Shaped large-formwork vertical thin-wall side wall and construction method

A large formwork and thin-walled technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as difficulty in guaranteeing construction quality, low height of one-time formwork support, long erection period, etc., to achieve improved waterproof effect and simple structure Reasonable and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principles of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

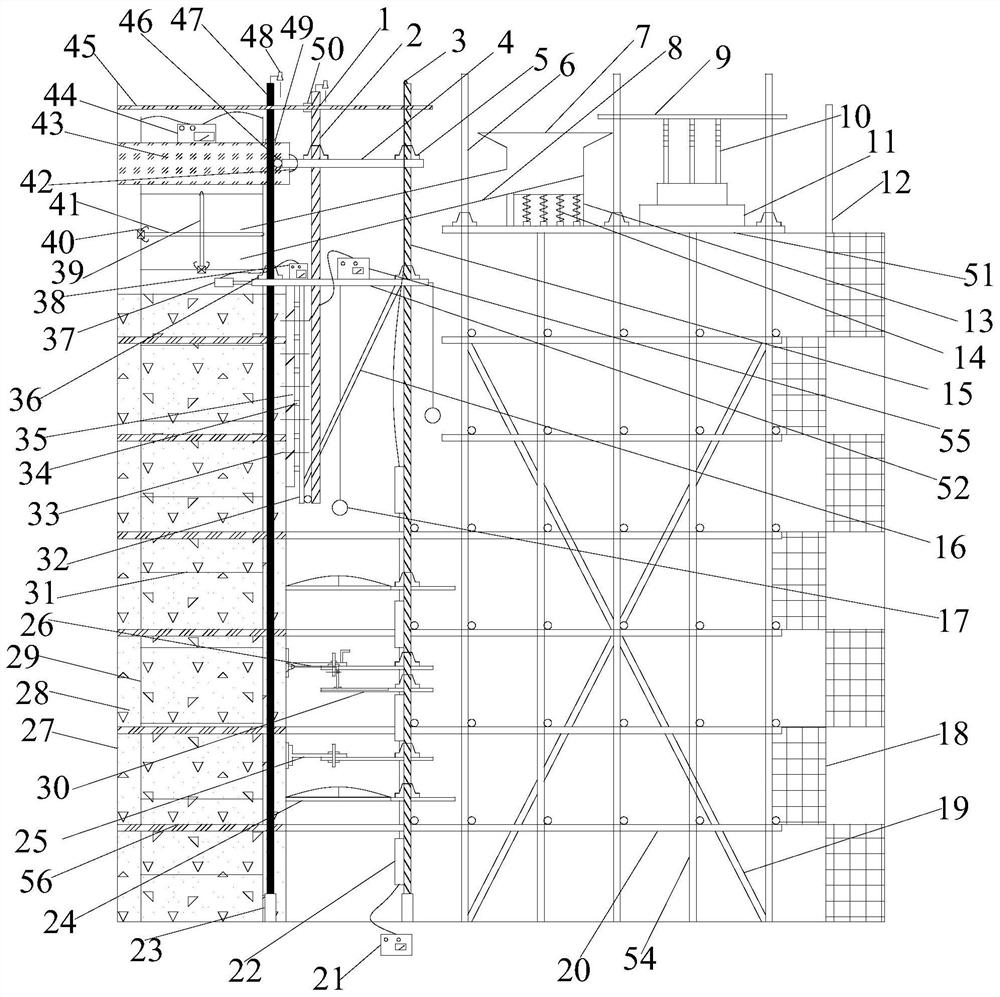

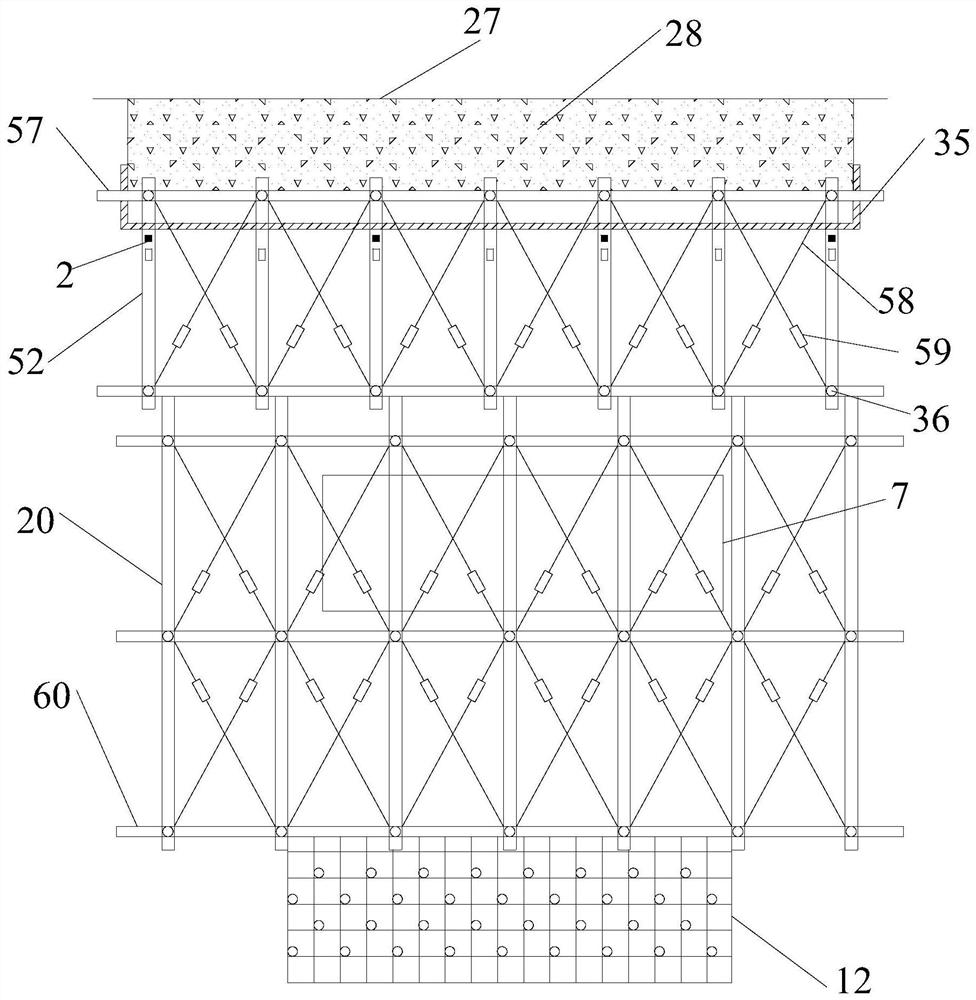

