Floor system construction method for fabricated building and fabricated plane floor system

A construction method and prefabricated technology, which is applied in the processing of building materials, construction, building components, etc., can solve the problems of unevenness of the underside of the floor, inconvenience of construction at the bottom of the floor, and influence on construction efficiency, so as to improve construction efficiency , saving ceiling decoration, efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

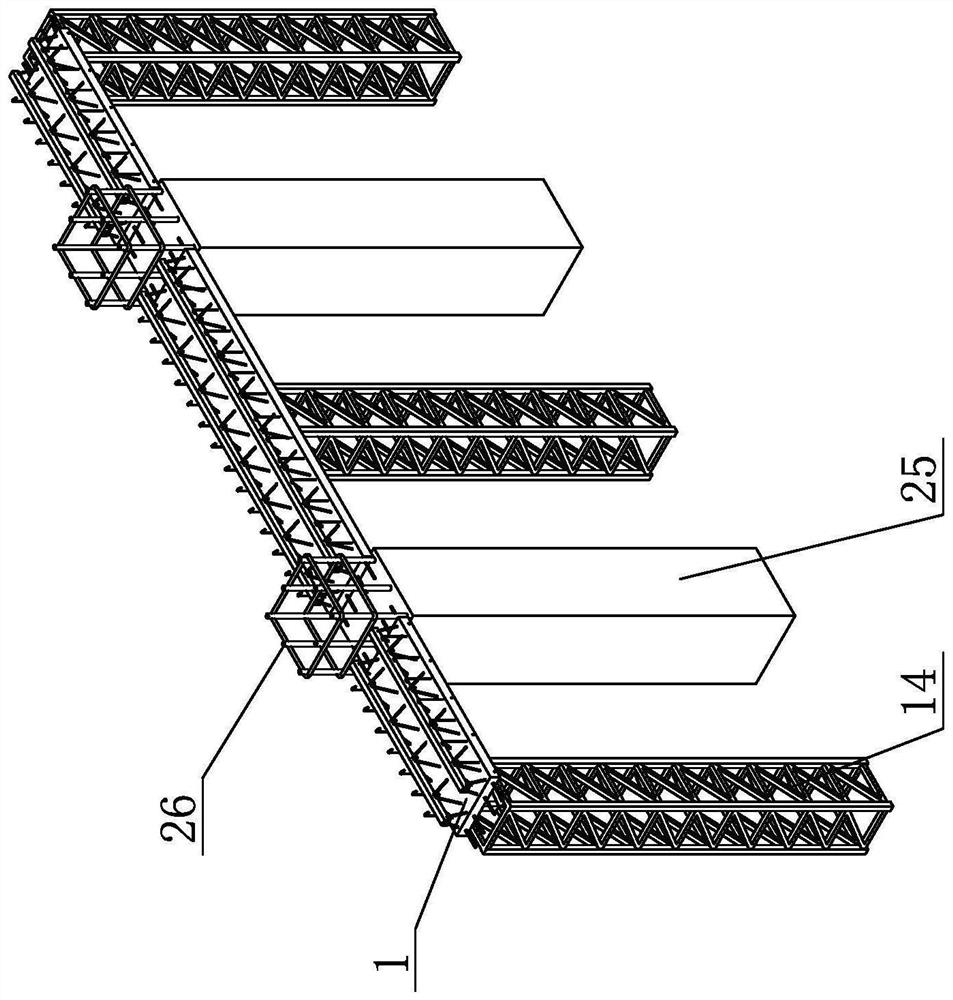

[0028] A floor construction method used in a prefabricated building according to the present invention, such as Figure 1-Figure 8 shown, including the following steps:

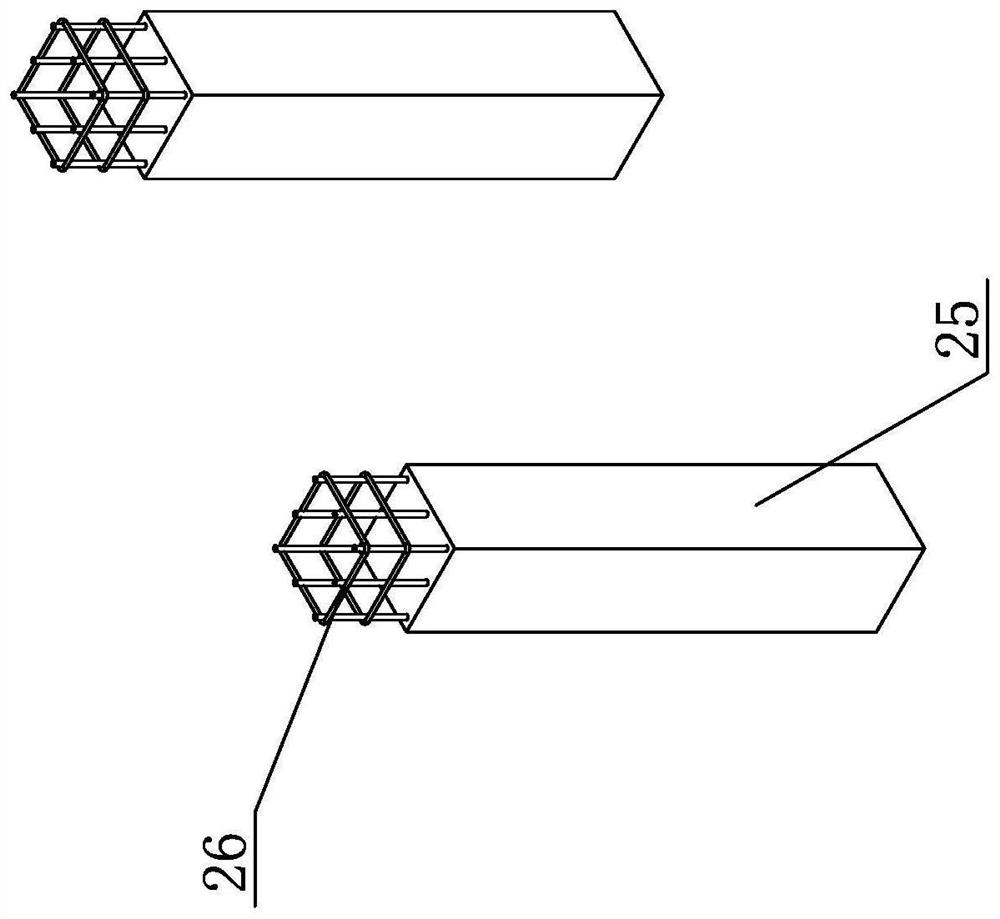

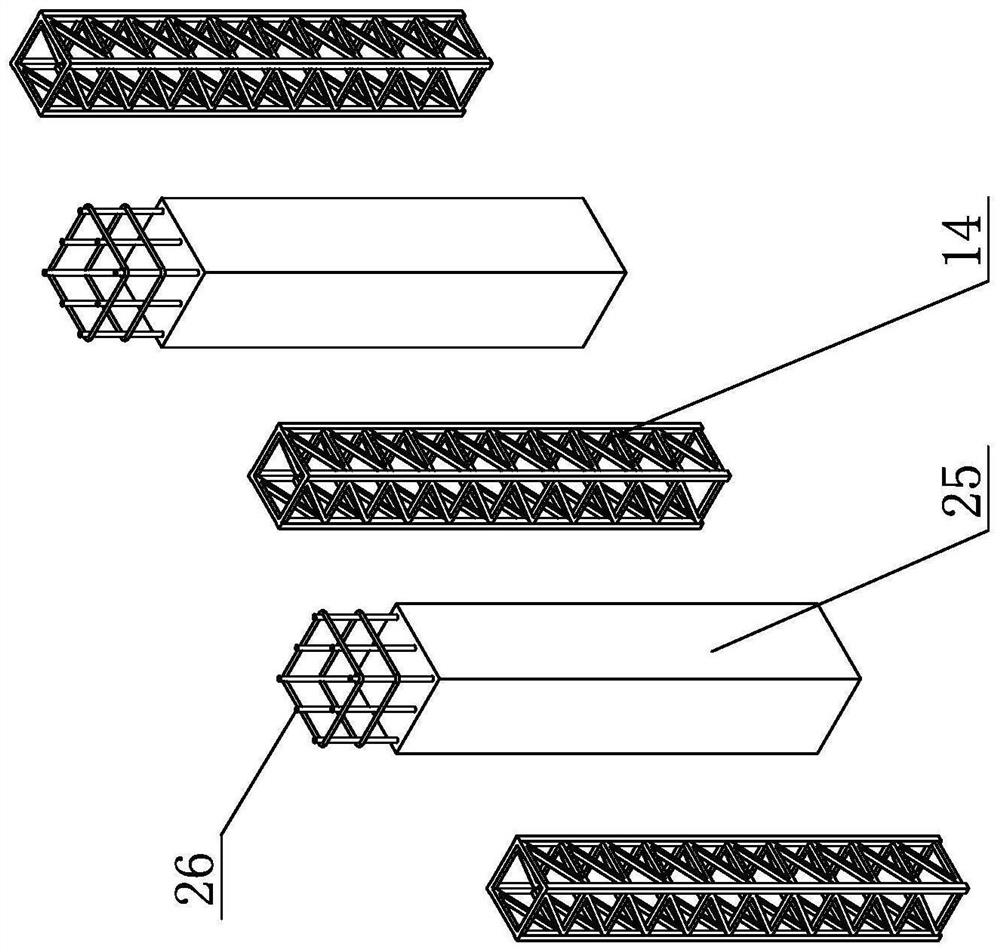

[0029] ① set column 25 at the position of the floor to be constructed;

[0030] ② After the setting of the column 25 is completed, the scaffolding 14 is built below the position of the longitudinal beam of the floor to be constructed;

[0031] ③ After the scaffolding 14 is built, the longitudinal beam truss plate 1 is placed between the adjacent columns 25 and on the scaffolding 14;

[0032] ④ After the longitudinal beam truss plate 1 is placed, the beam truss plate 2 is laid on the column 25, so that the beam truss plate 2 and the longitudinal beam truss plate 1 are vertically arranged, wherein both the longitudinal beam truss plate 1 and the beam truss plate 2 include The bottom plate 5 is provided with reinforcing bodies arranged along the length direction on the bottom plate 5, and several pre-embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com