pit,pavement of a mattress layer, construction of a concrete foundation, construction of a pressure foot body, installation of porous water-leaking tubes, installation of a door-type framework, installation of a side water-permeable cushion layer, construction of a covering tube cushion layer, construction of a gravel layer, construction of a medium coarse gravel layer, construction of back fill soil, installation of a heat preservation plate and construction of a coping soil layer. The construction method is easy and feasible, the obtained heat preservation porous combined blind ditch is high inindependent existence and reliable in quality, has the advantages of high water leaking efficiency, good heat preservation effect and the like for high-cold frozen earth areas, and the construction method has good economic technological benefits and is suitable for popularization and application.

Owner:ANHUI XINLU CONSTR ENG GRP

Shaped large-formwork vertical thin-wall side wall and construction method

ActiveCN112482434ASimple and reasonable structureGood economic and technical benefitsArtificial islandsFoundation testingRebarPolishing

The invention relates to a shaped large-formwork vertical thin-wall side wall. The shaped large-formwork vertical thin-wall side wall comprises a bottom fixed side pull anchor rod fixed adjustable guide rail system, a light steel jig frame pull fixed sliding rail, a concrete pouring sliding guide frame platform, a feeding platform, an easily disassembled sliding lifting type light steel jig frame,a scaffold main support cantilever support auxiliary supporting operation platform, a rapid connection circulation climbing formwork, an easily retractable wall surface rain-proof shed, a guide framepressing fixed film covering maintenance device, a sliding type integral plastering press polishing device, a rail sliding type spraying maintenance device and a construction monitoring system. The shaped large-formwork vertical thin-wall side wall has the beneficial effects that the construction monitoring system of the shaped large-formwork vertical thin-wall side wall is simple and reasonablein structure, can effectively improve the formwork installation construction quality, the concrete pouring surface pouring height and the steel bar binding quality, and achieves good economic and technical benefits; and a vertical thin-wall side wall formwork system is simple and reasonable in structure, can achieves rapid assembly and disassembly, saves the use of split bolts, and is economical and environmentally friendly.

Owner:浙江世润建创科技发展有限公司

Construction method of heat preservation porous combined blind ditch

ActiveCN107700632AQuality improvementSimple construction methodRoadwaysSewerage structuresWater leakEngineering

The invention discloses a construction method of a heat preservation porous combined blind ditch. The construction method comprises the following steps of excavation of a seepage ditch foundation pit,pavement of a mattress layer, construction of a concrete foundation, construction of a pressure foot body, installation of porous water-leaking tubes, installation of a door-type framework, installation of a side water-permeable cushion layer, construction of a covering tube cushion layer, construction of a gravel layer, construction of a medium coarse gravel layer, construction of back fill soil, installation of a heat preservation plate and construction of a coping soil layer. The construction method is easy and feasible, the obtained heat preservation porous combined blind ditch is high inindependent existence and reliable in quality, has the advantages of high water leaking efficiency, good heat preservation effect and the like for high-cold frozen earth areas, and the construction method has good economic technological benefits and is suitable for popularization and application.

Owner:ANHUI XINLU CONSTR ENG GRP

Construction method of assembly type prefabricated plate disassembly-free thin plate tire film prefabricated ring beam reinforcing system

ActiveCN111074921AFast constructionImprove bearing capacityFoundation engineeringArchitectural engineeringEconomic benefits

The invention provides a construction method of an assembly type prefabricated plate disassembly-free thin plate tire film prefabricated ring beam reinforcing system. The main construction steps comprise of (1) foundation pit excavation, (2) cushion layer construction, (3) component prefabrication, (4) installation of a lower assembly type prefabricated plate, (5) installation of a prefabricated ring beam, (6) hoisting of an upper assembly type prefabricated plate, (7) form installation, (8) installation of an upper supporting rod and a clamping groove type inner supporting frame and (9) grouting. According to the construction method, the engineering cost is effectively reduced, concentrated prefabrication and on-site assembly methods can be realized for construction, the construction speed is increased, and better technical and economic benefits can be obtained when the construction method is applied to actual engineering.

