Thin interlayer steam injection thermal production well mixing-proof well completion process

A thermal recovery well and interlayer technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of breaking the cement sheath, isolation failure, and prolonging the well construction period during perforation operations, and achieve economical Significant technical benefits, efficient and reliable isolation, and the effect of increasing construction risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

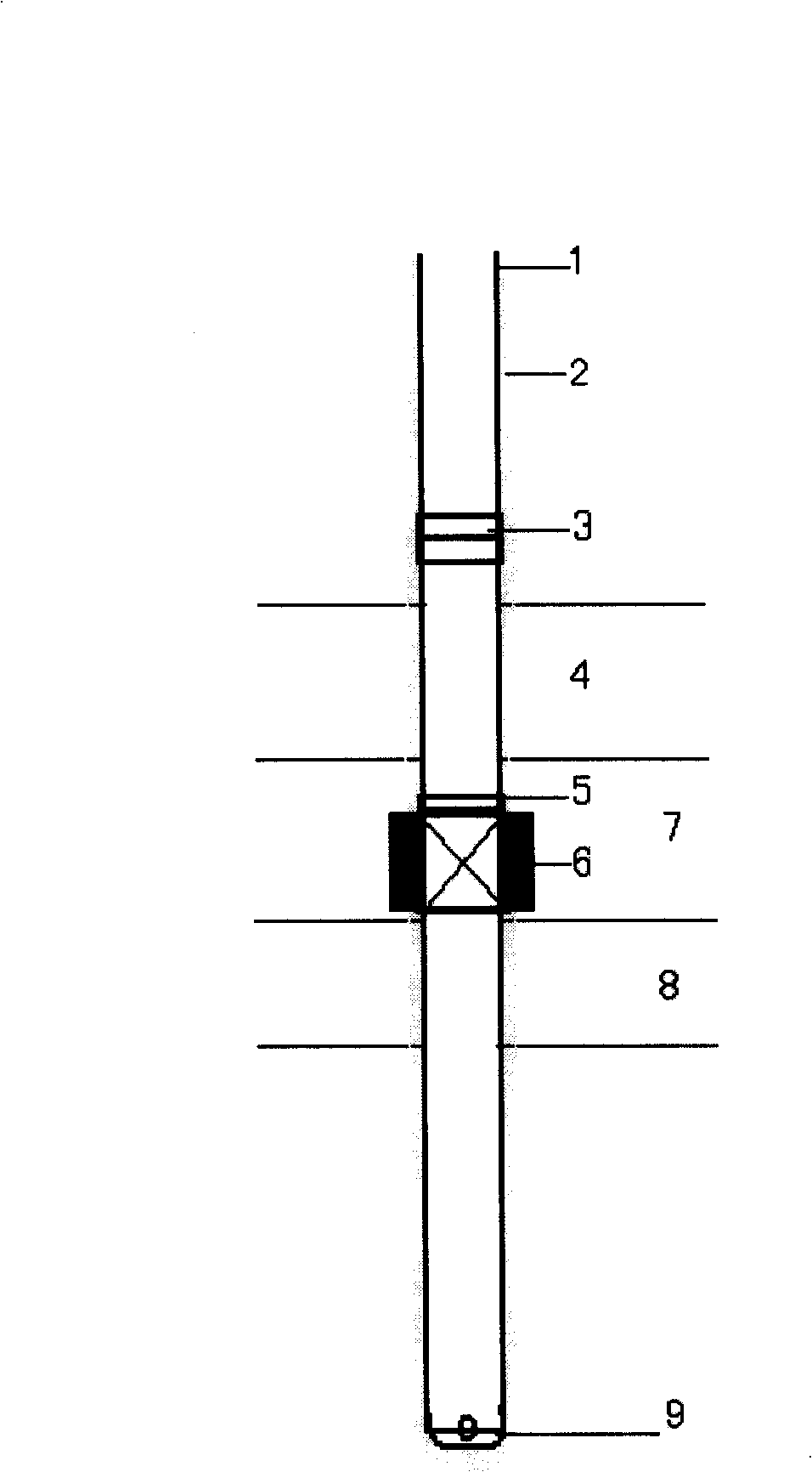

[0029] combined with Figure 1-3 , to further describe the inventive method:

