Active underpinning system of bridge pile foundation based on load servo and construction method thereof

A pile foundation and system technology, applied in foundation structure engineering, foundation structure test, construction, etc., can solve problems affecting construction period, high implementation cost, and failure to meet basic needs, etc., to achieve high economic and social benefits, settlement deformation Controllable, broad-spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention will be described in detail below in combination with specific embodiments.

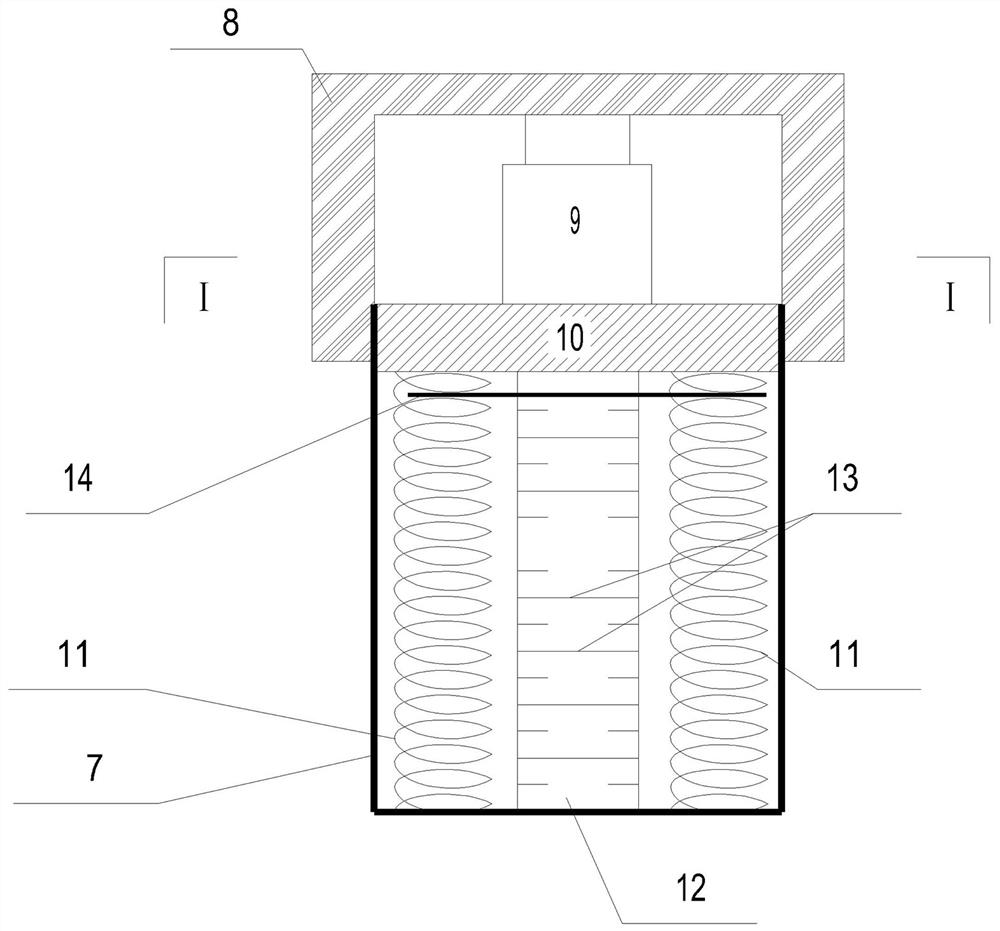

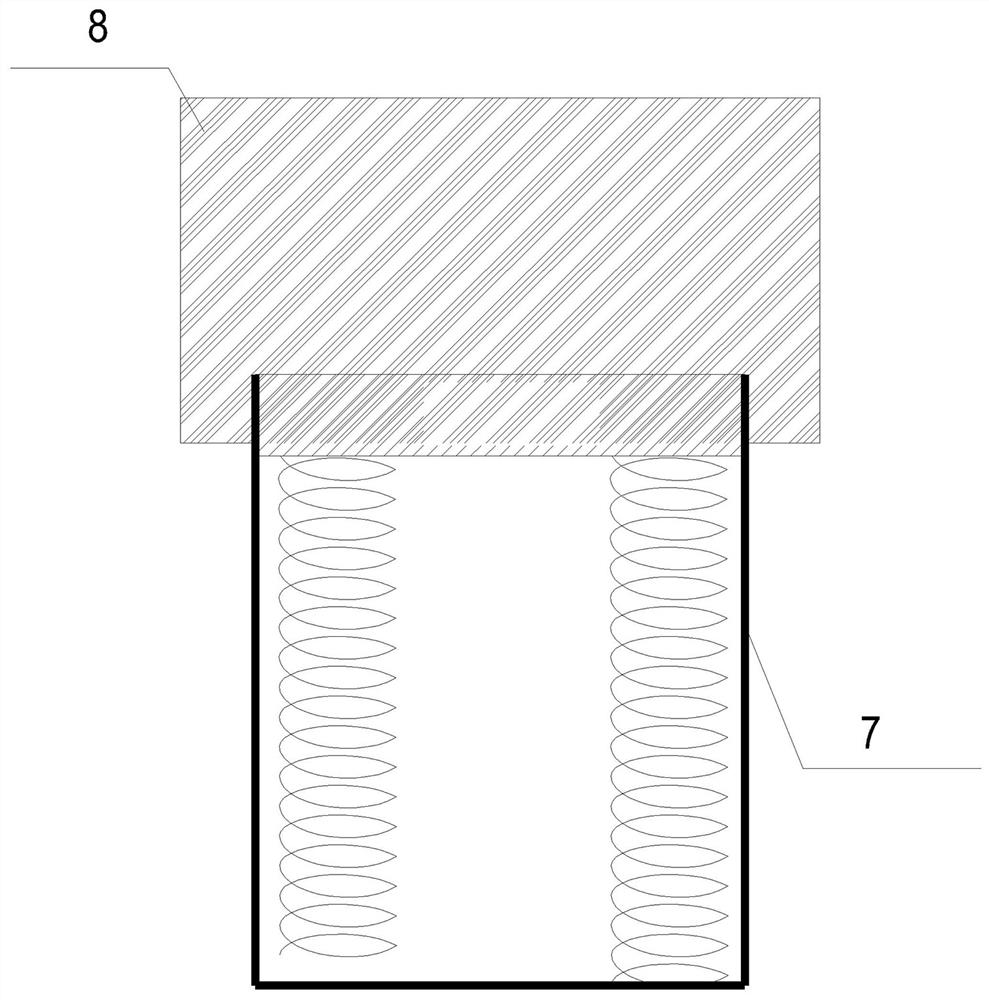

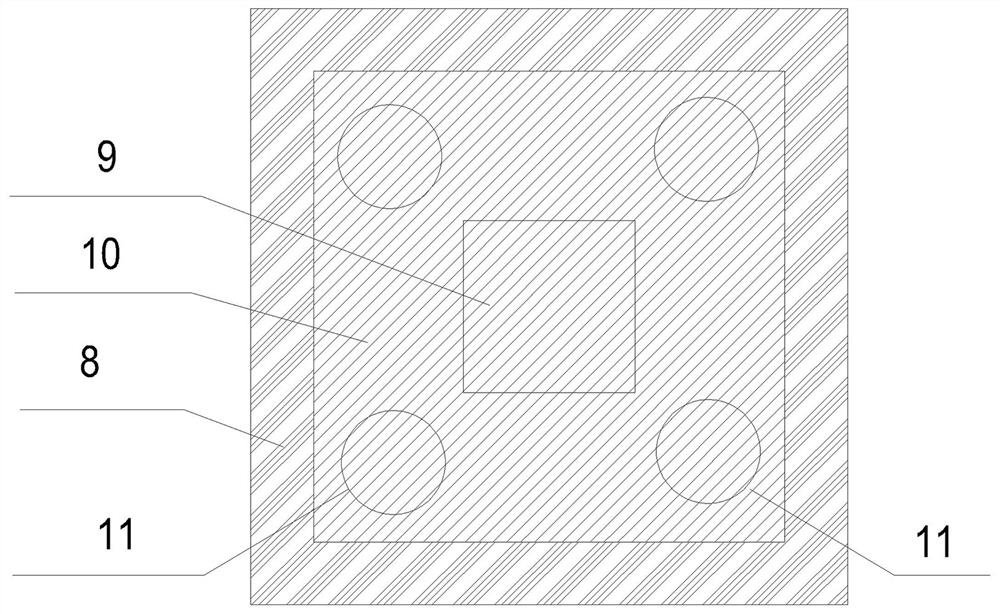

[0047] The invention relates to a bridge pile foundation active underpinning system based on load servo. The system includes an existing abutment 2 requiring load underpinning and several existing pile foundations 1 below it, and the space conflict between the new tunnel 3 and the existing pile foundation 1; The underpinning pile foundation 4 is constructed outside the existing pile foundation 1, and the underpinning pile cap 5 is constructed on the top of the underpinning pile foundation 4; The underpinning cushion cap 5 is located below the existing abutment 2, and a plurality of load servo bases 6 are set between the top surface of the underpinning cushion cap 5 and the bottom surface of the existing abutment 2.

[0048] The load servo base 6 comprises a steel cylinder 7 with an open top, a vertical high-performance compression spring 11 is arranged in the steel cylinder 7, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com