Owner:中峥建设集团有限公司

The Construction Method of Elevator Shaft Foundation Pit Water Seepage and Drainage Combined with Comprehensive Treatment

ActiveCN111088842BImprove stabilityImprove securitySewerage structuresVertical ductsStructural engineeringDrainage tubes

The invention provides a construction method combined with comprehensive treatment of water seepage and drainage in the foundation pit of an elevator shaft. The integral box formwork is used as a pit-in-pit membrane template, and an impermeable concrete structure layer is poured between the soil body and the box mold to form a concrete membrane. side wall. The bottom of the foundation pit adopts a prefabricated integral sump with permeable holes, which is drained through the suction pipe of the self-priming pump; the side wall of the foundation pit adopts a prefabricated plate with vertical and horizontal grooves without dismantling drainage, and the drainage pipe with holes is outsourced with reverse filter geotextile The flexible bandage is fixed in the longitudinal groove, and the combination of wall-mounted drainage strips assists in drainage, which can improve the drainage efficiency of the side wall; the waterproof membrane of the side wall is laid with a shaped guide frame, which is easy to operate and has high construction efficiency. Reduced labor intensity. The invention can greatly speed up the construction progress, increase the stability of the slope, enhance the safety of the construction of the elevator shaft foundation pit, realize automatic drainage during the construction period and the operation period, and at the same time adopt the method of mechanical paving to save labor costs, and has better economic and technical benefits.