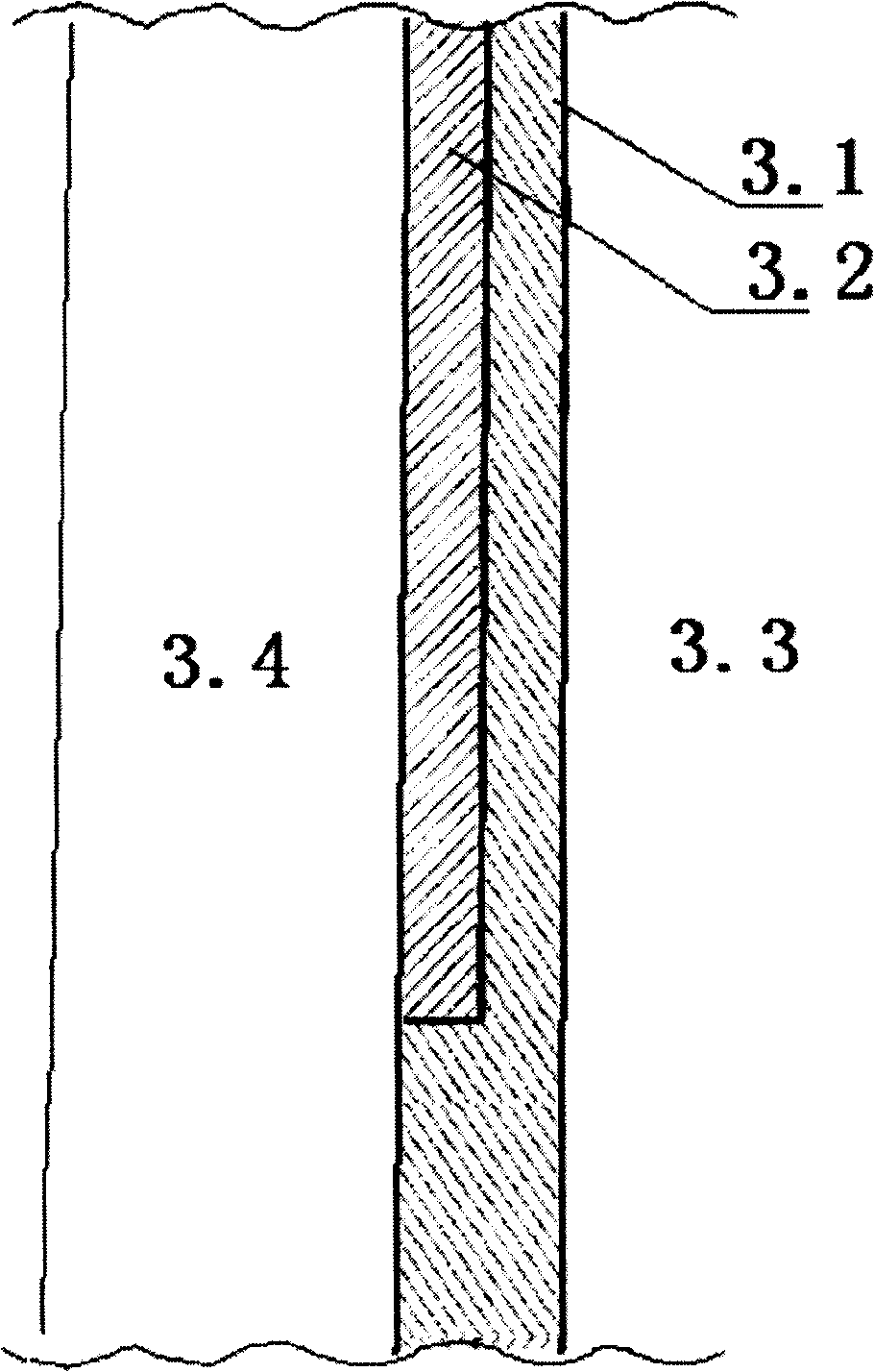

[0030] The completion string for the anti-channeling completion of the thin interlayer steam injection thermal production well is composed of the casing 1, the casing telescopic compensator 3, the special valve collar 5, the outer packer 6 and the cementing shoe 9; the casing telescopic The compensator, special valve hoop, outer pipe packer and cementing shoes are all connected in series by threads, and the casing, special valve hoop and outer pipe packer are connected by thread.

