Integrally-formed drainage ditch and construction method thereof

A technology of integral molding and drainage ditch, which is applied in the direction of waterway system, water supply device, sewer pipeline system, etc. It can solve the problems of cumbersome construction drainage ditch appearance and main body quality, increased difficulty of construction, and more manpower, so as to improve the molding rate of one pouring , Reduce the excavation process and manpower, and reduce the effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

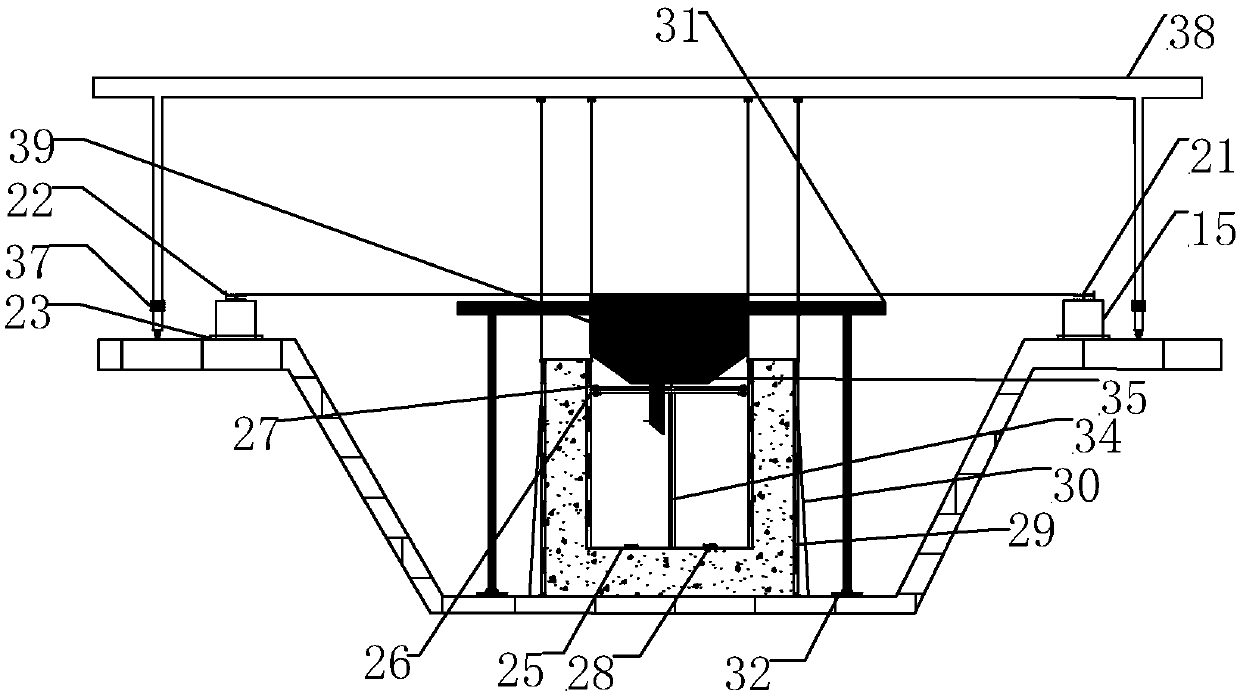

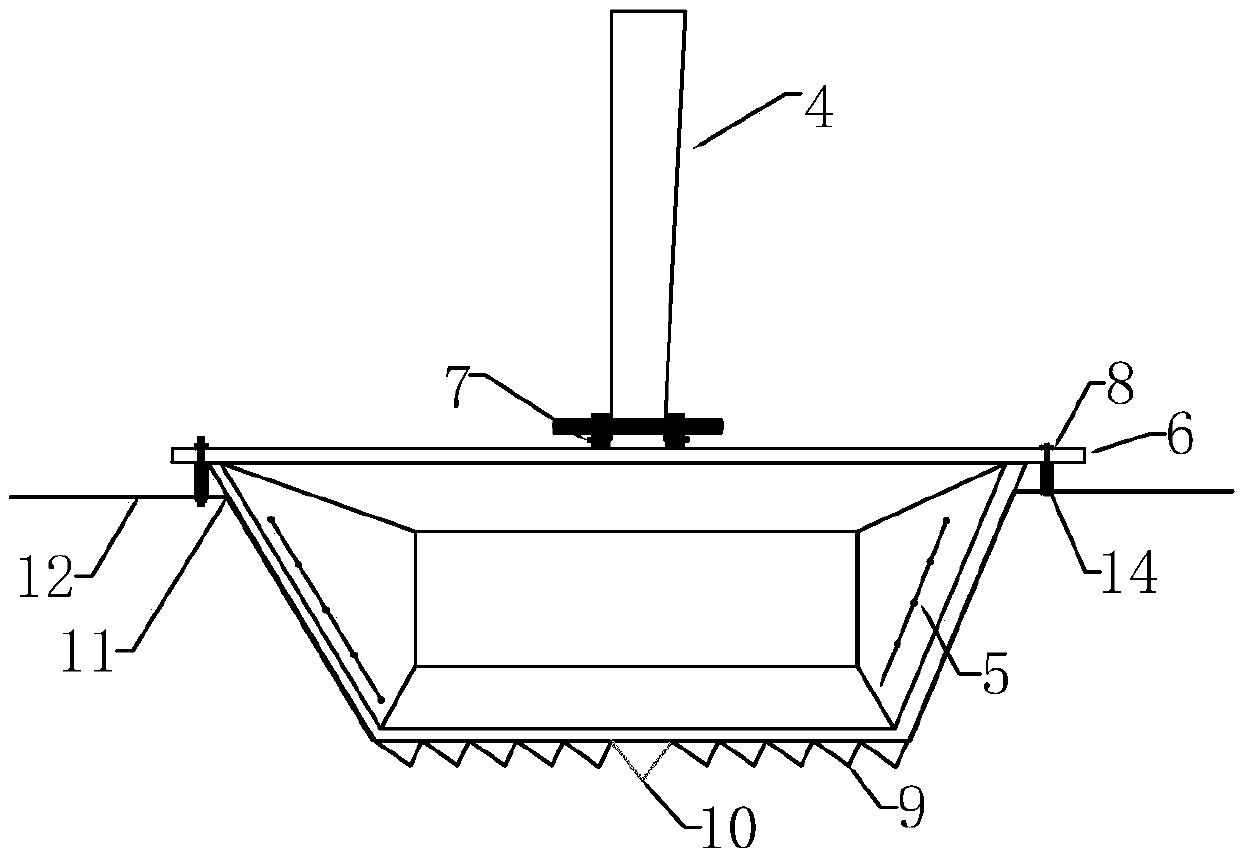

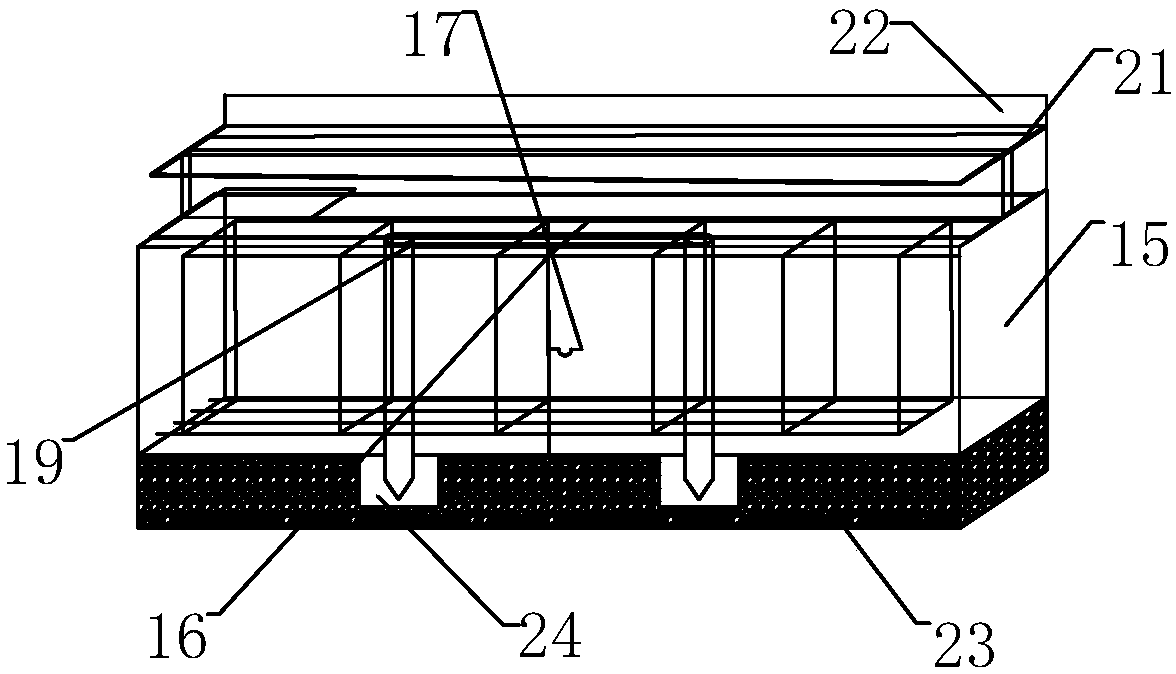

[0050] Example: such as Figure 1 to Figure 8 As shown, the integrated drainage ditch includes the drainage ditch body, and also includes a shaped bucket 5, a shaped slope scraper 11, a sliding form track 21, a shaped side form 29, and a bottom scraping beam frame 25, and a sliding form track 21 Assembled on both sides of the above-mentioned drainage ditch body, it can be used to move other excavating devices installed on the sliding form track 21. The above-mentioned stereotyped side mold 29 is arranged in the drainage ditch body for positioning the side of the drainage ditch body, and the side of the drainage ditch While shaping, the above-mentioned bottom scraping beam frame 25 is movably arranged at the bottom of the above-mentioned drain body, so that the bottom of the drain body remains flat, and the shaped side mold 29 can be fixedly installed on the above-mentioned bottom scraping beam frame 25, The above-mentioned bottom scraping beam frame 25 is connected to the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com