Beam and plate combined system for LOFT

A combined system and beam-slab technology, applied to floors, building components, buildings, etc., can solve problems such as inconvenient construction environment, design and use of components and construction methods, unmatched technical inventions, and difficulties in generalization of technologies and construction methods, etc., to achieve The effect of convenient and quick construction, perfect supporting technology, low requirements for construction personnel and construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

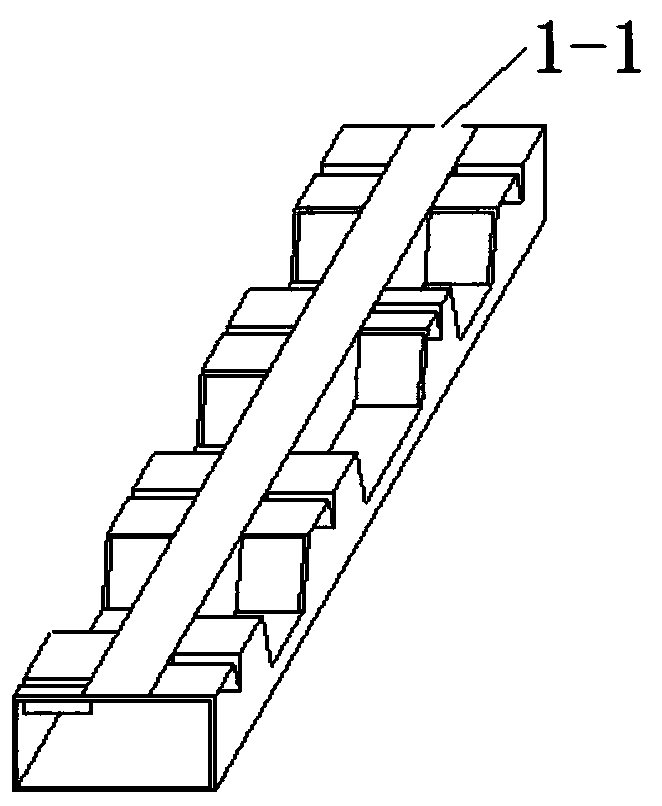

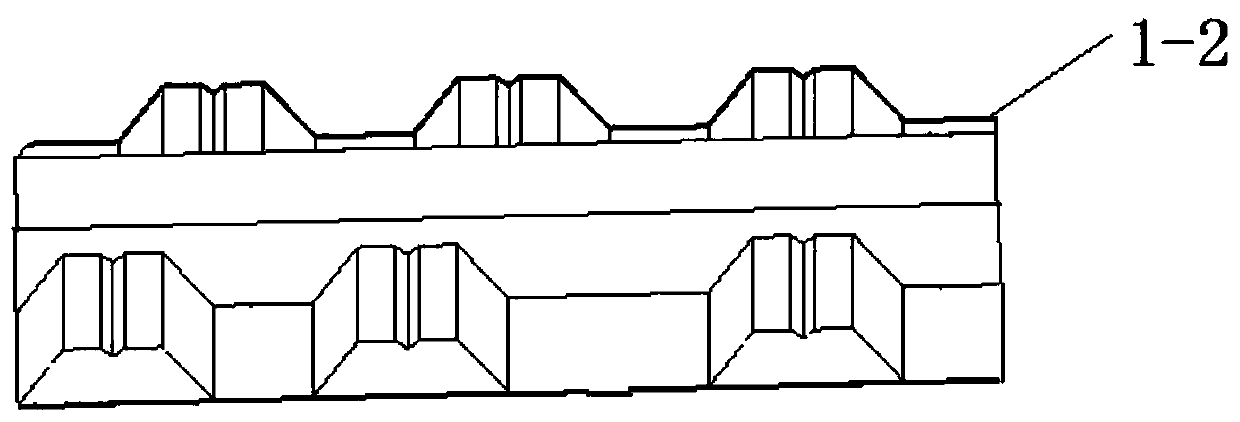

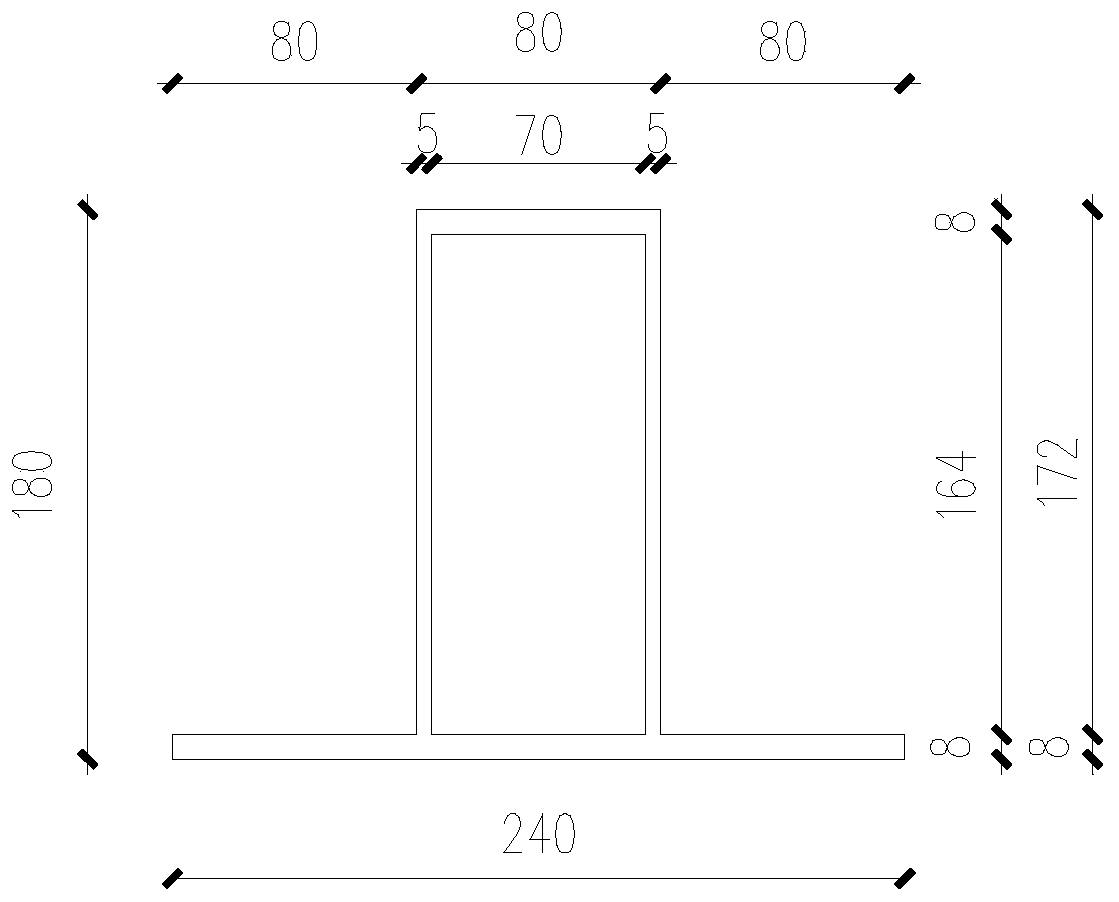

[0080] Such as Figure 18 to Figure 21 As shown, the novel LOFT beam-slab combination system provided by the present invention,

[0081] The system includes Picatinny beam 1, Picatinny plate 2, Picatinny support 3, cement pressure plate 4 and wooden floor 5, the main beam is Picatinny beam 1, and the cross-sectional height of the Picatinny beam h pb Calculate according to formula (1):

[0082]

[0083] Among them, L pb is the span of the Picatinny beam;

[0084] The deflection of the Picatinny beam satisfies the deflection limit:

[0085] f≤[ν] pb ·L pb (Formula 2)

[0086] Calculate the deflection f of the Picatinny beam according to formula (3), when the deflection f is calculated according to the standard value of permanent and variable loads, [ν] pb Take it as 1 / 500; when the deflection f is calculated according to the standard value of permanent load, [v] pb Take it as 1 / 400;

[0087]

[0088] where M pb_max is the maximum mid-span bending moment of the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com