Reinforced concrete combination column structure and simultaneous pouring construction method

A technology of reinforced concrete and composite columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of increasing the amount of liner pipes and welding times, increasing the construction period, increasing costs, etc., achieving outstanding economic and technical benefits, reducing cost, The effect of high shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In this embodiment, the technological requirements for the prefabrication of the steel pipe column, the technical requirements for the production and processing of the connecting ring plate, the technological requirements for the steel pipe column, and the concrete pouring technology will not be described in detail, and the embodiment of the reinforced concrete composite column structure involved in the present invention will be focused on.

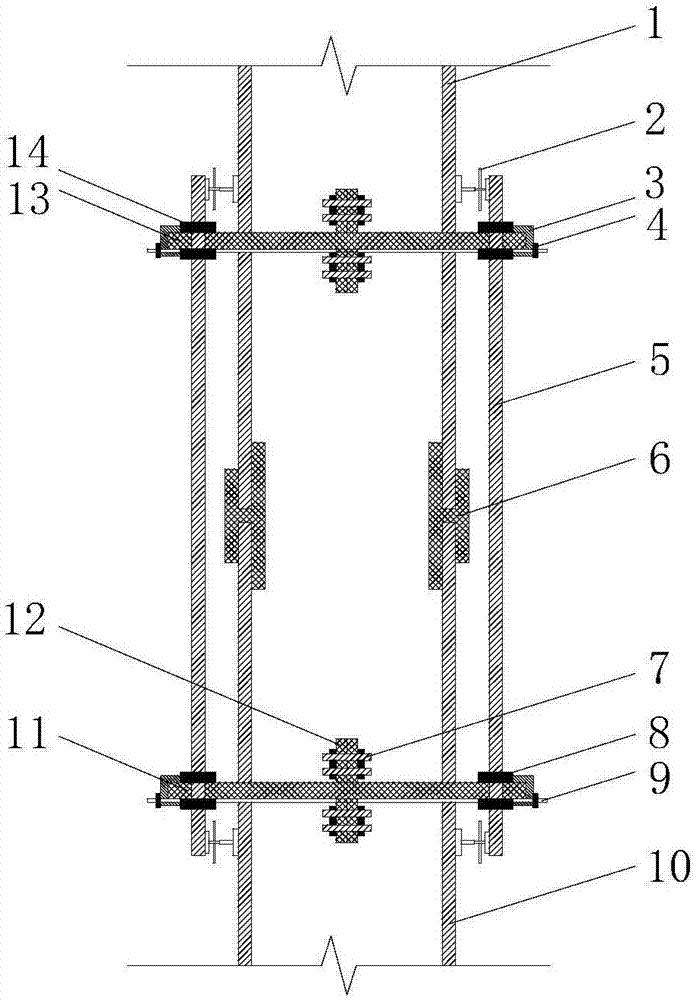

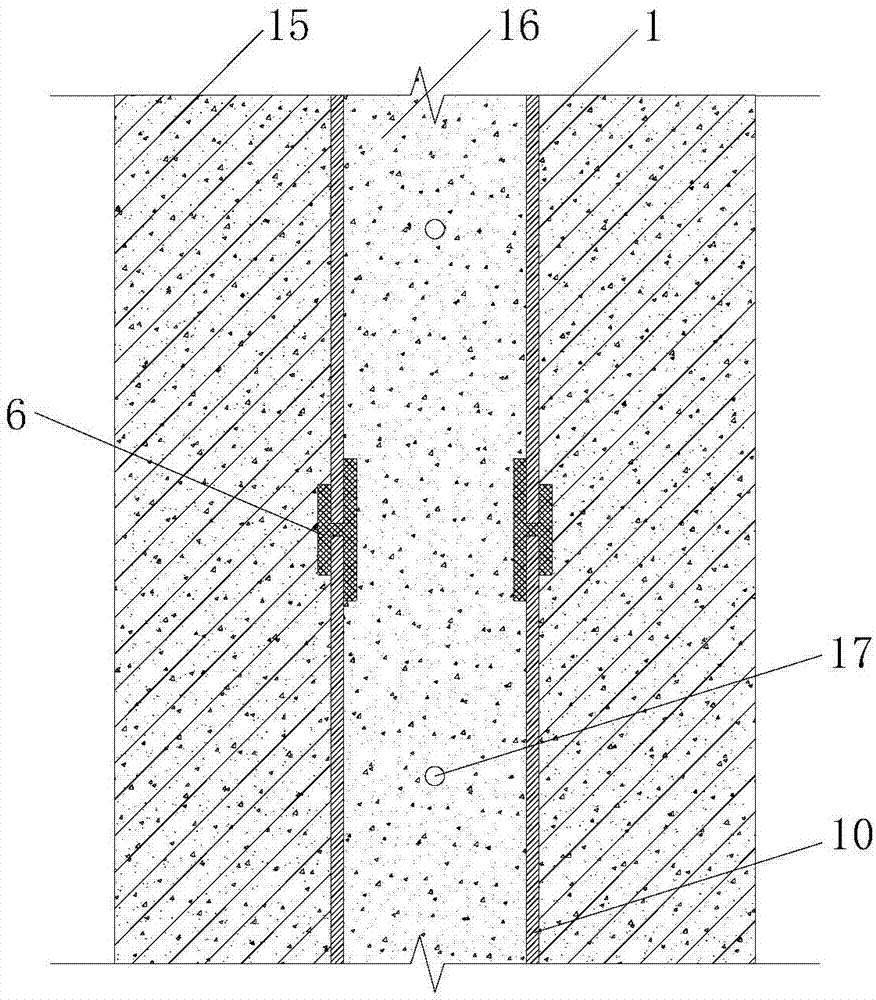

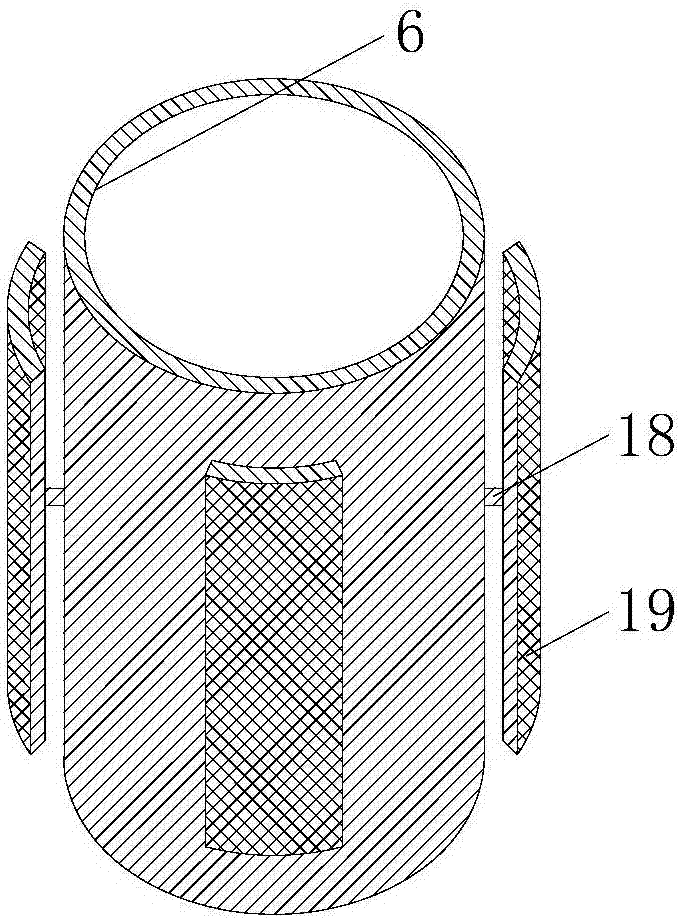

[0035] figure 1 It is a schematic diagram of the steel pipe column connection of the reinforced concrete composite column of the present invention, figure 2 It is a cross-sectional view of the reinforced concrete composite column of the present invention after concrete pouring, image 3 It is a schematic diagram of the lining pipe in the present invention, Figure 4 is a schematic diagram of the connecting ring plate of the present invention, Figure 5 It is a schematic diagram after the steel plate is cut off and closed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com