Owner:HANGZHOU JIANGRUN TECH LIMITED

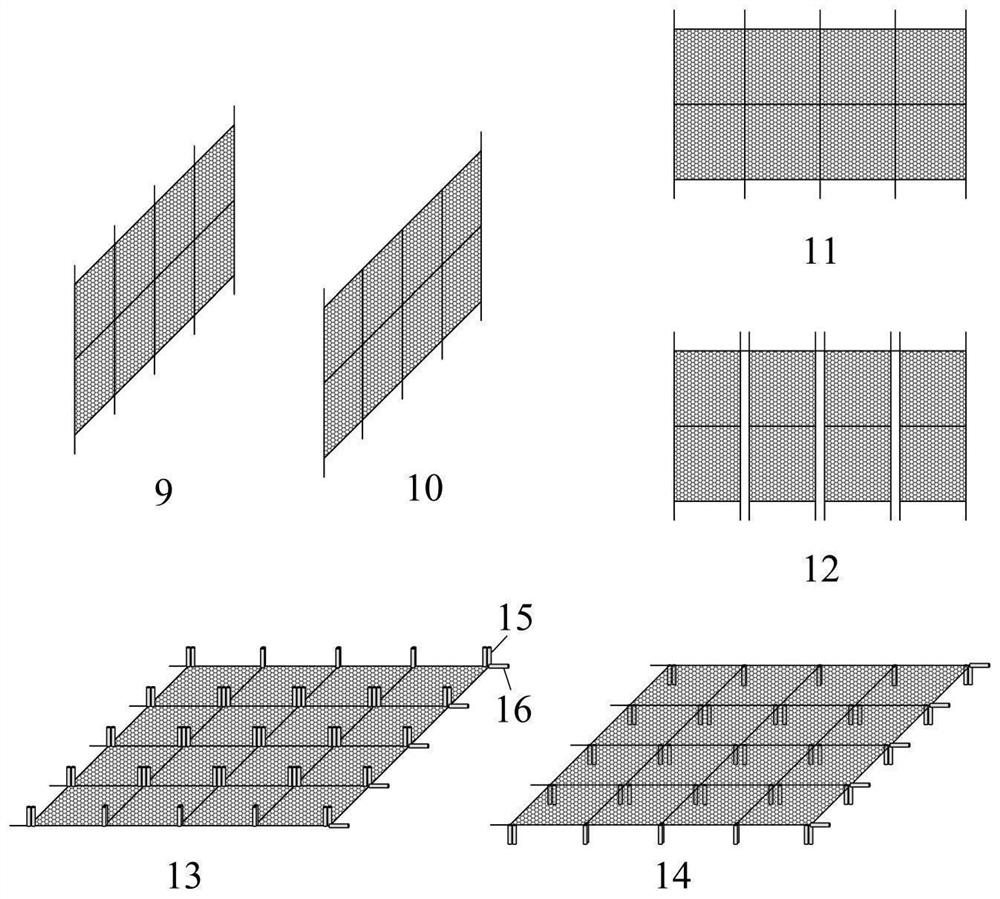

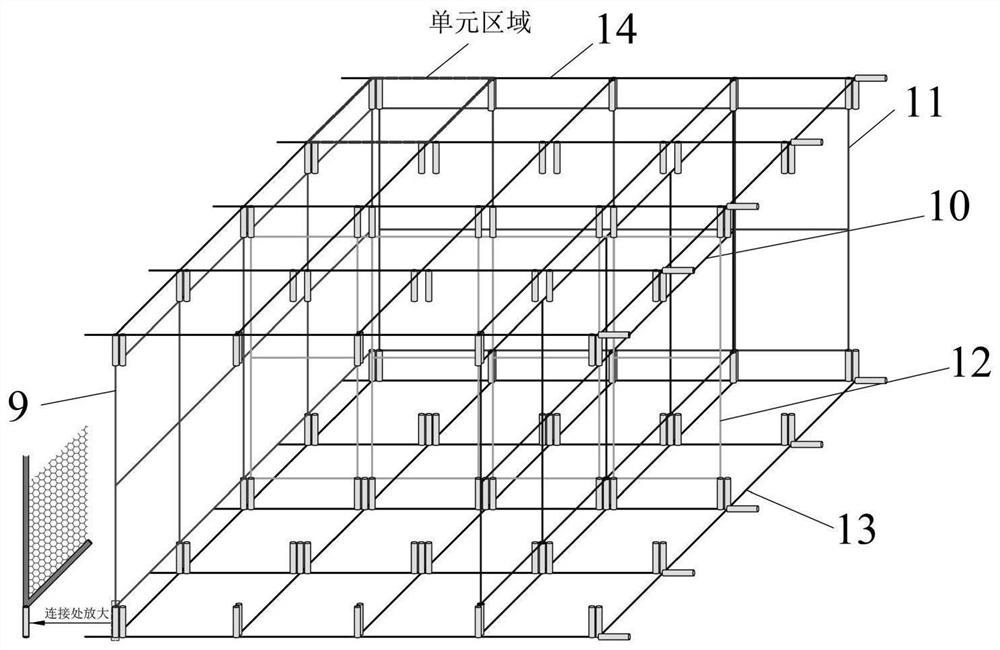

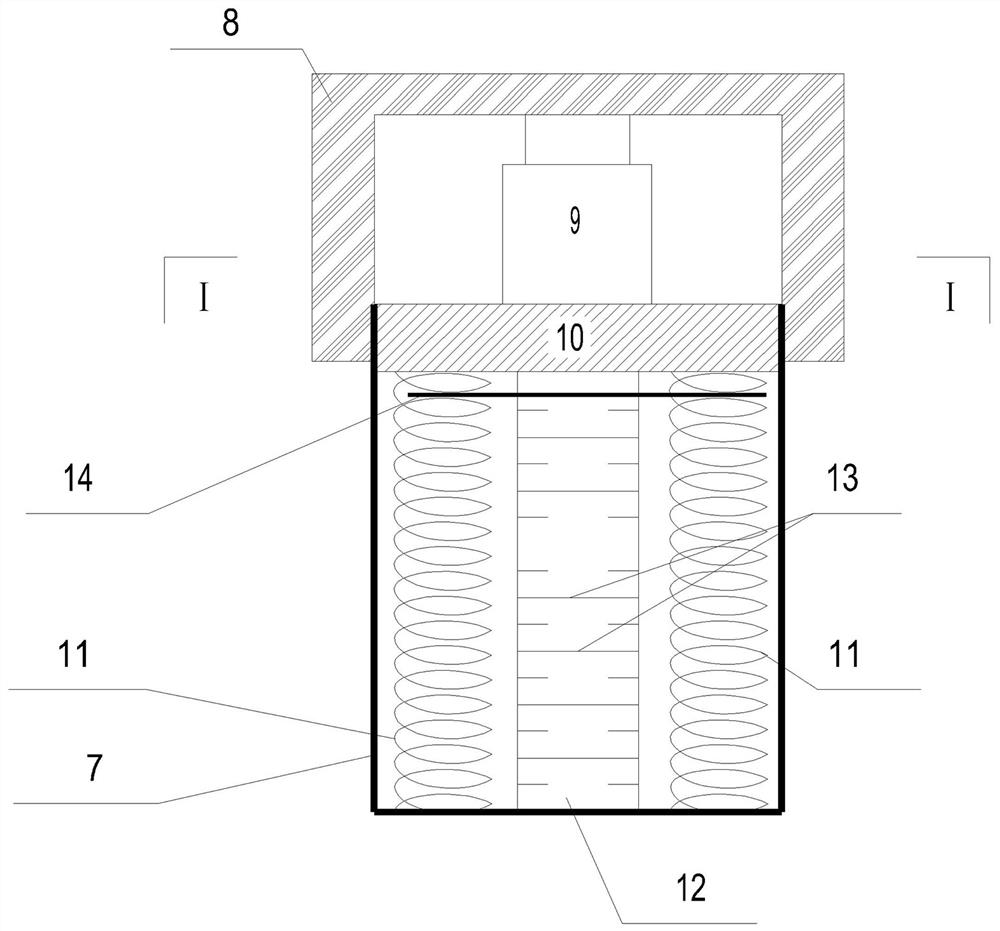

A kind of soft foundation treatment assembled grid grid replacement structure and construction method

ActiveCN111441207BHigh tensile strengthImprove integrityRoadwaysSoil preservationArchitectural engineeringRoad surface