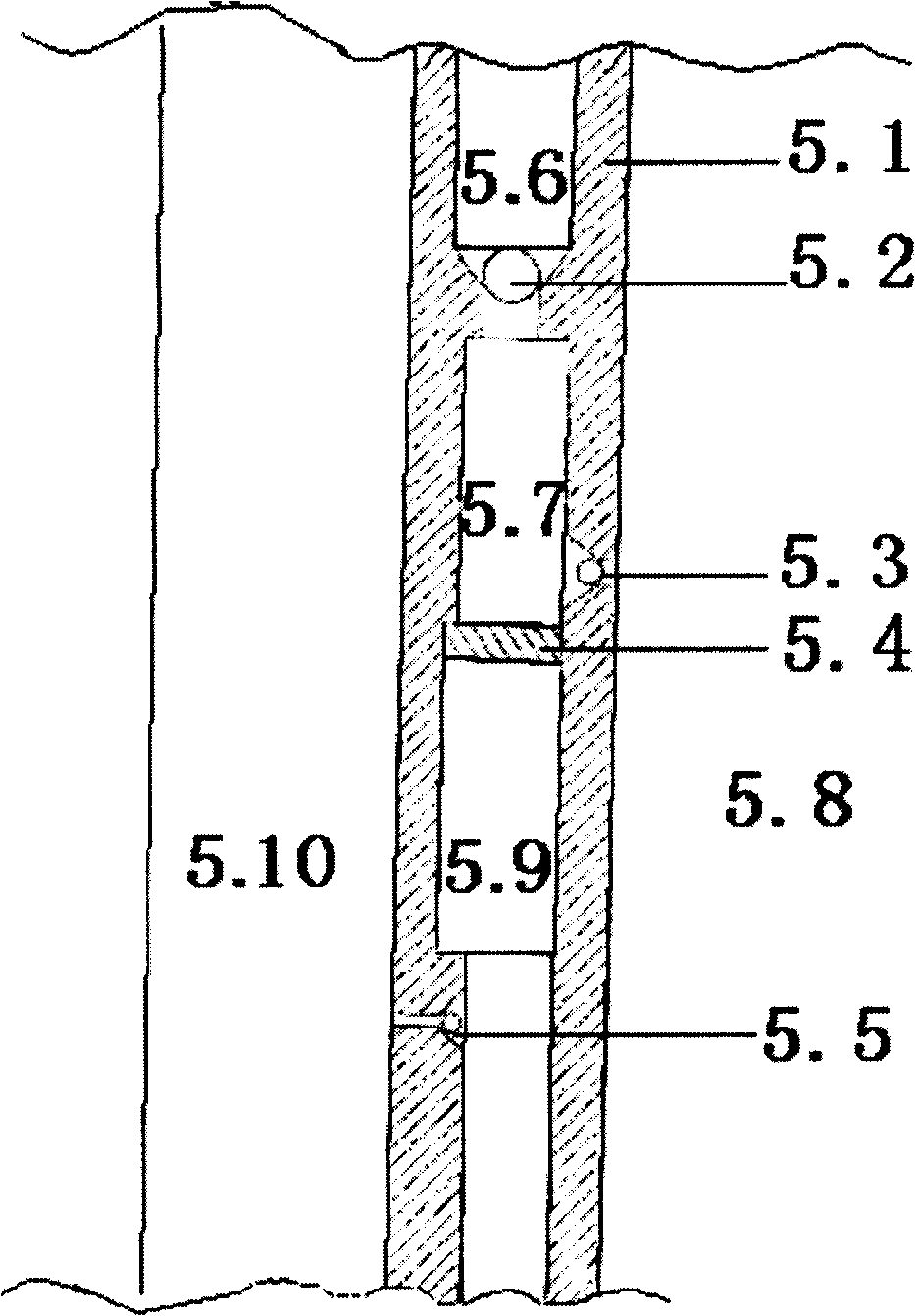

[0031] Among them, the upper end of the special valve hoop is connected to the casing through threads, and the lower end is connected to the outer pipe packer through threads; The flow channel 5.6 to the outer packer cavity, the cavity 5.7 and the piston cylinder 5.9 are composed of the flow channel, the cavity and the piston cylinder leading to the outer packer cavity in the outer shell, which lead to the tube A one-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com