Construction method for large steel structural embedded part in dense reinforcement distribution region

A construction method and a technology of embedded parts, which are applied in the directions of manufacturing tools, metal processing, building construction, etc., can solve the problems of complex structure of embedded parts of truss supports, cumbersome installation and construction of spiral hoops, and difficulties in positioning and reinforcement, and achieve economical Outstanding technical benefits, shortened post-operation time, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing, the present invention will be further described, but protection scope of the present invention is not limited to this:

[0043] In this embodiment, the installation process requirements of the concrete pouring formwork, the construction technical requirements of steel bar binding, the construction process requirements of concrete pouring, the welding process requirements, etc. belong to conventional technologies, and will not be repeated here, focusing on the dense reinforcement area involved in the present invention The implementation method of the construction of large-scale steel structure embedded parts.

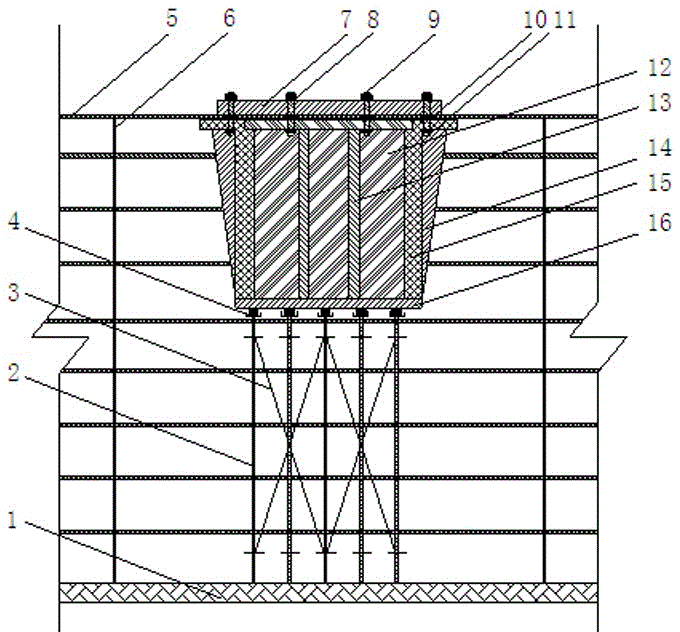

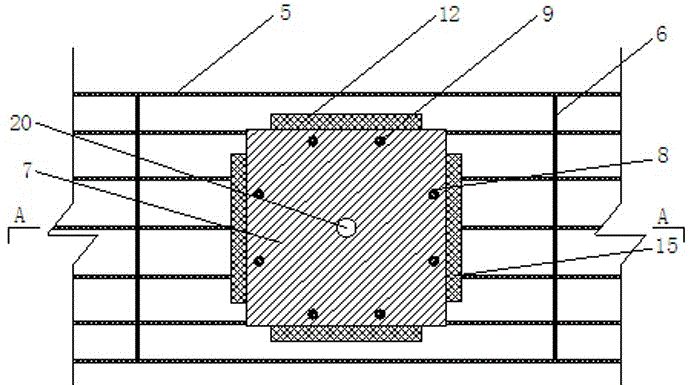

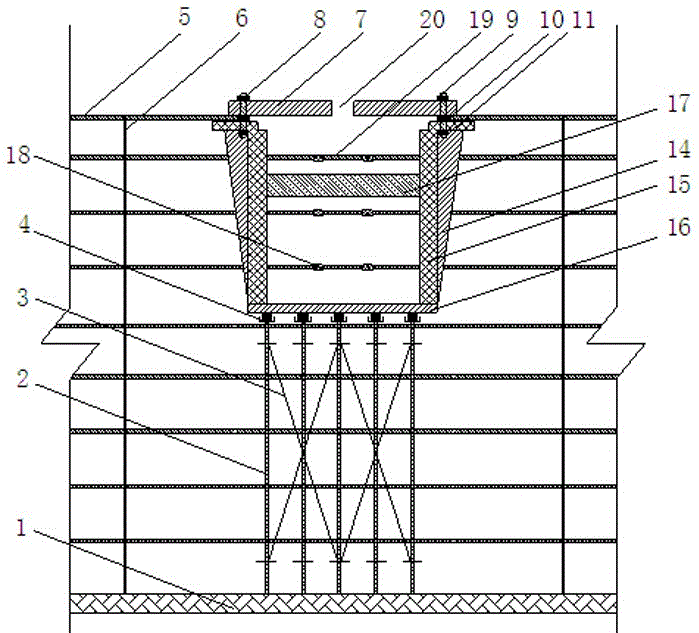

[0044] figure 1 It is the front view of the structure of the large-scale steel structure embedded parts in the dense reinforcement area of the present invention, figure 2 It is a top view of the structure of the large-scale steel structure embedded parts in the dense reinforcement area of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com