The invention relates to a soft ground treatment assembled bin grid replacement structure and a construction method. After the soft foundation section is cleared and the site is leveled, the bin grid structure is laid. The bin grid structure adopts front and rear and left and right directions. The steel bars extending from one side of the top and bottom members are inserted into the top and bottom members of the other top and bottom members for connection between the top and bottom of the binge grid. A side stud is connected, and a rectangular parallelepiped mold is arranged inside the unit area of the binge grid structure, and the mold is used for backfilling replacement materials. After the backfilling is completed, the mold is taken out, and the top member of the binge grid structure is covered. A bin grid structure is formed, and the upper part of the bin grid structure is a cushion layer, an embankment, and a pavement structure layer. The soft foundation treatment structure involved in the present invention forms an artificial replacement layer with high tensile strength and good integrity on the surface of soft soil, which can not only effectively reduce the settlement of the roadbed and improve the stability of the roadbed, but also save construction costs and speed up construction Progress and environmental protection, with good economic and technical benefits.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

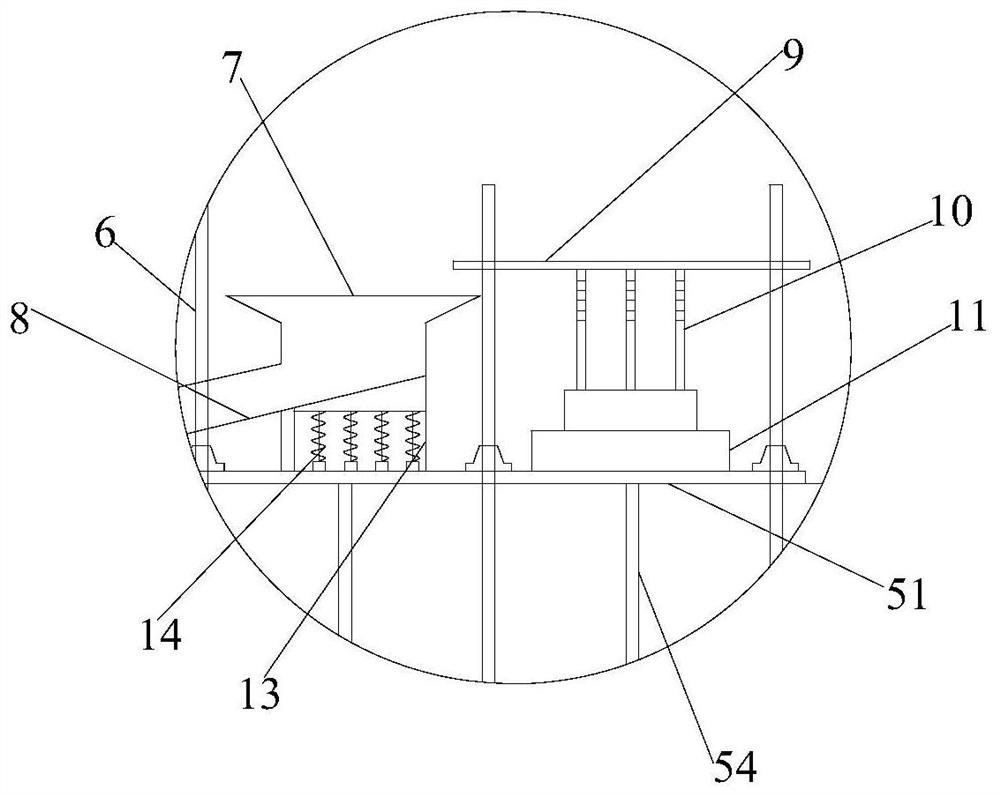

Active underpinning system of bridge pile foundation based on load servo and construction method thereof

PendingCN111997078ASatisfy securityProcess stabilityFoundation testingTunnelsArchitectural engineeringAbutment

The invention relates to an active underpinning system of a bridge pile foundation based on load servo and a construction method thereof. The system comprises an existing abutment needed to underpin aload and a plurality of existing pile foundations below the abutment, wherein a newly built tunnel has conflict with the existing pile foundations; underpinning pile foundations are applied to the outer sides of the existing pile foundations, an underpinning bearing platform is applied to the tops of the underpinning pile foundations; the underpinning bearing platform is located below the existing abutment and a plurality of load servo pedestals with active loading functions are arranged between the top surface of the underpinning bearing platform and the bottom surface of the existing abutment. The system is simple in process and site operation is facilitated due to quality. Under a circumstance that a newly built underpinning system has vertical compression deformation and deposition distance, vertical loads in a conversion period of a bearing system can be transferred continuously, so that the demand of controlling the vertical displacement of the existing abutment strictly is met.Based on fundamental philosophy of active loading and load servo, the load servo pedestals capable of converting the vertical loads effectively are put forward to meet the demand on controlling settlement deformation strictly in a conversion period of different bearing systems.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com