Counter-force system for rectangular shield tunneling

A rectangular shield and shield technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of uncertain force on the steel ring, potential safety hazards, and occupation of lifting space for construction materials, so as to increase the transportation space, The effect of reducing the number and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

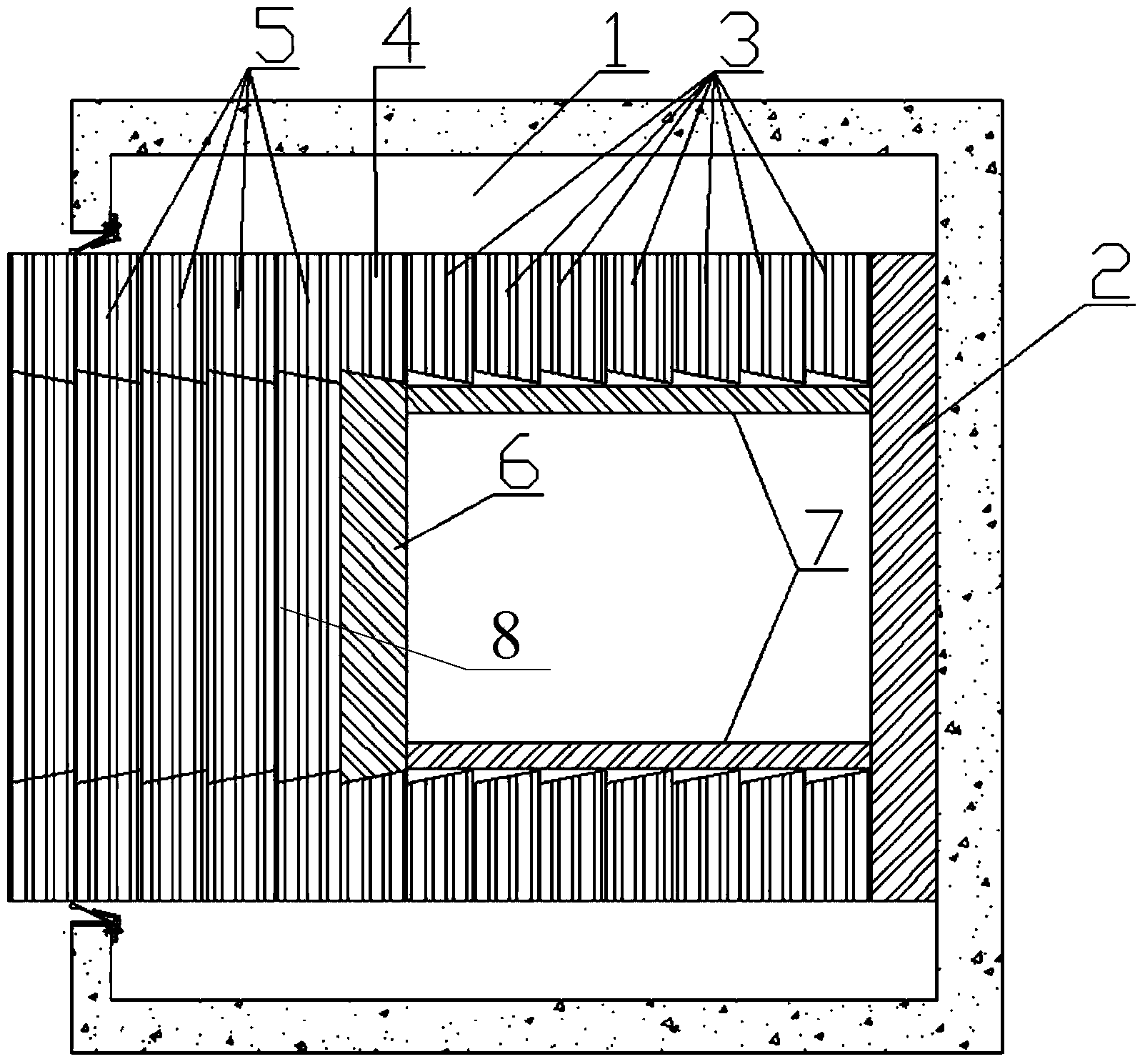

[0011] The following will combine figure 1 A detailed description of the reaction force system for rectangular shield tunneling provided by the present invention, which is an optional embodiment of the present invention, can be considered by those skilled in the art without changing the spirit and content of the present invention. Revise and polish it.

[0012] Please refer to figure 1 , this embodiment provides a reaction force system for rectangular shield tunneling, which is set in the originating shaft 1 and includes a reaction force frame 2, an open negative ring 3, a closed negative ring system and a steel beam 7. The reaction force frame 2, the open negative ring 3 and the closed negative ring system are sequentially connected along the direction of shield tunneling, and the reaction force frame 2 is fixed on the opening of the launch shaft 1 opposite to the opening of the launch shaft On the side wall, the closed negative ring system passes through the opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com