Underground station fabricated rail top air duct structure and construction method thereof

A technology for rail-top air ducts and underground stations, applied in underwater structures, infrastructure engineering, buildings, etc., can solve problems such as endangering structural safety, damage to interface parts, and affecting normal use of components, so as to ensure rapid installation and release on site Occupied for too long, the effect of significant economic and technical benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in combination with specific embodiments.

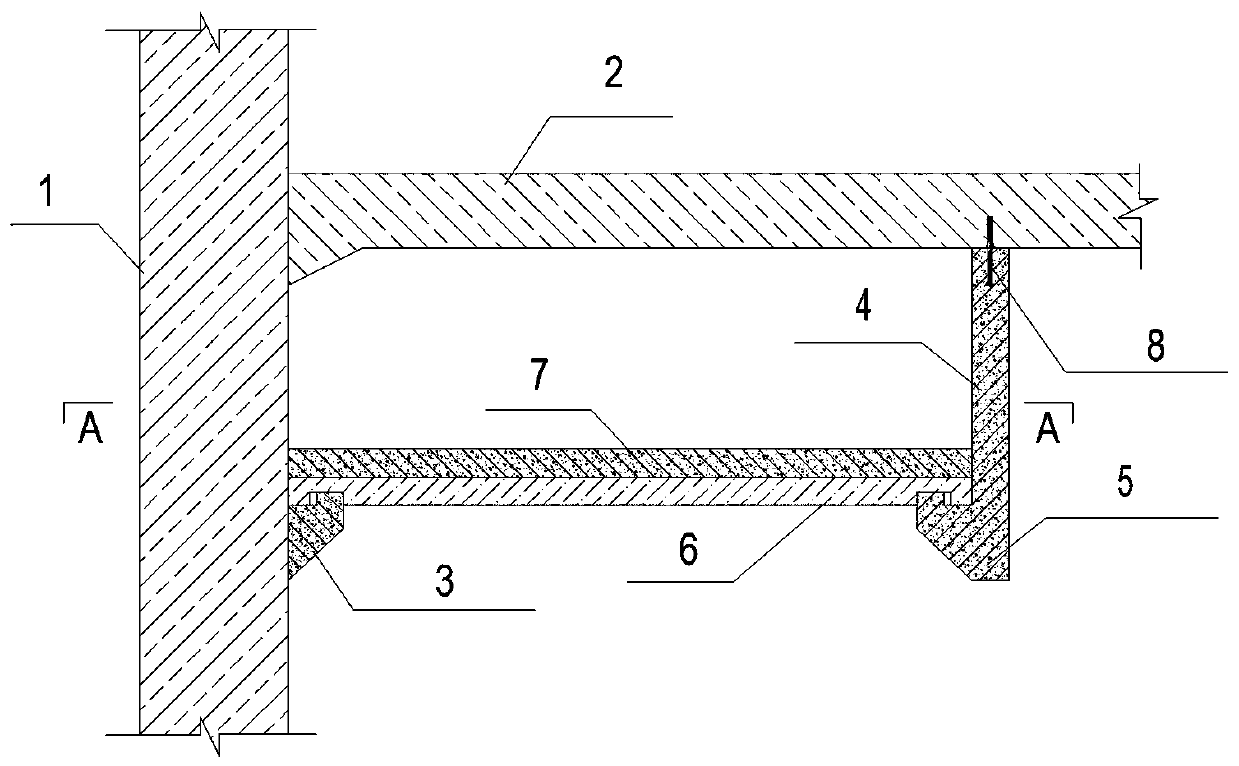

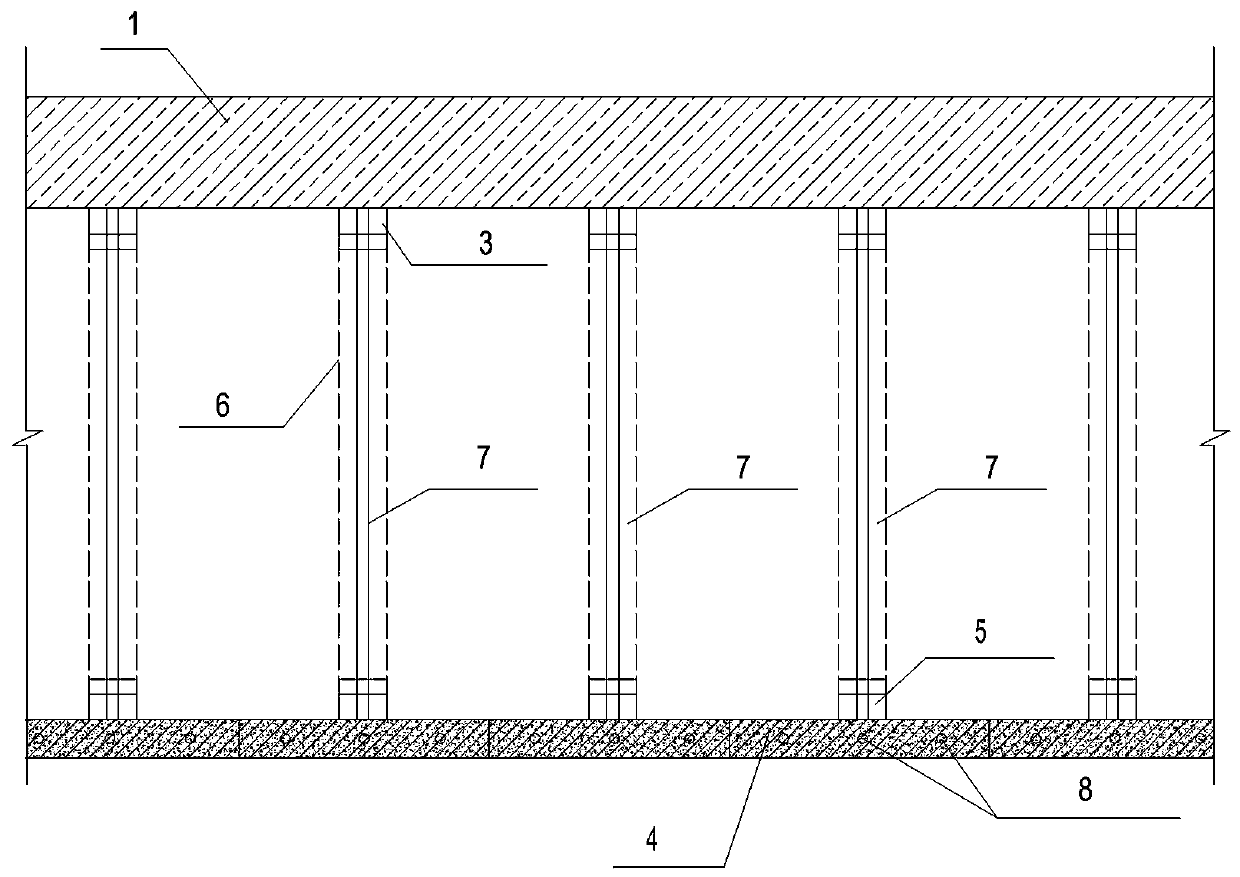

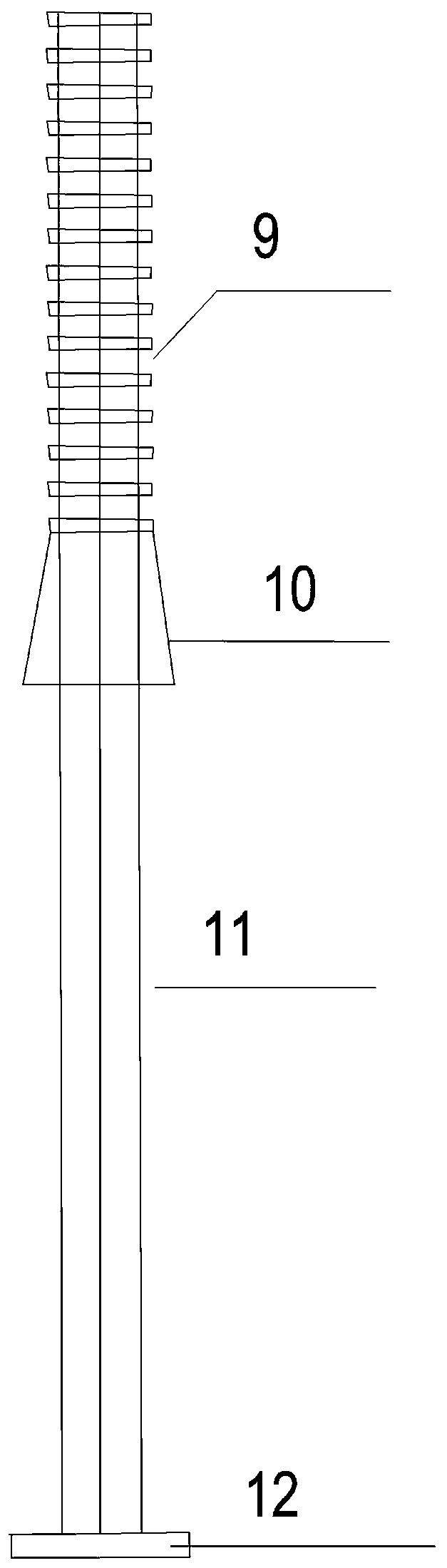

[0041] The present invention relates to a prefabricated rail top air duct structure and construction method of an underground station. A rail top air duct is built at the angle between the side wall 1 of the existing underground structure and the middle plate 2 of the structure. The air duct plate 7 is mainly supported by the lower beam 6. The beam 6 is supported on the corbels at both ends, one side of the corbel is poured synchronously with the side wall of the underground structure, and the other end of the corbel is poured synchronously with the air duct web 4 to form an air duct web 4 with corbel-shaped wing feet 5 , At the same time, the air duct web 4 is mechanically connected to the middle plate 2 of the underground structure by means of plug-in anchor bolts 8 .

[0042] The number of bolt-type anchor bolts 8 used to connect the air duct web 4 to the structural mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com