Roadbed splicing broadening structure and construction method

A technology of roadbed and pavement, applied in infrastructure engineering, roads, roads, etc., can solve problems such as aggravating disease, unsatisfactory effect, damage to old roadbed, etc., to achieve stable structure, improve bearing capacity and stability of roadbed, and prevent settlement. The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

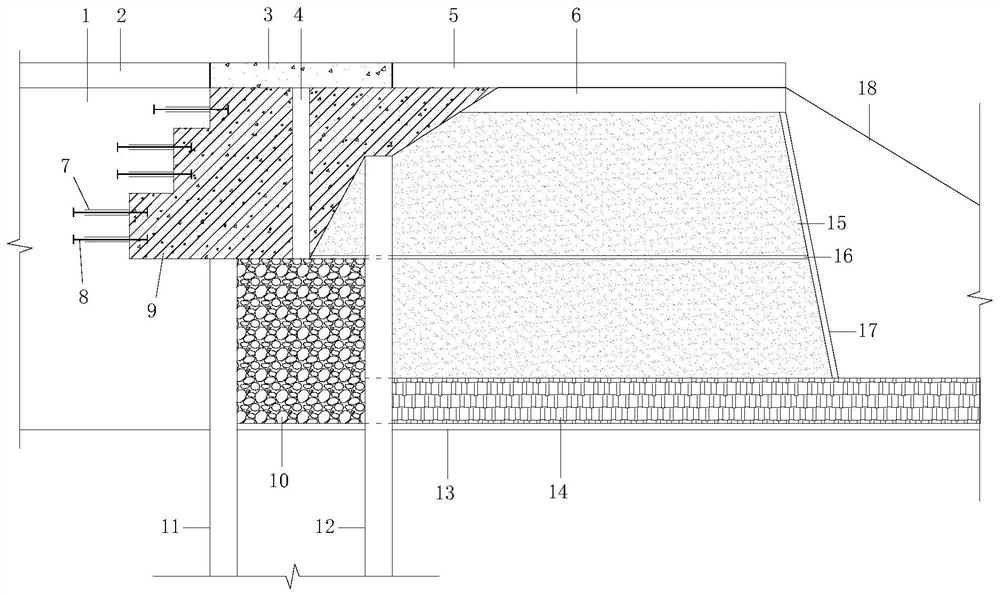

[0029] The subgrade splicing widening structure includes a transitional section 9 of the old and new subgrades arranged at the splicing place of the subgrade, and anchor bars 8 are fixedly connected to the original subgrade 1 through the guide holes 7. The transition section 9 of the old and new subgrades is provided with The vertical water passage 4 is provided with inner piles 11 and outer piles 12 at intervals below; the permeable gradation layer 10 is arranged below the vertical water passage 4 and between the inner and outer piles along the longitudinal length of the subgrade, and the water-permeable gradation layer 10 on the side of the outer pile 12 The bottom is connected to the horizontal drainage blind ditch 14 arranged at intervals, and the other end of the horizontal drainage blind ditch 14 is connected to the external drainage system, and the bottom of the permeable gradation layer 10 and the horizontal drainage blind ditch 14 is provided with a bottom waterproof la...

Embodiment 2

[0034] The construction method of the roadbed splicing widening structure comprises the following steps:

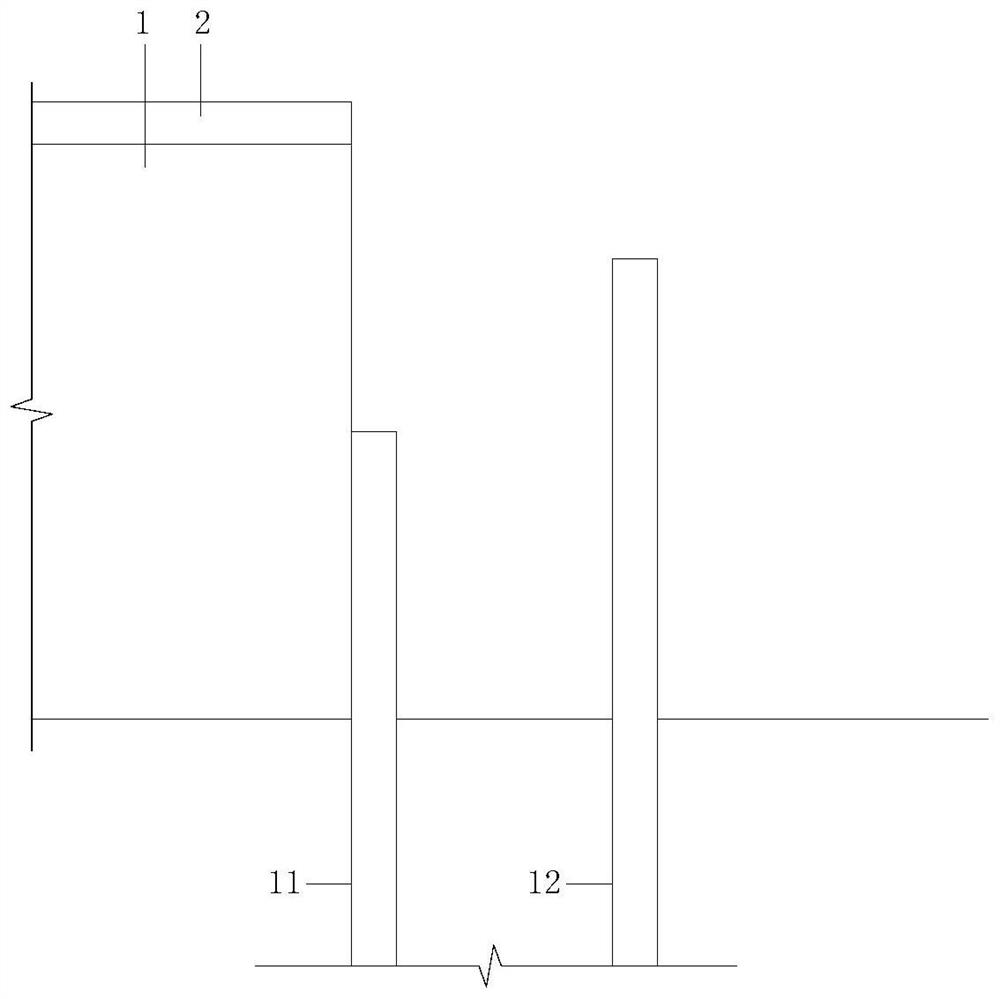

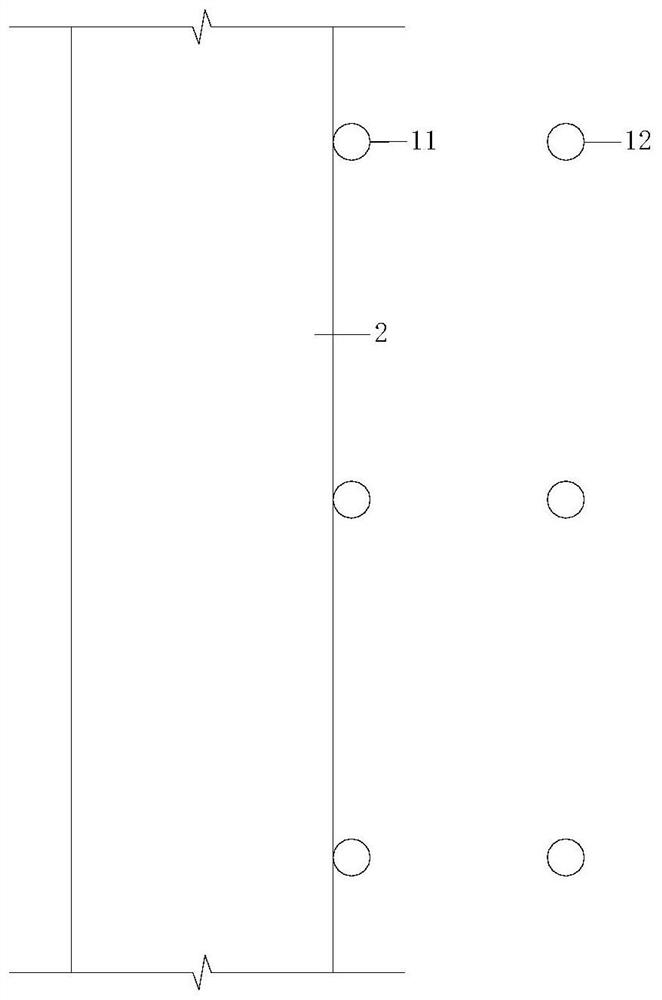

[0035] 1) if figure 2 , image 3 As shown, before construction, the floating soil, vegetation, tree roots and other construction waste on the surface of the original roadbed 1 slope should be cleaned up, and the floating soil along the original slope should be cleaned thoroughly. Use an excavator to trim the slope of the original old road soil shoulder at the joint site, cut it vertically to the design elevation of the foundation, and then drive the inner piles 11 and outer piles 12 parallel to each other at intervals along the original roadbed 1 section.

[0036] 2) if Figure 4 As shown, at the same time, a reverse soil step is built on the section of the original subgrade 1, and a drilling rig is used to open a pilot hole 7 on the step to install the anchor bar 8, and then bind the steel bars of the transitional section 9 of the old and new subgrade, and tie the anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com