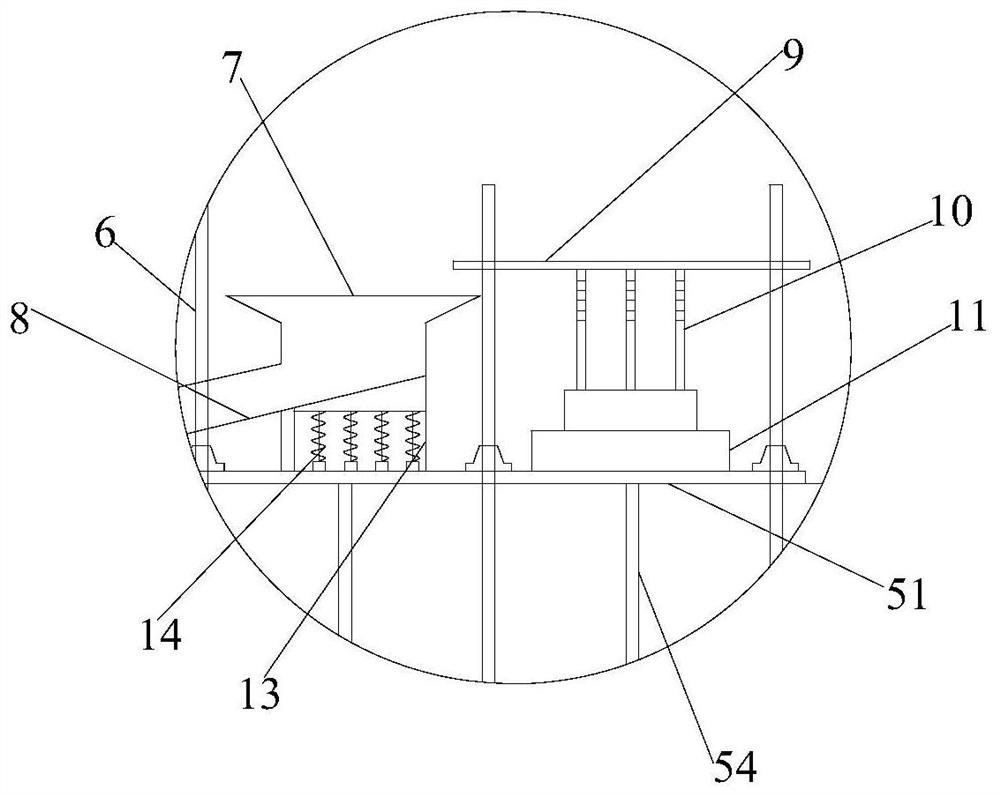

[0056] The stereotyped large formwork upright thin-walled side wall includes an upright thin-walled side wall formwork system, a revolvable steel bar binding tire frame fixed on the bedrock surface, an upright thin-walled side wall maintenance device, and a stereotyped large formwork upright thin-walled side wall. Wall construction monitoring system. The formwork support adopts the adjustable guide rail system 1 fixed by the bottom solid side pull anchor rod and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com