Construction method of heat preservation porous combined blind ditch

A construction method and composite technology, applied to waterway systems, water supply devices, drainage structures, etc., can solve problems such as relative misalignment of the internal structure of the culvert, poor structural integrity of the culvert, and difficulty in construction, and achieve a simple and economical construction method Technical benefits, effects suitable for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

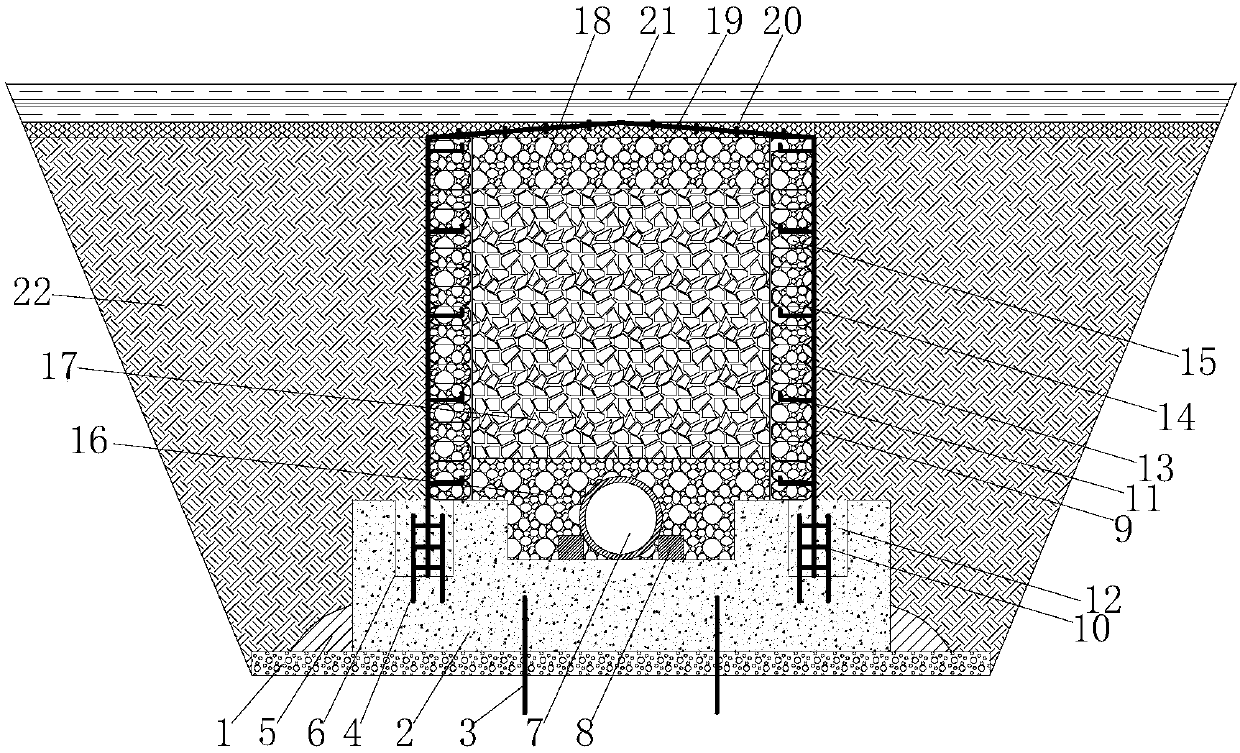

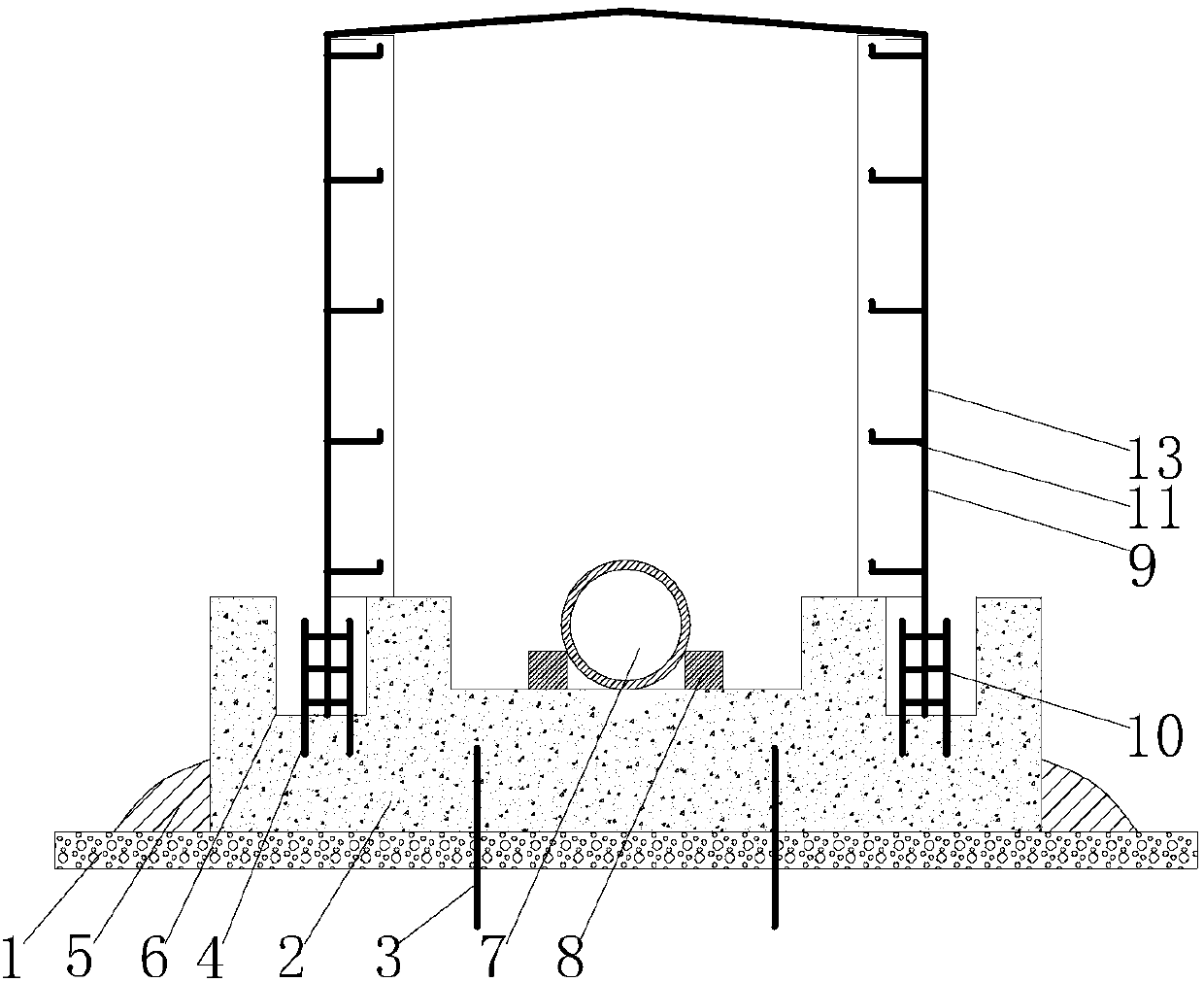

[0037] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

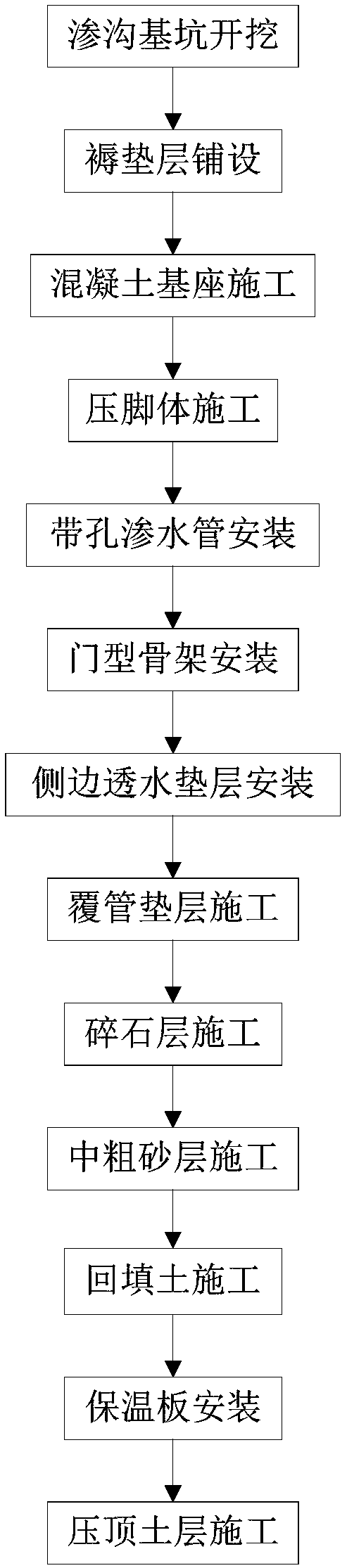

[0038] Such as figure 1 and figure 2 As shown, the construction method of the present invention's thermal insulation and water seepage compound type culvert comprises the following steps:

[0039] 1) Excavation of seepage ditch foundation pit: Excavate the foundation pit according to the setting-out line and level control point, and manually repair and straighten the pit wall;

[0040] 2) Laying of cushion layer 1: Lay cushion layer 1 at the bottom of the foundation pit, and adopt graded sandstone for cushion layer 1;

[0041] 3) Construction of the concrete base 2: The concrete base 2 is laid on the upper part of the cushion layer 1, and deformation joints are set on the concrete base 2, the reserved cup opening 6 is set on the concrete base 2, and a reserved Ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com