Assembled reinforced concrete beam-slab structural system with cast-in-situ layer in building structure

A reinforced concrete beam and reinforced concrete technology, applied in the field of prefabricated reinforced concrete beam-slab structure system, can solve the problems of cumbersome beam longitudinal reinforcement, low construction efficiency, and poor installation accuracy, so as to reduce the workload of steel bars and improve the integrity And seismic performance, reduce the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

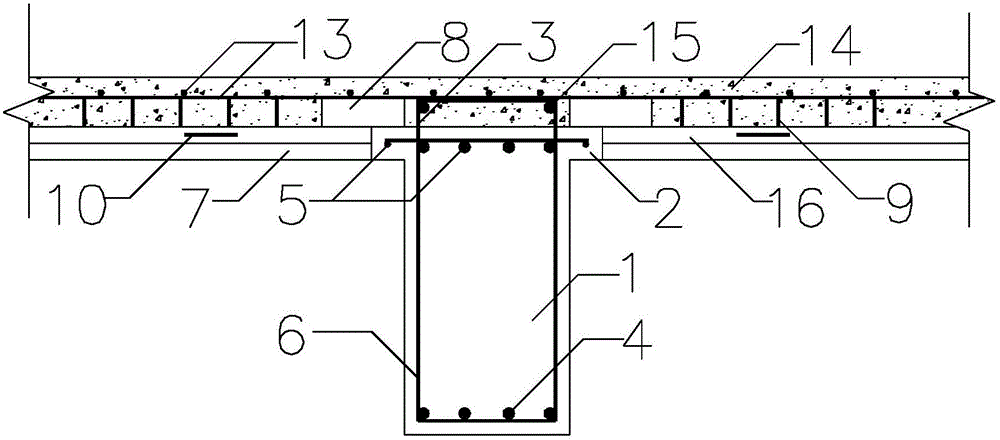

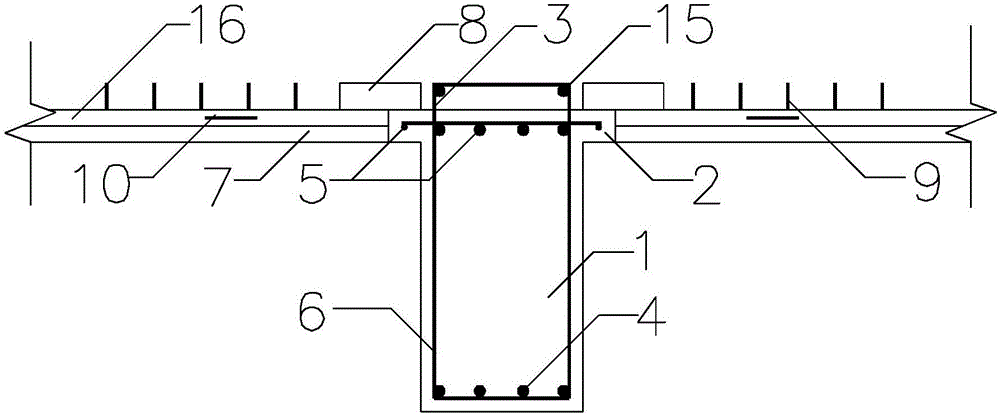

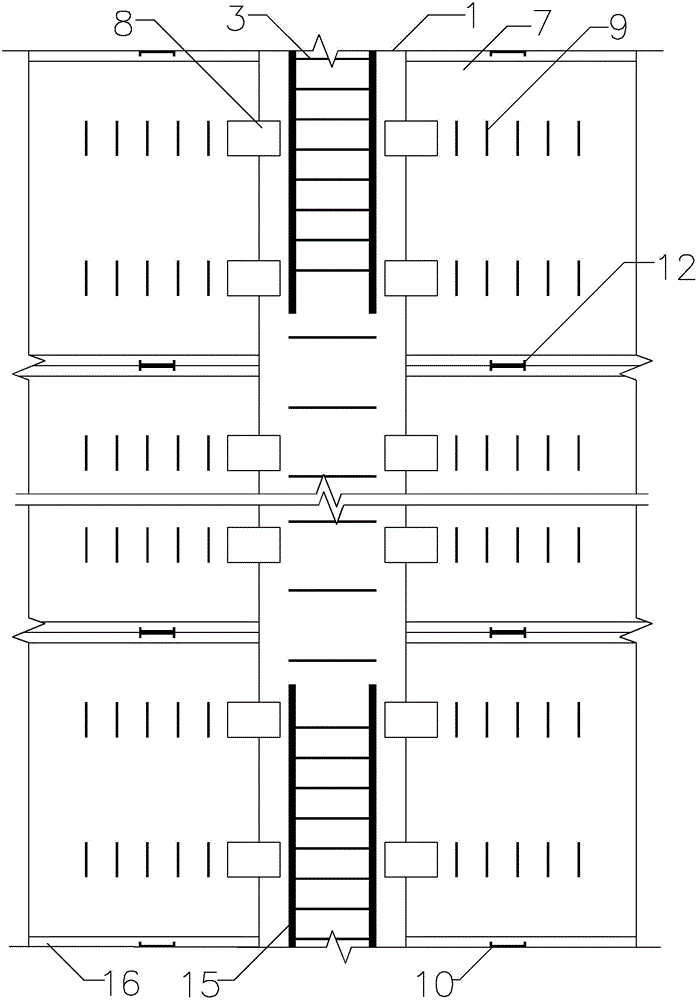

[0040] like Figure 1 to Figure 11 The prefabricated reinforced concrete beam-slab structure system with cast-in-place layer in the shown building structure includes a composite beam 1, a composite plate 7, a reinforced mesh sheet 13, a cast-in-place concrete composite layer 14 and a beam negative reinforcement 15. , the superimposed beam 1 is a reinforced concrete prefabricated beam, and the superimposed beam 1 is provided with an external overhang 2 on both sides at the upper part of the beam, and the external overhang 2 is a long strip beam set along the length direction of the superimposed beam 1 Vice, the lower surface of the outer pick-up groove 2 is flush with the lower surface of the laminated board 7, the laminated board 7 is set horizontally, the laminated board 7 is a reinforced concrete prefabricated board, and the two sides of the laminated board 7 are corresponding to the external pick-up groove 2 The position is provided with a cover plate type groove 8. The cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com