Large-diameter high-temperature-resistant aluminum alloy pipe flanging method and large-diameter high-temperature-resistant aluminum alloy pipe flanging device

An aluminum alloy tube and large-diameter technology, which is applied in the field of flanging methods and devices for large-diameter heat-resistant aluminum alloy tubes, can solve the problems of difficult quality assurance and heavy workload, and achieve low manufacturing cost, simple manufacturing process, and meet the design requirements. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

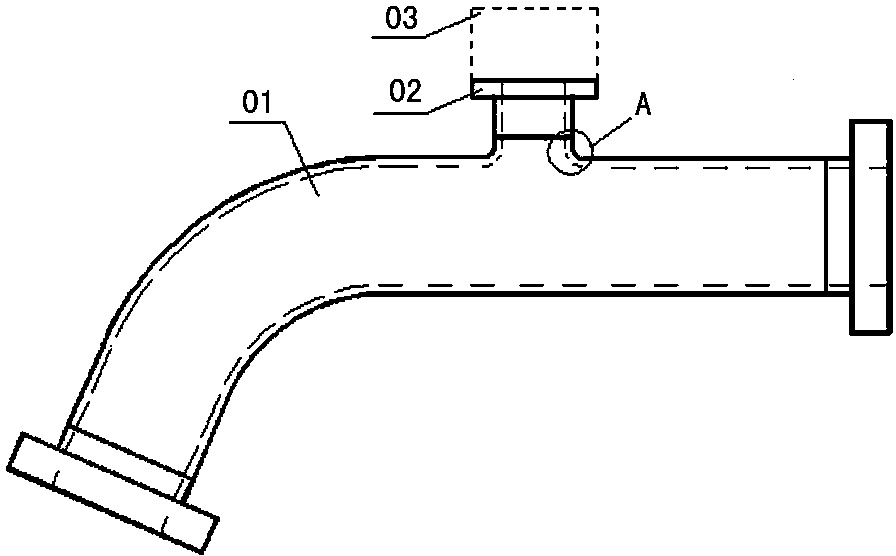

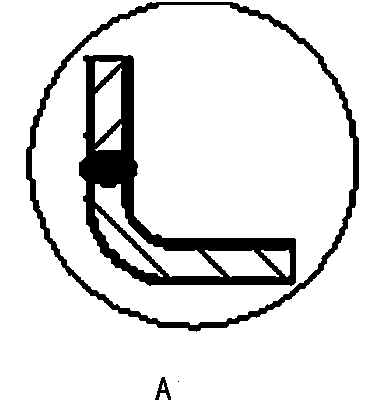

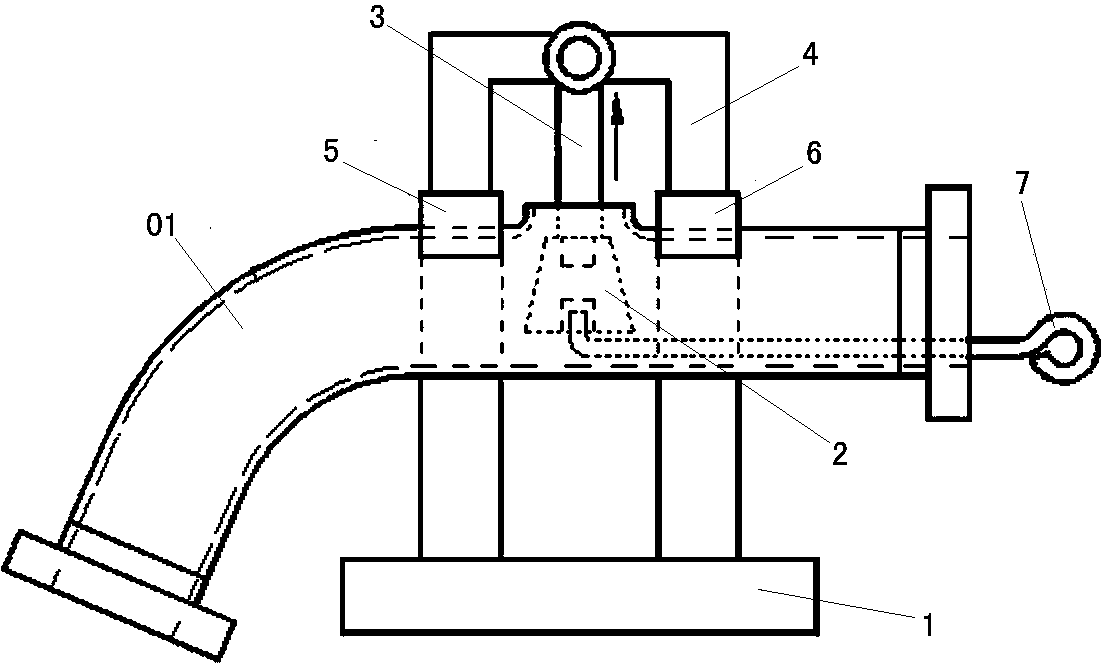

[0031] The method for flanging a large-diameter heat-resistant aluminum alloy pipe of the present invention uses the large-diameter heat-resistant aluminum alloy pipe flanging device of the present invention to flang the aluminum alloy pipe to form a cylindrical nozzle, including the following steps:

[0032] S1. Open an elliptical hole in the radial direction of the aluminum alloy tube, and the long axis direction of the elliptical hole is consistent with the axial direction of the aluminum tube; among them, the long axis L1 of the elliptical hole is calculated by the following formula (1):

[0033] L1=d-2H+(4-л)R (1)

[0034] In the formula, d is the outer diameter of the cylindrical nozzle, H is the height of the cylindrical nozzle, and R is the radius of the corner arc at the junction of the cylindrical nozzle and the aluminum alloy pipe;

[0035] In this embodiment, the outer diameter d of the cylindrical nozzle formed by the flanging required by the design is 20mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com